Patents

Literature

31results about How to "Uniform and dense cells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

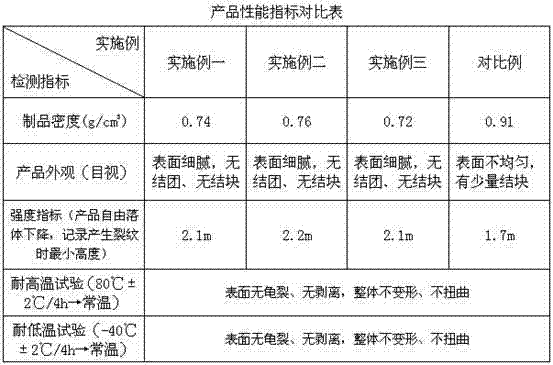

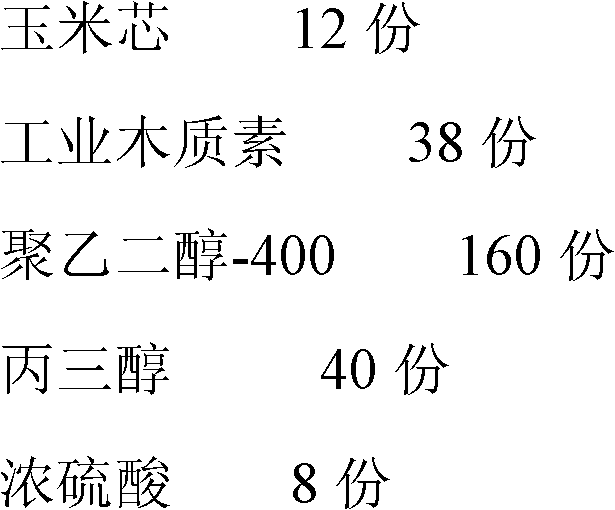

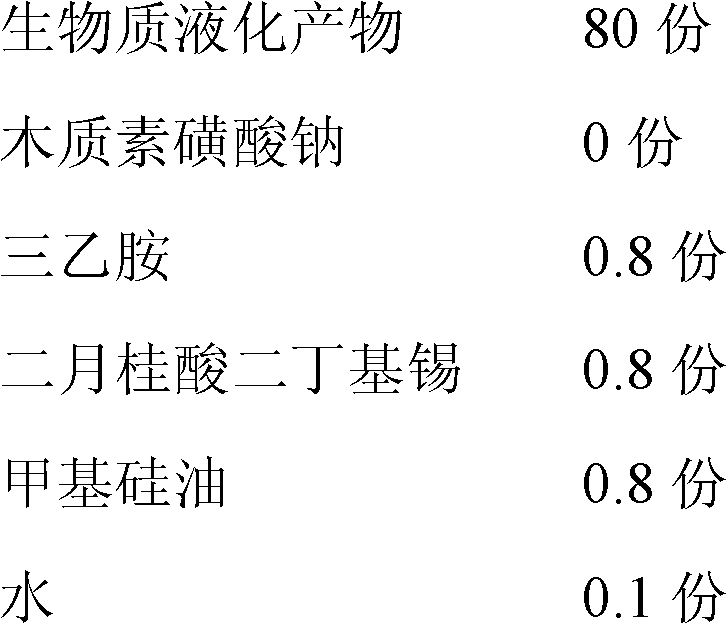

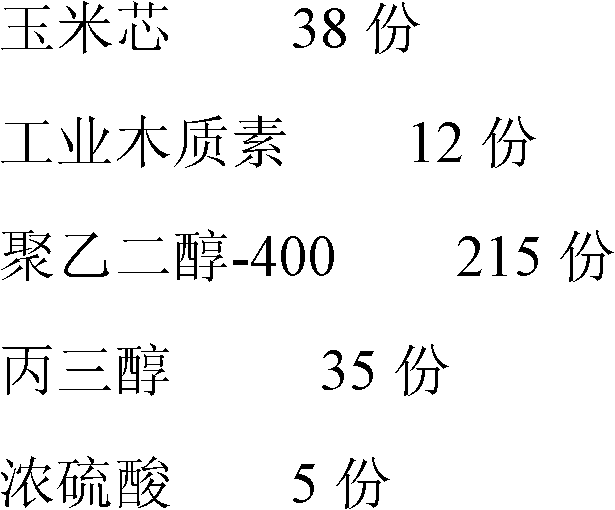

Preparation method of biomass-base polyurethane foam material

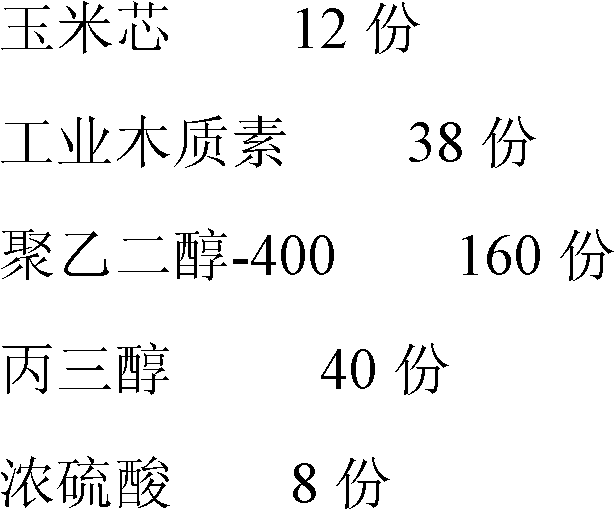

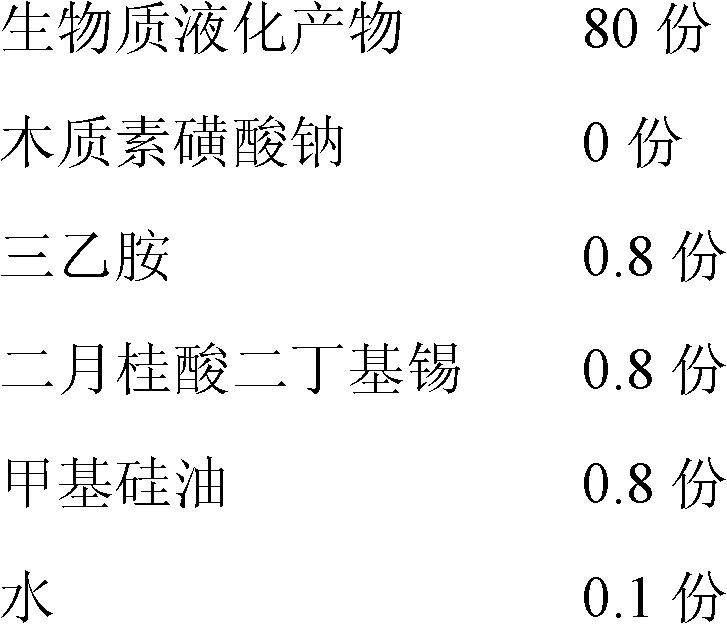

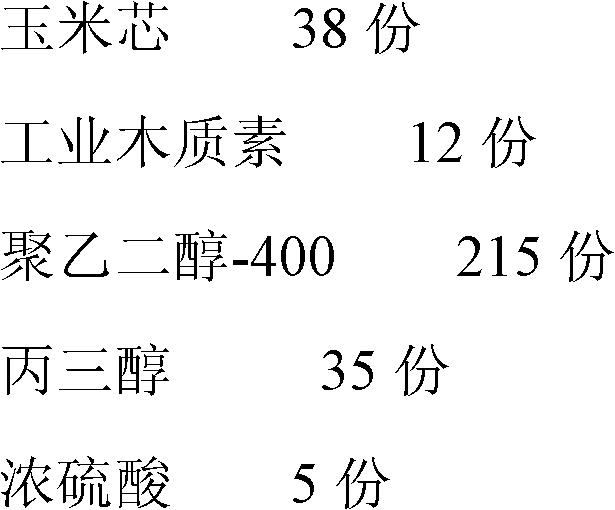

The invention discloses a preparation method of a biomass-base polyurethane foam material, belonging to the technical field of chemical industry. The method mainly comprises the following steps: mixing polybasic alcohol liquefier and liquefying catalyst, putting the mixture in a container, heating to 150-200 DEG C, adding biomass waste and industrial lignin, liquefying, and cooling to room temperature to obtain a biomass liquefied product; and mixing the prepared biomass liquefied product, foaming catalyst, foam stabilizer, foaming agent and lignosulphonate into a component A, using isocyanate as a component B, mixing the component A and component B in a mixing vessel, stirring at 20-40 DEG C at 8000-14000 rpm for 5-30 seconds, pouring the mixture into a die, naturally foaming for 5-60 seconds, standing at 80-120 DEG C for 8-24 hours, and storing at room temperature for 8-24 hours until the mixture is sufficiently aged and formed. The invention can obviously improve the properties of the biomass-base polyurethane foam.

Owner:CHINA AGRI UNIV

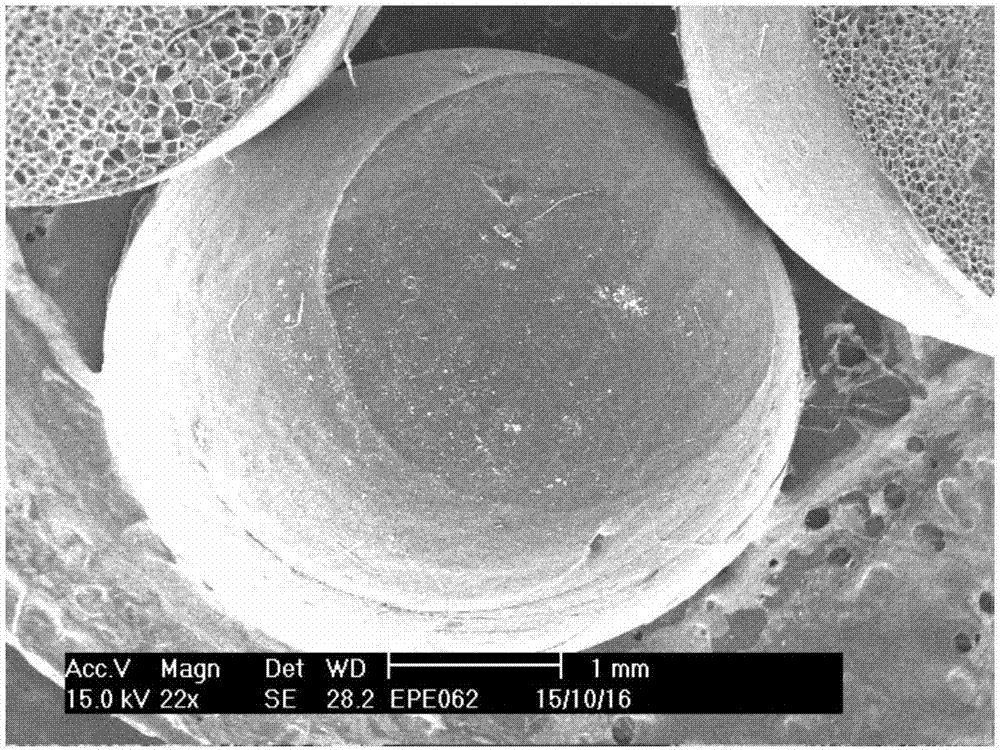

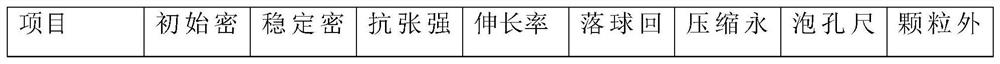

Extruded and foamed thermoplastic polyurethane elastomer particle and preparation method thereof

ActiveCN108239386AProduction environmental protectionSimple preparation processThermoplastic elastomerThermoplastic polyurethane

The invention relates to an extruded and foamed thermoplastic polyurethane elastomer particle and a preparation method thereof. The particle contains the following components in percentage by mass: (A) 65%-90% of a thermoplastic polyurethane elastomer, (B) 2%-30% of a thermoplastic resin polymer, (C) 0.5%-15% of a compatilizer and (D) 0.1%-5% of a foaming nucleating agent. The preparation method of a TPU formed particle comprises the following steps: uniformly mixing the thermoplastic polyurethane elastomer, the thermoplastic resin polymer, the compatilizer and the foaming nucleating agent, putting the mixture into melt extrusion equipment, and carrying out granulation, so as to obtain a blending alloy particle; and putting the blending alloy particle into foaming extrusion equipment, carrying out melting plastification so as to obtain a melt, dissolving supercritical carbon dioxide into the melt, foaming by virtue of a mouth mold, and carrying out underwater dicing, so as to obtain the formed particle. The prepared thermoplastic polyurethane foamed particle is stable in size and basically does not shrink, the surface is bright and plumy, and the diameters of foamed holes are uniform.

