Patents

Literature

42results about How to "Excellent high and low temperature impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet light polymerization adhesive and preparation method thereof

ActiveCN103819681AImprove temperature resistanceGood adhesionPolyureas/polyurethane adhesivesMacromolecular adhesive additivesAdhesiveUltraviolet lights

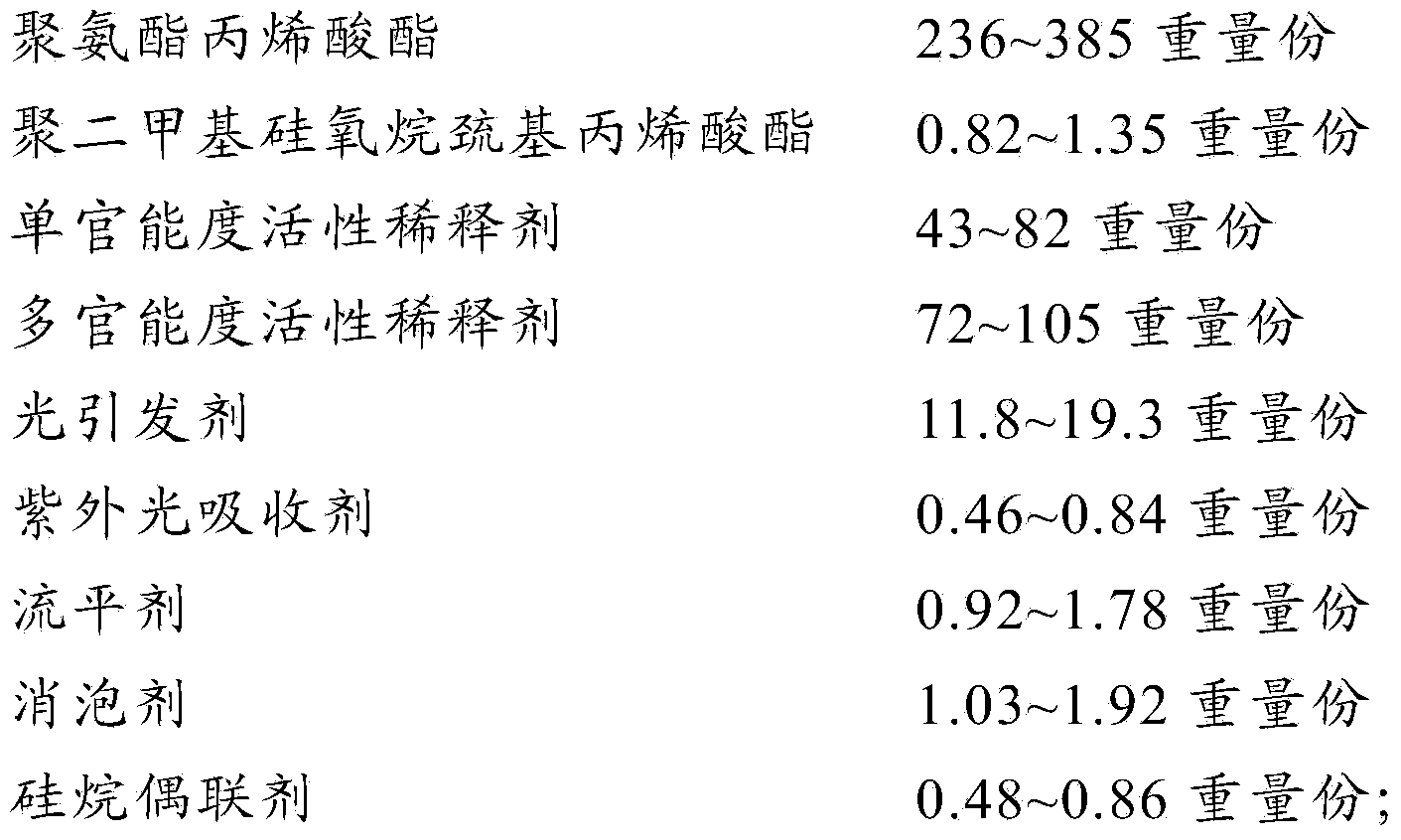

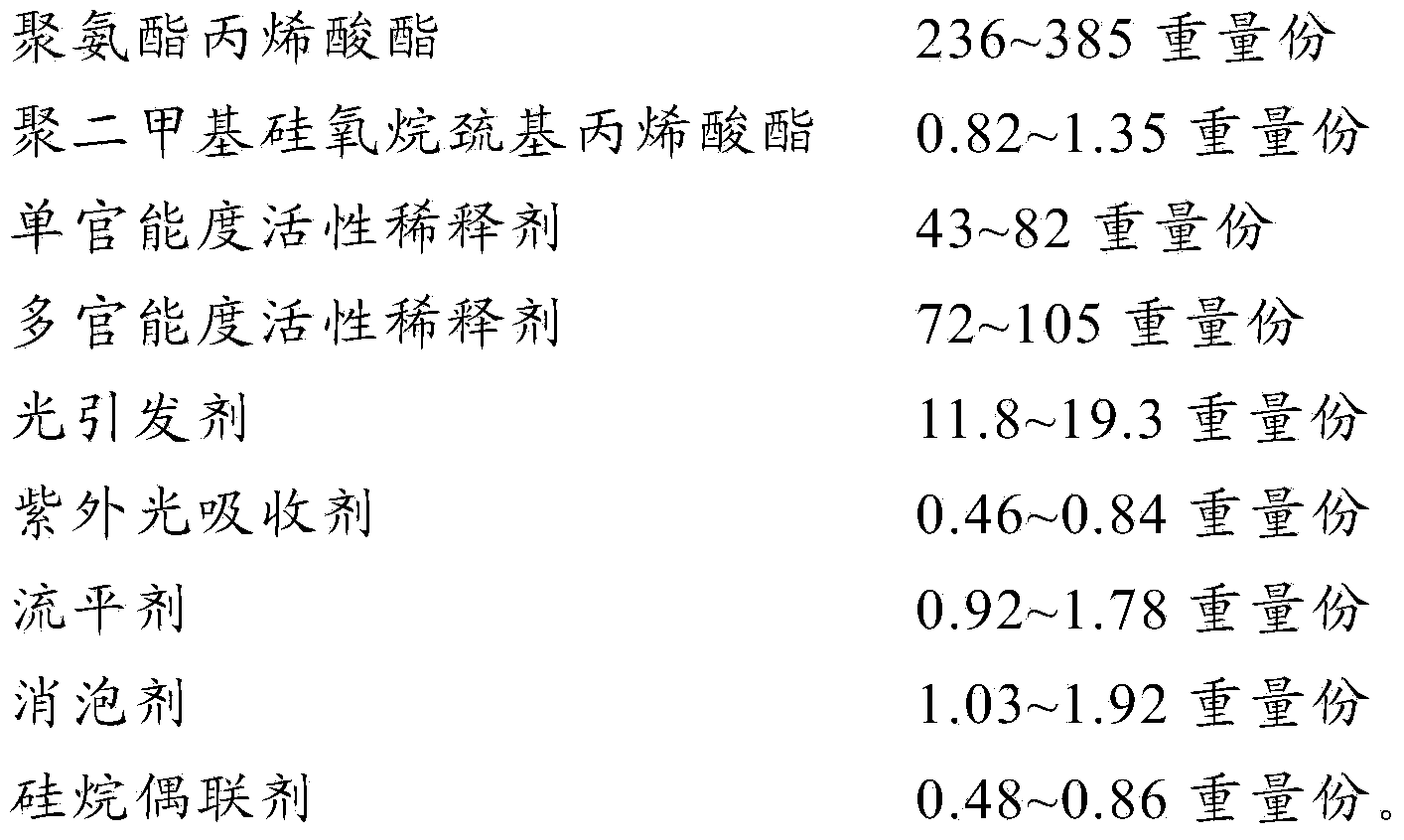

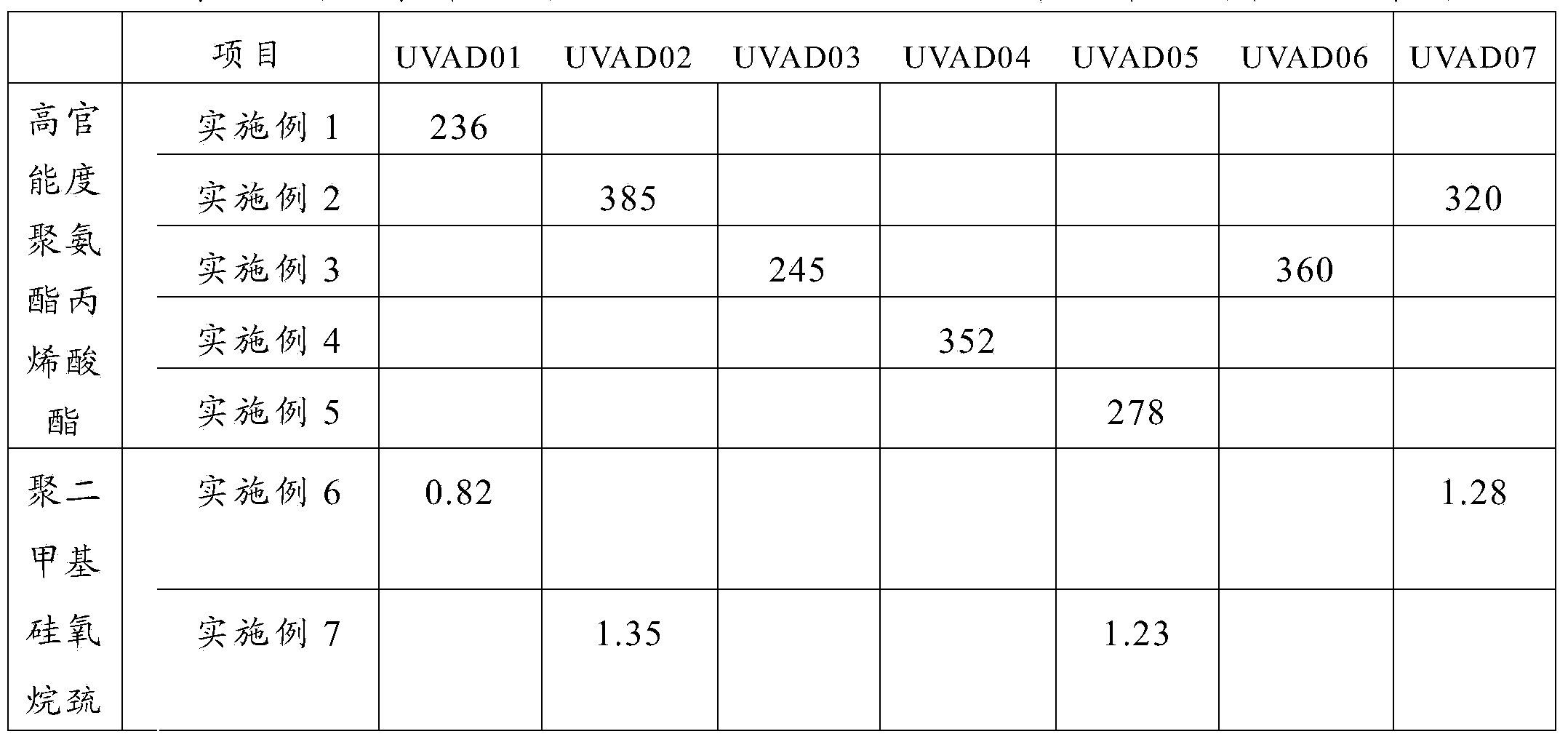

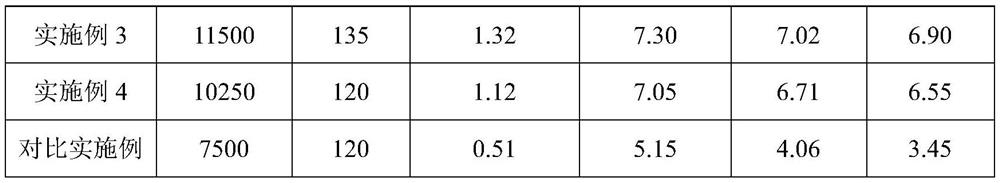

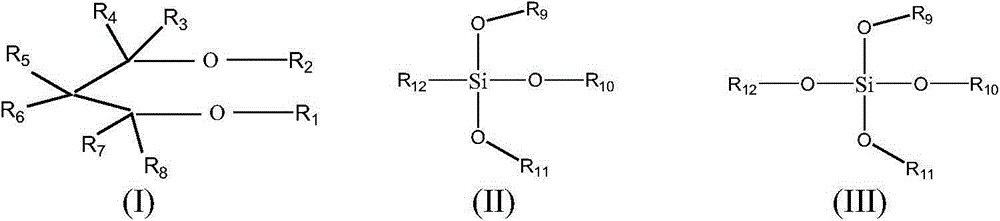

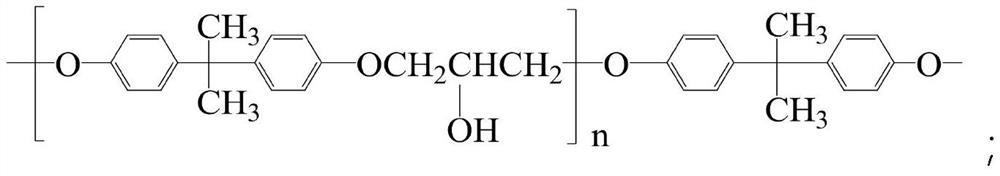

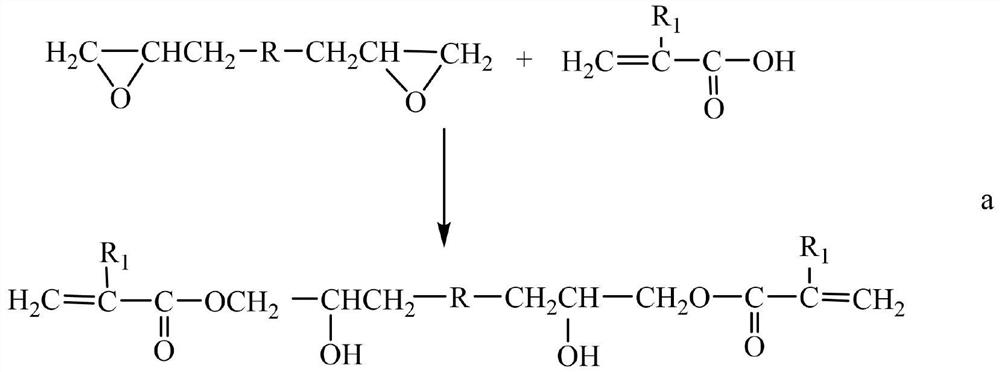

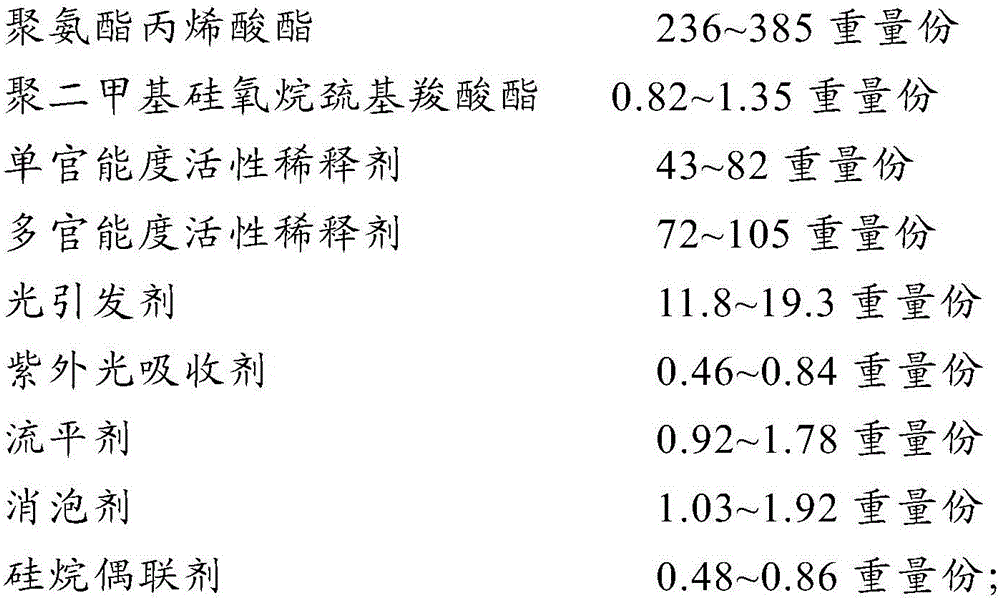

The invention provides an ultraviolet light polymerization adhesive and a preparation method thereof. The ultraviolet light polymerization adesive is prepared from the following components in parts by weight: 236-385 parts of polyurethane acrylate, 0.82-1.35 parts of polydimethylsiloxane mercapto acrylate, 43-82 parts of a monofunctional reactive diluent, 72-105 parts of a polyfunctional reactive diluent, 11.8-19.3 parts of a photoinitiator, 0.46-0.84 part of an ultraviolet light absorbent, 0.92-1.78 parts of a leveling agent, 1.03-1.92 parts of a foam killer and 0.48-0.86 part of a silane coupling agent. The ultraviolet light polymerization adhesive provided by the invention has better high-temperature impact resistance and excellent adhesion, has no cyano group, and is environment-friendly and nontoxic.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

High-initial-adhesion-strength moisture-curable polyurethane hot melt adhesive and preparation method thereof

InactiveCN111849408AExtended opening hoursHigh initial bond strengthPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a high-initial-adhesion-strength moisture-curable polyurethane hot melt adhesive and a preparation method thereof. The adhesive is prepared from the following raw materials inparts by weight: 20-50 parts of polyether polyol, 10-40 parts of crystalline polyester polyol, 5-30 parts of liquid polyester polyol, 10-20 parts of polyisocyanate, 10-35 parts of thermoplastic acrylic resin, 2-15 parts of tackifying resin, 0.1-0.5 parts of a catalyst and 0.1-1 part of an antioxidant. The moisture-curable polyurethane hot melt adhesive provided by the invention has the advantagesof long opening time, high initial adhesion strength, high curing speed, higher final adhesion strength, favorable damp-heat resistance and favorable high / low-temperature impact resistance, and can achieve the goals of no pressure maintaining and high-efficiency production of electronic products.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD +3

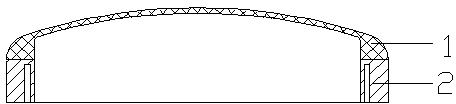

Combined antenna housing

The invention relates to an antenna housing and provided a combined antenna housing. The combined antenna housing comprises an arc-shaped housing body (1) and a steel base (2) in a hollow cylindrical structure, wherein the steel base (2) is located on the lower portion of the arc-shaped housing body (1), and the arc-shaped housing body is in a sandwiched composite structure. Compared with existing products, the combined antenna housing has the advantages of being good in electromagnetic permeability and high and low temperature shock resistance and capable of protecting antennas to be used in severe weather such as sand, high wind and humid rainy climate and in regions with large temperature differences.

