A kind of ultraviolet curing adhesive and preparation method thereof

A UV and adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of difficult deep curing of UV curing adhesives, limited UV penetration depth, and difficult to fully cure the adhesive layer. problem, to achieve the effect of "eliminating oxygen resistance", excellent cohesive energy, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

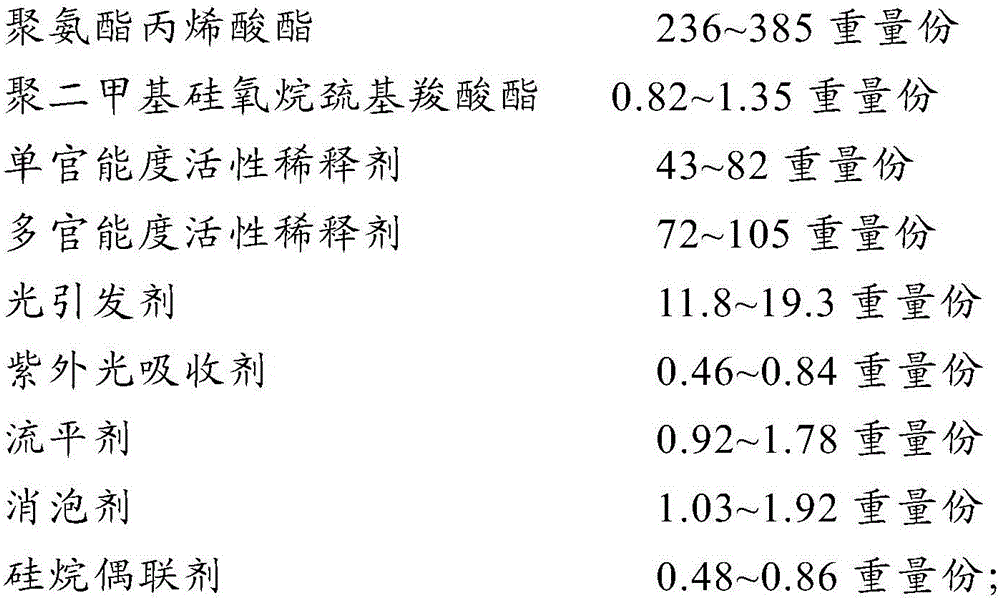

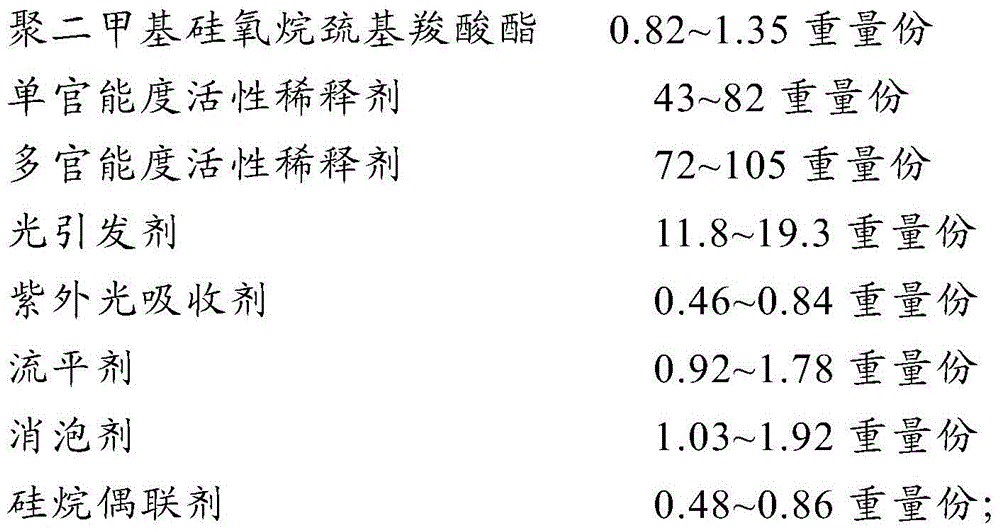

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a preparation method of polydimethylsiloxane mercapto carboxylate, which is characterized in that it comprises the following steps: preparing hydroxyl-terminated polydimethylsiloxane, carboxylic acid containing mercapto group, p-toluenesulfonic acid and an organic solvent that does not contain active hydrogen atoms to obtain polydimethylsiloxane mercapto carboxylate.

[0037]The carboxylic acid containing mercapto is preferably mercaptopropionic acid or mercaptoacetic acid; the organic solvent without active hydrogen atoms is preferably toluene, xylene, cyclohexanone, acetone or butanone, more preferably toluene, cyclohexanone or butanone; the number average molecular weight of the hydroxyl-terminated polydimethylsiloxane is preferably 1000 to 4000, more preferably 2000 to 3000; the hydroxyl-terminated polydimethylsiloxane, carboxylic acid containing mercapto, The mass ratio of p-toluenesulfonic acid and the organic solvent not containing active h...

Embodiment 1

[0074] Preparation of High Functional Polyurethane Acrylate

[0075] (a) Under the protection of nitrogen, add 100g number-average molecular weight to the three-necked bottle that is 1000 hydroxyl-terminated polybutadiene liquid rubber and 50g number-average molecular weight is the polybutylene adipate diol of 1000, is heated to 110 ℃, dehydrate at -0.98MPa for 1 hour, then lower the temperature to 75℃, under nitrogen protection, add 0.12g dibutyltin dilaurate and 10.6g trimethylolpropane, add 68g of 2,4 - Toluene diisocyanate, after the dropwise addition, reacted for 2 hours to obtain the first intermediate.

[0076] (b) Under the protection of nitrogen, the first intermediate obtained by the above reaction was warmed up to 85° C., and reacted for 1 hour; then 0.46 g of p-hydroxyanisole was added, and 130 g of pentaerythritol triacrylate was added dropwise at a speed of 6 ml / min, After the dropwise addition was completed, the reaction was continued for 2 hours to obtain a hi...

Embodiment 2

[0078] Preparation of High Functional Polyurethane Acrylate

[0079] (a) Under the protection of nitrogen, add 320g number average molecular weight to the three-necked bottle that is the polybutylene adipate diol that the number average molecular weight of 5000 is 5000 and the polybutylene adipate diol that 106g number average molecular weight is 6000, is heated to 120 ℃, dehydrate at -0.98MPa for 3 hours, lower the temperature to 80°C, under nitrogen protection, add 0.56g stannous octoate and 18.1g trimethylolpropane, drop 140g diphenylmethane-4 at a speed of 10ml / min, 4-diisocyanate, after the dropwise addition, reacted for 4 hours to obtain the first intermediate.

[0080] (b) Under nitrogen protection, the first intermediate obtained by the above reaction was warmed up to 90° C., and reacted for 3 hours; then 0.72 g of hydroquinone was added, and 264 g of dipentaerythritol pentaacrylate was added dropwise at a speed of 15 ml / min, After the dropwise addition, the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com