Owner:WANHUA CHEM GRP CO LTD

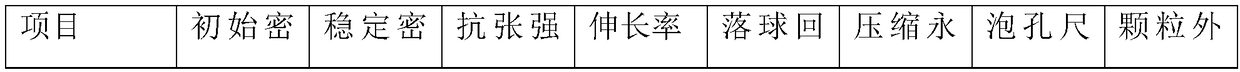

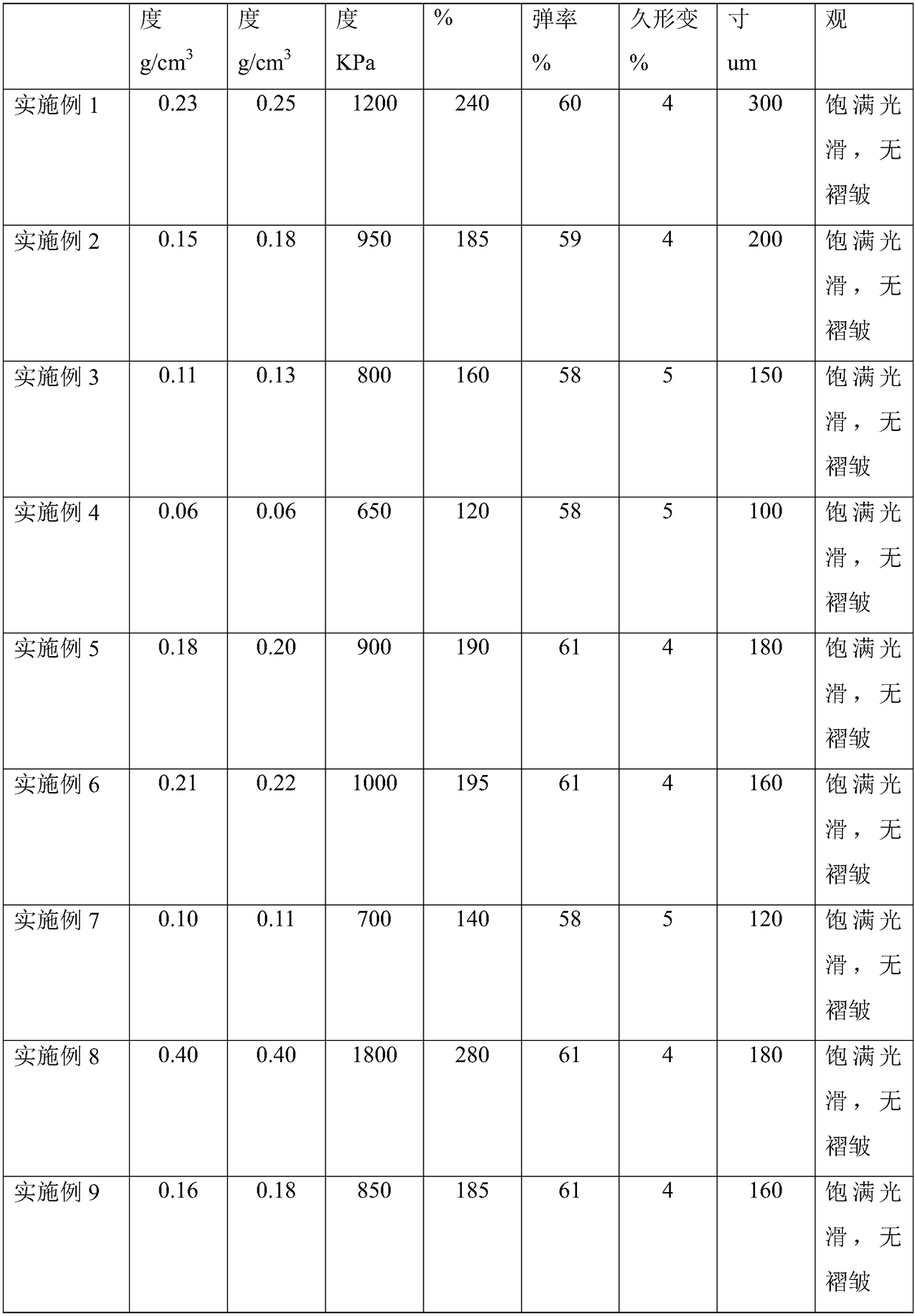

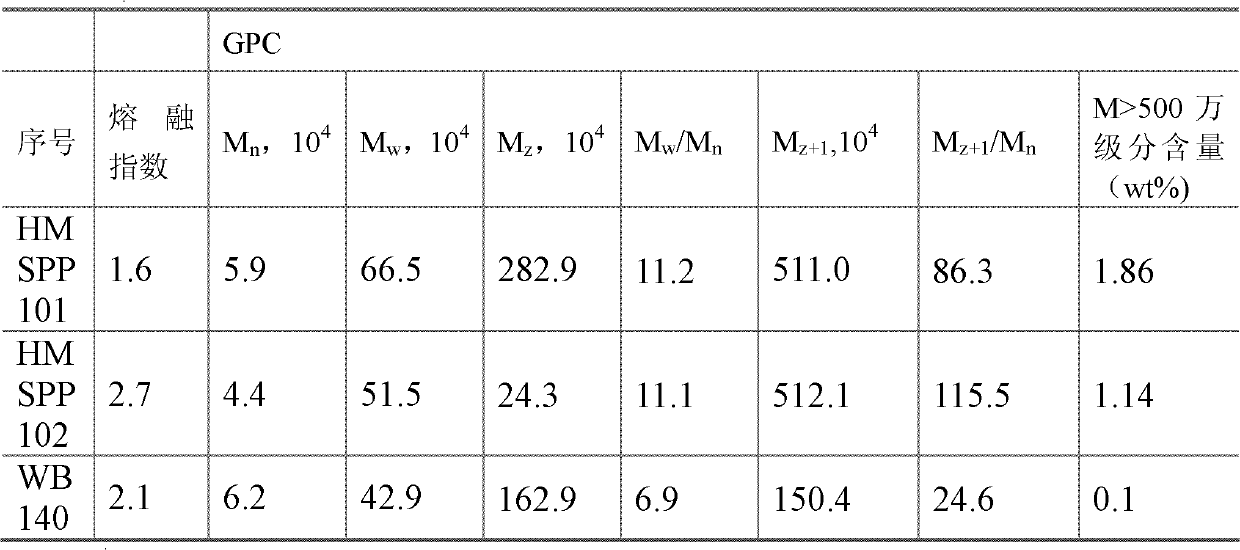

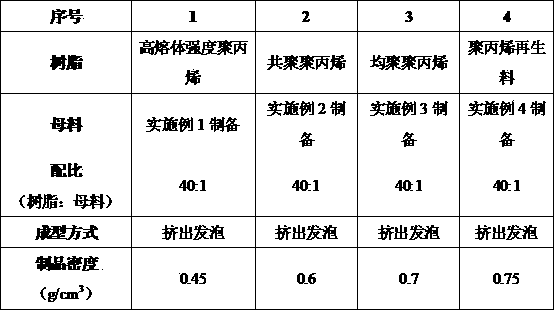

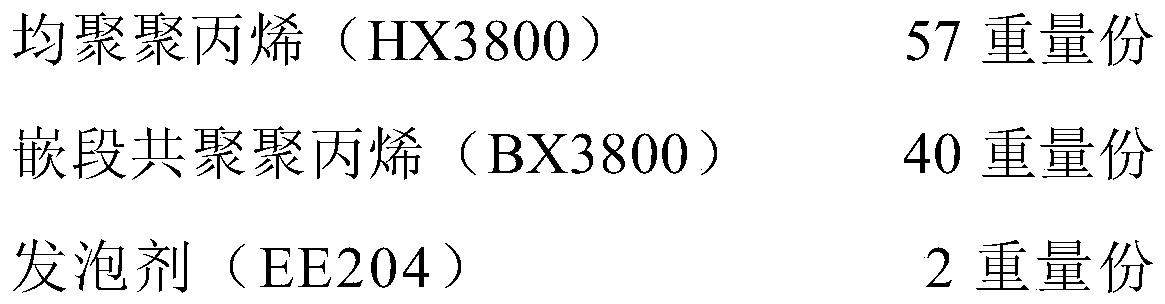

Polypropylene resin foam concentrate and preparation method thereof

ActiveCN102604223AAdvantages and Notable ImprovementsImprove melt strengthMasterbatchPolymer science

The invention relates to a polypropylene resin foam concentrate and a preparation method thereof. The foam concentrate is prepared by taking irradiation modified polypropylene resins as basic raw materials through the steps of adding additives such as a chemical foaming agent, a nucleating agent and a lubricant and the like into the basic raw materials, and uniformly mixing the mixture in a high-speed mixer; and then, adding the obtained mixture into a tandem extruder to carry out extrusion and granulation, thereby obtaining the polypropylene resin foam concentrate. The polypropylene resin foam concentrate provided by the invention can be applied to the extrusion of polypropylene foamed sheets, foamed pipes and foamed profiles; the polypropylene resin foam concentrate is high in modulus of foaming products, good in heat resistance, uniform in foaming hole, and adjustable in density, thereby opening up a new way for the extrusion and foaming of polypropylenes.

Owner:上海萍青工贸有限公司

Micro-foaming polypropylene composite material and preparation method thereof

The invention discloses a micro-foaming polypropylene composite material and a preparation method thereof. The micro-foaming polypropylene composite material is composed of the following components by weight: 100 parts of polypropylene, 40 to 60 parts of bamboo powder, 10 to 15 parts of foaming agent, 1 to 5 parts of foaming assistant, 1 to 5 parts of antioxygen, 1 to 3 parts of nucleating agent and 5 to 10 parts of compatilizer. The micro-foaming polypropylene composite material is wide in raw material resource, low in cost, simple to operate and wide in application prospect. The micro-foaming polypropylene composite material which has small bubble holes, is even, compact, light in weight, good in impact performance and environment-friendly.