Owner:洛阳双瑞橡塑科技有限公司

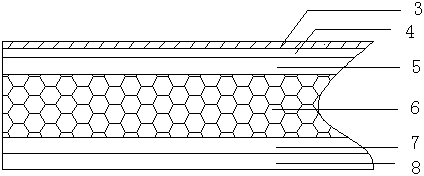

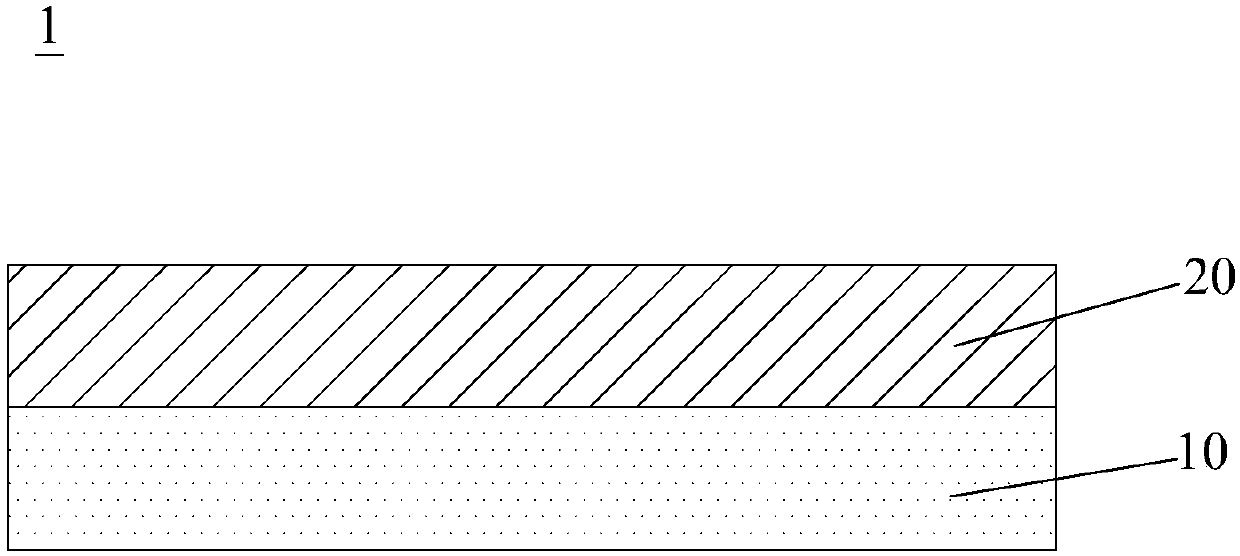

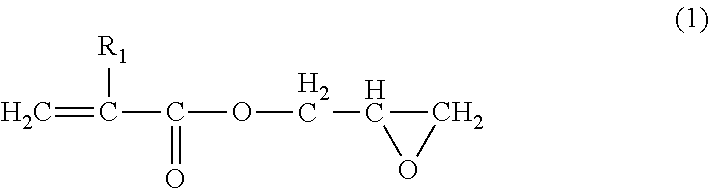

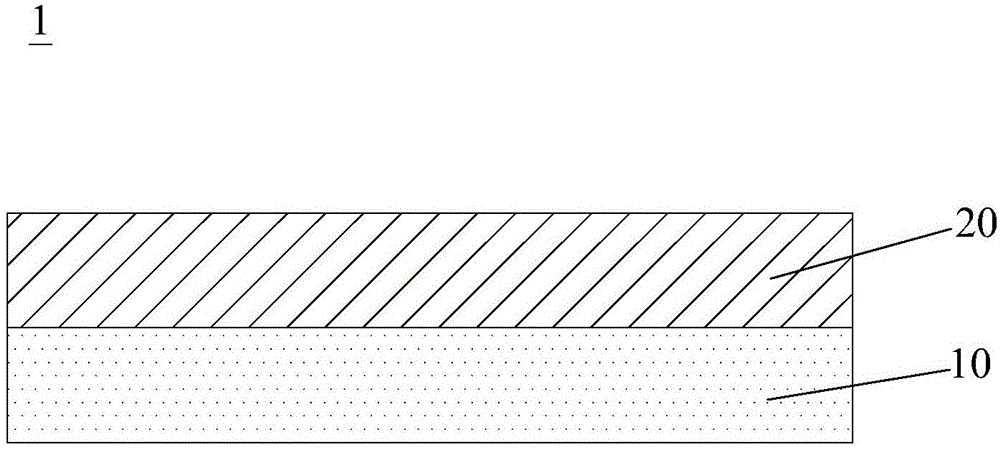

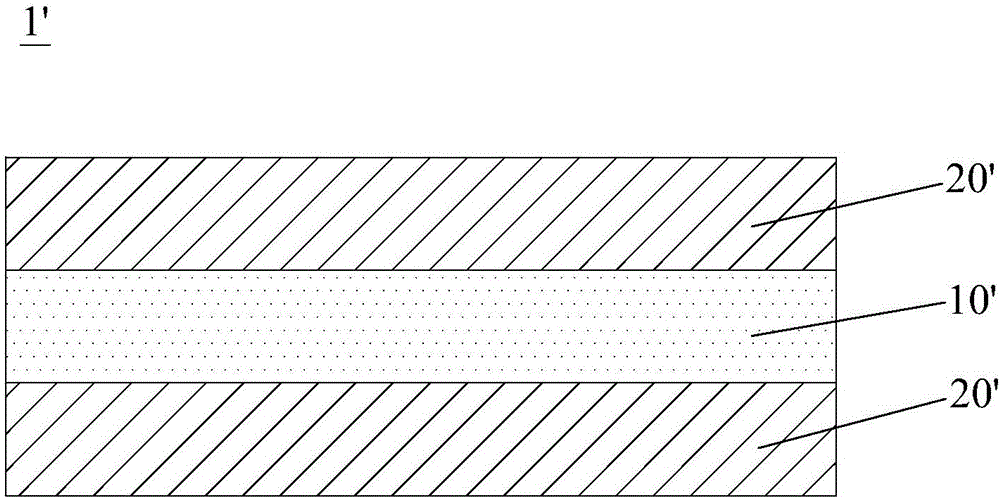

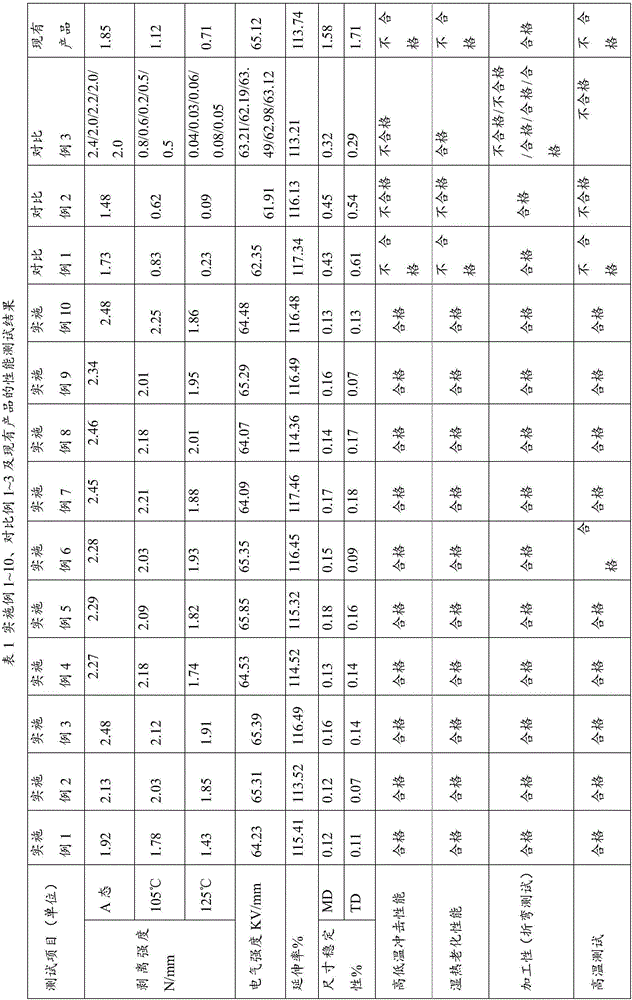

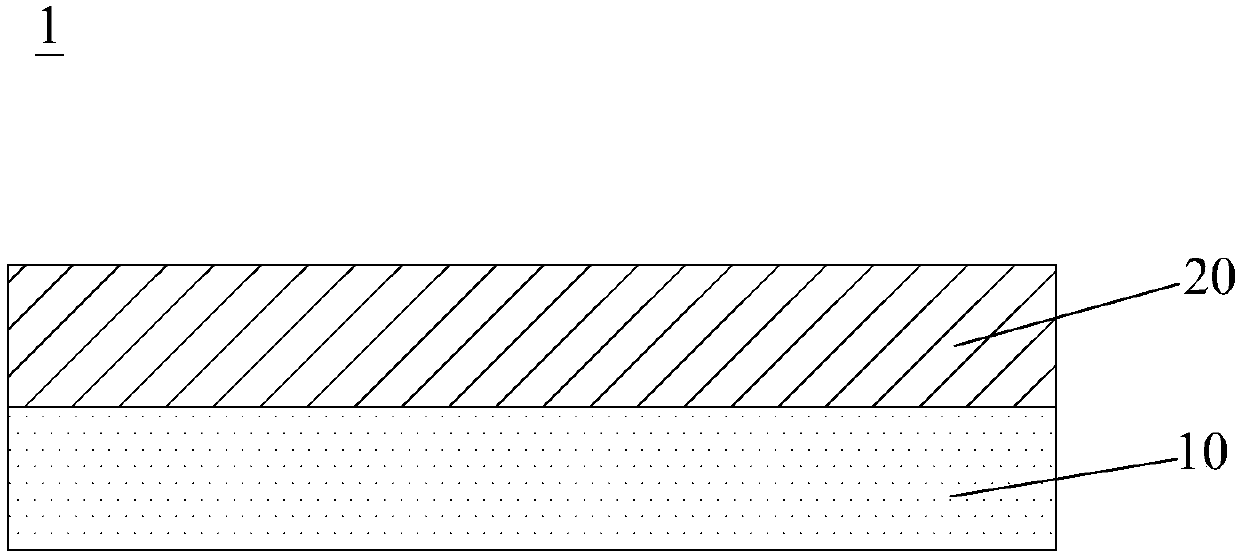

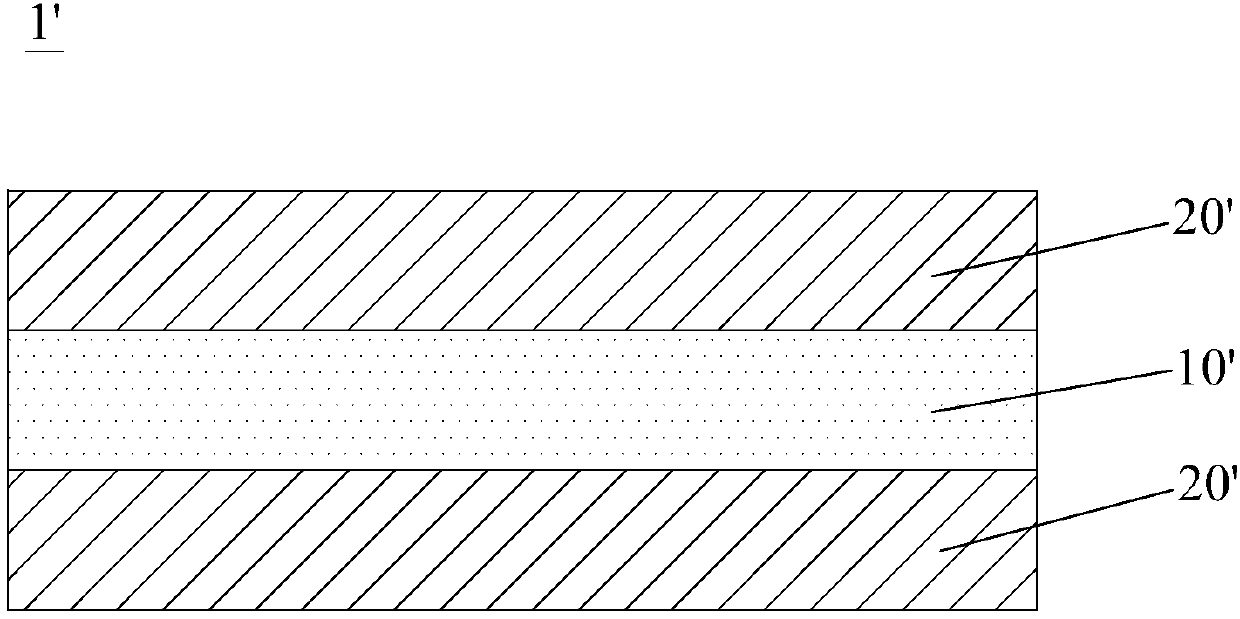

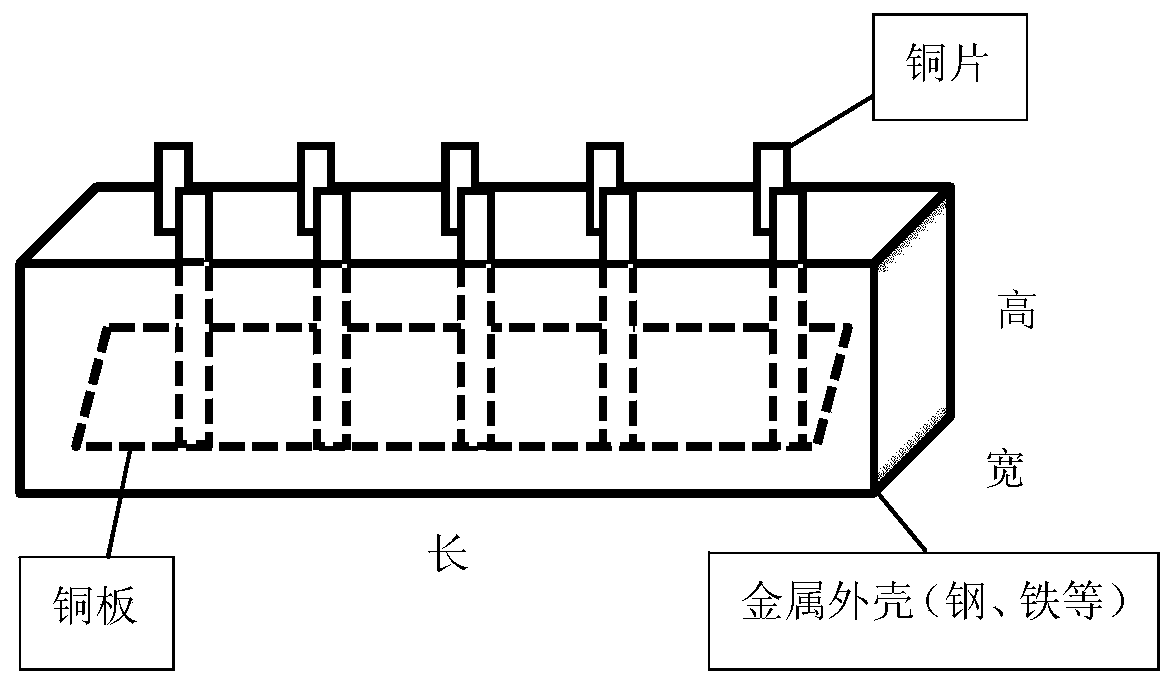

Halogen-free resin composition, adhesive and laminated busbar insulating adhesive film prepared therefrom, and preparation method of insulating adhesive film

InactiveCN106700428AImprove heat resistanceGood adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesProduct systemAdhesive

The invention provides a halogen-free resin composition. The halogen-free resin composition comprises the following components in parts by mass: 40-110 parts of saturated polyester resin, 5-40 parts of phenolic resin, 1-20 parts of a curing agent, 10-150 parts of a halogen-free flame retardant, 0-100 parts of a filler, 0.01-1 part of an antioxidant and 0.01-5 parts of a coupling agent. In the halogen-free resin composition, the phenolic resin has good flame retardance and excellent heat resistance, and both the saturated polyester resin and the phenolic resin contain hydroxyl groups and can react with the curing agent to form an interpenetrating polymer network, so that the obtained cured product system has excellent high-temperature adhesion and flame retardance. The invention further provides an adhesive and a laminated busbar insulating adhesive film prepared from the halogen-free resin composition, and a preparation method of the laminated busbar insulating adhesive film.

