Impact-resistant polypropylene foamed sheet with high melt strength and preparation method therefor

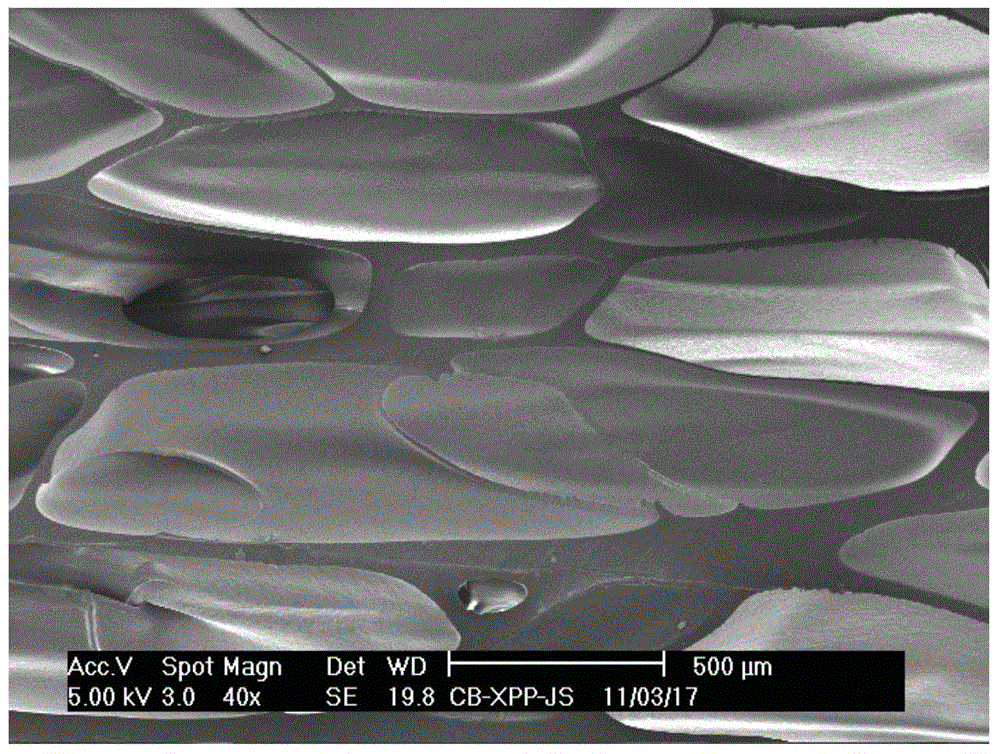

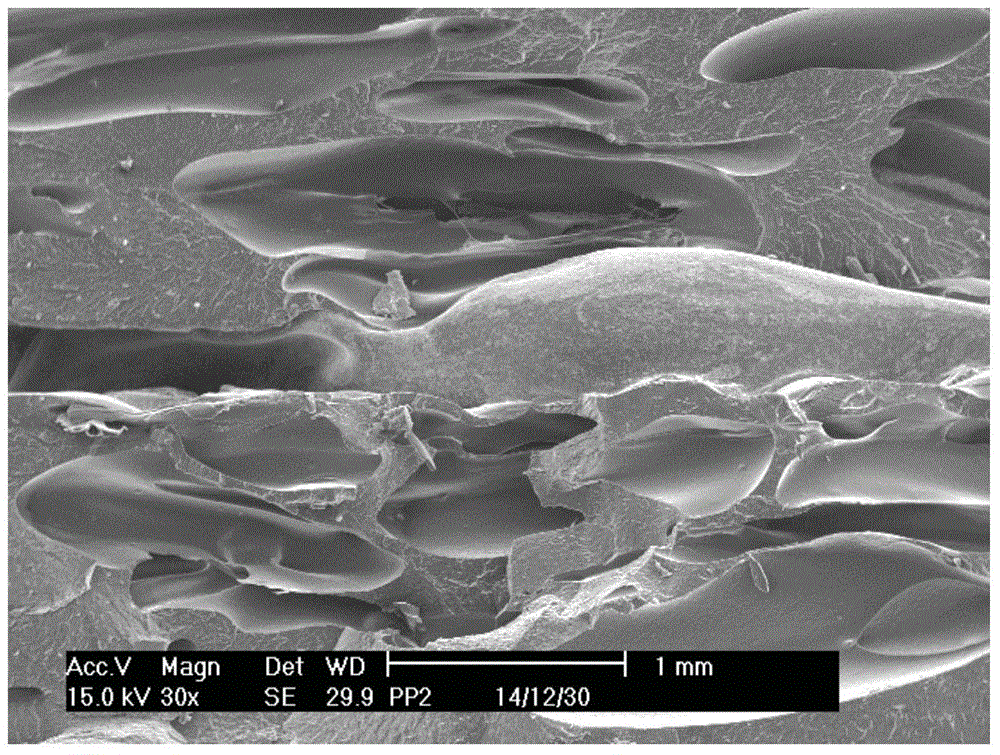

A high melt strength, foamed sheet technology, applied in the field of polymer materials, can solve the problems of poor molding ability, cell merger and rupture, low melt strength, etc., and achieve low foaming ratio and dense and uniform cells , the effect of high closed cell rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

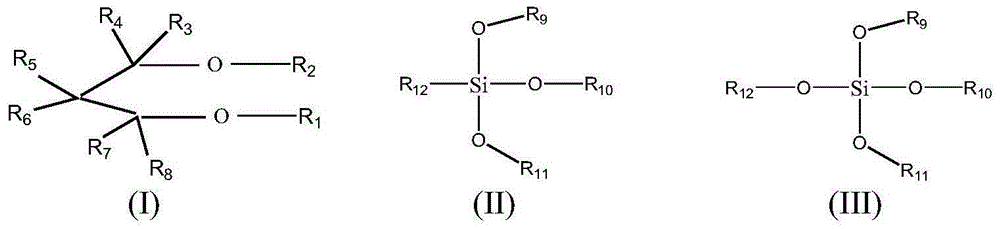

Method used

Image

Examples

preparation example Construction

[0099] Preparation of polypropylene base resin HMSPP701:

[0100] The propylene polymerization reaction is carried out on a polypropylene unit, and the main equipment of the unit includes a prepolymerization reactor, a first loop reactor, a second loop reactor and a third gas phase reactor. The polymerization method and steps are as follows.

[0101] (1) Prepolymerization reaction

[0102] The main catalyst (DQC-401 catalyst, provided by Beijing Aoda Branch of Sinopec Catalyst Company), co-catalyst (triethylaluminum), and the first external electron donor (isopropylcyclopentyldimethoxysilane, IPCPMS) were After pre-contacting at 6°C for 20 minutes, it is continuously fed into a continuous stirred tank