Owner:常熟市威腾进出口有限公司

Composite foaming agent and polypropylene foam material prepared from same

The invention discloses a composite foaming agent and a polypropylene foam material prepared from the same. The foaming agent comprises the following components in parts by weight: 100 parts of azodicarbonamide, 10-20 parts of N,N'-dimethyl-N,N-dinitrosoterephthalamide, 10-30 parts of zinc oxide and 10-30 parts of sodium citrate. The polypropylene foam material comprises the following blended components in parts by weight: 100 parts of high-melt strength polypropylene and 3-15 parts of composite foaming agent. The composite foaming agent disclosed by the invention has controllable foaming temperature, uniform foam cell, smooth surface and high physical heat resistance; and the polypropylene foam material prepared from the composite foaming agent meets the environmental protection requirement, is degradable and low in production cost, and is suitable for continuous large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

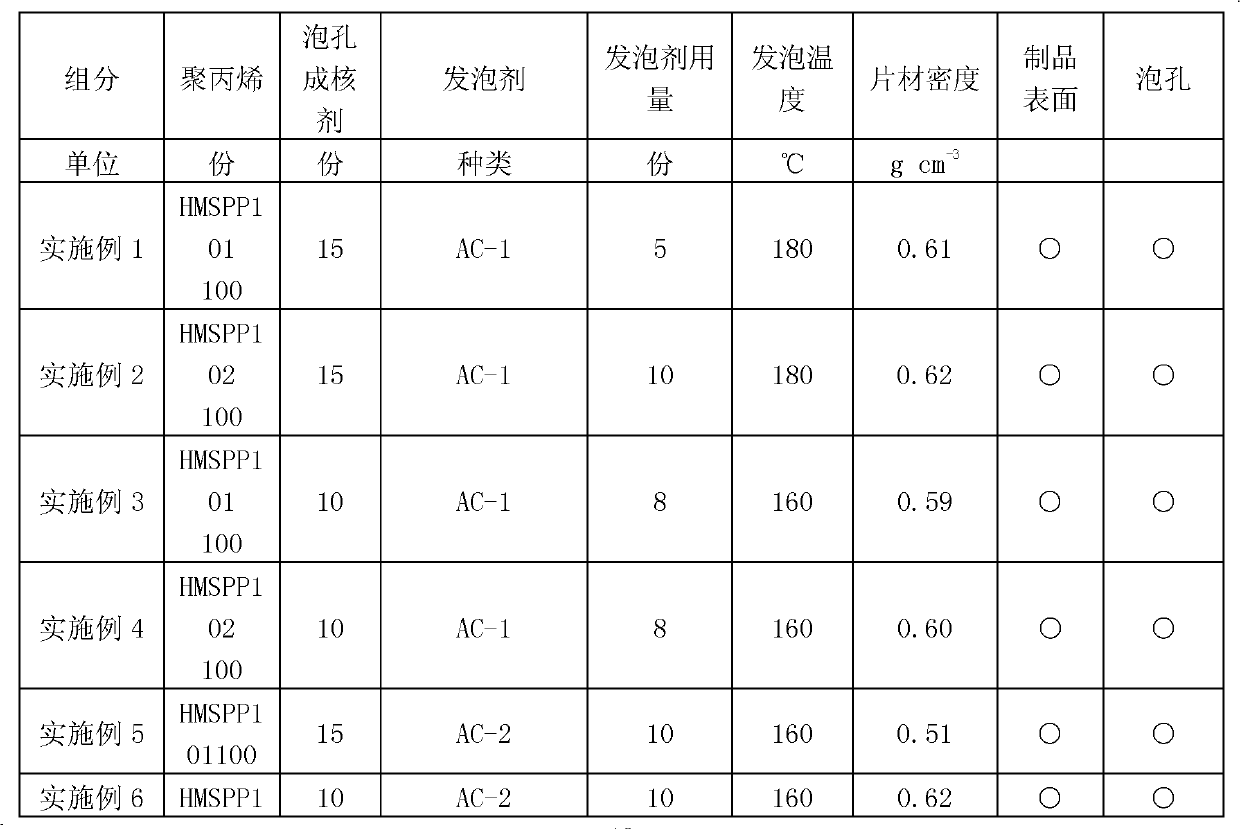

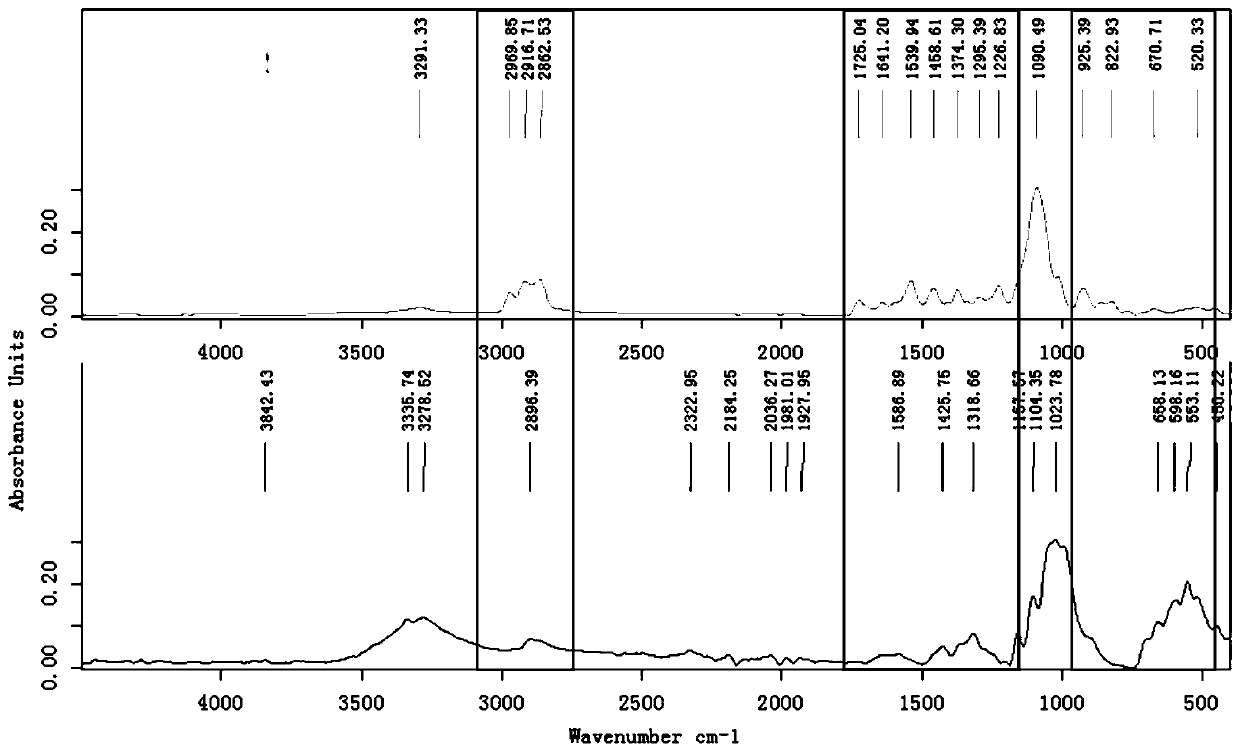

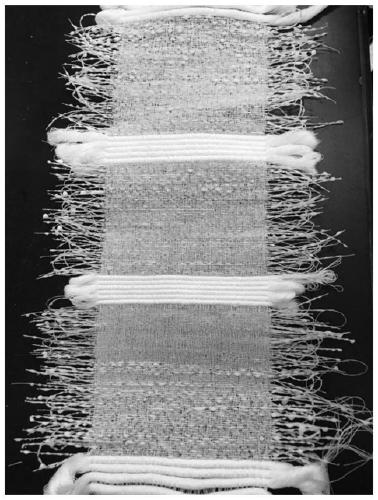

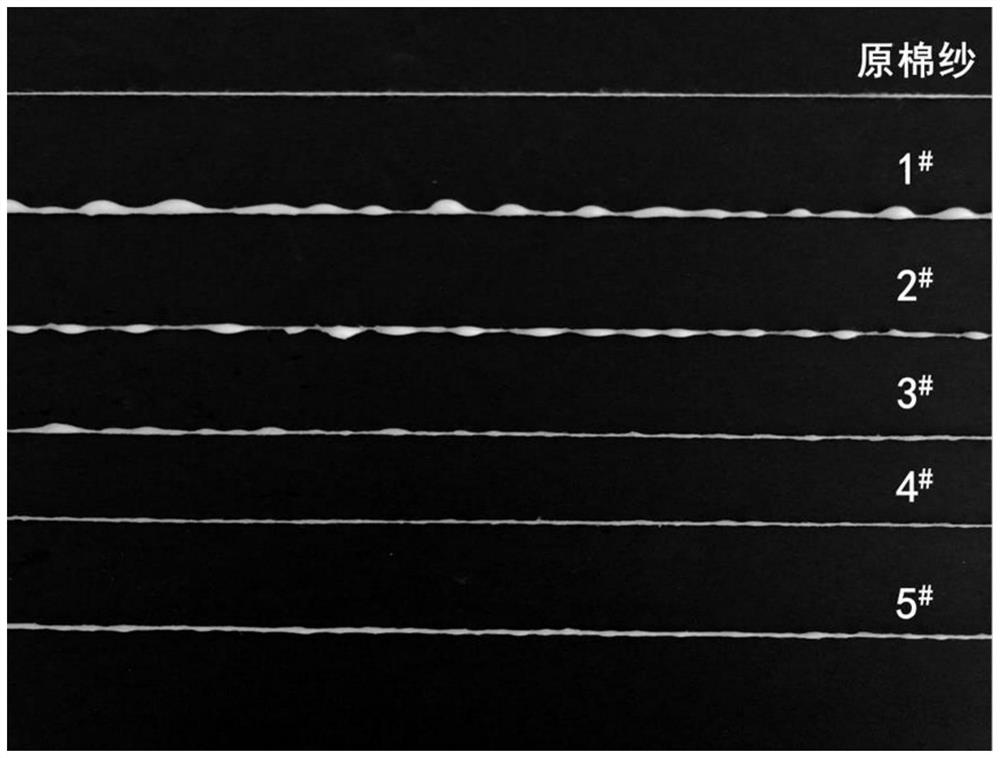

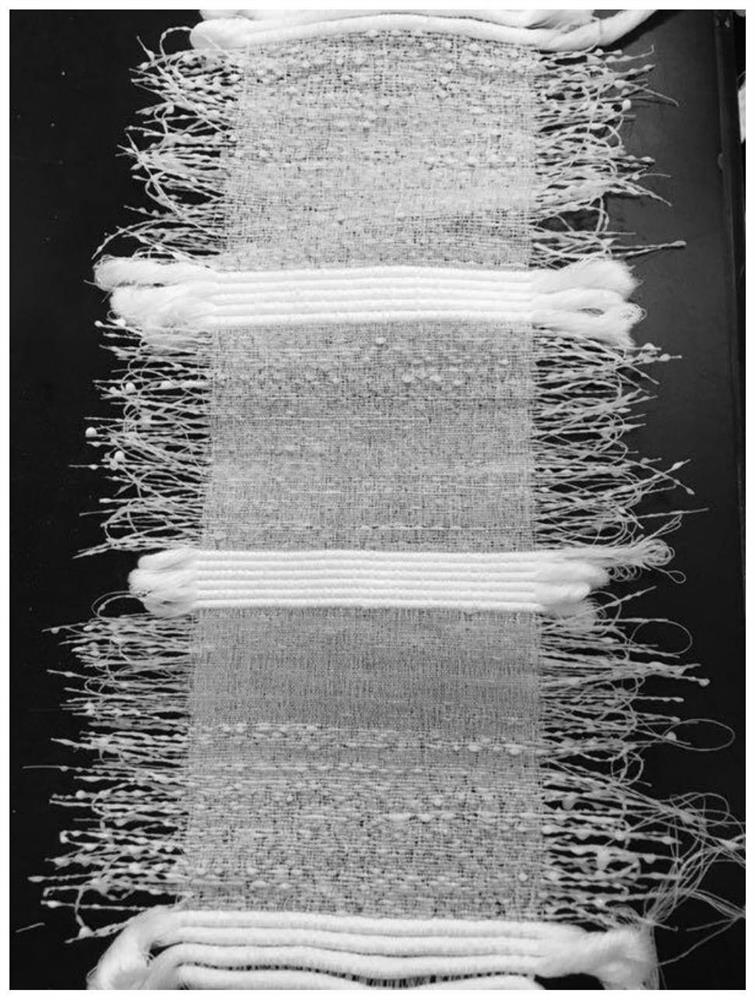

Preparation method for foamed yarns

ActiveCN110219177AUnique appearanceImprove plasticityVegetal fibresLiquid/gas/vapor yarns/filaments treatmentYarnPolymer science