Owner:GUANGDONG SHENGYI SCI TECH

Polyarylene sulfide-derived resin composition and insert molded body

InactiveUS20170096557A1Mobility is suitableExcellent highSynthetic resin layered productsElectrical equipmentGlass fiberEnd-group

A polyarylene sulfide-derived resin composition which has flowability optimal for insert molding and which can impart superior high- and low-temperature impact properties to a molded body, and an insert-molded body using the resin composition. The resin composition includes a polyarylene sulfide resin having carboxylic terminal groups, an olefin-derived copolymer, glass fibers and calcium carbonate. The weight-average molecular weight of the polyarylene sulfide resin is 15,000-40,000; as copolymerization components, the olefin-derived copolymer includes α-olefins, glycidyl esters of α,β-unsaturated acids, and acrylic esters, and the content of the copolymerization component derived from the glycidyl esters in the resin composition is 0.2-0.6 mass %. Further, the fiber diameter of the glass fibers is 9-13 μm, the average particle diameter of the calcium carbonate is 10-50 μm, and the total content of glass fibers and the calcium carbonate is 45-55 mass % of the resin composition.

Owner:POLYPLASTICS CO LTD

Flame-retardant resin composition, adhesive prepared from flame-retardant resin composition, insulation adhesive film used for laminated busbar, and preparation method of insulation adhesive film

InactiveCN106674916AImprove flame retardant performanceImprove heat resistanceHeat-activated film/foil adhesivesCross-linkAdhesive

The invention provides a flame-retardant resin composition, which comprises, by mass part, 40-110 parts of a saturated polyester resin, 5-40 parts of a phenolic resin, 1-20 parts of a curing agent, 10-100 parts of a fire retardant, 0.01-1 part of an anti-oxidant and 0.01-5 parts of a coupling agent. A small amount of phenolic resin is added in the flame-retardant resin composition, so that aromatic rings are introduced to the flame-retardant resin composition and thermal resistance and flame resistance of the flame-retardant resin composition are improved. Both of the phenolic resin and the saturated polyester resin contain hydroxyl groups, which react with the curing agent for a cross-linking curing reaction, so that interpenetrating polymer networks are formed and a condensate excellent in thermal resistance, flame retardance and high-temperature bonding performance is obtained. The invention further provides an adhesive prepared from the flame-retardant resin composition, an insulation adhesive film used for a laminated busbar, and a preparation method of the insulation adhesive film.

Owner:GUANGDONG SHENGYI SCI TECH

High-strength halogen-free epoxy molding compound, and preparation method thereof

ActiveCN102321340AExcellent high and low temperature impact resistanceHigh mechanical strengthPolymer scienceFirming agent

The invention discloses a high-strength halogen-free epoxy molding compound, and a preparation method thereof. The molding compound comprises raw materials of: 100 parts of modified epoxy resin, 0 to 100 parts of epoxy resin, 20 to 100 parts of a curing agent, 140 to 250 parts of a strengthening material, 100 to 250 parts of a filling material, 100 to 250 parts of a fire retardant and CTI modifier, and 10 to 50 parts of an auxiliary agent. The preparation method comprises steps that: the materials are well mixed, crushed, mixed, fused and mixed, cooled and crushed, and packaged. The preparation method of the modified epoxy resin comprises steps that: 100 parts of epoxy resin and 5 to 20 parts of liquid rubber are mixed for 4 to 6 hours under a temperature of 100 DEG C to 130 DEG C, the product is cooled, and the product is crushed to a size below 20 meshes. The invention is advantages in that: with the high-strength halogen-free epoxy molding compound prepared by the invention, the produced product has high mechanical strength, small molding shrinkage, good high / low temperature impact resistance, excellent electrical property under bad surroundings, and environment friendliness.

Owner:WUXI CHUANGDA ELECTRONICS

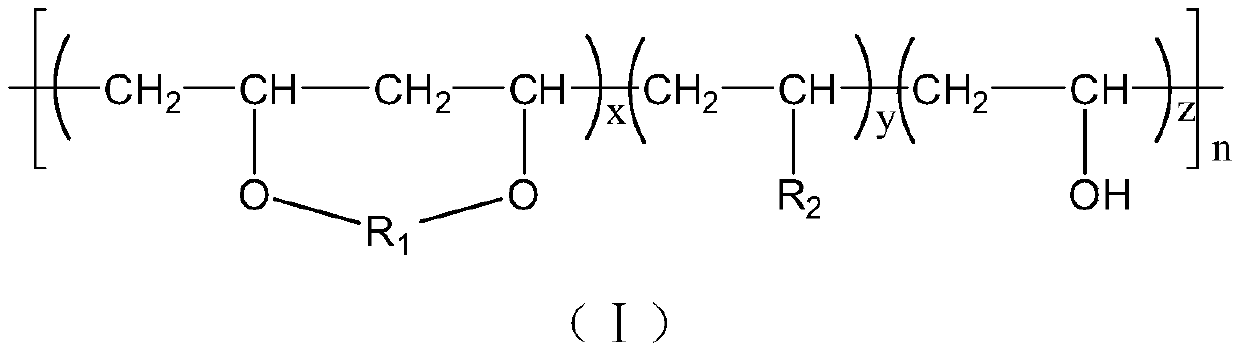

Thermoplastic resin composition and adhesive prepared from same, insulation adhesive film used for laminated bus bar and preparation method of insulation adhesive film

InactiveCN106700498AGood aging performanceGood bonding performanceNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryAging property

The invention provides a thermoplastic resin composition. The thermoplastic resin composition comprises the following components in parts by mass: 50-85 parts of thermoplastic polyurethane resin, 5-20 parts of saturated polyester resin, 0.5-8 parts of a compatilizer, 0.1-1 part of an antioxidant and 20-100 parts of a flame retardant, wherein the thermoplastic polyurethane resin has excellent flexibility and high and low temperature resistance; and the saturated polyester resin has low melting point, poor high temperature resistance, good aging property and excellent adhesive property with metal and an insulation film. The thermoplastic polyurethane resin and the saturated polyester resin are blended and modified, a small amount of the compatilizer is added, polymer alloy with excellent compatibility can be obtained, and the polymer alloy has good high and low temperature impact property, aging property and adhesive property. The resin composition does not contain a curing agent, has good high temperature liquidity and can meet low temperature lamination requirements. The invention also provides an adhesive made by adopting the thermoplastic resin composition, an insulation adhesive film used for a laminated bus bar and a preparation method of the insulation adhesive film.

Owner:GUANGDONG SHENGYI SCI TECH

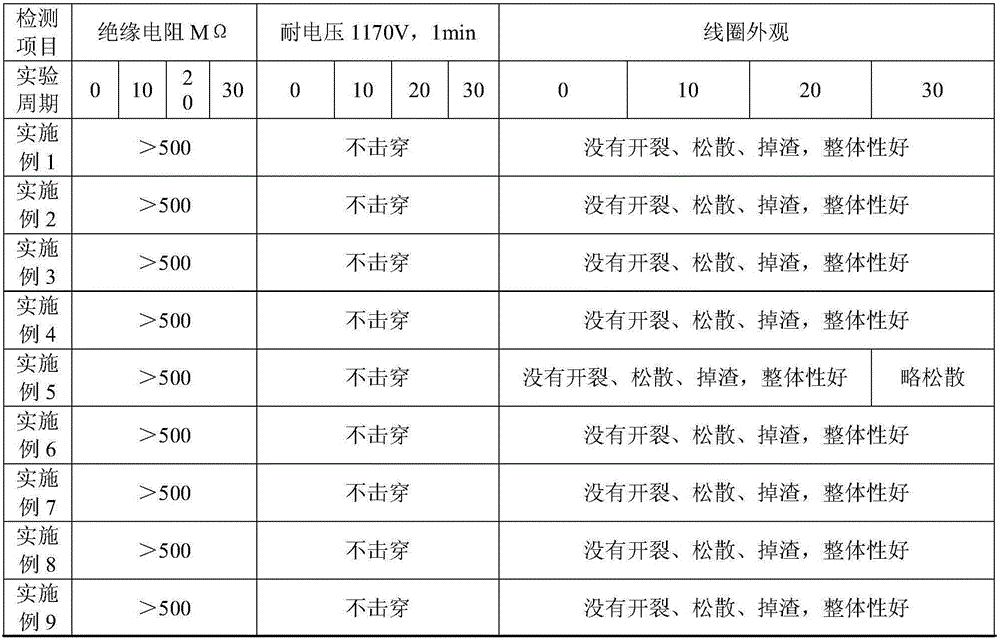

Low-temperature-resistant insulation resin for motor and preparation method thereof

ActiveCN106009527AConvenient heat preservationLow viscosityPlastic/resin/waxes insulatorsStress concentrationUltimate tensile strength

The invention relates to low-temperature-resistant insulation resin for a motor and a preparation method thereof. The insulation resin is prepared from the following ingredients in parts by weight: 100 parts of an epoxy resin composition, 90 to 120 parts of an anhydride curing agent and 0.1 to 0.4 part of a latent accelerator, wherein the epoxy resin composition is a mixture consisting of 20 to 30 parts of bisphenol F epoxy resin, 20 to 40 parts of hyperbranched epoxy resin, 10 to 25 parts of polyfunctional glycidyl amine epoxy resin and 10 to 20 parts of acrylic acid modified organosilicone epoxy resin. The epoxy resin composition, the anhydride curing agent and the latent accelerator according to a specific recipe are used to take a reaction; the molecular chain intensity improvement and the heat-resistant performance improvement are facilitated; the external load is born; the stress concentration is relieved, so that good high-temperature and low-temperature impact resistance performance is realized; the viscosity of the resin is effectively reduced; the insulation treatment of the motor is facilitated.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST +1

