Short-cut nitrification and denitrification treatment process for coking wastewater

A technology for coking wastewater and short-range nitrification, which is used in reflux water treatment, water treatment parameter control, biological water/sewage treatment, etc. It can solve the problems of long pipelines, high air pollution, heavy maintenance workload, etc. , The difficulty of operation and control is small, and the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Table 1 shows the concentration fluctuation range of main pollutants in coking cyanide wastewater (one of coking wastewater) after pretreatment.

[0070] Table 1: Indicators of coking wastewater in biochemical treatment system

[0071]

[0072] The effluent index after being treated by the self-circulating biological treatment reactor of the present invention is shown in Table 2 (pH value of effluent: 6-7).

[0073] Table 2: Indicators of coking wastewater in biochemical treatment system

[0074]

Embodiment 2

[0076] The concentration fluctuation range of main pollutants in the coking area wastewater is shown in Table 3.

[0077] Table 3: Wastewater indicators in the coking area

[0078]

[0079] After being treated by the self-circulating biological treatment reactor of the present invention, the indicators listed in Table 3 in the effluent all meet the emission indicator requirements specified in GB16171-2012.

experiment example

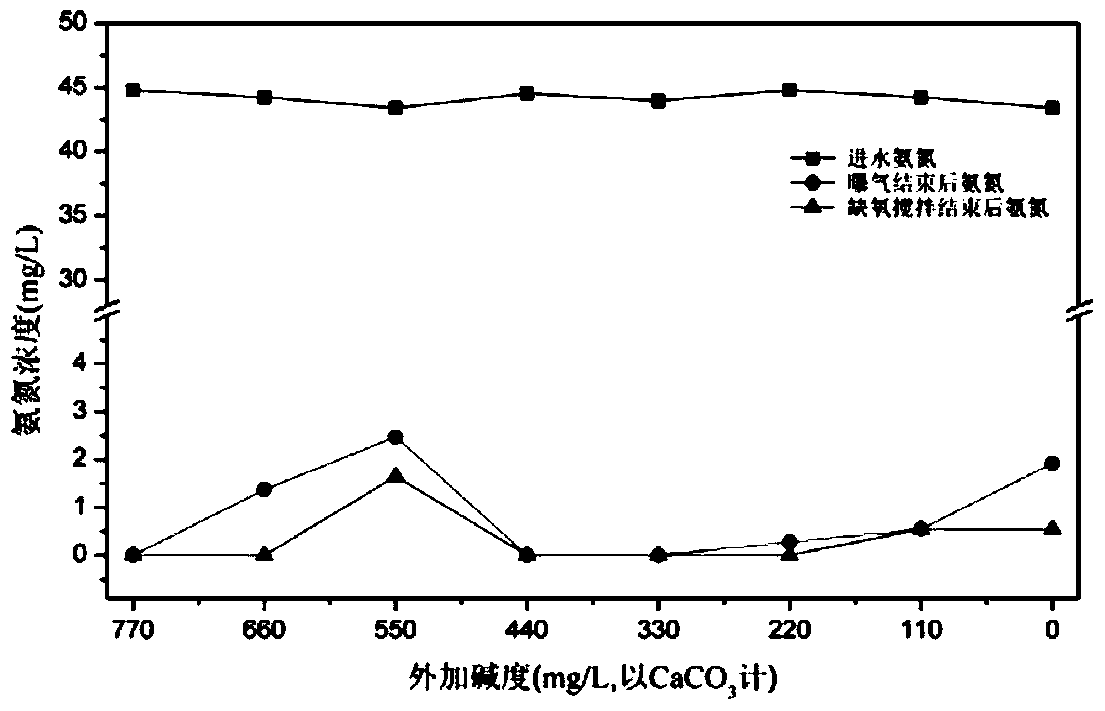

[0081] The inventor has studied the influence of the alkalinity in the coking wastewater in the method of the present invention on the removal of ammonia nitrogen, and the results are as follows image 3 , Figure 4 and Figure 5 shown; in the figure, the "after the aeration" refers to the relevant indicators in the coking wastewater after the low dissolved oxygen reaction step, and the "after the anoxic stirring" refers to the coking wastewater after the anoxic reaction step Related indicators in wastewater.

[0082] It can be seen from the figure that with the decrease of the alkalinity of coke water, the loss of total nitrogen in the aeration process tends to increase, and the concentration of nitrite nitrogen produced decreases, but the removal rate of ammonia nitrogen is basically stable. It is deduced that there may be heterotrophic nitrifying and aerobic denitrifying bacteria in the reactor, which use organic matter instead of or As a carbon source, the reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com