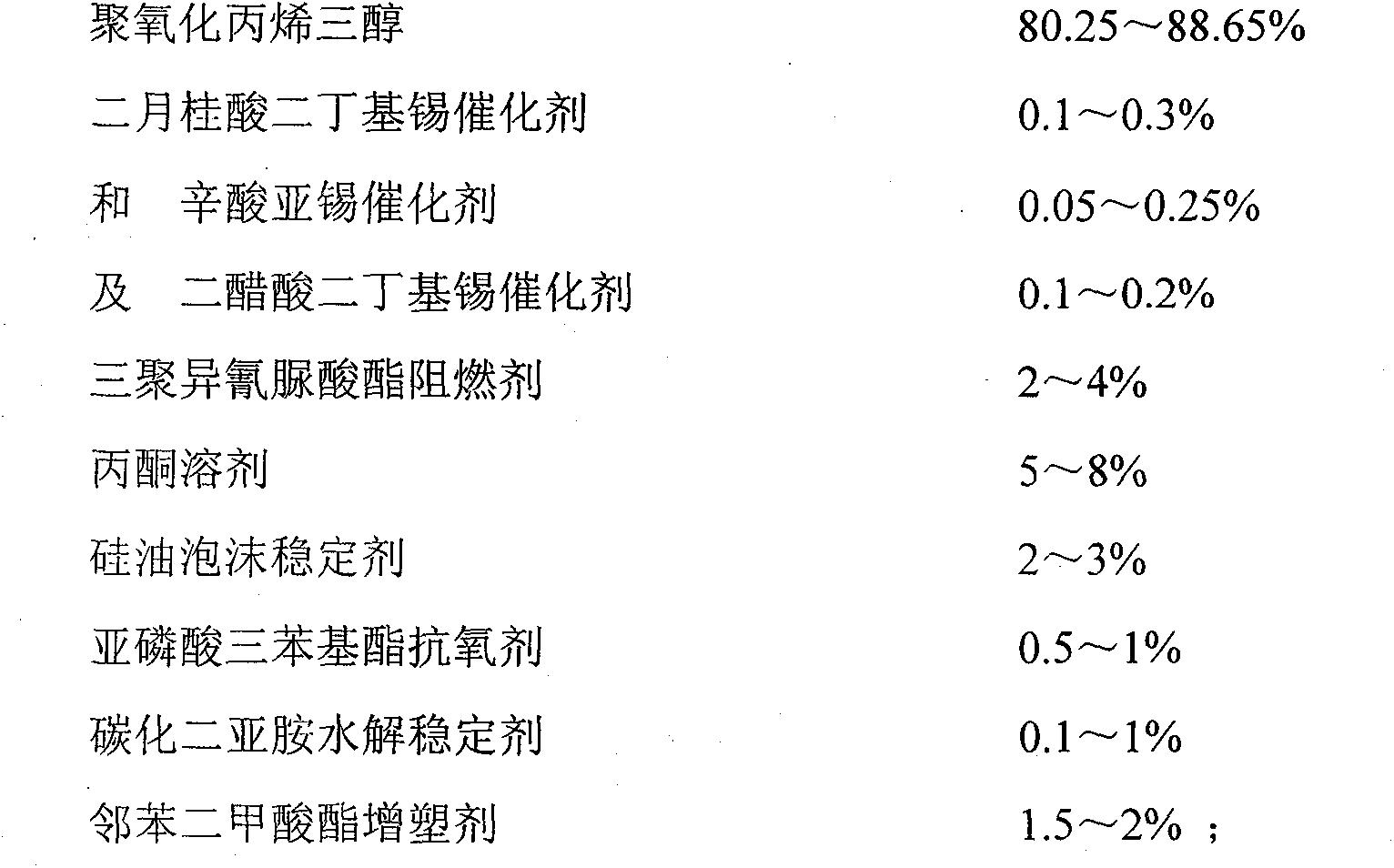

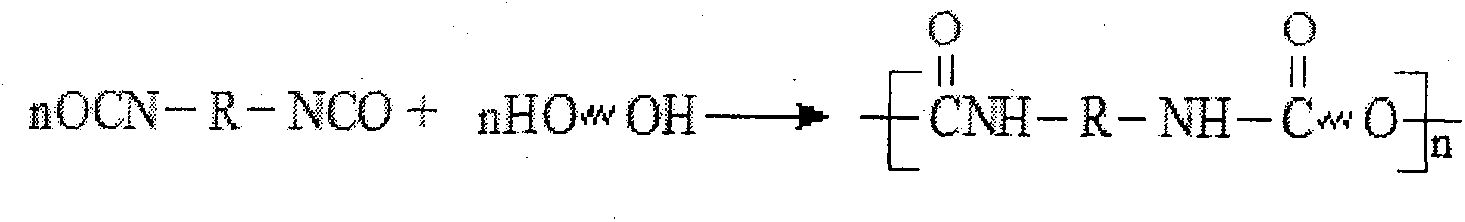

The invention discloses a preparation method for foamed yarns. The preparation method includes preparation of a main material, preparation of an auxiliary agent, padding treatment and preparation of the foamed yarns. The preparation method has the advantages that polyether polyol, isocyanate and a tin catalyst are mixed to obtain the main material, a mixed solution of the polyether polyol, an amine catalyst, a foaming agent and a foam stabilizer is used as the auxiliary agent, an in-situ polymerization method is applied, the raw materials required for reaction are respectively padded on two yarns, solution mixing is simulated through twisting, uniform and compact polyurethane foam is formed by the yarns from inside to outside, the adhesion of a foam film layer is improved, and accordingly,the foamed yarns with unique appearances are obtained; different base materials can be prepared into fabrics with different shapes according to needs, and accordingly, the plasticity is high; the preparation method is simple, the consumed time is short, the equipment requirements are low, and wide application can be realized.

Owner:WUHAN TEXTILE UNIV

TPE (Thermoplastic Elastomer) material for foamed floating cable extruded by common extruder and method

ActiveCN107057380AImprove structural stabilityGood dispersionClimate change adaptationInsulated cablesElastomerPolypropylene

The invention relates to a TPE (Thermoplastic Elastomer) material for a foamed floating cable extruded by a common extruder and a method. According to the technical scheme, the TPE material comprises at least one of ultra-high molecular weight SEBS and ultra-high molecular weight SEEPS, 10-100 parts of long chain branch olefin polymers, 20-50 parts of white oil, 20-160 parts of reinforced resins, 5-30 parts of maleic anhydride grafted polypropylene, 5-30 parts of nano-clay, 10-40 parts of aids, and 20-200 parts of a TPE base material foamed water master batch. The material has the beneficial effects that by utilizing the low temperature sensitive and strain hardening phenomena of long chain branch olefin polymers and the characteristics of low melt viscosity and high melt strength of ultra-high molecular weight elastomers, the foamed melt has good foam structure stability at a certain temperature, the dependence on equipment and processing parameters is reduced, the product processing stability is improved, and the production cost is reduced; and moreover, foaming extrusion of the common extruder can be realized, the foaming agent is uniformly dispersed, the foaming process is stable, foam is uniform and dense, and the foamed product is fine, smooth and soft in surface, high in strength and high in weather resistance.

Owner:济南泰瑞丰高分子新材料有限公司

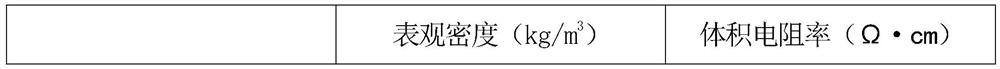

Carbon-series modified high-conductivity foaming ethylene propylene diene monomer

The invention discloses a carbon-series modified high-conductivity foaming ethylene propylene diene monomer, which is prepared from the following raw materials in parts by weight: 100 parts of raw ethylene propylene diene monomer, 5-10 parts of zinc oxide, 1-3 parts of stearic acid, 30-60 parts of carbon black, 20-40 parts of light calcium carbonate, 15-35 parts of paraffin oil, 3-6 parts of an accelerant, 0.5-1.0 part of sulfur, 5 parts of a foaming agent and 5-15 parts of a carbon-series composite component. The material prepared by the invention can realize good combination of foaming, low density and conductivity, and is suitable for rubber sealing elements.