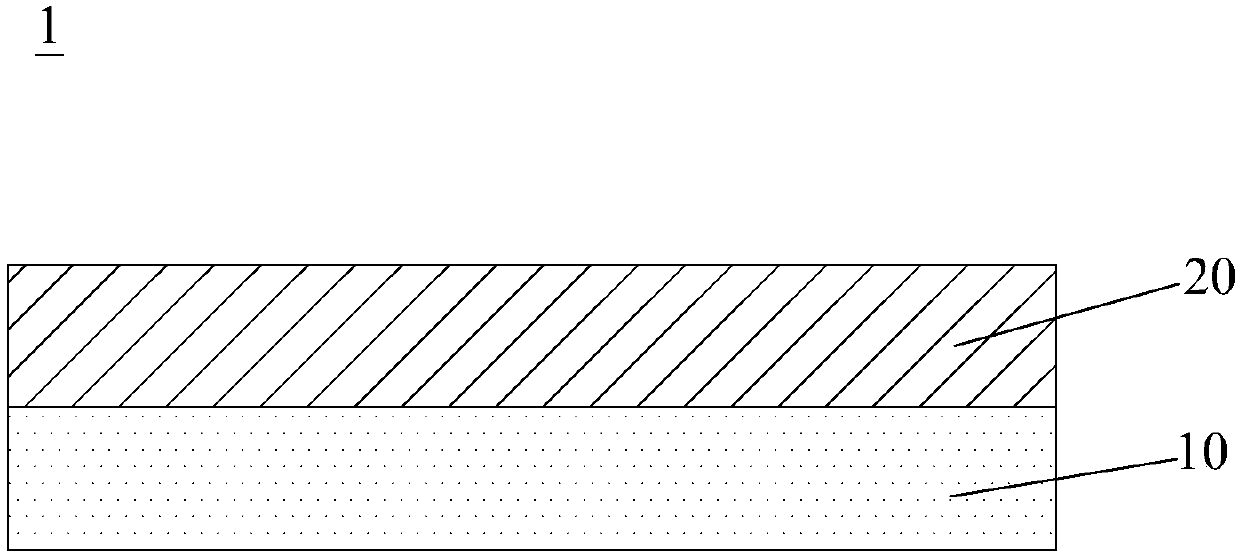

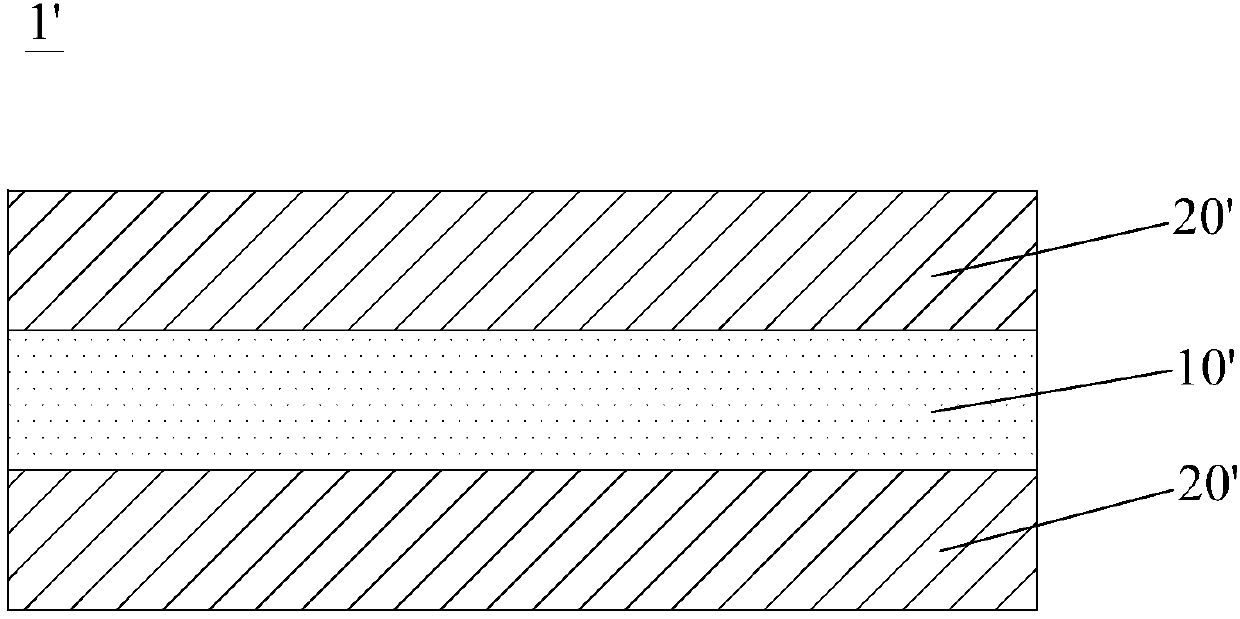

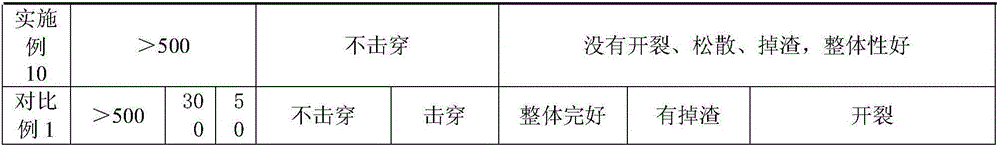

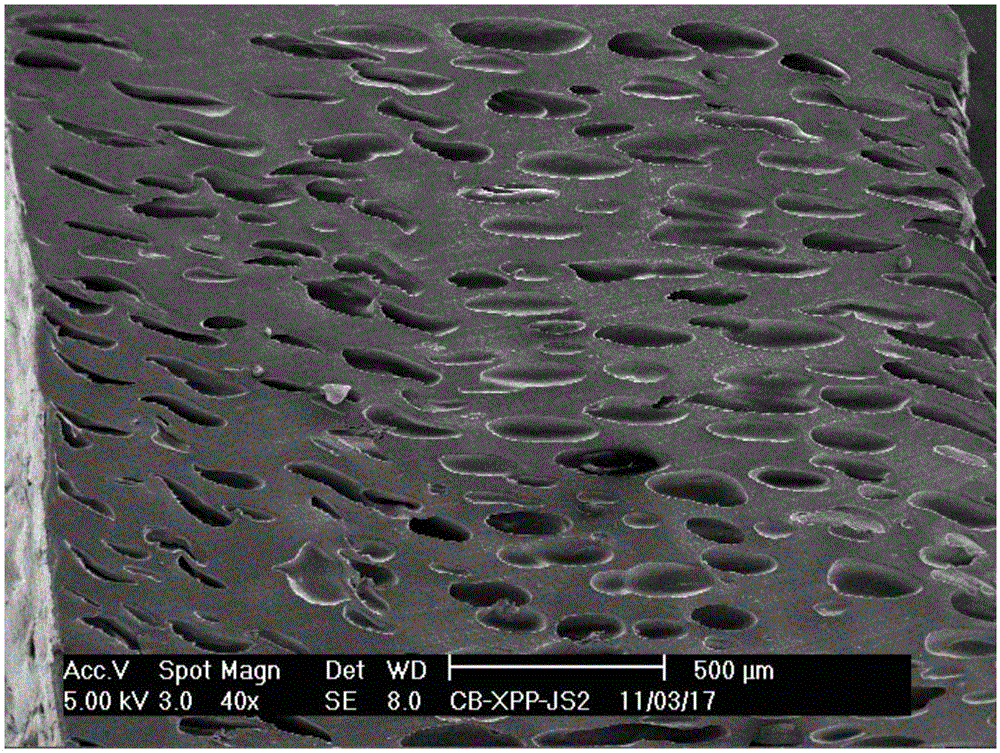

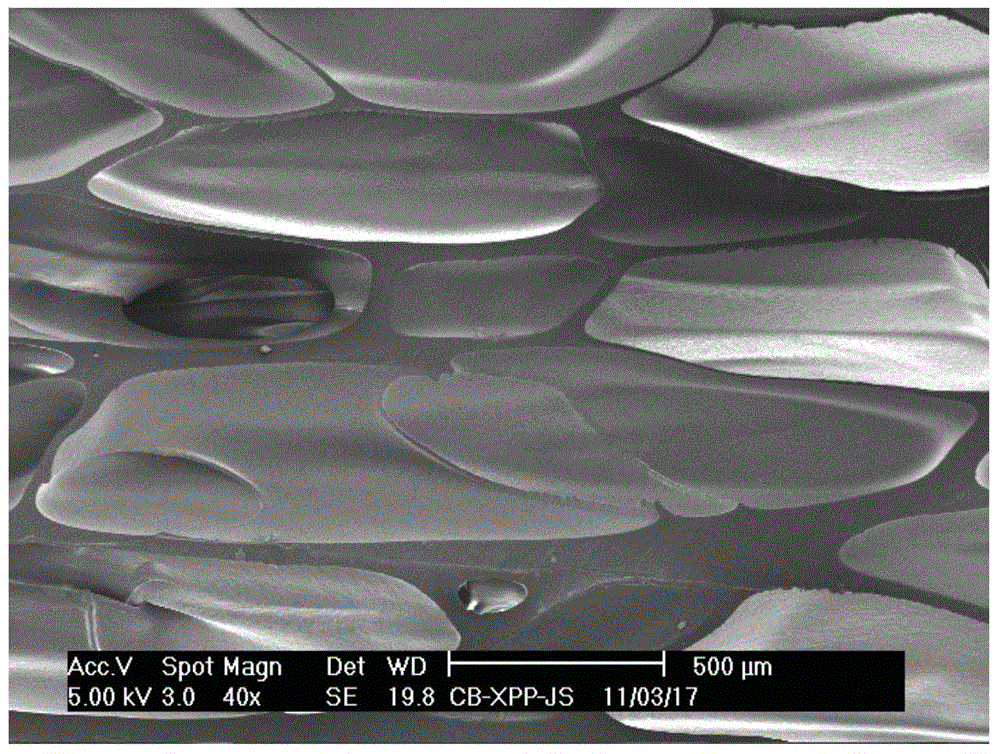

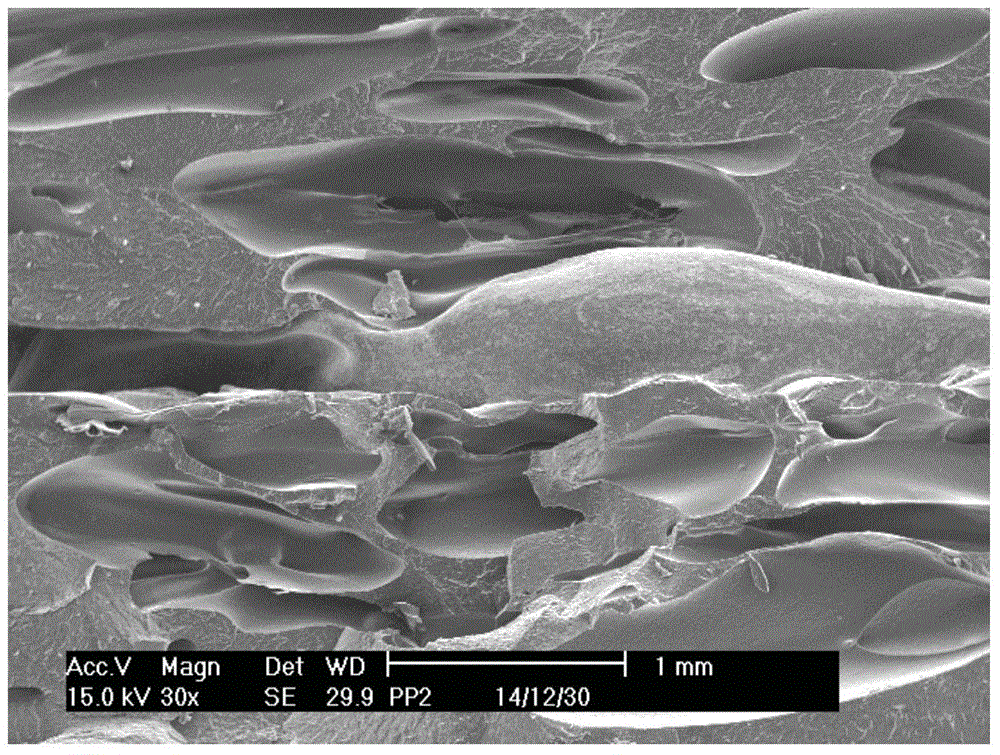

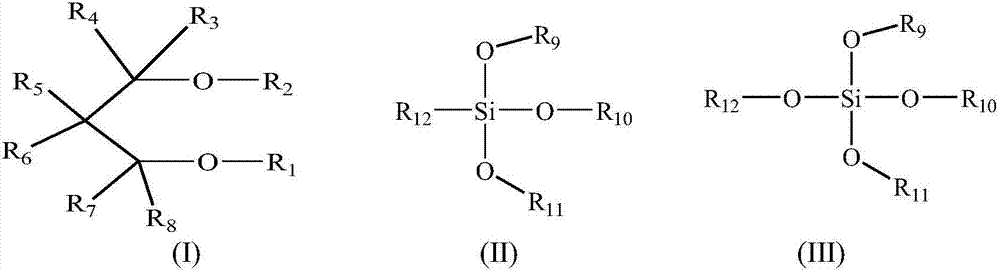

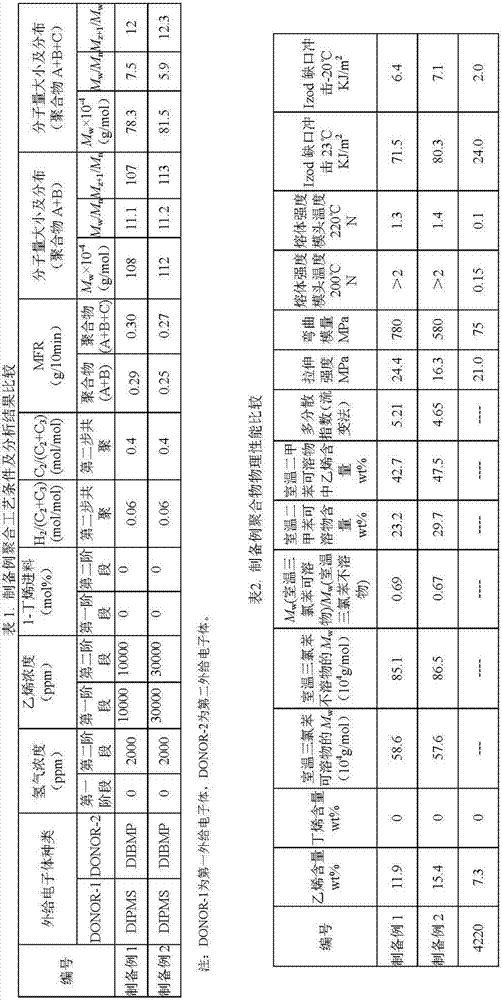

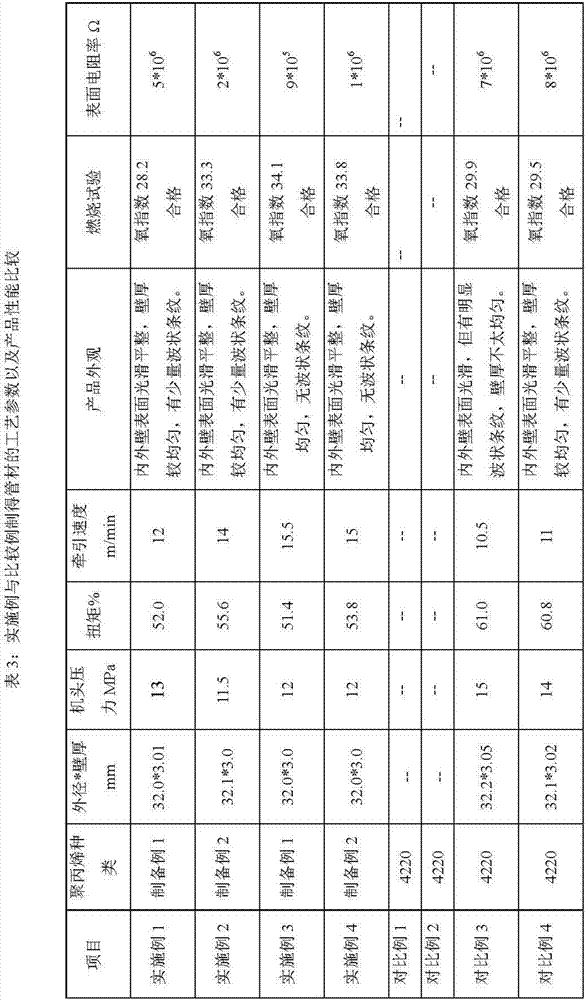

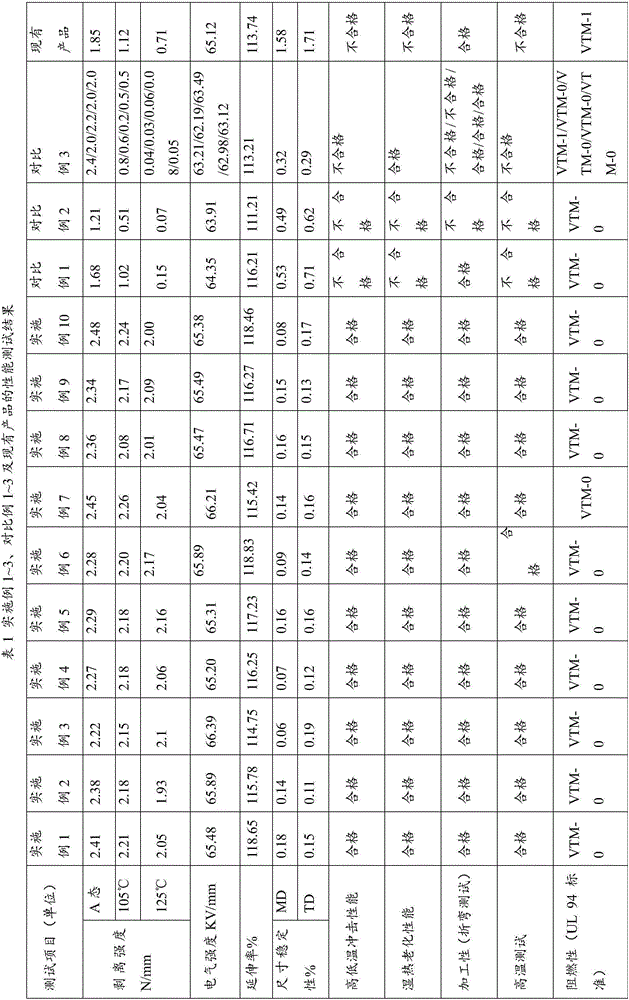

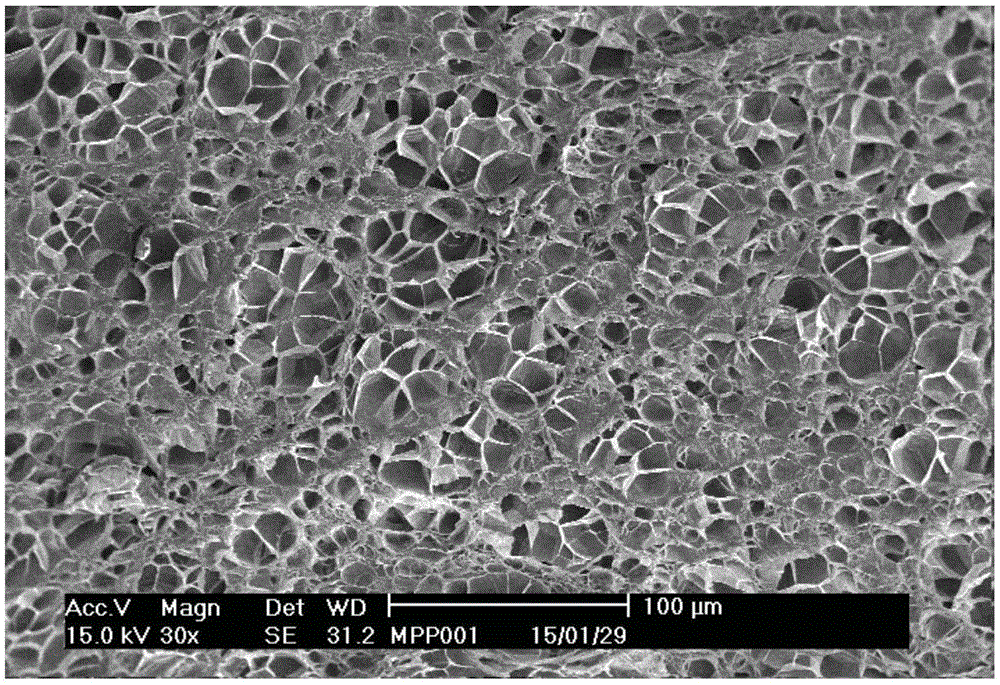

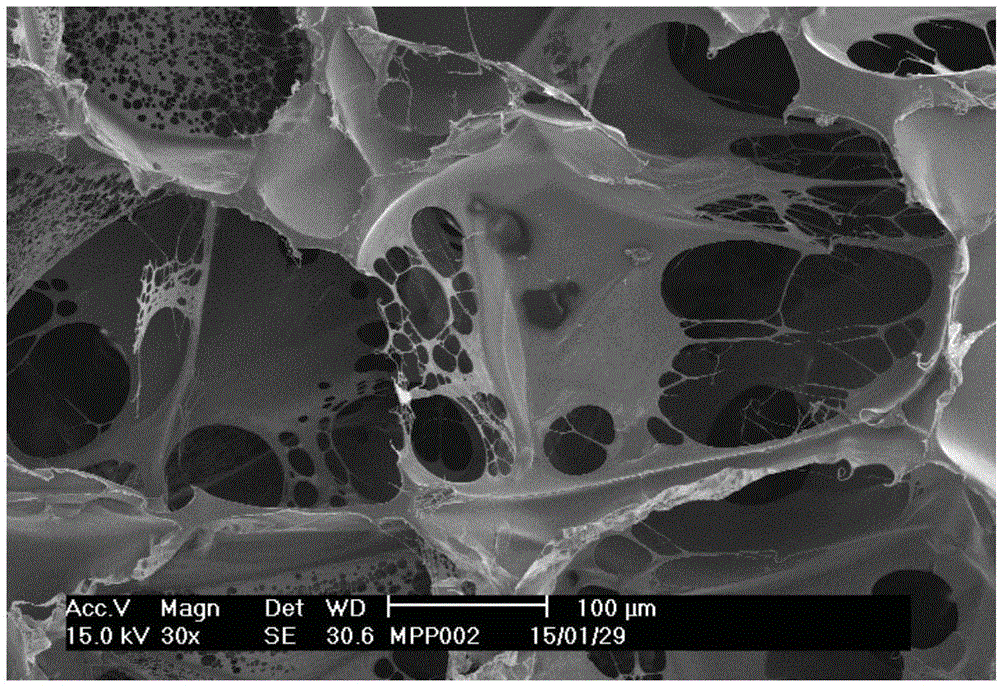

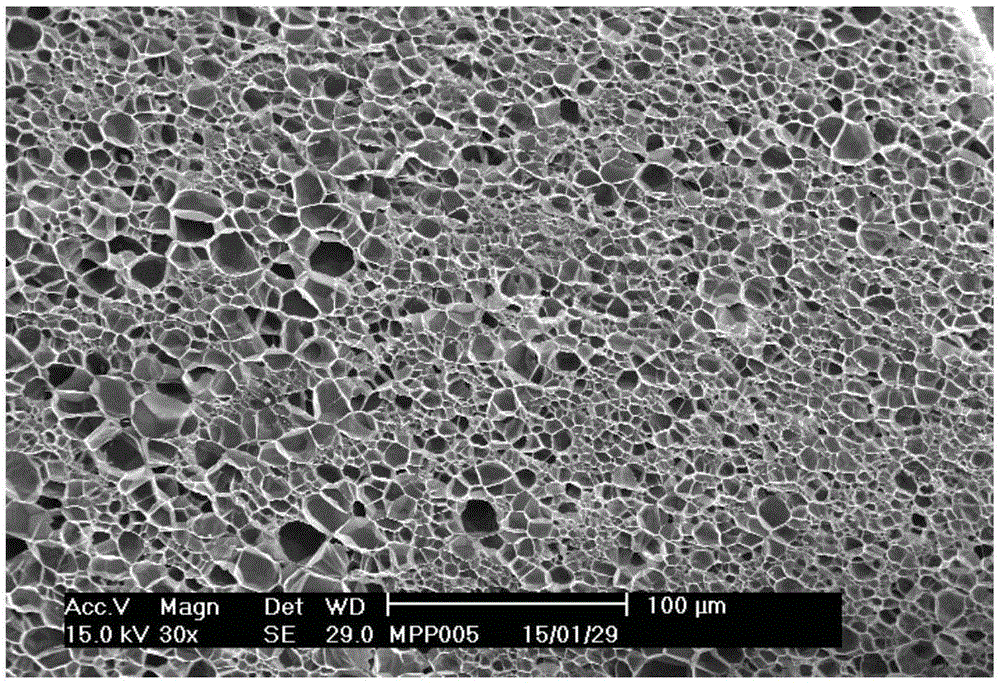

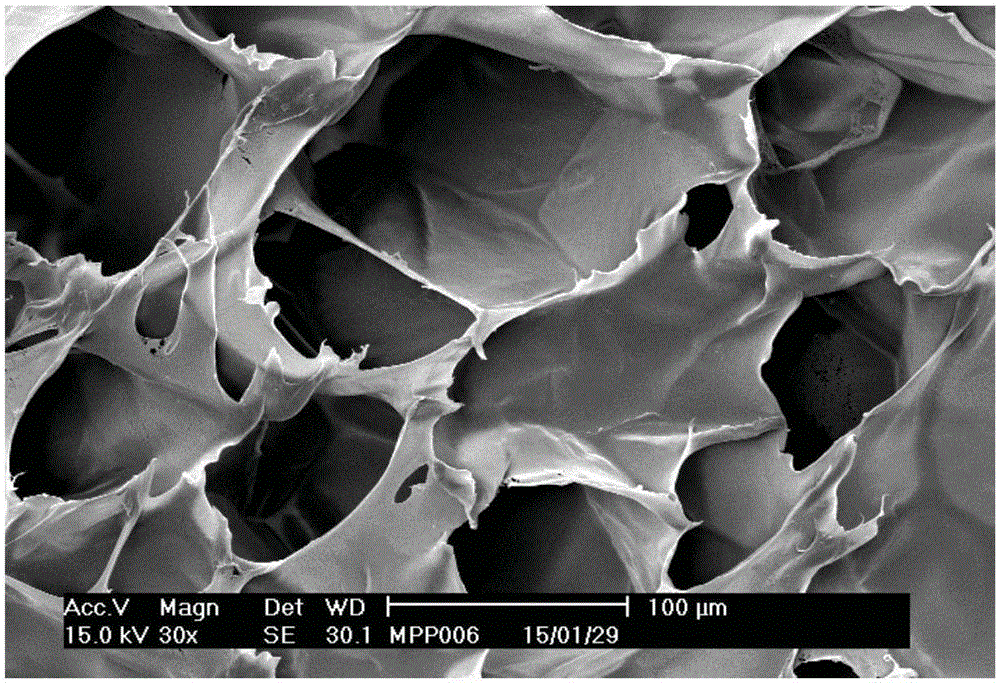

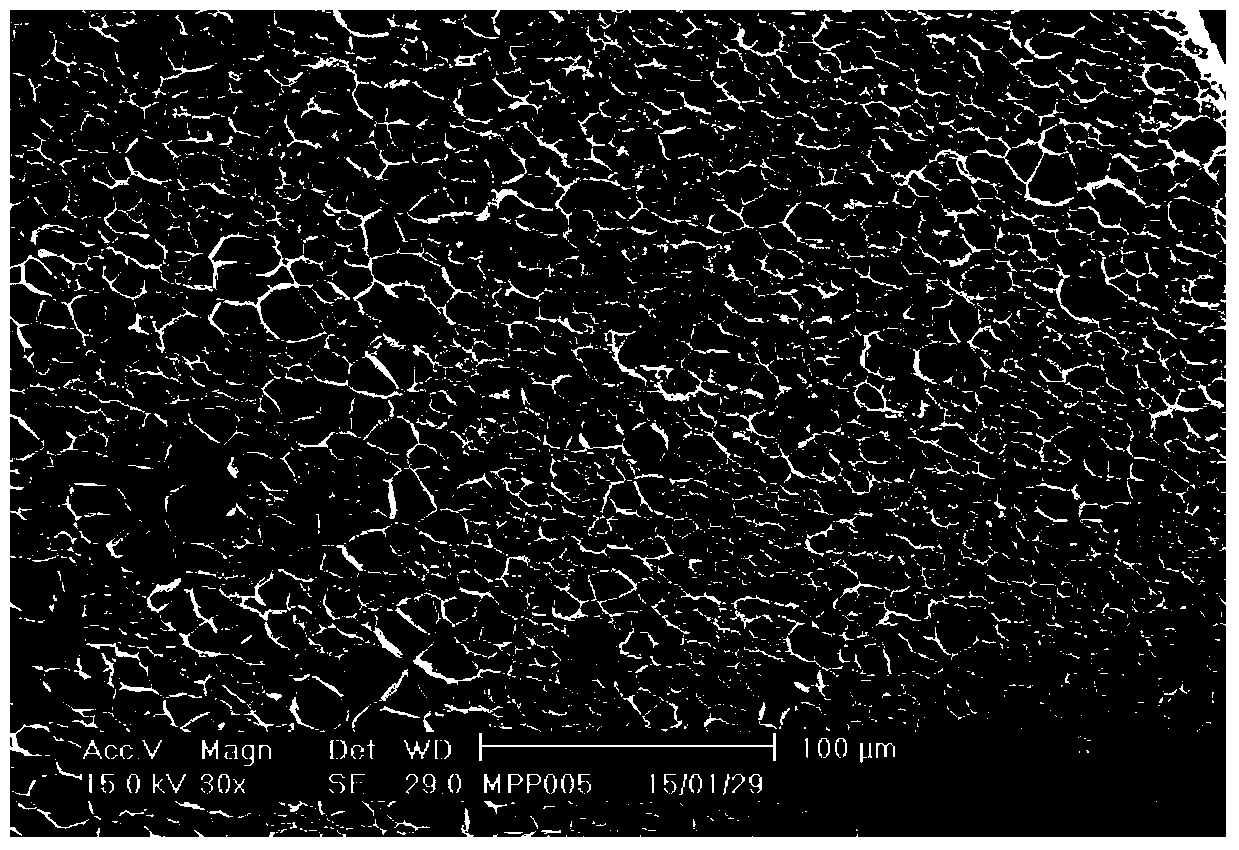

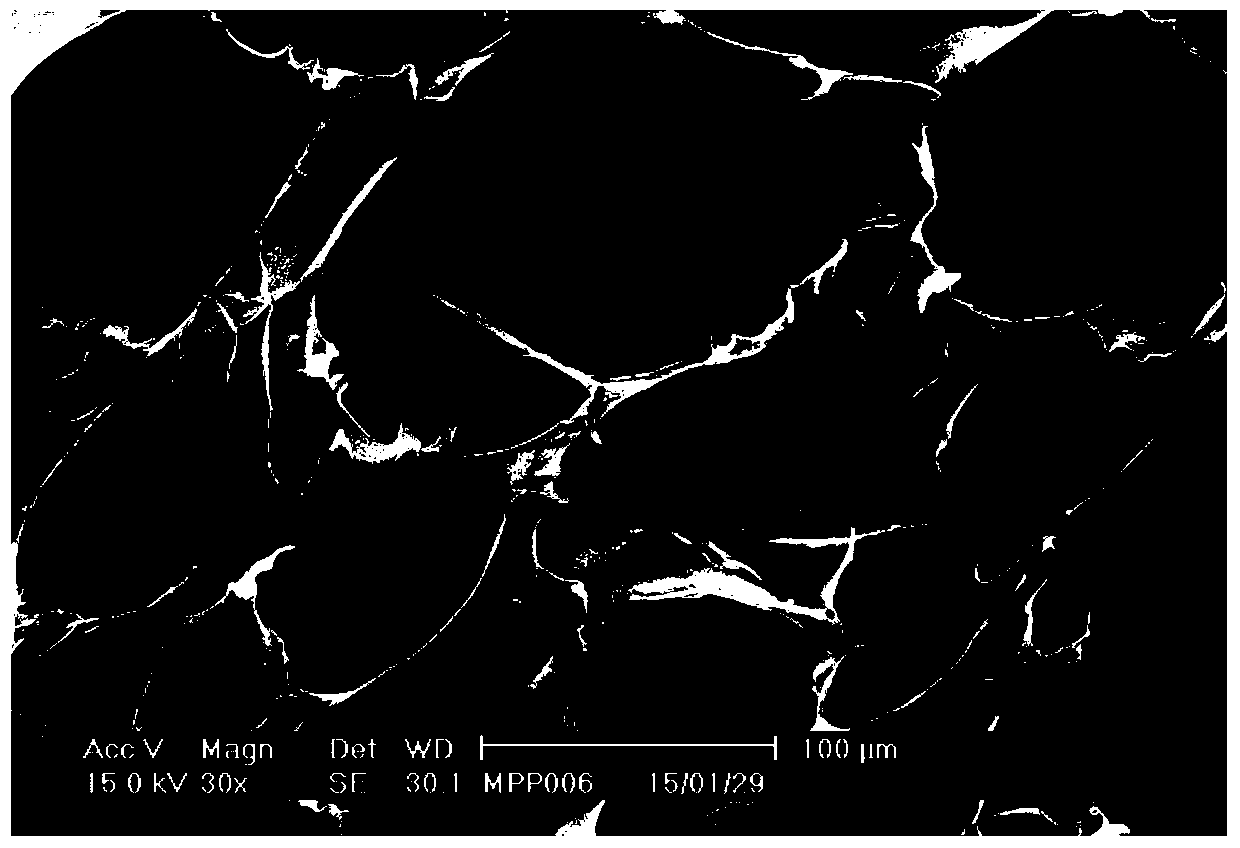

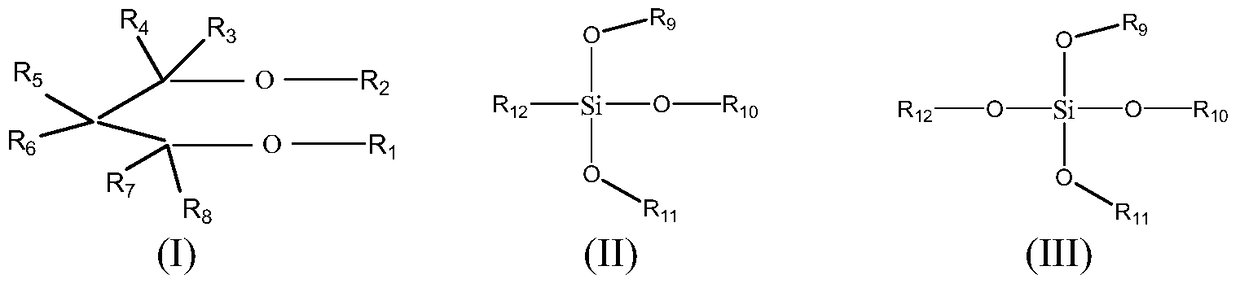

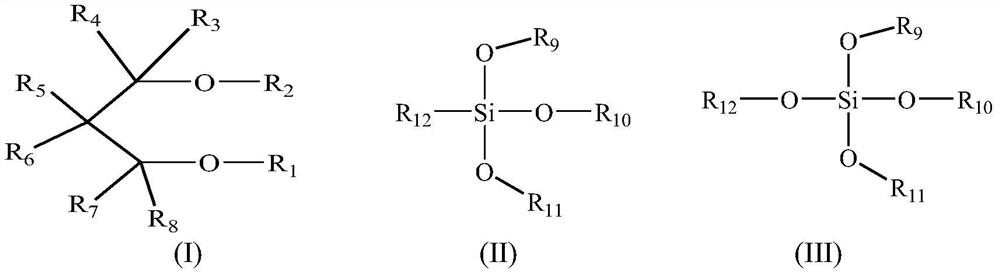

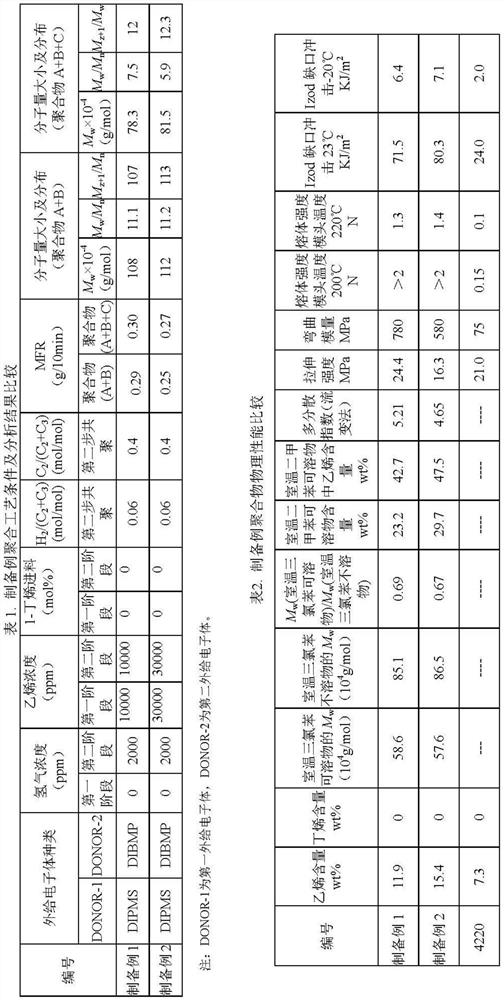

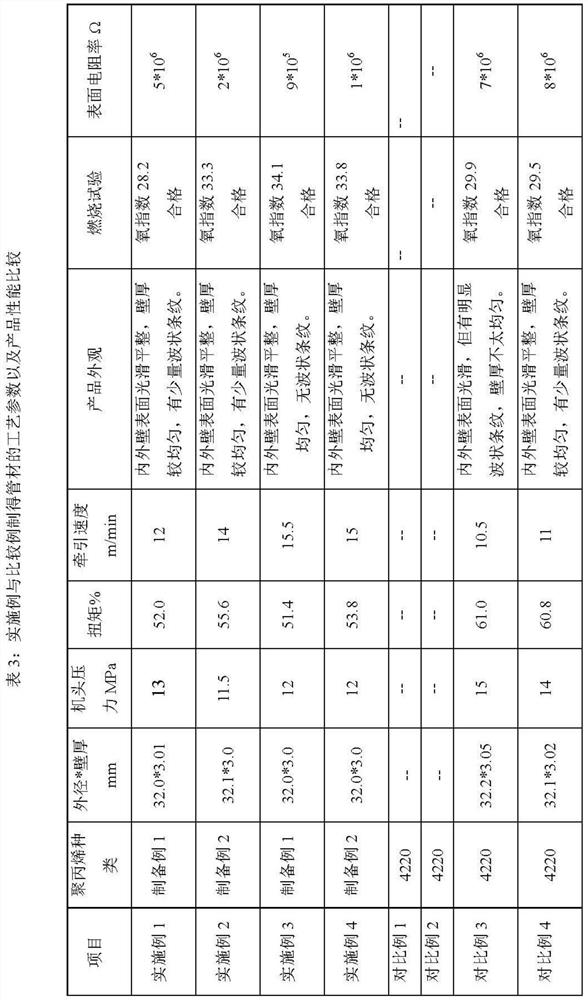

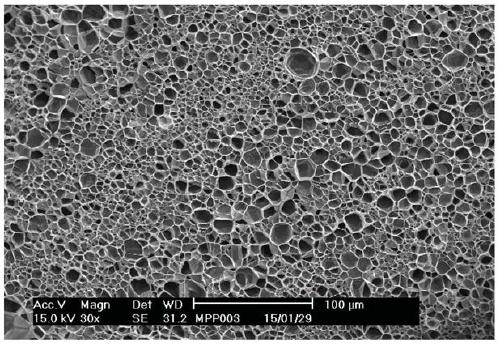

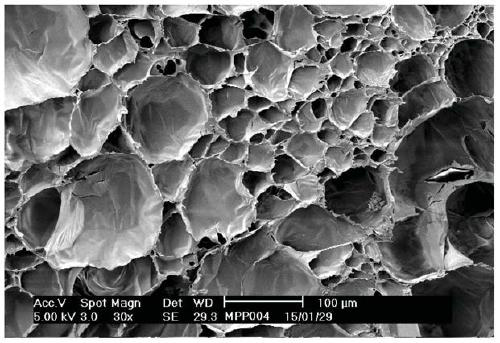

Impact polypropylene foam plate with high melt strength and method for preparing impact polypropylene foam plate

The invention provides a polypropylene foam plate and a method for preparing the same. Impact polypropylene with high melt strength is used as basic resin for the polypropylene foam plate and is foamed and rolled to obtain the polypropylene foam plate. The impact polypropylene with the high melt strength comprises random copolymerization polypropylene continuous phases and propylene-ethylene copolymer rubber dispersion phases, the content of room-temperature dimethylbenzene soluble matters in the impact polypropylene is higher than or equal to 10% and is lower than or equal to 35% by weight, a proportion of the Mw (molecular weight) of room-temperature trichlorobenzene soluble matters in the impact polypropylene to the Mw of room-temperature trichlorobenzene insoluble matters in the impact polypropylene is higher than 0.4 and is lower than or equal to 1. The polypropylene foam plate and the method have the advantages that the polypropylene foam plate has smooth surfaces and bubbles, is uniform in pore diameter distribution, good in high-temperature and low-temperature impact resistance and high in melt strength and can be widely applied to the fields of automobile components, food and electronic packaging, building decoration and the like; the method is simple and is easy to implement and low in cost, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Impact-resistant polypropylene foamed sheet with high melt strength and preparation method therefor

The invention provides a polypropylene foamed sheet and a preparation method therefor. The foamed sheet is prepared by taking impact-resistant polypropylene with high melt strength as base resin and carrying out foaming and rolling, wherein the impact-resistant polypropylene with high melt strength contains a propylene homopolymer ingredient and an ethylene-1-butylene copolymer ingredient, and the ratio of Mw of room-temperature trichlorobenzene soluble matters of the impact-resistant polypropylene with high melt strength to Mw of room-temperature trichlorobenzene insoluble matters of the impact-resistant polypropylene with high melt strength is greater than 0.5 and smaller than or equal to 1; and the content of room-temperature dimethylbenzene soluble matters in the impact-resistant polypropylene with high melt strength is higher than 10wt% and lower than 30wt%. The polypropylene foamed sheet provided