High-initial-adhesion-strength moisture-curable polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive and moisture-curing technology, which is applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of lower production efficiency, long holding time, and low initial adhesion of PUR hot-melt adhesives And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

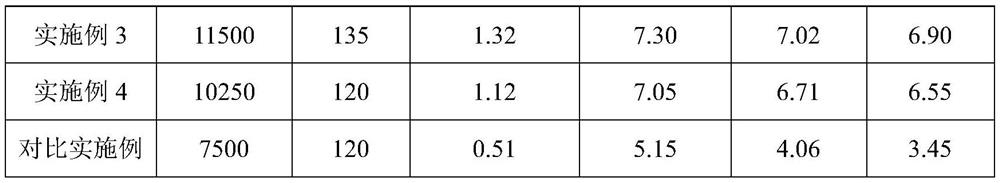

Examples

preparation example Construction

[0023] The preparation method of reactive polyurethane hot melt adhesive follows the steps below:

[0024] Step 1: Put polyether polyol, polyester polyol, acrylic resin, antioxidant and tackifying resin into the reaction kettle according to the metering ratio, heat to 120°C, and vacuum (vacuum degree -0.09Mpa~-0.1Mpa) Stir and dehydrate for 2h;

[0025] Step 2: Cool down to 70°C, add diphenylmethane diisocyanate under nitrogen protection, slowly raise the temperature to 95°C, and stir for 2 hours under nitrogen protection;

[0026] Step 3: Add bismorpholino diethyl ether under the protection of nitrogen, stir and react at 95°C for 15 minutes, vacuum defoam, seal and store to prepare a polyurethane hot melt adhesive.

Embodiment 1

[0028] 270g of polyether polyol, 210g of a mixture of polydodecanoic acid-1,6-hexanediol ester diol and polyadipate-1,6-hexanediol ester diol, 107g of liquid polyester polyol, hydroxyl Add 250g of acrylic resin, 30g of tackifying resin and 1.9g of antioxidant into the reaction kettle, heat to 120°C, vacuumize (vacuum degree -0.09Mpa~-0.1Mpa) and stir and dehydrate for 2h; cool down to 70°C, add di 130g of phenylmethane diisocyanate, slowly heated up to 95°C, stirred and reacted for 2h under the protection of nitrogen; added 2g of catalyst bismorpholino diethyl ether under the protection of nitrogen, stirred and reacted at 95°C for 15min, vacuum defoamed, sealed and stored, prepared Obtain polyurethane hot melt adhesive.

Embodiment 2

[0030] 270g of polyether polyol, 210g of polysebacate-1,6-hexanediol and polyadipate-1,6-hexanediol mixture, 107g of liquid polyester polyol, and 250g of acrylic resin , Add 30g of tackifying resin and 1.9g of antioxidant into the reaction kettle, heat to 120°C, vacuumize (vacuum degree -0.09Mpa~-0.1Mpa) and stir and dehydrate for 2h; cool down to 70°C, add diphenylmethane under nitrogen protection 127g of diisocyanate, slowly heated up to 95°C, stirred and reacted for 2h under the protection of nitrogen; under the protection of nitrogen, 2g of catalyst bismorpholino diethyl ether was added, stirred and reacted at 95°C for 15min, vacuum defoamed, sealed and stored, and the polyurethane thermal Melt glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com