Owner:HEBEI HUAMI RUBBER

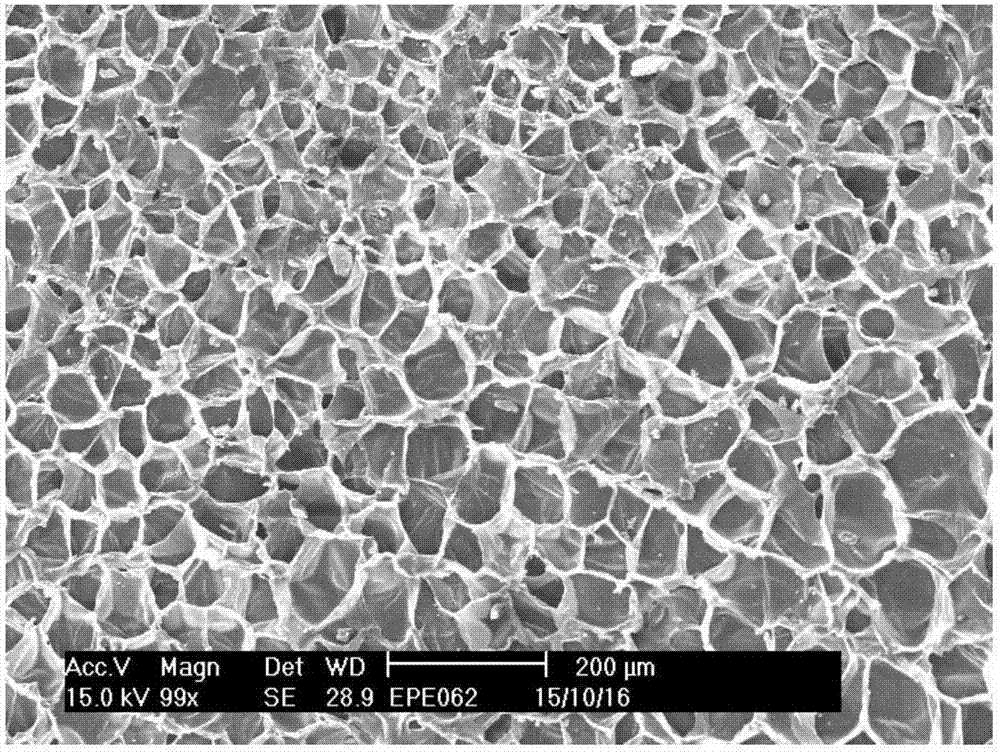

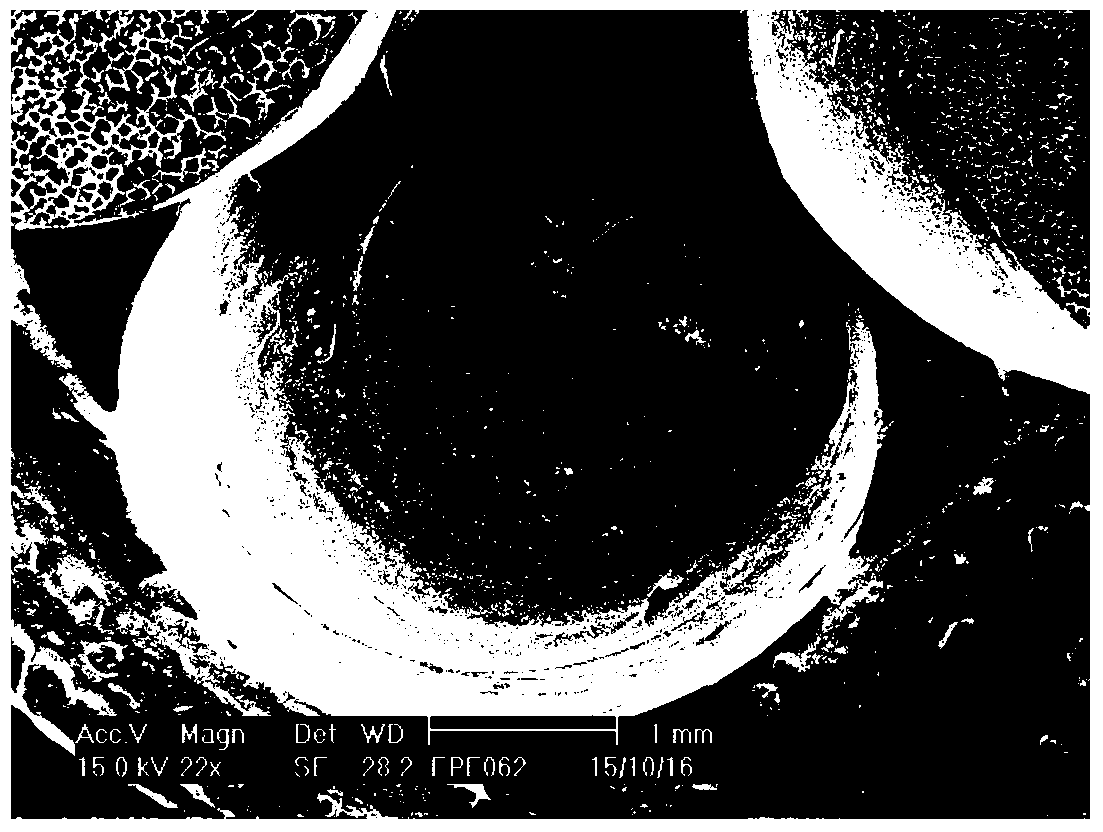

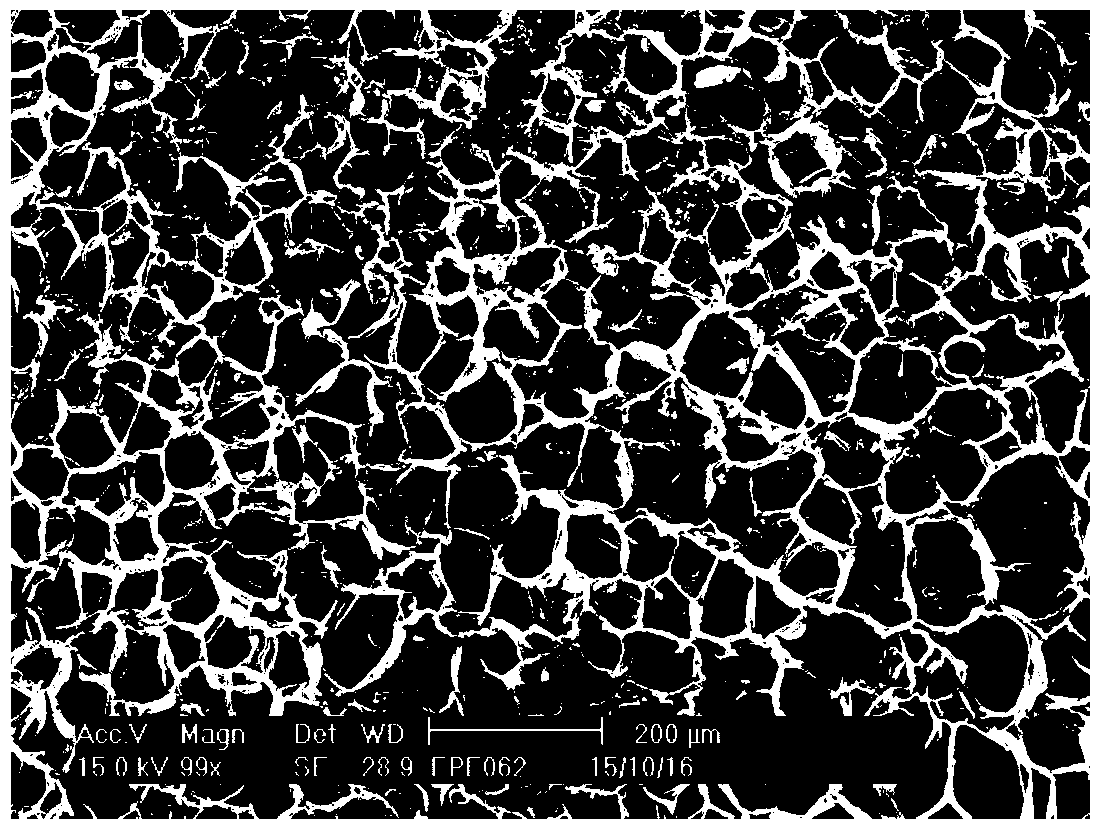

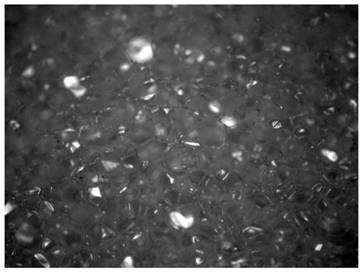

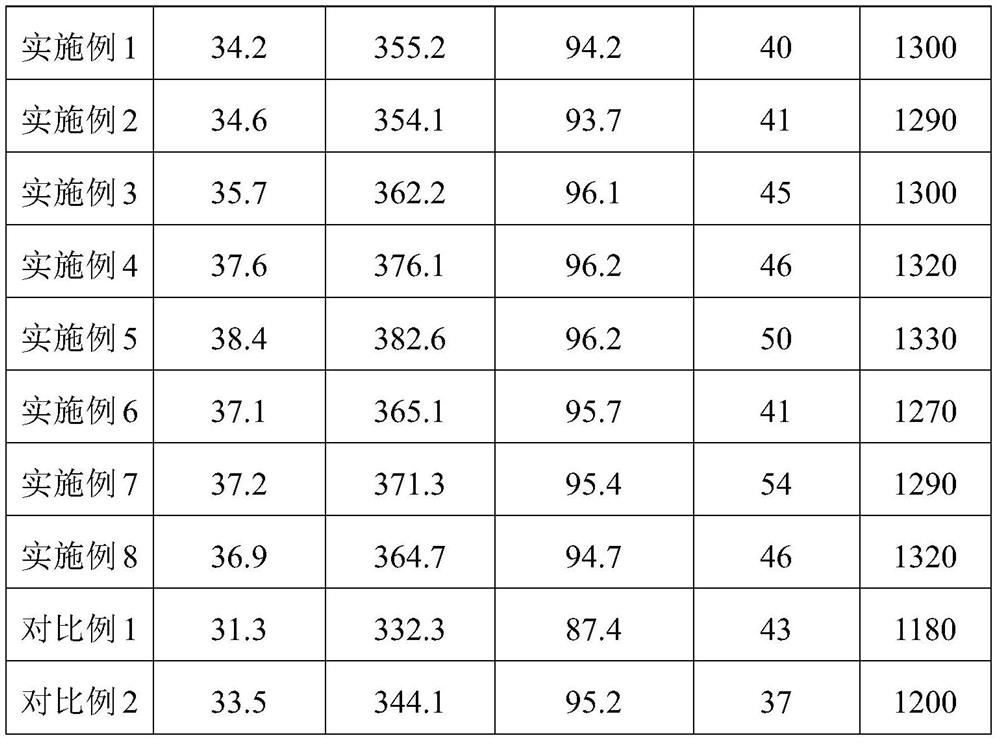

Polyethylene composition, foamed bead and preparation method thereof, and foamed bead molding body

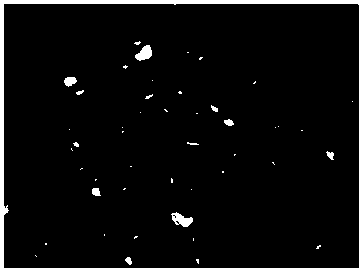

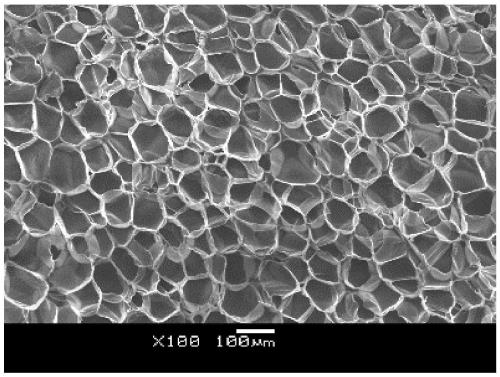

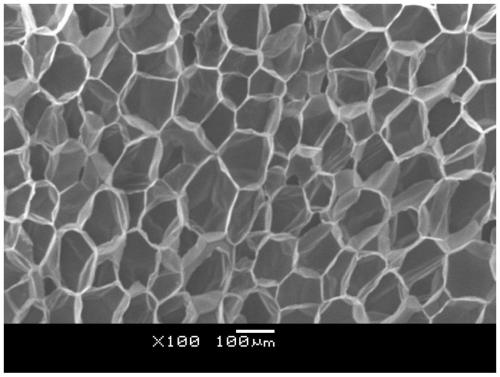

ActiveCN107312233AUniform and dense cellsHigh compressive strengthLow-density polyethyleneLinear low-density polyethylene

The present invention relates to the field of polymers, and particularly provides a polyethylene composition, a foamed bead and a preparation method thereof, and a foamed bead molding body. The polyethylene composition comprises a component A, a component B, a component C and a cell nucleating agent, wherein the component A is ethylene / alpha-olefin copolymerized linear low-density polyethylene, has the melt index MIA of 0.01-2 g / 10 min, and has the density [rho]A of 0.880-0.936 g / cm<3>, the component B is ethylene / alpha-olefin copolymerized linear low-density polyethylene, has the melt index MIB of 2.1-9.9 g / 10 min, and has the density [rho]B of 0.910-0.930 g / cm<3>, and the component C is ethylene / alpha-olefin copolymerized linear low-density polyethylene, has the melt index MIC of 10-80 g / 10 min, and has the density [rho]C of 0.880-0.930 g / cm<3>. The foamed bead prepared from the polyethylene composition has the uniform and compact cells, and the prepared foamed bead molding body has the high compressive strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly light brush plate for urban cleaning vehicle and preparation method of environment-friendly light brush plate

The invention discloses an environment-friendly light brush plate for an urban cleaning vehicle. The brush plate is light in dead weight, high in homogeneity, capable of effectively improving the work efficiency of cleaning equipment and low in production cost. The brush plate is prepared from the following materials in parts by weight: 75-80 parts of a PP regenerated material, 12-18 parts of a PE regenerated material, 2.5-4 parts of modified polypropylene, 0.4-1 part of sodium bicarbonate, 0.4-1 part of azodicarbonamide, 0.05-0.1 part of tetra(3.5-bitertiary butyl-4-hydroxyl) phenylpropionic acid pentaerythritol ester, 0.05-0.1 part of stearic acid, 0.05-0.1 part of paraffin and 1-2 parts of a color master batch. The invention also provides a preparation method of the environment-friendly light brush plate for the urban cleaning vehicle.

Owner:安徽环美刷业股份有限公司

Preparation method of biomass-base polyurethane foam material

The invention discloses a preparation method of a biomass-base polyurethane foam material, belonging to the technical field of chemical industry. The method mainly comprises the following steps: mixing polybasic alcohol liquefier and liquefying catalyst, putting the mixture in a container, heating to 150-200 DEG C, adding biomass waste and industrial lignin, liquefying, and cooling to room temperature to obtain a biomass liquefied product; and mixing the prepared biomass liquefied product, foaming catalyst, foam stabilizer, foaming agent and lignosulphonate into a component A, using isocyanate as a component B, mixing the component A and component B in a mixing vessel, stirring at 20-40 DEG C at 8000-14000 rpm for 5-30 seconds, pouring the mixture into a die, naturally foaming for 5-60 seconds, standing at 80-120 DEG C for 8-24 hours, and storing at room temperature for 8-24 hours until the mixture is sufficiently aged and formed. The invention can obviously improve the properties of the biomass-base polyurethane foam.