by the invention has the advantages of smooth surface, uniform bubble and pore size distribution, good high- / low-temperature impact resistance, high melt strength and the like and can be extensively applied to the field of automotive parts, food and electronic packages, architectural decoration and the like; and the preparation method for the polypropylene foamed sheet is simple and is easy in operation and low in cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame-retardant antistatic random copolymerization polypropylene composition and pipe

The invention relates to a flame-retardant antistatic random copolymerization polypropylene composition, which includes a basic random copolymerization polypropylene resin, a fire retardant and a conductive filling material. The basic random copolymerization polypropylene resin includes a random copolymerization polypropylene continuous phase and a propylene-ethylene copolymer rubber disperse phase, wherein the random copolymerization polypropylene continuous phase at least comprises first random copolymerization polypropylene and second random copolymerization polypropylene, which are independently selected from propylene / ethylene random copolymer, propylene / butylene random copolymer and propylene / ethylene / butylene ternary random copolymer. The content of a xylene soluble substance of basic random copolymerization polypropylene resin at the room temperature is more than 10 wt% and less than 35 wt%. The ratio of Mw of a trichloro-benzene soluble substance to Mw of a trichloro-benzene insoluble substance is more than 0.4 and less than 1. The invention further relates to a pipe made from the composition and a preparation method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame-retardant resin composition, adhesive and laminated busbar insulating adhesive film prepared from same, and preparation method for insulating adhesive film

InactiveCN106751538AImprove heat resistanceGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesHeat resistanceBusbar

The invention provides a flame-retardant resin composition, which comprises the following components in parts by mass: 50 to 110 parts of a saturated polyester resin, 15 to 40 parts of a polyurethane resin, 5 to 20 parts of a curing agent, 30 to 200 parts of a flame retardant, 0.01 to 1 part of an antioxidant and 0.01 to 5 parts of a coupling agent. A small amount of polyurethane resin is added into the flame-retardant resin composition, and then carboxy groups can be introduced into the flame-retardant resin composition to increase functional groups capable of performing a crosslinking reaction with the curing agent in the flame-retardant resin composition and improve the crosslinking density of the flame-retardant resin composition, so that the heat resistance of the flame-retardant resin composition is improved. Moreover, the carboxy groups in the polyurethane resin and hydroxyl groups in the saturated polyester resin can both perform a crosslinking reaction with the curing agent, and an interpenetrating polymer network can be formed after curing, so that the compatibility of the polyurethane resin and the saturated polyester resin is improved. The invention also provides an adhesive and laminated busbar insulating adhesive film prepared from the flame-retardant resin composition, and a preparation method for the laminated busbar insulating adhesive film.

