Flame-retardant resin composition, adhesive prepared from flame-retardant resin composition, insulation adhesive film used for laminated busbar, and preparation method of insulation adhesive film

A technology of flame-retardant resin and insulating film, which is applied in the direction of adhesives, film/sheet adhesives, heat-activated films/sheets, etc., and can solve the problem of high-temperature bonding that cannot meet the application requirements of laminated busbars at working temperatures. Reduced strength and other issues, to achieve excellent high-temperature peel strength, improve heat resistance and flame retardancy, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

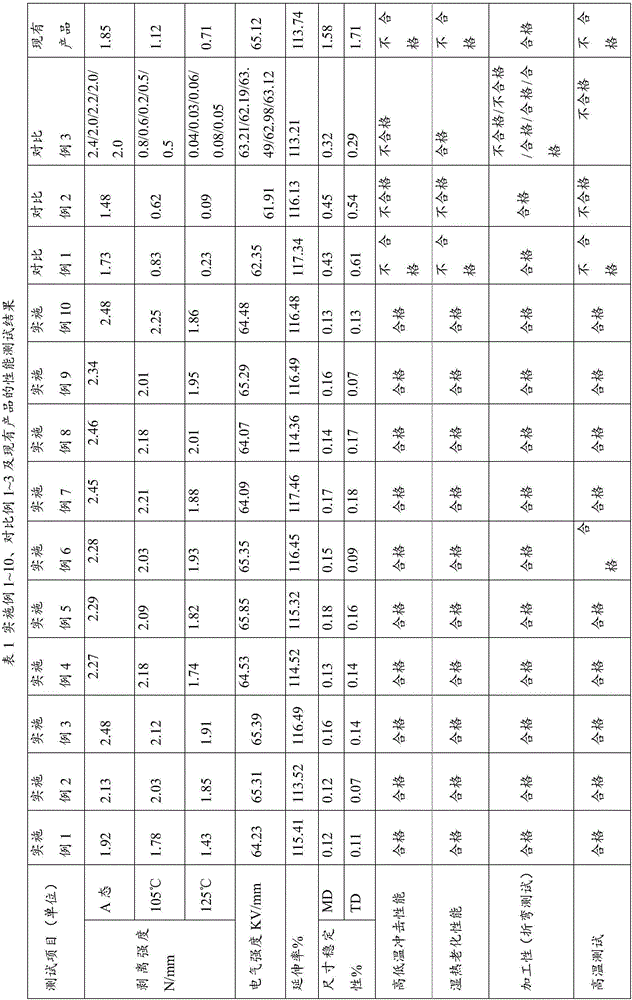

Embodiment 1

[0037] A flame-retardant resin composition, comprising 40 parts by weight of saturated polyester resin B (L952), 5 parts by weight of thermoplastic phenolic resin, 5 parts by weight of aliphatic isocyanate curing agent, and 10 parts by weight of antimony trioxide , 20 parts by weight of decabromodiphenylethane, 10 parts by weight of aluminum hydroxide, 0.2 parts by weight of antioxidant (1010), and 0.09 parts by weight of coupling agent (KH560).

[0038] The flame-retardant resin composition is applied to an insulating adhesive film for a laminated busbar.

[0039] The preparation method of the insulating adhesive film for laminated busbars containing the flame-retardant resin composition: first use methyl ethyl ketone to adjust the composition of the saturated polyester resin B, thermoplastic phenolic resin, aliphatic isocyanate curing agent, antimony trioxide, and ten Brominated diphenyl ethane, aluminum hydroxide, antioxidant, coupling agent in liquid dispersion (solid cont...

Embodiment 2

[0044] A flame-retardant resin composition, comprising 22 parts by weight of saturated polyester resin A (ES450), 53 parts by weight of saturated polyester resin B (ES901), 15 parts by weight of thermosetting phenolic resin, aromatic isocyanate curing 10 parts by weight of antimony pentoxide, 10 parts by weight of antimony pentoxide, 18 parts by weight of hexabromocyclododecane, 9 parts by weight of magnesium hydroxide, 0.15 parts by weight of antioxidant (168), and 0.2 parts by weight of coupling agent (KH530).

[0045] The flame-retardant resin composition is applied to the laminated busbar insulation adhesive film.

[0046] The preparation method of the insulating adhesive film for laminated busbars containing the flame-retardant resin composition: first use cyclohexanone to adjust the composition of the saturated polyester resin A, saturated polyester resin B, thermosetting phenolic resin, and aromatic isocyanate curing agent. , antimony pentoxide, hexabromocyclododecane, ...

Embodiment 3

[0051] A flame-retardant resin composition, comprising 30 parts by weight of saturated polyester resin A (S1611), 75 parts by weight of saturated polyester resin B (ES600), 35 parts by weight of thermoplastic phenolic resin, and alicyclic isocyanate 8 parts by weight of curing agent, 13 parts by weight of antimony trioxide, 38 parts by weight of ethylene bistetrabromophthalimide, 0.1 part by weight of antioxidant (168), and 0.5 parts by weight of coupling agent (KH172).

[0052] The flame-retardant resin composition is used for the insulating adhesive film for laminated busbars.

[0053] The preparation method of the insulating adhesive film for laminated busbars containing the flame-retardant resin composition: first use ethyl acetate to regulate the solidification of the saturated polyester resin A, saturated polyester resin B, thermoplastic phenolic resin, and alicyclic isocyanate. Antimony trioxide, ethylene bistetrabromophthalimide, antioxidant, and coupling agent in liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com