Owner:CHINA AGRI UNIV

Polypropylene resin foam concentrate and preparation method thereof

ActiveCN102604223BAdvantages and Notable ImprovementsImprove melt strengthMasterbatchPolymer science

The invention relates to a polypropylene resin foam concentrate and a preparation method thereof. The foam concentrate is prepared by taking irradiation modified polypropylene resins as basic raw materials through the steps of adding additives such as a chemical foaming agent, a nucleating agent and a lubricant and the like into the basic raw materials, and uniformly mixing the mixture in a high-speed mixer; and then, adding the obtained mixture into a tandem extruder to carry out extrusion and granulation, thereby obtaining the polypropylene resin foam concentrate. The polypropylene resin foam concentrate provided by the invention can be applied to the extrusion of polypropylene foamed sheets, foamed pipes and foamed profiles; the polypropylene resin foam concentrate is high in modulus of foaming products, good in heat resistance, uniform in foaming hole, and adjustable in density, thereby opening up a new way for the extrusion and foaming of polypropylenes.

Owner:上海萍青工贸有限公司

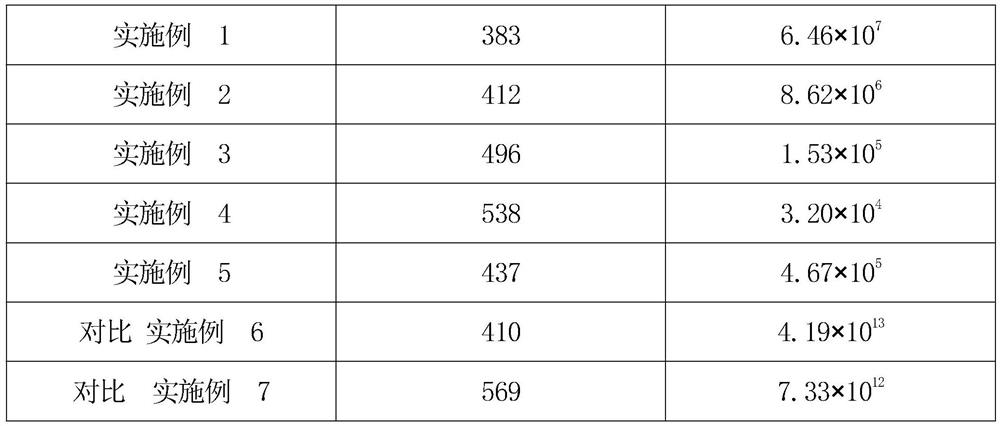

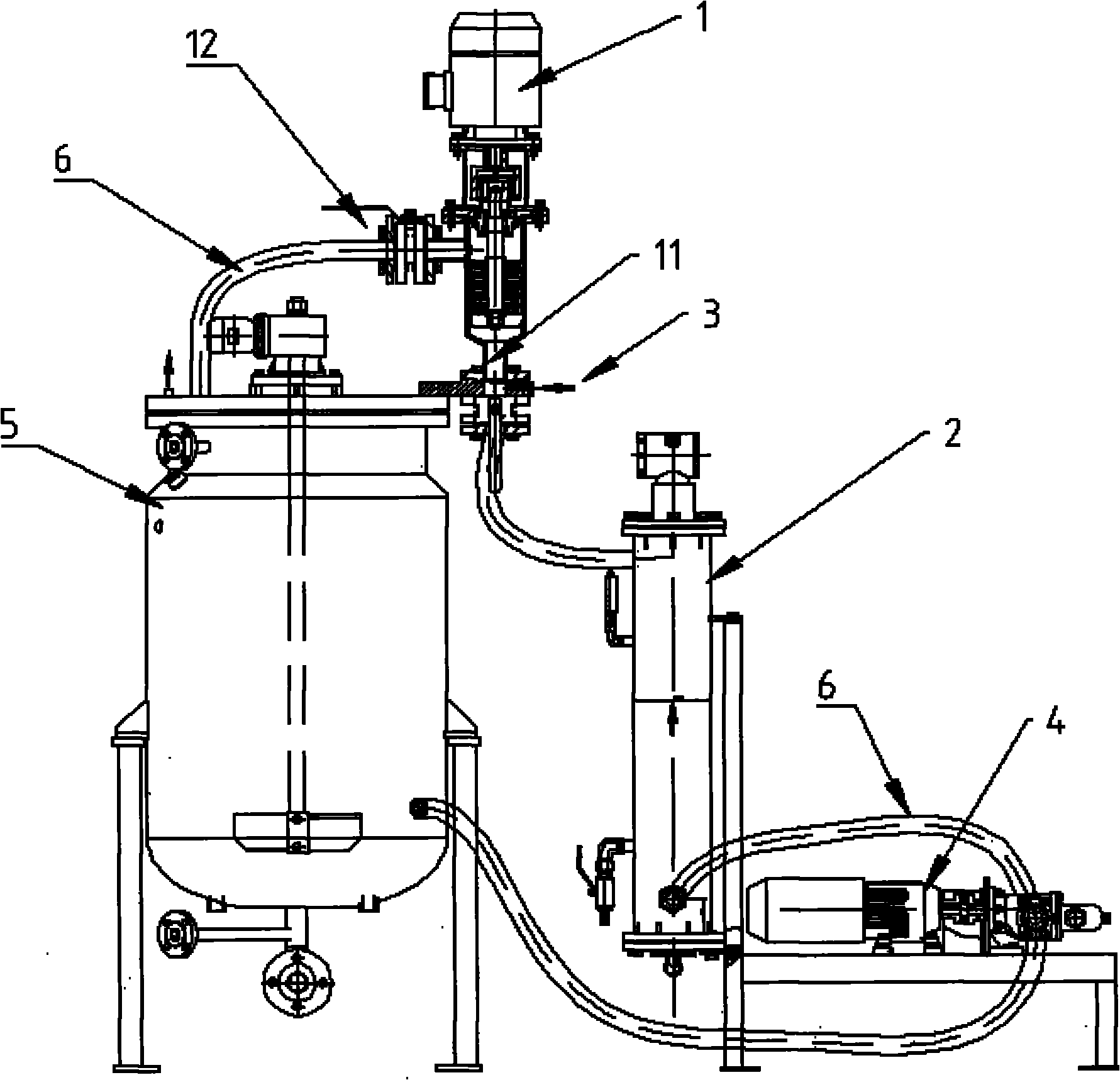

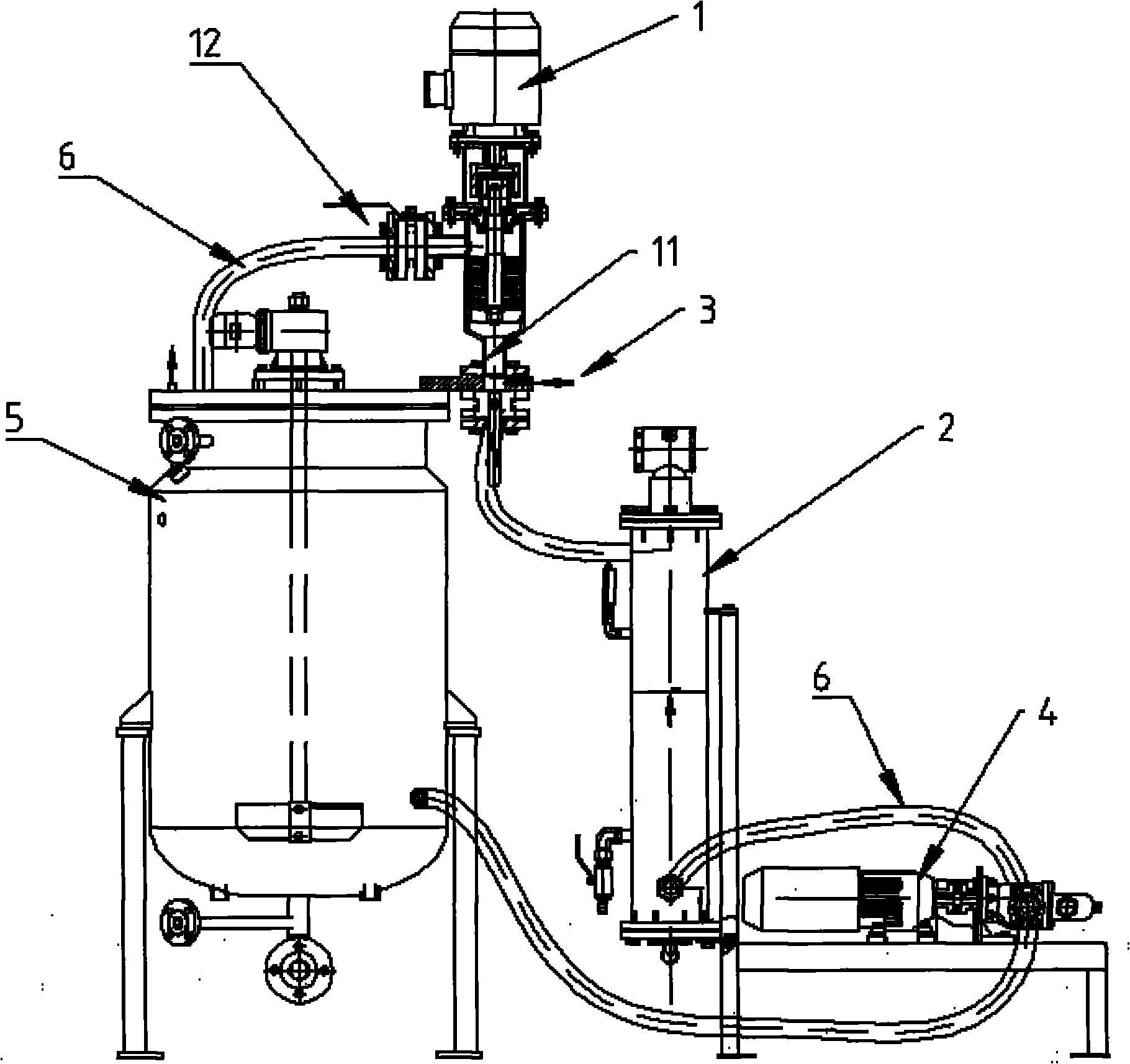

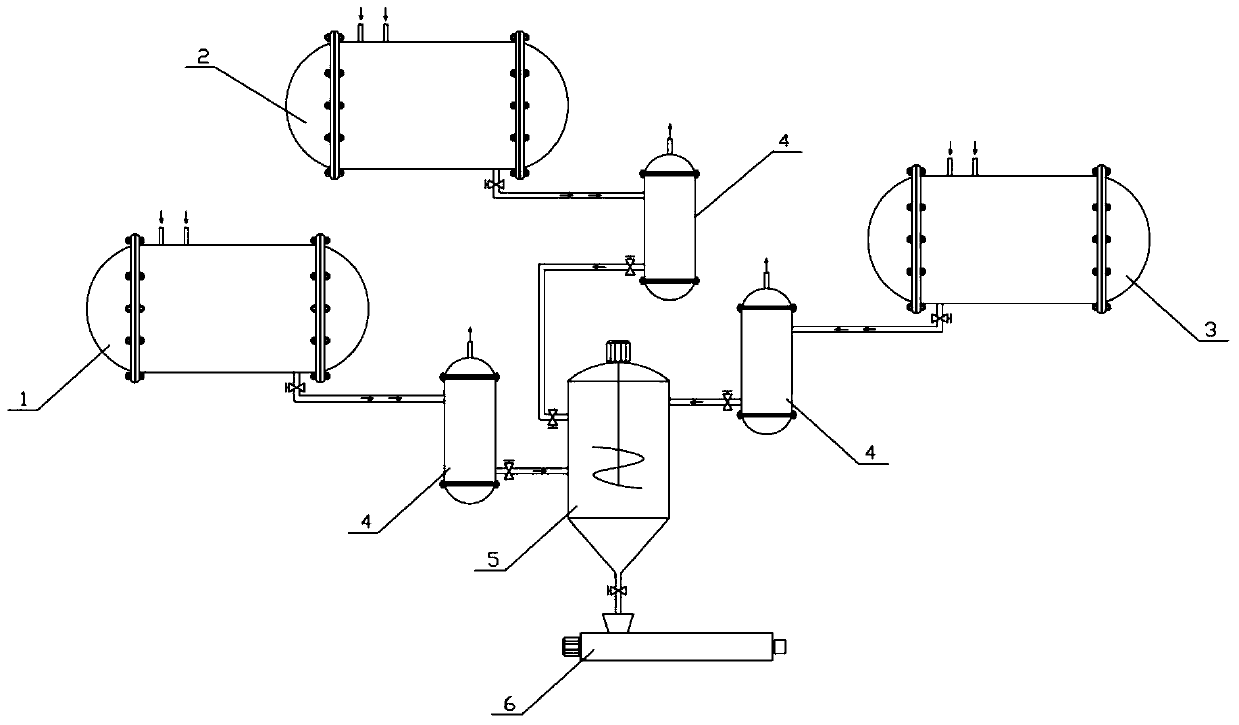

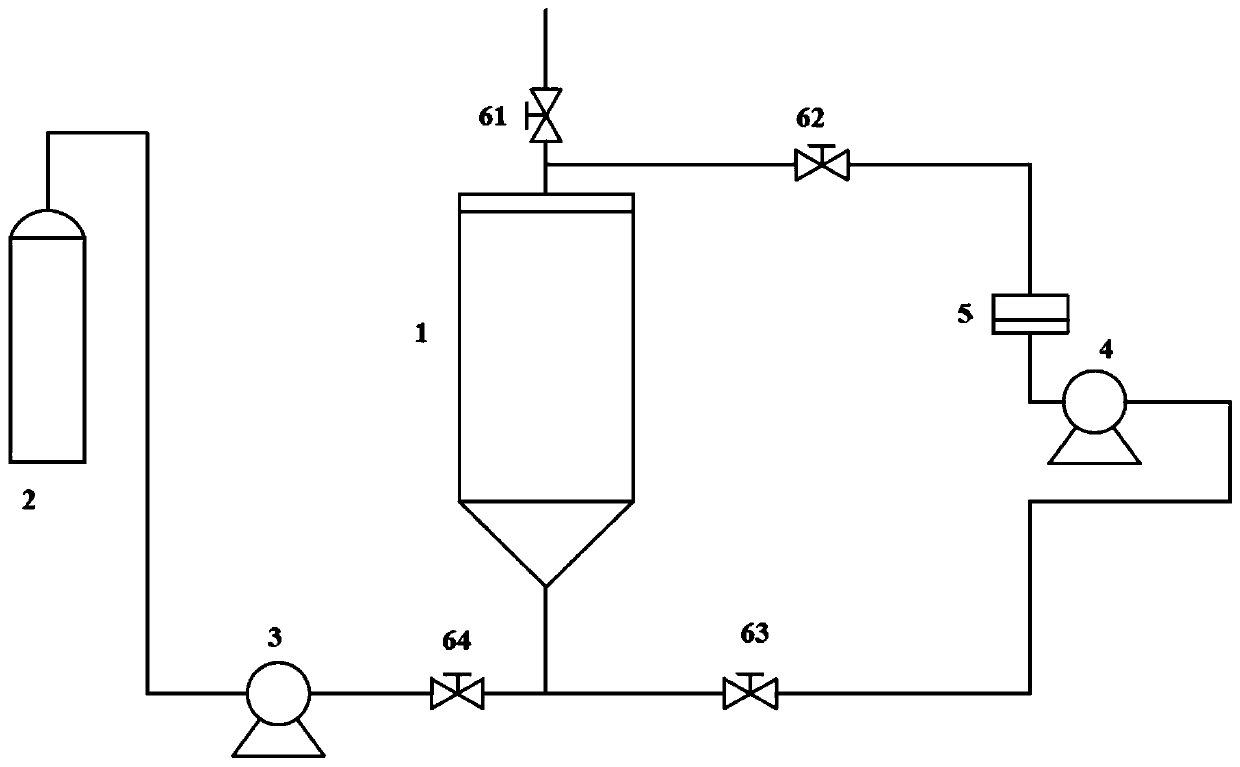

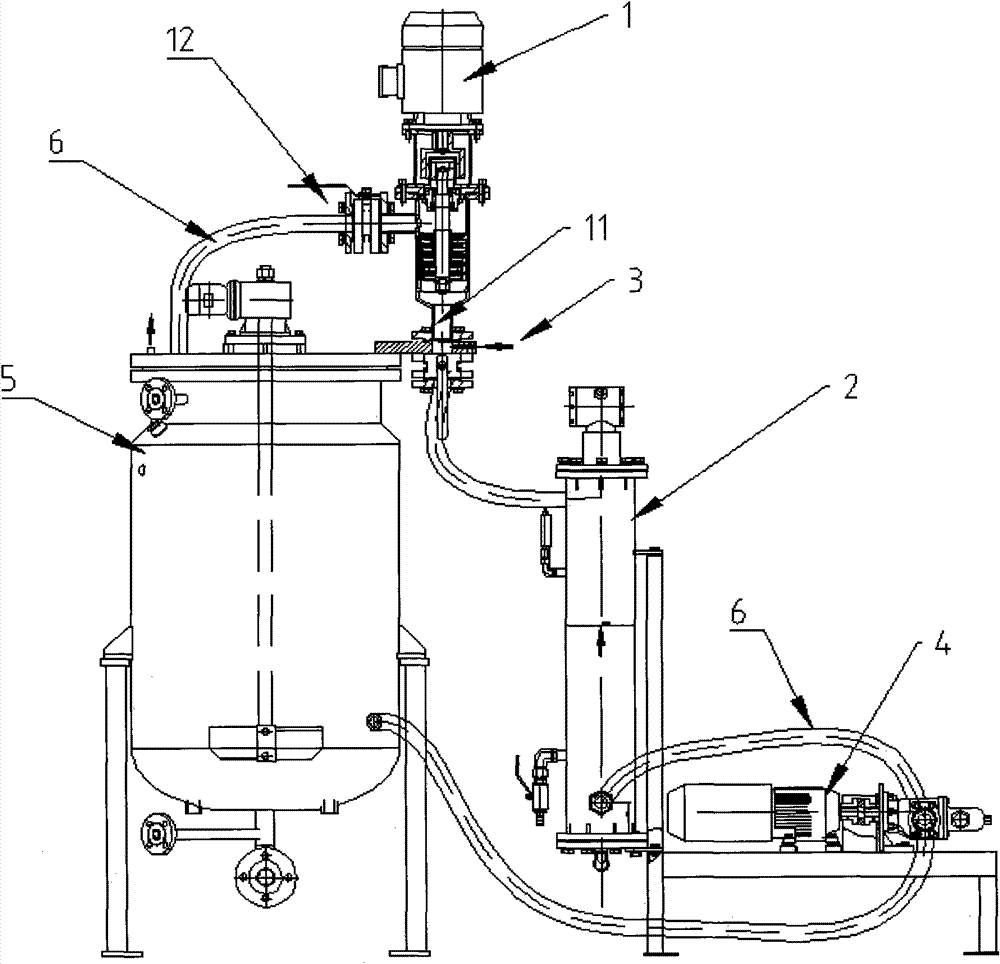

Material coring device of polyurethane foaming machine

ActiveCN102152436AUniform and dense cellsImprove mold filling qualitySteering wheelPulp and paper industry

The invention discloses a material coring device of a polyurethane foaming machine, comprising the following composing units of: a coring machine, a density meter, an air inlet and a conveying pump component, wherein the density meter and the air inlet are connected with a gas inlet of the coring machine; and the conveying pump component is connected with an input end of the density meter. An output hole of the coring machine and the conveying pump component are respectively and correspondingly communicated with the top end and the bottom part of a polyether polyalcohol material tank; the composing units are connected with one another through a pipeline; and an output end of the density meter is connected with a control unit of the coring machine. The material coring device cores the polyether polyalcohol materials, improves the mold charging quality and the surface quality of the products for producing the self-skinned vehicle steering wheels or polyether self-skinned foam products so that the foam holes of the foam plastic are compact and uniform, and the product quality is greatly improved.

Owner:张家港力勤机械有限公司

High-load brush disc for window wiper and production technology thereof