Owner:GUANGDONG SHENGYI SCI TECH

Composition used for preparing polypropylene foaming material and prepared foaming formed body

The invention provides a composition used for preparing a polypropylene foaming material. The composition comprises high melt-strength anti-punching polypropylene as a base resin, the high melt-strength anti-punching polypropylene comprises a propylene homopolymer ingredient and a propylene-ethylene copolymer ingredient, and is characterized in that the molecular weight distribution Mw / Mn is less or equal to 10, and is greater or equal to 4; Mz+1 / Mw is greater than 10 and less than 20; the content of a room-temperature xylene soluble substance is greater than 10 wt% and less than 30 wt%; and the ratio of a room-temperature trichloro-benzenes soluble substance Mw to a room-temperature trichloro-benzenes insoluble substance is greater than 0.4 and less than 1. The invention also provides a polypropylene injection foaming formed body produced by the composition through injection foaming and a preparation method thereof, and the formed body is suitable for the fields with special requirements on the part shapes such as automobile, aircraft, and high-speed rail internal and external decoration.

Owner:CHINA PETROLEUM & CHEM CORP +1

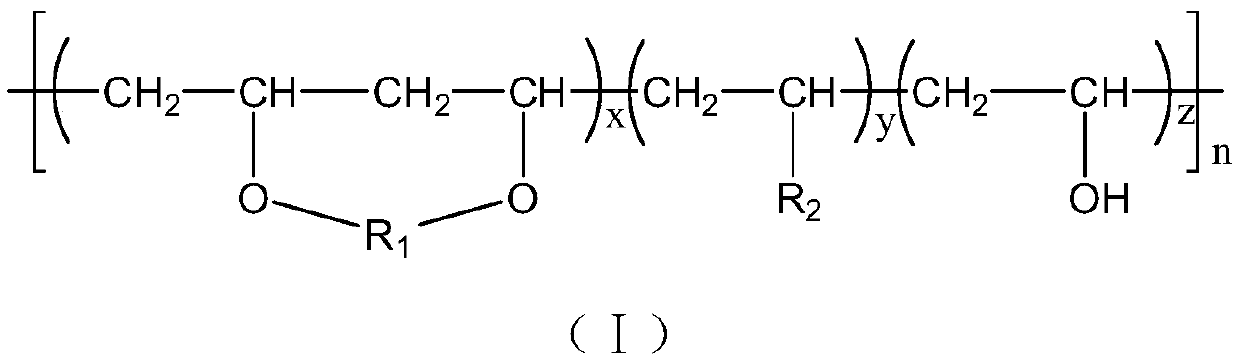

High-wettability environment-friendly three-proofing adhesive and preparation method thereof

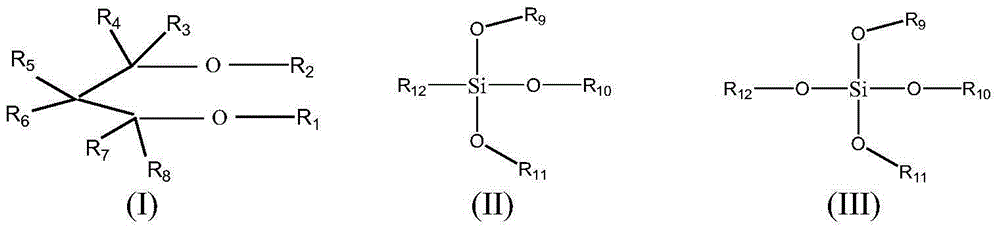

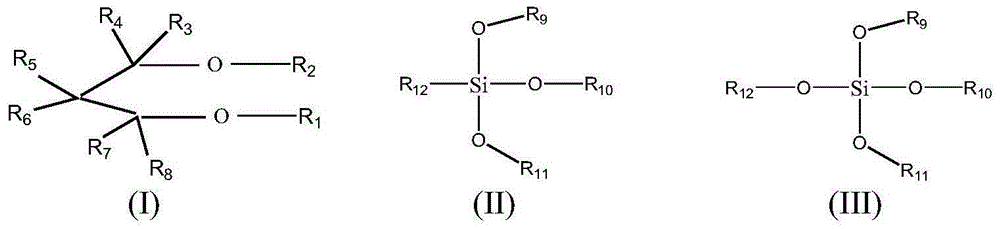

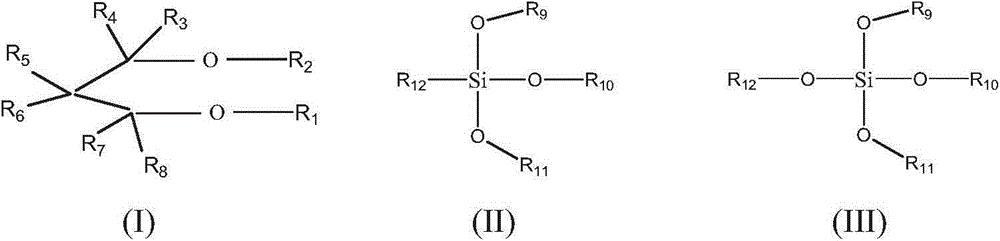

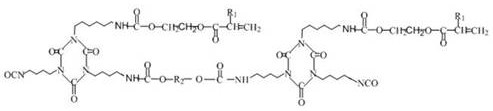

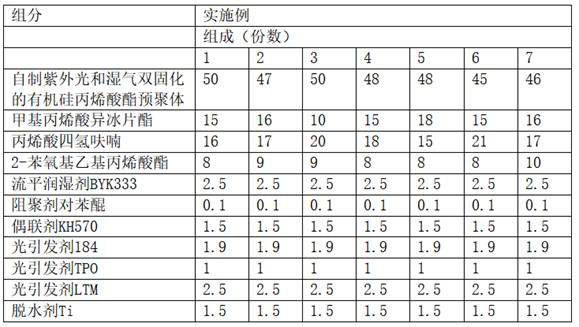

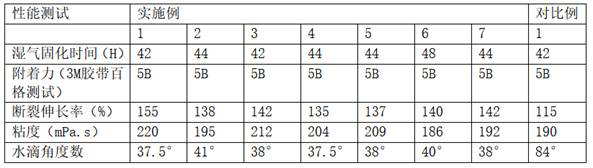

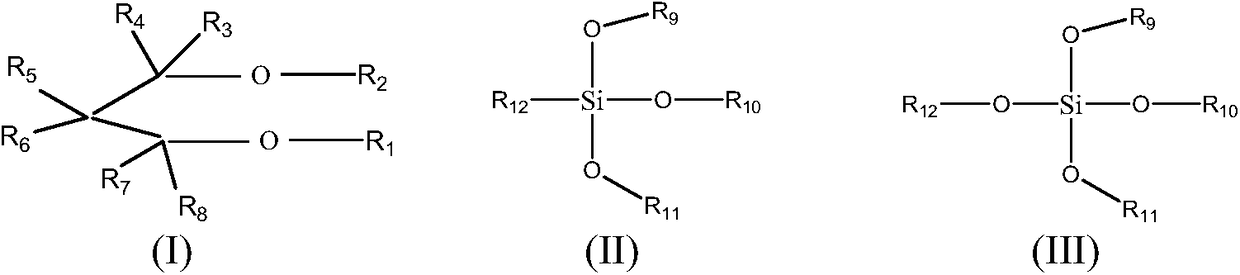

PendingCN114163972AExcellent high and low temperature impact resistanceReduce surface tensionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerIsocyanate

Owner:YANTAI SEAYU NEW MATERIALS CORP LTD

High-strength cracking-resistant liquid pouring sealant and preparation method thereof

PendingCN111234751AImprove crack resistanceImprove bondingNon-macromolecular adhesive additivesMacromolecular adhesive additivesThermal dilatationFiber

The invention discloses a high-strength cracking-resistant liquid pouring sealant and a preparation method thereof. The high-strength cracking-resistant liquid pouring sealant is prepared by mixing 70-110 parts by weight of a component A and 10-30 parts by weight of a component B, wherein the component A is formed by mixing toughened liquid epoxy resin, epoxy resin, an epoxy reactive diluent, a defoaming agent, aluminum hydroxide, spherical silica powder and reinforced chopped fibers; the component B is formed by mixing an anhydride curing agent and an accelerant; the preparation method comprises the following steps: preparing the toughened liquid epoxy resin, adding other materials, uniformly dispersing to prepare the component A, and directly and uniformly mixing the component B. The pouring sealant disclosed by the invention is moderate in viscosity and convenient to use, has the characteristics of high bonding strength, low thermal expansion coefficient, low stress, high strength,excellent insulativity, excellent high and low temperature impact resistance and the like after being heated and cured, and is suitable for insulating packaging of power electronic containers relatedto large steel, copper and other special metal materials.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Dual-component silica gel material and preparation method and application thereof

InactiveCN105482775AImprove heat resistanceExcellent high and low temperature impact resistanceNon-macromolecular adhesive additivesHeating element materialsHydrogenMetallurgy

The invention relates to the technical field of high-temperature-resistant silica gel and particularly discloses a dual-component silica gel material and a preparation method and application thereof. The dual-component silica gel material is prepared from a component A and a component B. The component A is prepared from vinyl silicon oil, hydrogen containing silicone oil, an inhibitor, ceramic powder and antioxygen. The component B is prepared from vinyl silicon oil, a tackifying agent, a catalyst, ceramic powder and antioxygen. The raw materials of the component A and the raw materials of the component B are placed in stainless steel or ceramic lined tanks according to the mass ratio to be mixed and stirred and ground and dispersed through a ceramic three-roller grinding machine, heavy paste A and heavy paste B are prepared, the heavy paste A and the heavy paste B are mixed according to the mass ratio of 1:1 during use, the curing temperature ranges from 150 DEG C to 200 DEG C, and curing time ranges from 1 h to 2 h. The product is used for binding and sealing of ceramic heating sheets and aluminum sheets of a PTC heater, the heat-resistant performance and binding performance of the PTC heater are improved, the service life is prolonged, production cost is reduced, and the material is suitable for large-scale production.

Owner:陕西工业职业技术学院

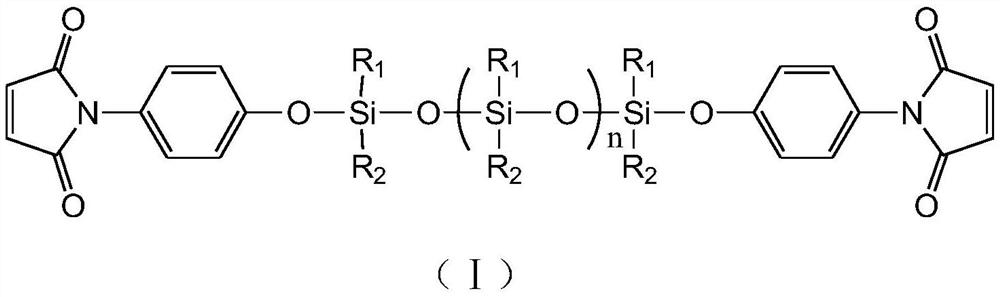

High-heat-resistance single-component adhesive and preparation method thereof

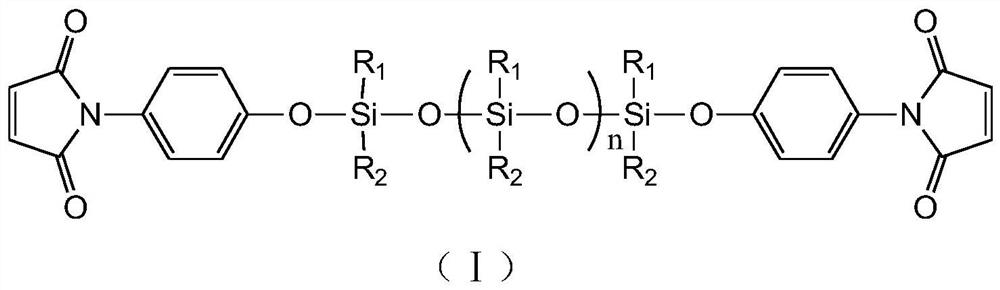

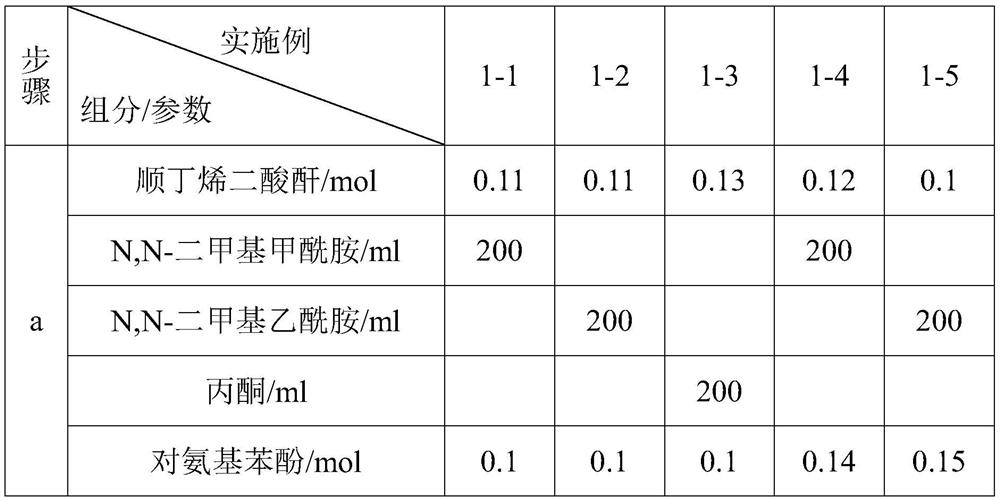

PendingCN113736401AWide reaction temperature rangeExothermic stableNon-macromolecular adhesive additivesEpoxynovolac adhesivesImidePolymer science

The invention discloses a high-heat-resistance single-component adhesive and a preparation method thereof. The high-heat-resistance single-component adhesive is characterized by being prepared by mixing the following components in parts by weight: 5 to 30 parts of toughening modified bismaleimide resin, 15 to 55 parts of epoxy resin, 0.1 to 5 parts of epoxy active diluent, 3 to 18 parts of a latent curing agent, 0.01 to 0.5 part of a defoaming agent, 0.01 to 0.5 part of a wetting dispersant, 0.1 to 5 parts of a catalyst and 5 to 60 parts of an inorganic filler. The preparation method comprises the following steps: preparing bismaleimide resin, carrying out toughening modification treatment, adding the toughening modified bismaleimide resin and other raw materials into a vacuum planetary mixer, and carrying out mixing. The high-heat-resistance single-component adhesive disclosed by the invention has the characteristics of gentle heat release in a curing process, high heat resistance of a cured product, high toughness, low thermal expansion coefficient, good high and low temperature impact resistance and the like, and is suitable for bonding and sealing of electronic and electric appliance elements and metal and nonmetal devices with heat resistance and environment temperature requirements.

