Lengthened shaft roller double-row conveying chain and technology thereof

A conveyor chain and lengthened technology, applied in the field of conveyor chains, can solve the problems of mismatched conveying steps in synchronous operation, large spacing difference of punching chain plates, poor corrosion resistance, etc., and achieve super corrosion resistance, Conveyor step matching, strength and high bearing area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

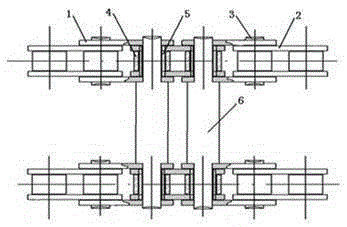

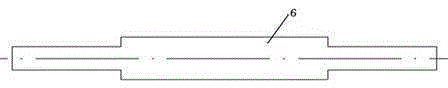

[0024] The implementation method is: combined Figure 1-2 , an extended shaft-roller double-row conveyor chain, including a chain plate, a pin shaft 3, a roller 4 and a sleeve 5, the chain plate is divided into an outer chain plate 1 and an inner chain plate 2, and there are two chain plates with a certain interval Conveyor chain, the two conveyor chains are connected by shaft rollers 6, the shape of the two ends of the shaft roller 6 is the same as that of the pin shaft 3 and replaces the position of the pin shaft 3, the middle part is thicker than the two ends, and the shaft rollers 6 and the pin shaft 3 are arranged alternately .

[0025] The specific process is as follows: firstly, the chain plate blanking abrasive tool is made of high-strength alloy steel overall slow-moving wire cutting, which improves the manufacturing accuracy of each blanking process and realizes the equal-pitch punching of multiple chain plates, thereby achieving high-precision and constant-speed cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com