The invention discloses a high-load brush disc for a window wiper. The high-load brush disc is characterized by being prepared from the following raw materials in parts by weight: 75 to 80 parts of a PP (Polypropene) reworked material, 12 to 18 parts of a PE (Polyethylene) reworked material, 5 to 14 parts of modified PP, 10 to 20 parts of ammonium trimethyl methyl sulfate, 4 to 10 parts of sodium bicarbonate, 5 to 8 parts of azodicarbonamide, 2 to 6 parts of pentaerythritol phenylpropionate, 30 to 35 parts of fatty alcohol polyoxyethylene ether, 2 to 4 parts of azodiisobutyronitrile, 6 to 8 parts of amino-2-methyl-1-propanol, 10 to 20 parts of a lubricant, 10 to 20 parts of a coupling agent, 1 to 2 parts of masterbatches and 2 to 3 parts of an antioxidant. According to the high-load brush disc disclosed by the invention, the PP reworked material and the PE reworked material are utilized as basic materials, full foaming and uniform extruding are carried out on the PP reworked material and the PE reworked material, heat absorption and heat release are balanced during a foaming process, higher melt strength of polypropene is kept, bubble pores are uniform and dense, no cracking exists, the homogeneity of a brush disc product can be increased, the density and the self weight of the brush disc product are reduced, and load during a working process can be borne to a larger extent by using the brush disc product as the brush disc of the window wiper.

Owner:安徽环美刷业股份有限公司

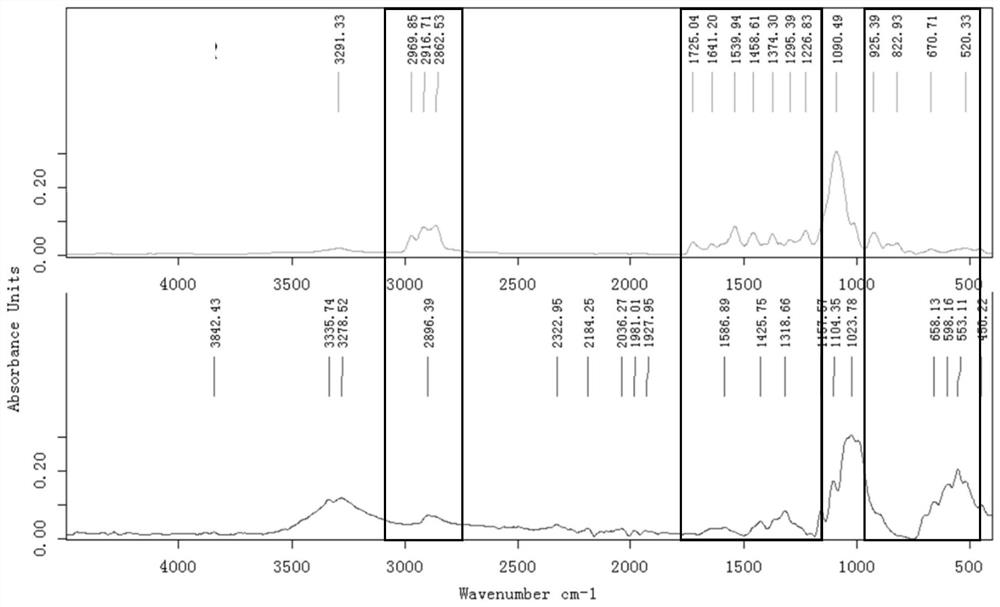

A kind of preparation method of foam yarn

ActiveCN110219177BUnique appearanceImprove plasticityVegetal fibresLiquid/gas/vapor yarns/filaments treatmentYarnPolymer science

The invention discloses a preparation method of foam yarn. The preparation process includes the preparation of main materials, the preparation of auxiliary agents, the padding treatment and the preparation of foam yarn; the method is to mix polyether polyol, isocyanate and tin catalyst into The main material, and then the mixed solution of polyether polyol, amine catalyst, foaming agent, and foam stabilizer is used as auxiliary agent, and the raw materials required for the reaction are padd on two yarns by in-situ polymerization method, respectively. Simulate solution mixing by twisting, so that the yarn can form a uniform and dense polyurethane foam from the inside out, and increase the adhesion of the foam film layer, so as to obtain a foam yarn with a unique appearance, which can be used in different applications according to needs. It can be used as a base material to produce fabrics of different shapes, and has strong plasticity; and the preparation method is simple, time-consuming, and requires low equipment, and can be widely used.