Owner:艾蒙特成都新材料科技有限公司

SiC crystal whisker enhanced Sn-Bi series solder and preparation method thereof

InactiveCN109175768AImprove mechanical propertiesHindered dislocationWelding/cutting media/materialsSoldering mediaWhiskersMechanical property

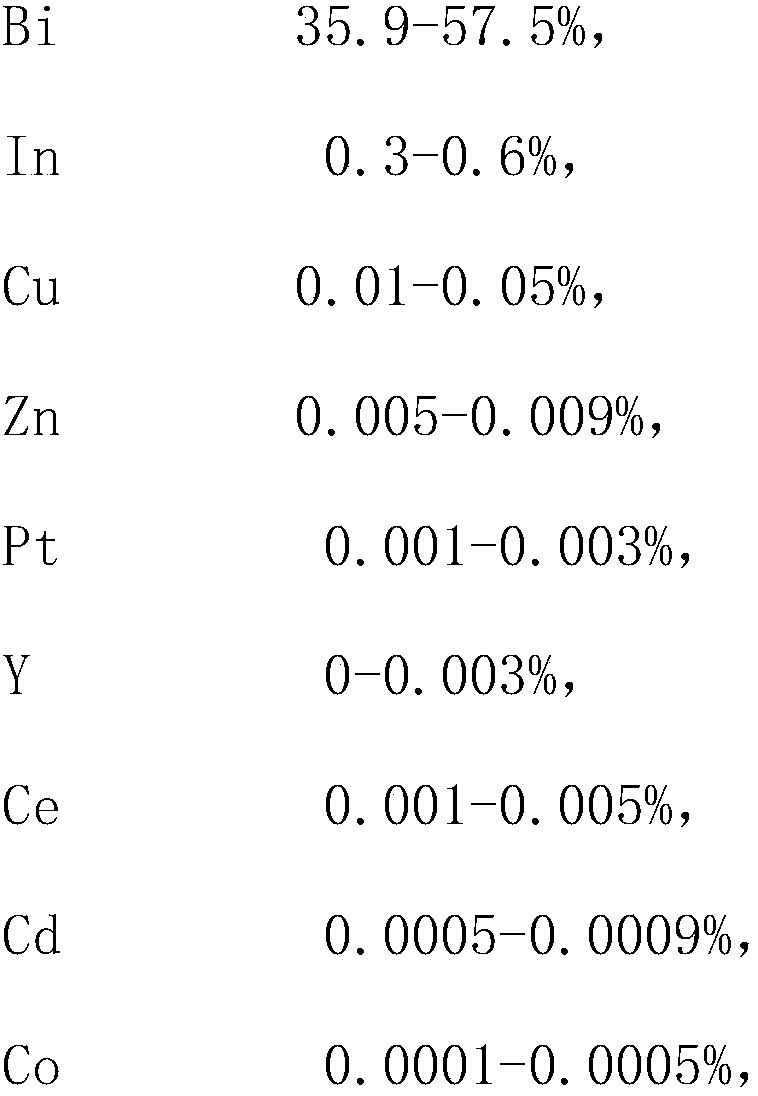

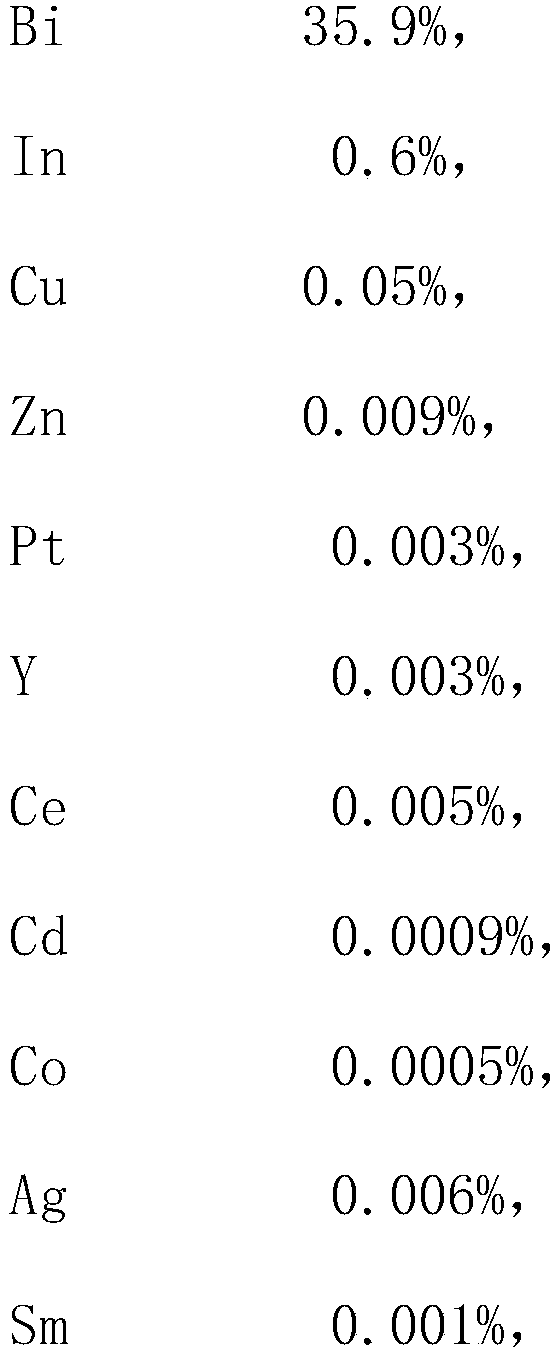

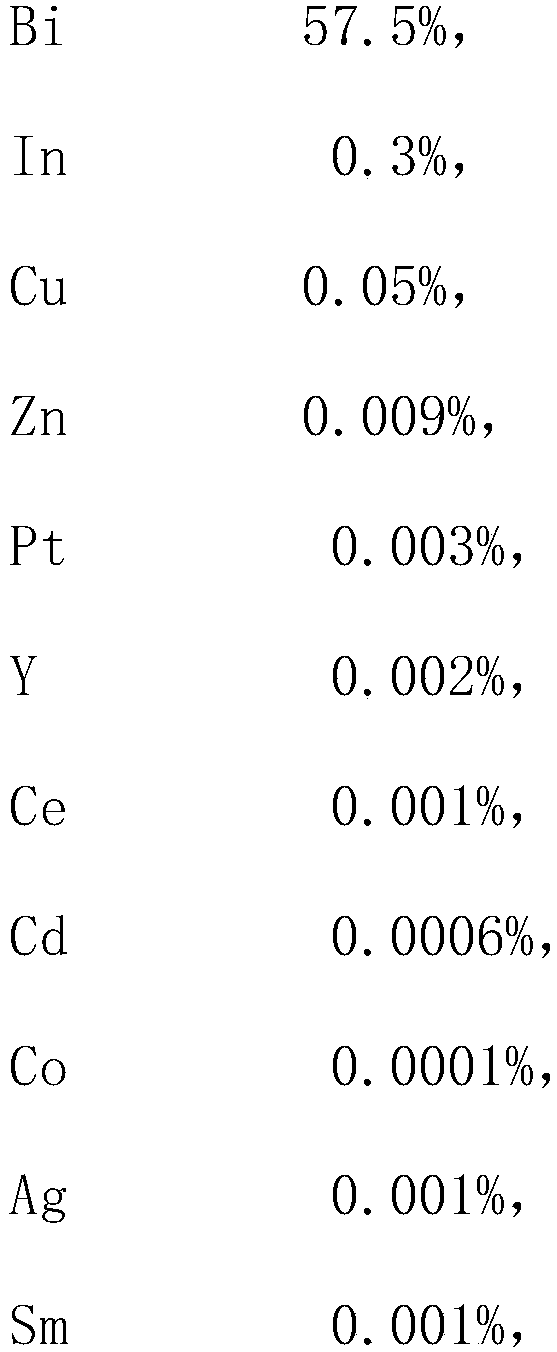

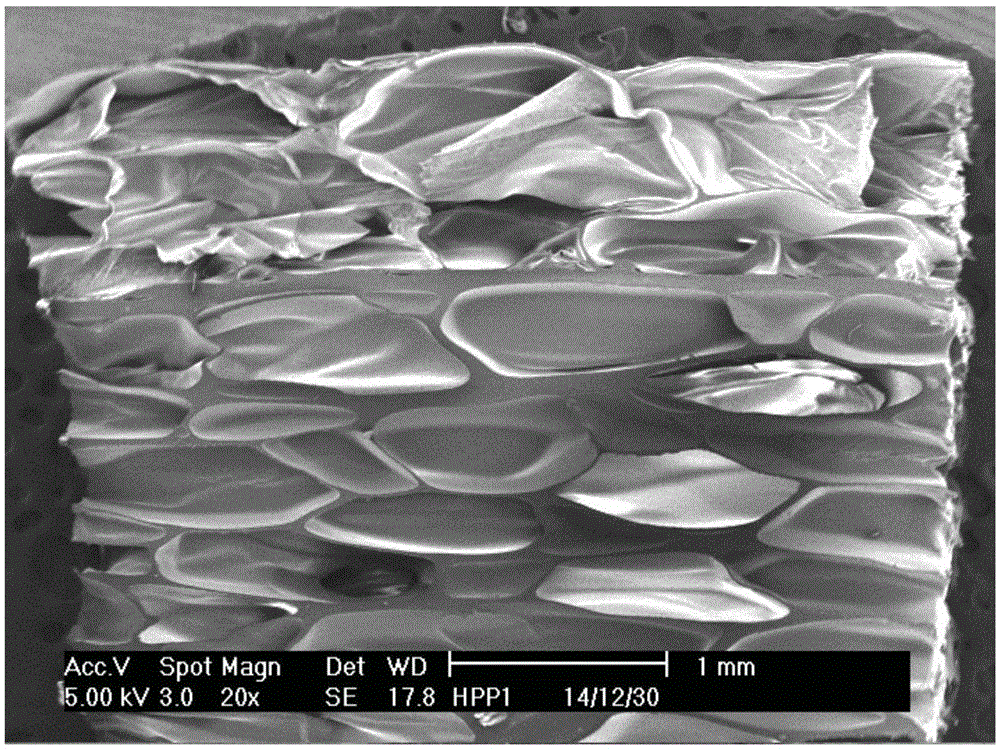

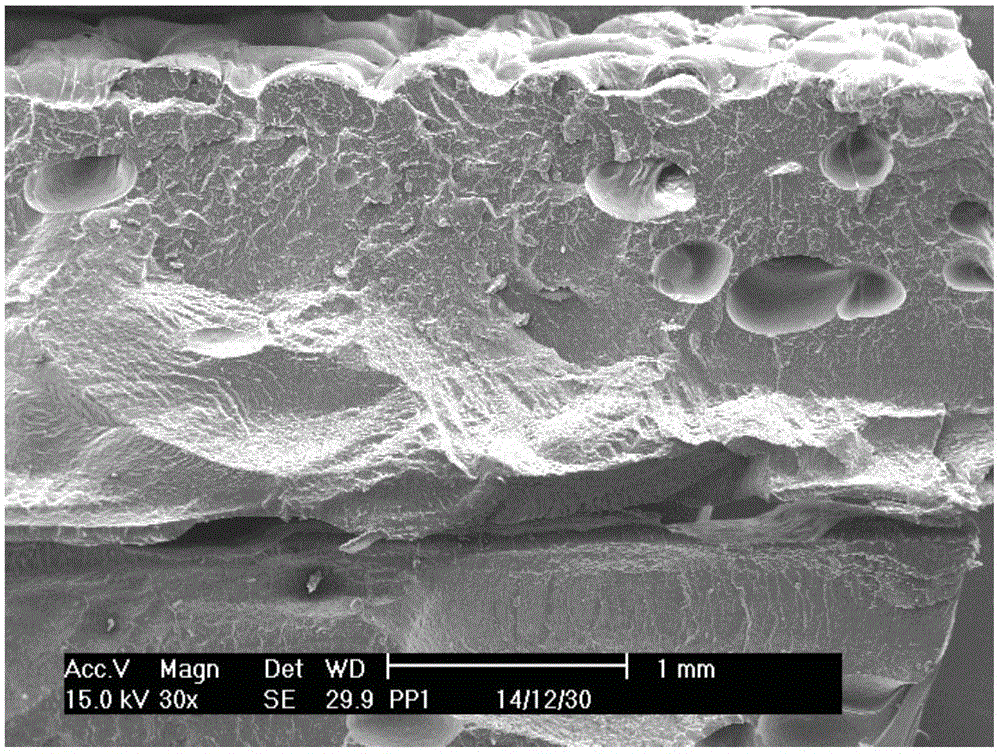

The invention discloses SiC crystal whisker enhanced Sn-Bi series solder which comprises the following components in part by weight: 3-6 parts of SiC crystal whisker and 40-80 parts of Sn-Bi series microalloy powder, wherein the Sn-Bi series microalloy powder comprises the following components in percentage by mass: 35.9-57.5% of Bi, 0.3-0.6% of In, 0.01-0.05% of Cu, 0.005-0.009% of Zn, 0.001-0.003% of Pt, 0-0.003% of Y, 0.001-0.005% of Ce, 0.0005-0.0009% of Cd, 0.0001-0.0005% of Co and the balance of Sn and unavoidable impurities. The invention further discloses a preparation method of the SiC crystal whisker enhanced Sn-Bi series solder. The SiC crystal whisker enhanced Sn-Bi series solder prepared through the preparation method disclosed by the invention has high wettability to a matrixand has high mechanical performance.

Owner:EUNOW ELECTRONICS TECH CO LTD SUZHOU

High-melt-strength anti-impact polypropylene foamed board and preparation method thereof

The invention provides a high-melt-strength anti-impact polypropylene foamed board and a preparation method thereof. The foamed board is prepared with high-melt-strength anti-impact polypropylene serves as matrix resin through foaming and rolling. The high-melt-strength anti-impact polypropylene is composed of a propylene homopolymer component and a propylene-ethylene copolymer component and has the characteristics that molecular weight distribution Mw / Mn is smaller than or equal to 10 and larger than or equal to 4, Mz+1 / Mw is larger than 10 and smaller than 20, the room temperature dimethylbenzene soluble component content is larger than 10 wt% and smaller than 30 wt%, and the ratio of Mw of room temperature trichlorobenzene soluble components to Mw of room temperature trichlorobenzene insoluble components is larger than 0.4 and smaller than 1. The polypropylene foamed board has the advantages of being flat in surface, uniform in foam pore and aperture size distribution, good in high-and-low-temperature anti-impact performance, high in melt strength and the like, can be widely used in the fields of vehicle parts, food and electronic packaging, building decoration and the like, and is simple in preparation method, easy to operate and low in cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

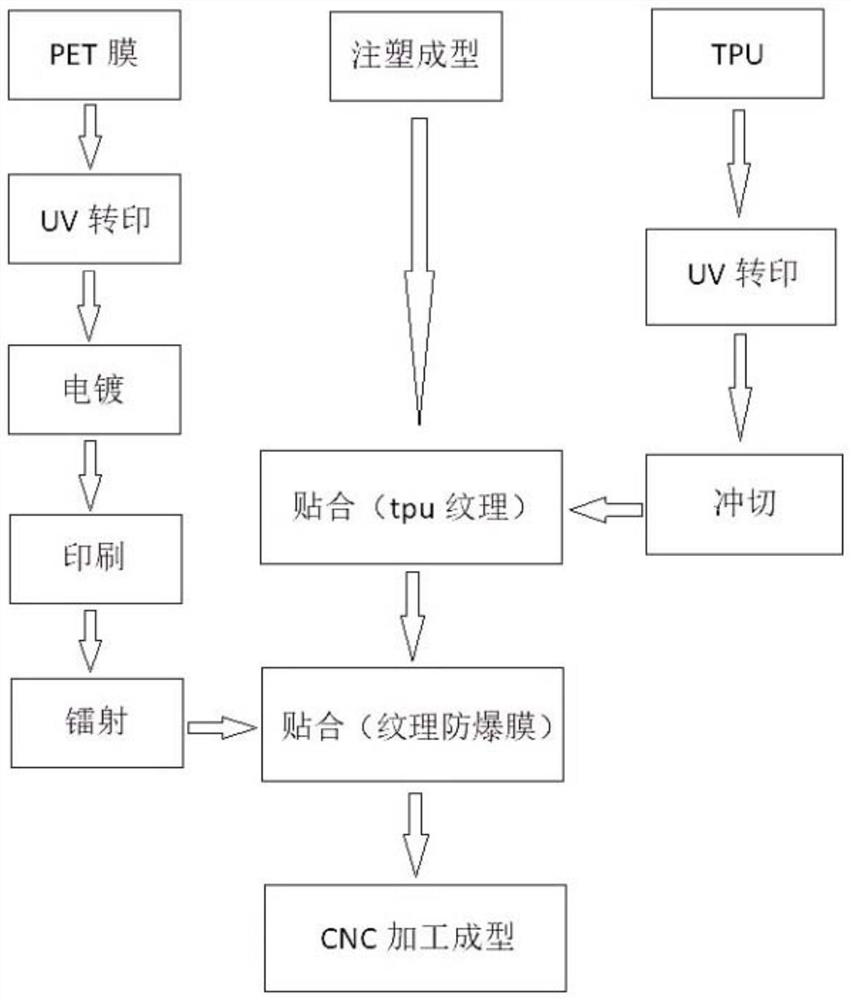

Preparation method of external texture mobile phone cover

PendingCN113276402AAvoid edge lightSimple preparation processTelephone set constructionsEngineeringMechanical engineering

The invention discloses a preparation method of an external texture mobile phone cover. The preparation method comprises the following steps of molding an injection molded part, carrying out UV embossing treatment on the surface of TPU, carrying out texture pressing on the TPU, transferring the texture to the outer surface of the injection molded part through hardening liquid, attaching the inner surface of the injection molded part subjected to transferring to an explosion-proof film, and carrying out CNC machining on the injection molded part with the explosion-proof film attached. The preparation method is simple in preparation process, a small number of preparation procedures steps are performed, and light transmission of the edges of the periphery of a cover plate, a fingerprint hole, a camera hole and the like is avoided; and the mobile phone cover prepared by adopting the preparation method is high in plasticity, good in impact resistance, low in electromagnetic signal shielding, small in electromagnetic wave loss, high in hardness, relatively good in wear resistance, corrosion resistance, high and low temperature impact resistance and aging resistance, light transmission of the mobile phone rear cover is reduced, and the light texture is enhanced.

