Ultra-light graphene rubber foamed insole and preparation method thereof

A technology of rubber foaming and graphene, applied in insoles, footwear, applications, etc., can solve the problems of poor hygroscopicity, foot odor, foot sweat, poor mechanical properties such as rebound rate, poor wearing comfort, etc., to achieve Good hygroscopicity, high rebound rate, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]An ultra-light graphene rubber foam insole is made of the following raw materials in parts by weight: 65-72 parts of ethylene-vinyl acetate copolymer, 18-22 parts of liquid polyisoprene rubber, methyl vinyl phenyl 5-7 parts of silicone rubber, 6-9 parts of graphene, 12-19 parts of EVA masterbatch, 4-7.2 parts of aluminum silicate fiber tube, 1.5-2.5 parts of foaming agent, 0.9-1.2 parts of micropore regulator, 3-6 parts of oxidizing agent, 2-4.2 parts of crosslinking agent and 4-6 parts of zinc stearate.

[0039] The present invention also provides a kind of preparation method of described ultralight graphene rubber foam insole, comprises the following steps:

[0040] A. Weigh ethylene-vinyl acetate copolymer, liquid polyisoprene rubber, methyl vinyl phenyl silicone rubber, graphene, EVA color masterbatch, aluminum silicate fiber tube, foaming agent, Cell regulators, antioxidants, crosslinkers and zinc stearate;

[0041] B. Send ethylene-vinyl acetate copolymer, liquid...

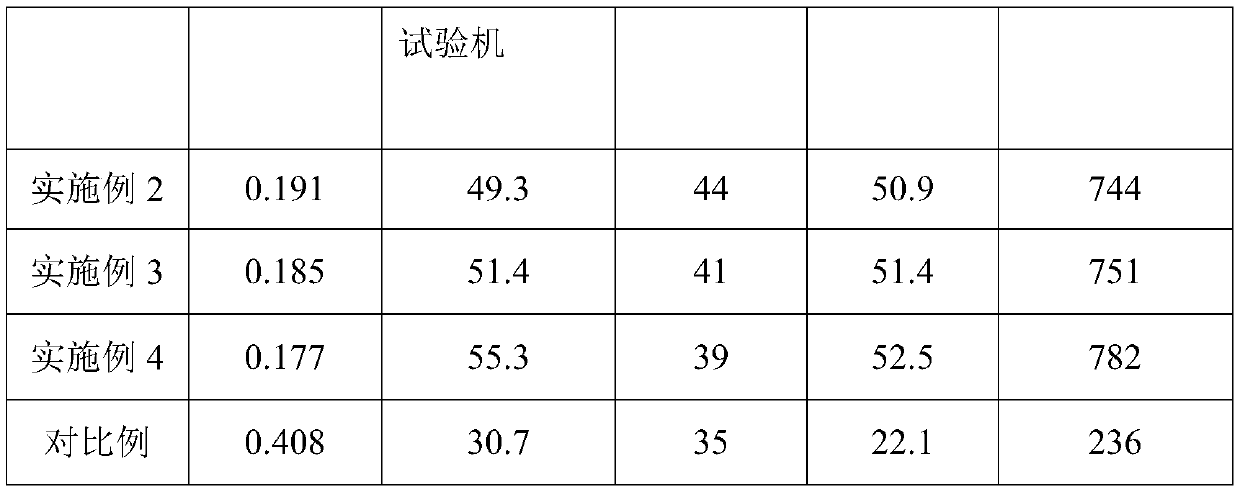

Embodiment 2

[0045] A kind of ultra-light graphene rubber foaming insole, is made by the raw material that comprises following parts by weight: ethylene-vinyl acetate copolymer 65 parts, liquid polyisoprene rubber 18 parts, methyl vinyl phenyl silicone rubber 5 parts , 6 parts of graphene, 12 parts of EVA masterbatch, 4 parts of aluminum silicate fiber tube, 1.5 parts of foaming agent, 0.9 parts of micropore regulator, 3 parts of antioxidant, 2 parts of crosslinking agent, 4 parts of zinc stearate .

[0046] In this embodiment, the foaming agent is foaming agent AC.

[0047] In this embodiment, the pore regulator is hydroxyl-terminated reactive silicone oil.

[0048] In this embodiment, the pore regulator is a mixture of hydroxyl-terminated vinyl methyl silicone oil and hydroxyl-terminated polymethicone oil.

[0049] In this embodiment, the mass ratio of hydroxyl-terminated vinyl methyl silicone oil and hydroxyl-terminated polymethicone oil in the mixture of hydroxyl-terminated vinyl met...

Embodiment 3

[0060] A kind of ultra-light graphene rubber foaming insole, is made by the raw material that comprises following parts by weight: ethylene-vinyl acetate copolymer 72 parts, liquid polyisoprene rubber 22 parts, methyl vinyl phenyl silicone rubber 7 parts , 9 parts of graphene, 19 parts of EVA masterbatch, 7.2 parts of aluminum silicate fiber tube, 2.5 parts of foaming agent, 1.2 parts of micropore regulator, 6 parts of antioxidant, 4.2 parts of crosslinking agent, 6 parts of zinc stearate .

[0061] In this embodiment, the foaming agent is foaming agent AC.

[0062] In this embodiment, the pore regulator is hydroxyl-terminated reactive silicone oil.

[0063] In this embodiment, the pore regulator is a mixture of hydroxyl-terminated vinyl methyl silicone oil and hydroxyl-terminated polymethicone oil.

[0064] In this embodiment, the mass ratio of hydroxyl-terminated vinyl methyl silicone oil and hydroxyl-terminated polymethicone oil in the mixture of hydroxyl-terminated vinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com