Low-temperature-resistant insulation resin for motor and preparation method thereof

A technology of insulating resin and low temperature resistance, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems affecting the application of epoxy resin, and achieve good insulation treatment, good high and low temperature impact resistance, strength and heat resistance. The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

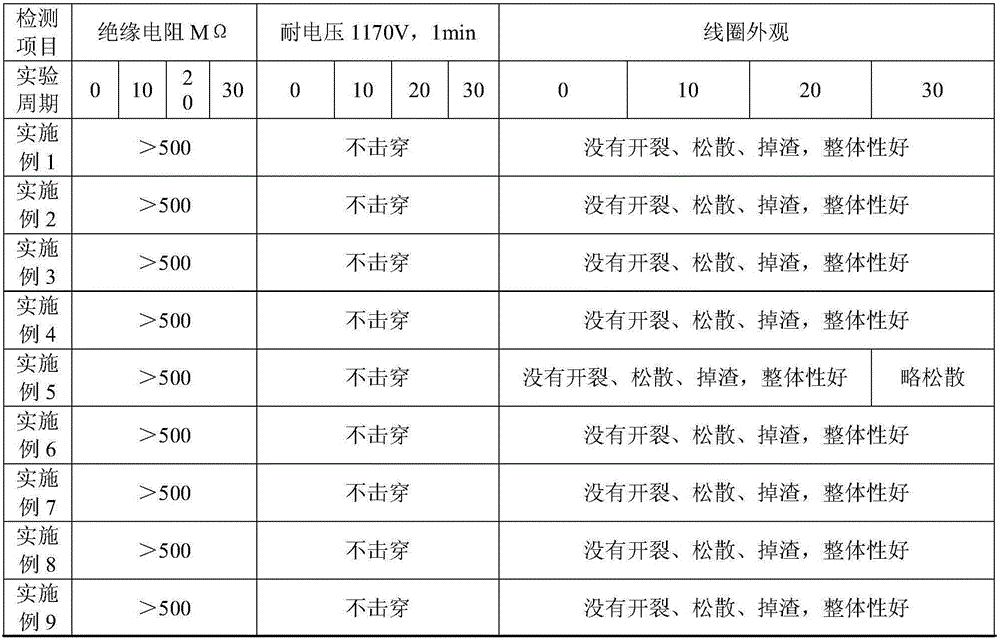

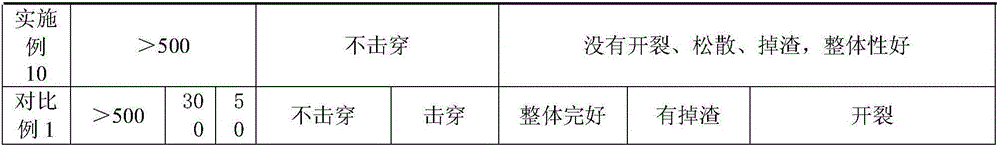

Examples

Embodiment 1

[0024] This embodiment provides an insulating resin for a low-temperature resistant motor, which includes the following components in parts by weight:

[0025] 100 parts of epoxy resin composition;

[0026] Anhydride curing agent (methyl Nadic anhydride) 100 parts;

[0027] Latent accelerator (aluminum acetylacetonate) 0.2 parts;

[0028] The epoxy resin composition is 30 parts of bisphenol F epoxy resin (Dow DER354 epoxy resin, epoxy value 0.59mol / 100g), 40 parts of hyperbranched epoxy resin (Wuhan hyperbranched resin HyPer E101, epoxy value 0.32mol / 100g), 10 parts of tetrafunctional glycidylamine epoxy resin (AG-80) and 20 parts of acrylic modified silicone epoxy resin;

[0029] Among them, the synthetic method of acrylic-modified silicone epoxy resin is as follows: Weigh 100g of 1,3-bis(3-glycidylpropyl)-1,1,3,3-tetramethyldisiloxane and add it to three mouths Into the bottle, add 0.5g hydroquinone (polymerization inhibitor), slowly raise the temperature while stirring, slowly add ...

Embodiment 2

[0034] This embodiment provides an insulating resin for a low-temperature resistant motor. The raw materials and preparation methods used are the same as those in Example 1. The difference is that the weight of the raw materials is inconsistent. It includes the following components by weight: epoxy resin 100 parts of the composition, 120 parts of acid anhydride curing agent (methyl nadic acid anhydride) and 0.4 parts of latent accelerator (aluminum acetylacetonate).

Embodiment 3

[0036] This embodiment provides an insulating resin for a low-temperature resistant motor. The raw materials and preparation methods used are the same as those in Example 1. The difference is that the weight of the raw materials is inconsistent. It includes the following components by weight: epoxy resin 100 parts of the composition, 90 parts of acid anhydride curing agent (methyl nadic acid anhydride), and 0.1 part of latent accelerator (aluminum acetylacetonate).

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com