Single-component polyurethane foam rubber and preparation method thereof

A polyurethane foam, one-component technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of odor and low environmental performance, and achieve dense cells and foaming. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

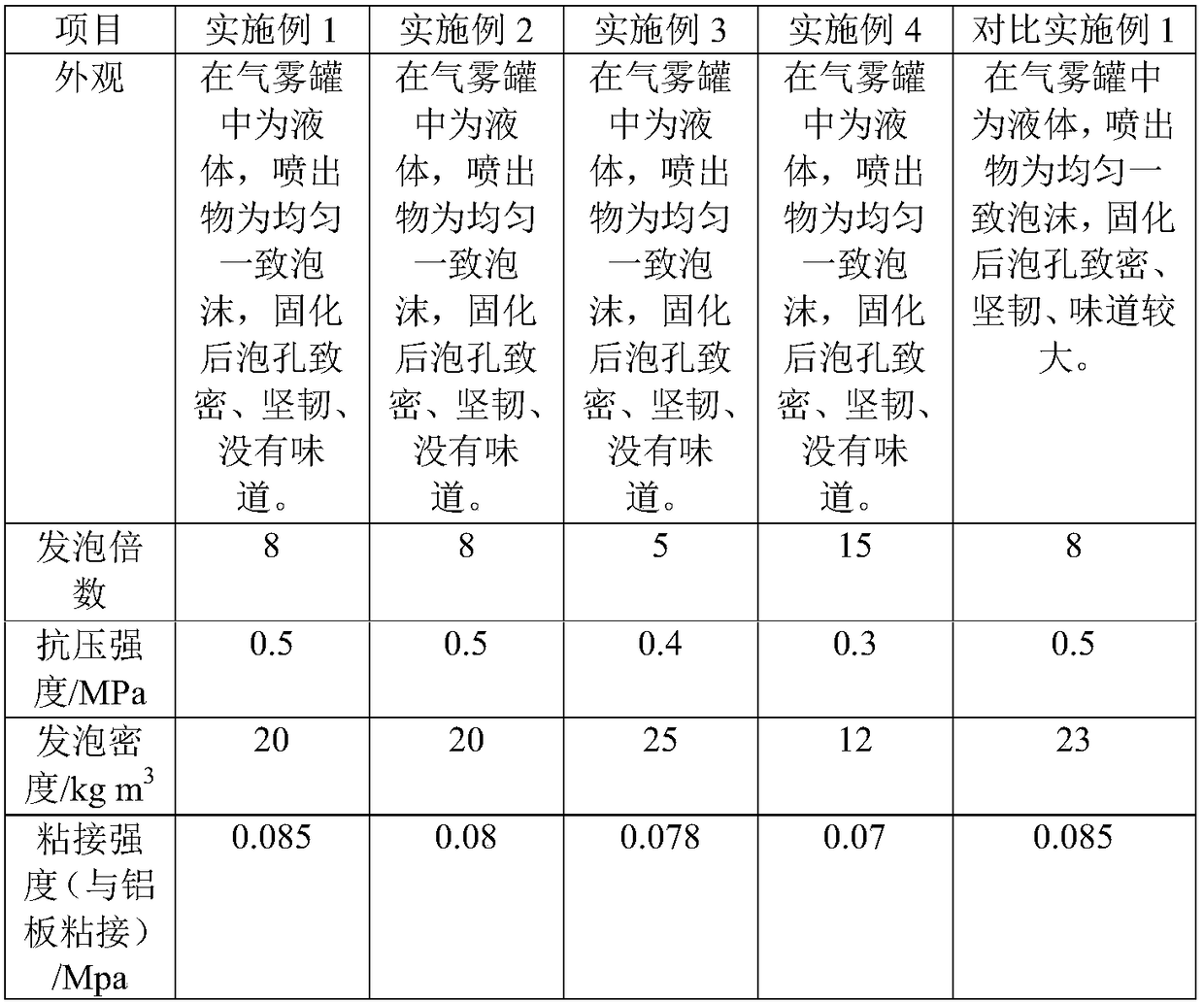

Examples

Embodiment 1

[0052]This example provides a one-component polyurethane foam, including the following components: 60 parts of polyether polyol 330N, 30 parts of polyether polyol 305, 10 parts of polyester polyol PE-2010, 5 parts of trihydroxy Methylpropane, 10 parts Niax L-6164, 2 parts fumed silica, 2 parts SC-54, 2.5 parts bismorpholino diethyl ether, 0.5 parts dibutyltin dilaurate, 80 parts polyphenylmethane Diisocyanate, 5 parts of supercritical carbon dioxide with a pressure of 5Mpa.

[0053] The preparation method of above-mentioned one-component polyurethane foam glue is:

[0054] (1) Polyether polyol 330N, polyether polyol 305, polyester polyol PE-2010, Niax L-6164, fumed silica, SC-54, bismorpholino diethyl Ether and dibutyltin dilaurate are evenly mixed to obtain a white material; the white material is poured into an aerosol can using aerosol can equipment;

[0055] (2) Pour polyphenylmethane diisocyanate into the aerosol can in parts by mass;

[0056] (3) Pump the supercritical...

Embodiment 2

[0058] This embodiment provides a one-component polyurethane foam, including the following components: 30 parts of polyether polyol 220, 45 parts of polyether polyol 204, 15 parts of polyester polyol PE-2320, 5 parts of 1, 4 butanediol, 5 parts of Niax L-5154, 4 parts of fumed silica, 1 part of SC-54, 3 parts of bismorpholino diethyl ether, 1 part of dibutyltin dilaurate, 50 parts of polyphenyl Methane diisocyanate, 6 parts of supercritical nitrogen with a pressure of 5Mpa.

[0059] The preparation method of the one-component polyurethane foam of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0061] This example provides a one-component polyurethane foam, including the following components: 15 parts of polyether polyol 310, 50 parts of polyether polyol 3050D, 5 parts of polyester polyol PE-2020, 2.5 parts of 1, 4 butanediol, 8 parts of Niax L-5154, 5 parts of fumed silica, 3 parts of SC-54, 3.5 parts of bismorpholino diethyl ether, 1.5 parts of dibutyltin dilaurate, 80 parts of polyphenyl Methane diisocyanate, 4 parts pressure is 14Mpa supercritical carbon dioxide.

[0062] The preparation method of the one-component polyurethane foam of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com