prepolymerization reactor for prepolymerization. The flow of triethylaluminum (TEA) entering the prepolymerization reactor is 6.33g / hr, the flow of isopropylcyclopentyldimethoxysilane is 0.3g / hr, the flow of main catalyst is 0.6g / hr, TEA / IPCPMS The ratio is 50 (mol / mol). The ...

Embodiment 1-12

[0118] Preparation of polypropylene base resin

[0119] The high melt strength impact polypropylenes HMSPP701, HMSPP702, HMSPP703 and HMSPP704 used as base resins were respectively prepared according to the above preparation methods of HMSPP701, HMSPP702, HMSPP703 and HMSPP704.

[0120] Foaming and rolling process

[0121] Add the above-mentioned base resin, foaming agent, cell control agent and processing aid according to the formula shown in Table 3 into a high-speed mixer and mix at high speed for 1 minute to obtain a premixed polypropylene foam board. Wherein, cell control agent is selected talcum powder for use; Antioxidant adopts the compound mixture of calcium stearate: antioxidant 1010 (BASF): antioxidant 168 (BASF)=1: 2: 2 (weight ratio) ; The lubricant uses MB50-002 (high molecular weight polysiloxane).

[0122]Adjust the temperature of the extruder to the foaming temperature shown in Table 3, then put the premix into the middle layer twin-screw of the extruder, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com