Owner:KUNSHAN SANJING SCI & TECH

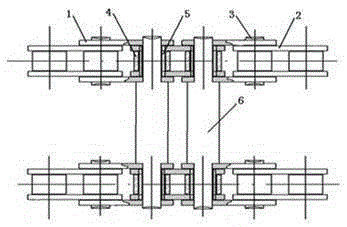

Lengthened shaft roller double-row conveying chain and technology thereof

ActiveCN105257781AHigh tensile strengthImprove impact resistanceConveyorsHauling chainsWear resistantEngineering

A lengthened roller double-row conveying chain comprises chain plates, pin shafts, rollers and sleeves. The chain plates include the outer chain plate and the inner chain plate. Two conveying chain bodies spaced by a certain distance are arranged and connected through shaft rollers. The two ends of the shaft rollers and the pin shafts are the same in shape and replace the positions of the pin shafts. The middle parts of the shaft rollers are thicker than the two ends of the shaft rollers. All parts of the conveying chain bodies are processed through multiple special machining technologies, for example, the strengthening carbon supplementing thermal treatment technology and the metal seepage technology are sequentially carried out on the surfaces of the pin shafts and the shaft rollers. The strength of the conveying chain bodies is high, the bearing area of the conveying chain bodies is large, the bearing capability and transmission precision are high, and the rotating speed is even. The synchronous running conveying step pitch is matched, the anti-impact performance and wear-resistant performance are high, and ultra-high corrosion-resisting performance is achieved.

Owner:HANGZHOU CHIZHENG TECH

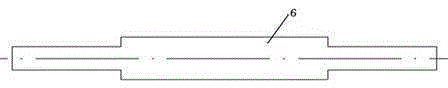

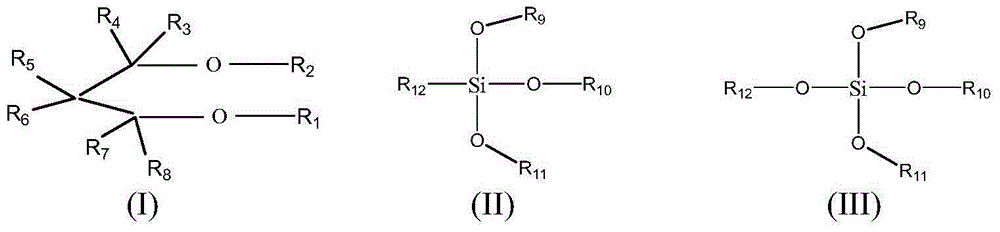

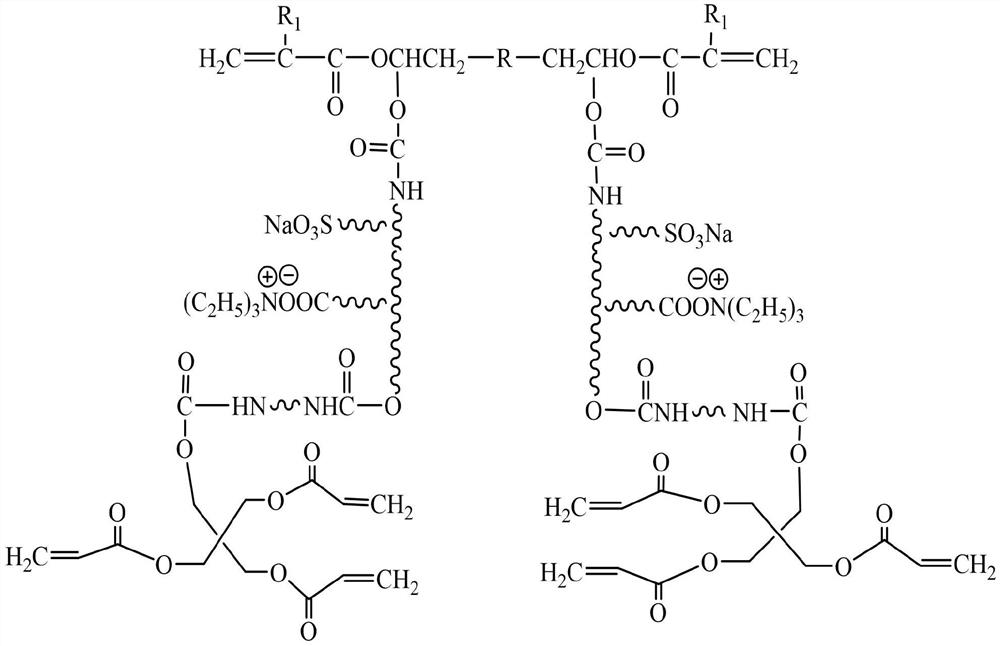

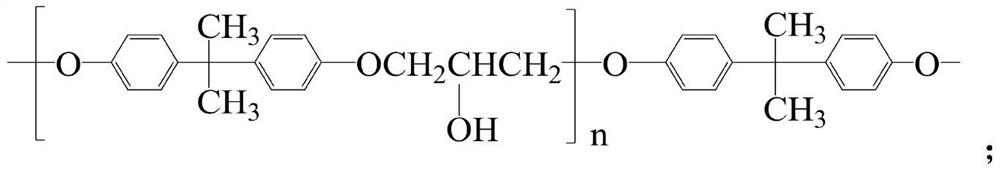

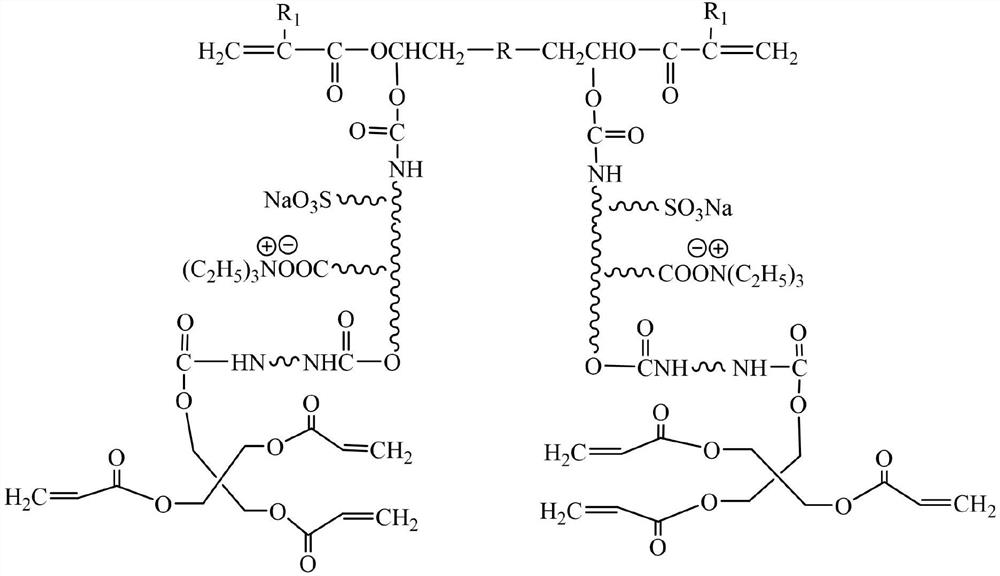

Water-based UV resin for UV-Monocoat and preparation method of UV-Monocoat

PendingCN113683741AGood additive colorGood anti-adhesionPolyurea/polyurethane coatingsPolymer sciencePolyethylene terephthalate glycol

The invention relates to a water-based UV (ultraviolet) resin for UV-Monocoat and a preparation method of the water-based UV resin. The water-based UV resin is sulfonate anionic polyurethane modified acrylate and contains eight active functional groups. The water-based UV resin disclosed by the invention can be made into water-based UV-Monocoat with aluminum paste, transparent color paste, a delustering agent, a photoinitiator, an auxiliary agent and water. A paint film has excellent adhesive force, wear resistance, alcohol resistance, boiling resistance, flexibility, scratch resistance, hand perspiration resistance, high temperature and high humidity resistance, pollution resistance, aging resistance, adhesion resistance and skin feeling, the metal feeling of the paint film is strong, the recoatability is not influenced, and the paint film is safe and environment-friendly. The water-based UV resin can be used for primary coating on the surfaces of plastic substrates such as ABS (acrylonitrile butadiene styrene), PC (polycarbonate), PET (polyethylene terephthalate), ABS+PC, ABS+glass fiber, PC+glass fiber and the like of pen televisions, mobile phones, mice, keys, household appliances, switches, packaging materials, automotive upholstery and the like, and can also be used for surface coating on primer or powder primer of various metal alloy substrates.

Owner:GUANGZHOU JOINTAS CHEM

A kind of ultraviolet curing adhesive and preparation method thereof

ActiveCN103819681BImprove temperature resistanceGood adhesionPolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolymer scienceUltraviolet lights

The invention provides an ultraviolet light polymerization adhesive and a preparation method thereof. The ultraviolet light polymerization adesive is prepared from the following components in parts by weight: 236-385 parts of polyurethane acrylate, 0.82-1.35 parts of polydimethylsiloxane mercapto acrylate, 43-82 parts of a monofunctional reactive diluent, 72-105 parts of a polyfunctional reactive diluent, 11.8-19.3 parts of a photoinitiator, 0.46-0.84 part of an ultraviolet light absorbent, 0.92-1.78 parts of a leveling agent, 1.03-1.92 parts of a foam killer and 0.48-0.86 part of a silane coupling agent. The ultraviolet light polymerization adhesive provided by the invention has better high-temperature impact resistance and excellent adhesion, has no cyano group, and is environment-friendly and nontoxic.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Composition for preparing polypropylene foaming material and foaming forming body prepared from same

The invention provides a composition for preparing a polypropylene foaming material. The composition comprises high melt strength impact polypropylene, and the high melt strength impact polypropylene comprises a random copolymerization polypropylene continuous phase and a propylene-ethylene copolymer rubber dispersion phase. The content of room temperature dimethylbenzene solvend is larger than or equal to 10 wt%, and smaller than or equal to 35 wt%. The ratio of room temperature Mw of trichlorobenzene solvend to Mw of room temperature trichlorobenzene insoluble is larger than 0.4 and smaller than or equal to 1. The invention further provides a polypropylene injection foaming forming body made of the composition by injection foaming and a preparation method thereof. The forming body is suitable for the fields having special requirements for shapes, such as automobile, aircraft and high-speed rail inside and outside decoration components and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

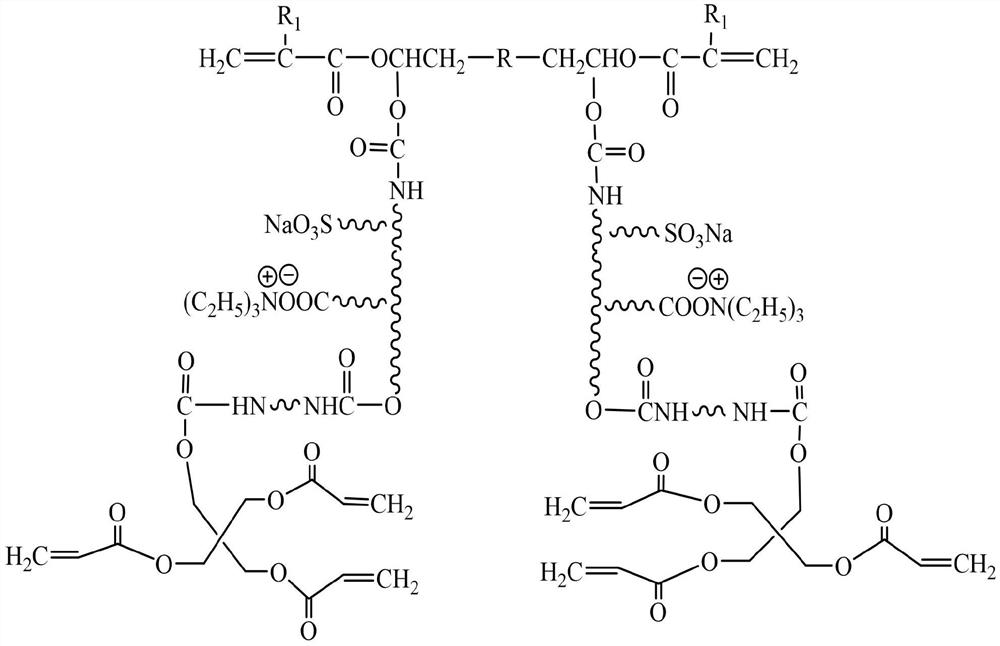

Water-based UV-Monocoat colored coating for plastic base material and construction process

PendingCN113698863AStrong adhesionImprove wear resistancePolyurea/polyurethane coatingsEpoxyPolymer science

The invention relates to a water-based UV-Monocoat colored coating for a plastic base material and a construction process. The water-based UV-Monocoat colored coating is prepared from water-based UV resin, aluminum paste, color concentrate or color paste, pearl powder, a solvent, an auxiliary agent, a photoinitiator and water. The water-based UV resin is 8-functional-group sulfonate anionic epoxy modified polyurethane acrylate; according to the water-based UV-Monocoat for the plastic base material, a paint film of the water-based UV-Monocoat is high in metal feeling, and the water-based UV-Monocoat has excellent adhesive force, wear resistance, alcohol resistance, boiling resistance, flexibility, scratch resistance, hand perspiration resistance, humidity and heat resistance, pollution resistance and skin feeling; the recoatability is not influenced, and moreover, the construction is convenient, safe and environment-friendly. The coating can be used for 3C products such as plastic base materials such as ABS, PC, ABS+PC, ABS+glass fibers and PC+glass fibers, such as stylus televisions, mice, keys, mobile phones, household appliances, switches, packaging materials and automotive upholstery, and can also be used for surface coating of various metal alloy primers.

Owner:GUANGZHOU JOINTAS CHEM

Surface treating method of aluminum alloy material

InactiveCN101413122BImprove adhesionAccelerated corrosionAnodisationLiquid/solution decomposition chemical coatingPlasma electrolytic oxidationChemical plating

The invention discloses a method for processing the surface of an aluminum alloy material, which comprises the following steps: forming a micro-arc oxidation film on the surface of the aluminum alloy material; removing part of the micro-arc oxidation film on the surface of the aluminum alloy material to expose part of the surface of the aluminum alloy material; performing preimpregnation and zincimpregnation; and performing chemical plating to deposit a metal layer on the exposed part, wherein in the preimpregnation process, an acidulous preimpregnation liquid is adopted to perform the preimpregnation on the aluminum alloy material. With the method, an aluminum alloy product with special requirement can be obtained, and the aluminum alloy product not only can obtain various excellent performances endowed by the micro-arc oxidation film without being influenced at all, but also can obtain function that part region needs electric conductance.

Owner:海盐宏茂五金制品有限公司

Composition for preparing polypropylene foam material and foamed molded body thereof

The invention provides a composition for preparing a polypropylene foaming material. The composition comprises high melt strength impact polypropylene, and the high melt strength impact polypropylene comprises a random copolymerization polypropylene continuous phase and a propylene-ethylene copolymer rubber dispersion phase. The content of room temperature dimethylbenzene solvend is larger than or equal to 10 wt%, and smaller than or equal to 35 wt%. The ratio of room temperature Mw of trichlorobenzene solvend to Mw of room temperature trichlorobenzene insoluble is larger than 0.4 and smaller than or equal to 1. The invention further provides a polypropylene injection foaming forming body made of the composition by injection foaming and a preparation method thereof. The forming body is suitable for the fields having special requirements for shapes, such as automobile, aircraft and high-speed rail inside and outside decoration components and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A flame retardant and antistatic random copolymer polypropylene composition and pipe

ActiveCN107325411BExcellent flame retardant, antistatic and impact resistanceImprove melt strengthXylyleneBenzene

The invention relates to a flame-retardant antistatic random copolymerization polypropylene composition, which includes a basic random copolymerization polypropylene resin, a fire retardant and a conductive filling material. The basic random copolymerization polypropylene resin includes a random copolymerization polypropylene continuous phase and a propylene-ethylene copolymer rubber disperse phase, wherein the random copolymerization polypropylene continuous phase at least comprises first random copolymerization polypropylene and second random copolymerization polypropylene, which are independently selected from propylene / ethylene random copolymer, propylene / butylene random copolymer and propylene / ethylene / butylene ternary random copolymer. The content of a xylene soluble substance of basic random copolymerization polypropylene resin at the room temperature is more than 10 wt% and less than 35 wt%. The ratio of Mw of a trichloro-benzene soluble substance to Mw of a trichloro-benzene insoluble substance is more than 0.4 and less than 1. The invention further relates to a pipe made from the composition and a preparation method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composition for preparing polypropylene foam material and foamed molded body thereof

ActiveCN106317611BIncrease production costUniform cell distributionRoom temperatureEthylene Homopolymers

The invention provides a composition used for preparing a polypropylene foaming material. The composition comprises high melt-strength impact-resistant polypropylene as base resin, the high melt-strength impact-resistant polypropylene comprises a propylene homopolymer component and an ethylene-1-butylene copolymer component, and the ratio of room-temperature trichlorobenzene soluble Mw of the high melt-strength impact-resistant polypropylene to room-temperature trichlorobenzene insoluble Mw of the high melt-strength impact-resistant polypropylene is greater than 0.5 and is smaller than or equal to 1; and the content of the room-temperature xylene soluble substance is greater than 10 wt% and is less than 30 wt%. The invention also provides a polypropylene injection foaming formed body prepared by the composition through injection foaming and a preparation method thereof. The formed body is suitable for the fields of parts with special shape requirements for internal and external decoration in automobile, aircraft and high-speed rail.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com