High temperature resistant cable

A high-temperature-resistant cable technology, applied in the field of high-temperature-resistant cables, can solve problems such as inconvenient fixing, poor high-temperature resistance, and single fixing method, and achieve the effect of increasing the fixing method, increasing the heat dissipation function, and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

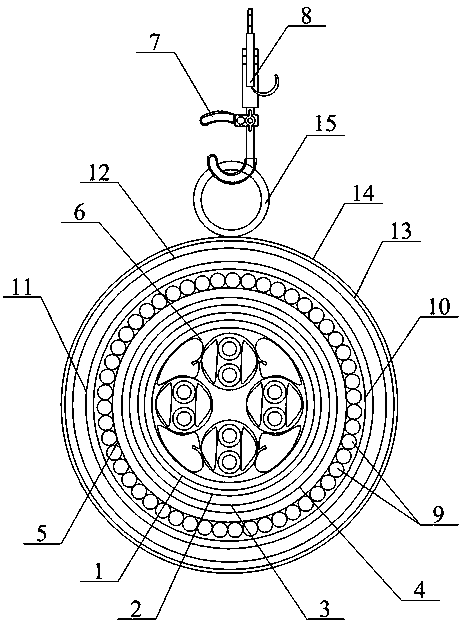

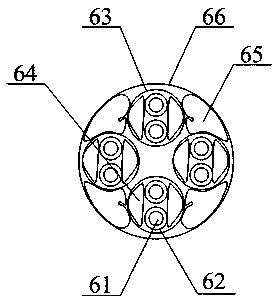

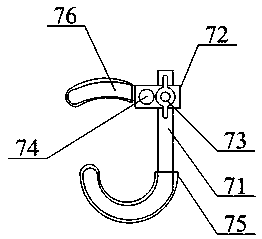

[0029] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a high-temperature-resistant cable includes a wire insulation sleeve 1, a first shielding layer 2, a first heat dissipation film 3, a heat conduction paste layer 4, an insulation layer 5, a heat dissipation insulation protection wire structure 6, and an adjustable hooking and fixing seat structure 7. Fixed rotating plate structure 8, reinforcing wire 9, rubber sleeve 10, second shielding layer 11, protective jacket 12, first protective sleeve 13, connecting sleeve 14 and articulated ring 15, the first shielding layer 2 Sleeved on the outer wall of the wire insulation sleeve 1; the first heat dissipation film 3 is wrapped on the outer wall of the first shielding layer 2; the heat conduction paste layer 4 is applied on the outer wall of the first heat dissipation film 3; the insulation layer 5 is socketed on the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com