Liquid foaming agent injection method

A foaming agent, liquid technology, applied in the field of natural gas exploitation, can solve the problems of large capillary usage, limited usage, and high cost, and achieve the effects of improving utilization, reducing usage, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

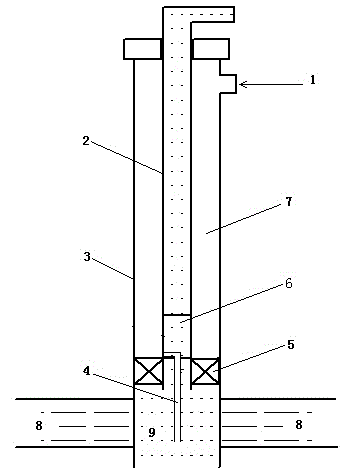

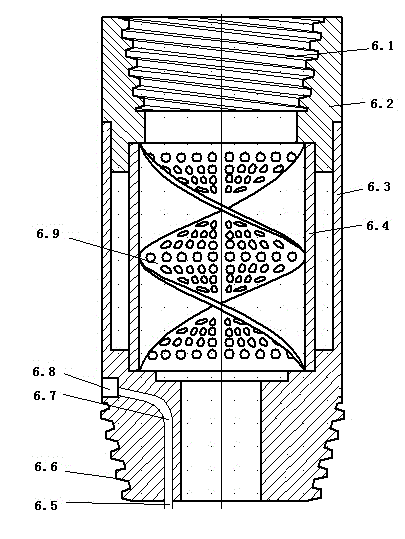

[0015] combined with figure 1 and figure 2 , to further describe the present invention:

[0016] A method for injecting a liquid foaming agent provided by the invention is realized by the following method:

[0017] (1) Install a packer 5 at the shoe of the tubing 2 to isolate the oil casing annulus 7 from the well bottom 9;

[0018] (2) A shorting 6 is installed on the upper part of the packer 5. There is a foaming agent channel on the side of the shorting to connect the oil jacket annulus with the lower part of the shorting. The lower part of the shorting is provided with a capillary interface, and the capillary 4 is installed on the lower part of the shorting 6 The interface is connected to the liquid accumulation in the middle and lower part of the well bottom 9, and the center of the short-circuit is provided with a twisted porous plate, which is connected with the tubing 2;

[0019] (3) The foaming agent is injected into the oil casing annulus 7 from the foaming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com