Owner:WUHAN TEXTILE UNIV

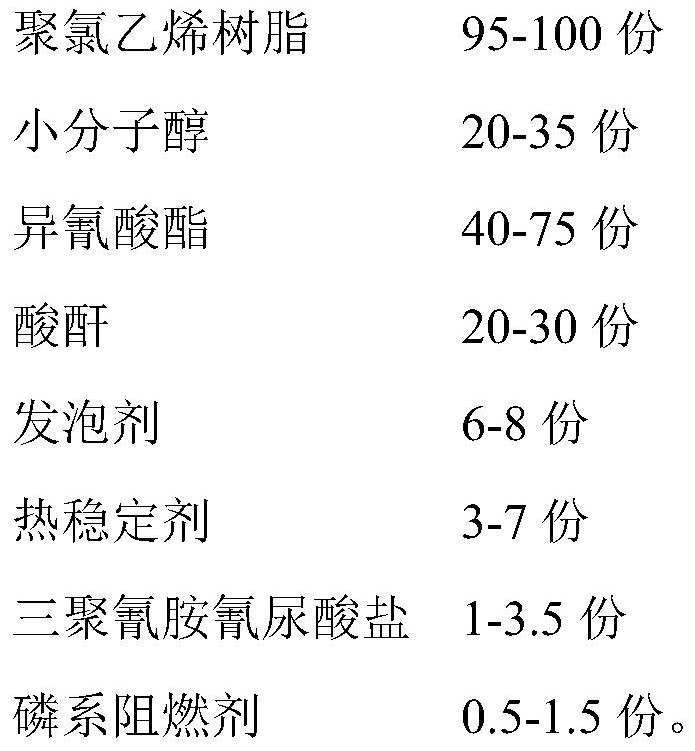

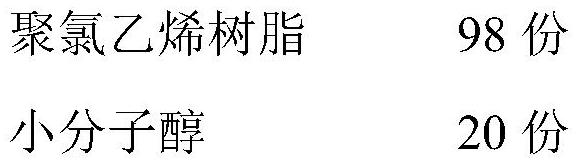

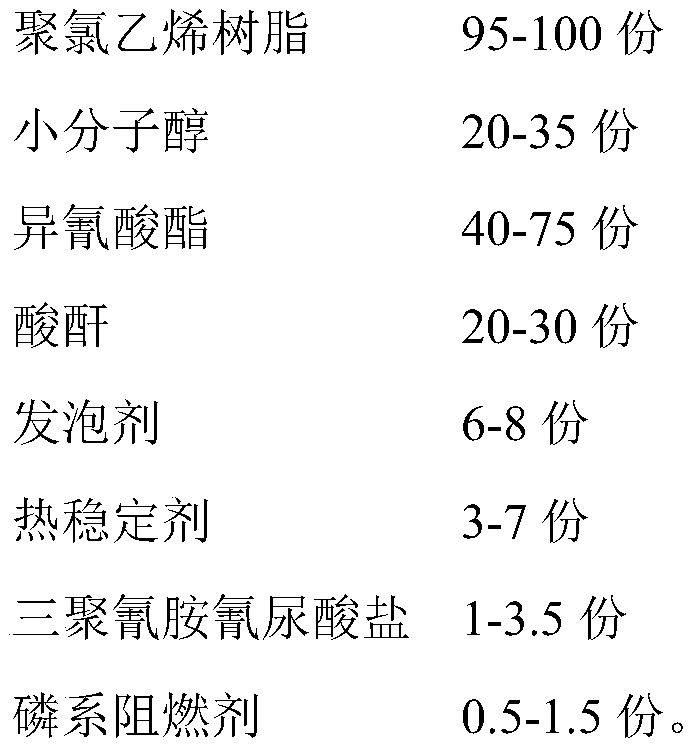

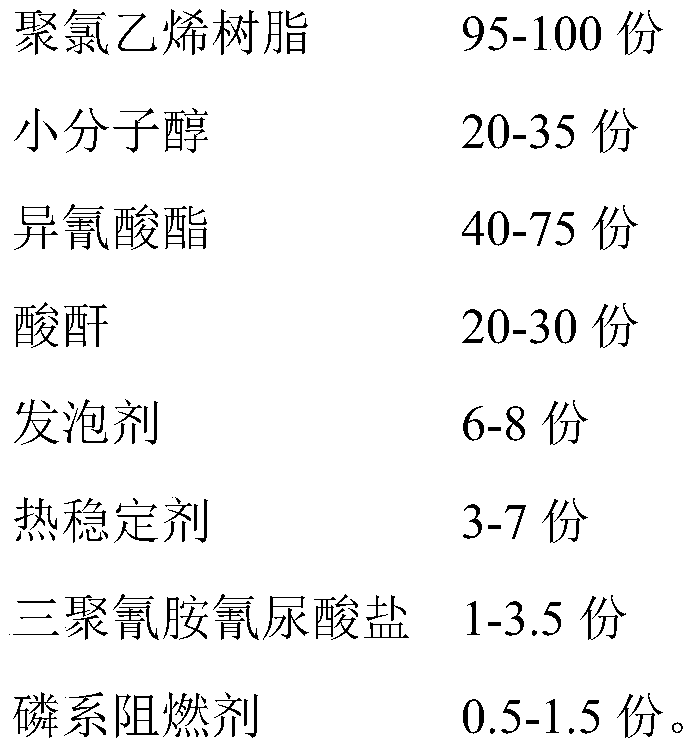

Microporous PVC foam and preparation method thereof

The invention belongs to the technical field of PVC foam, and in particular relates to a microporous PVC foam and a preparation method thereof. The raw material consists of 95-100 parts of polyvinyl chloride resin, 20-35 parts of small molecule alcohol, 40-75 parts of isocyanate, 20-30 parts of anhydride, 6-8 parts of foaming agent, 3-7 parts of heat stabilizer, melamine cyanurate It is composed of 1-3.5 parts of salt and 0.5-1.5 parts of phosphorus flame retardant. The microporous PVC foam of the present invention has dense and uniform cells, high compressive strength and tensile strength, and good flame retardancy; the preparation method is simple and controllable, beneficial to construction, easy to operate, and easy to produce. High efficiency, suitable for industrial production.

Owner:东营瑞致新材料有限公司

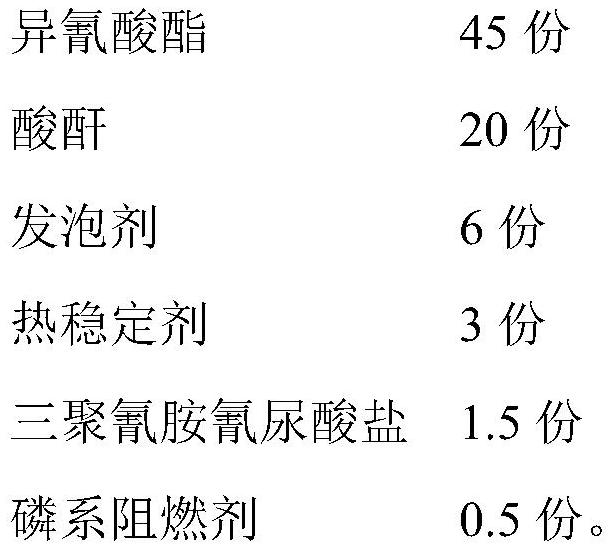

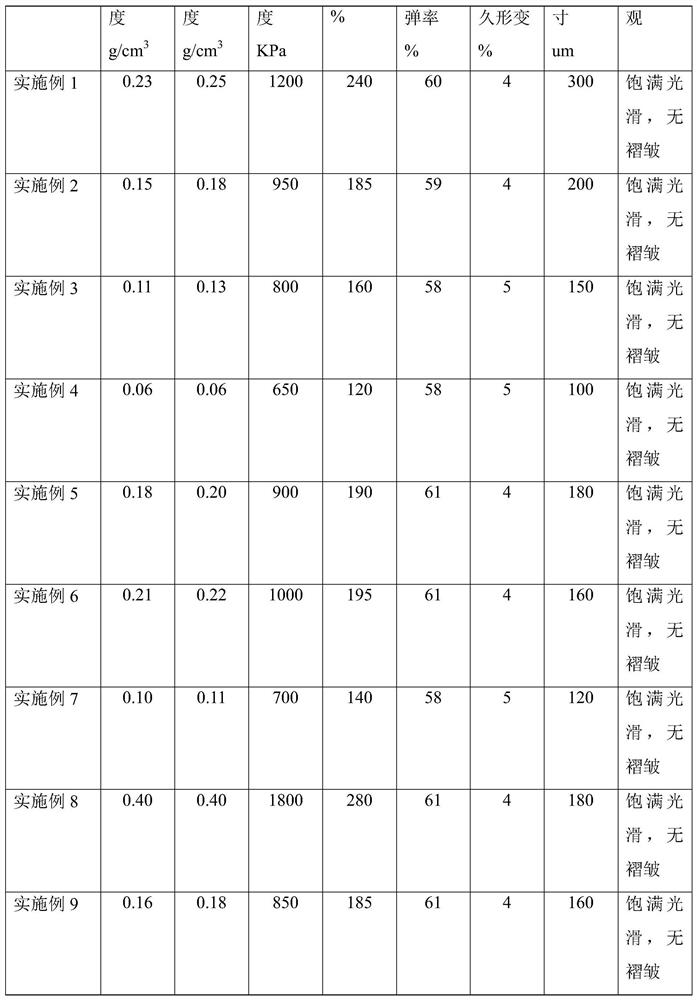

Method for preparing degradable cushioning materials

The invention relates to a method for preparing degradable cushioning materials, and belongs to the field of aloe vera husk powder treatment and application. The method for preparing the degradable cushioning materials includes mixing starch and distilled water with each other to prepare starch adhesive with the starch mass concentration of 50%, sequentially adding plasticizers and aloe vera huskpowder into the starch adhesive and stirring the plasticizers, the aloe vera husk powder and the starch adhesive at the constant temperature of 60-70 DEG C for 30 min to obtain mixtures; placing the mixtures in molds, carrying out foaming by plate vulcanizing machines at the processing temperatures of 150 DEG C under the pressures of 5 MPa for the foaming time of 1 min and carrying out cooling until the temperature reach the room temperature to obtain the degradable cushioning materials. The method has the advantages that the environmental problems and resource waste due to inappropriate treatment on the aloe vera husk powder can be effectively solved by the aid of the method, and research bases and practical guidance significance can be provided to applying the aloe vera husk powder to the field of biomass materials.

Owner:DALIAN POLYTECHNIC UNIVERSITY

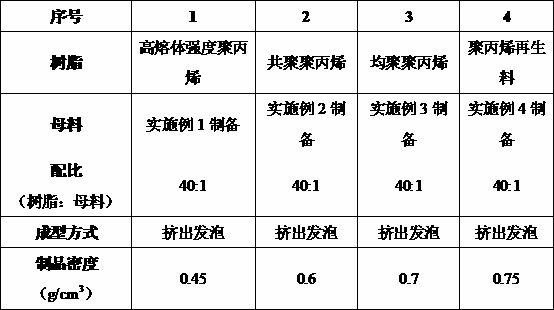

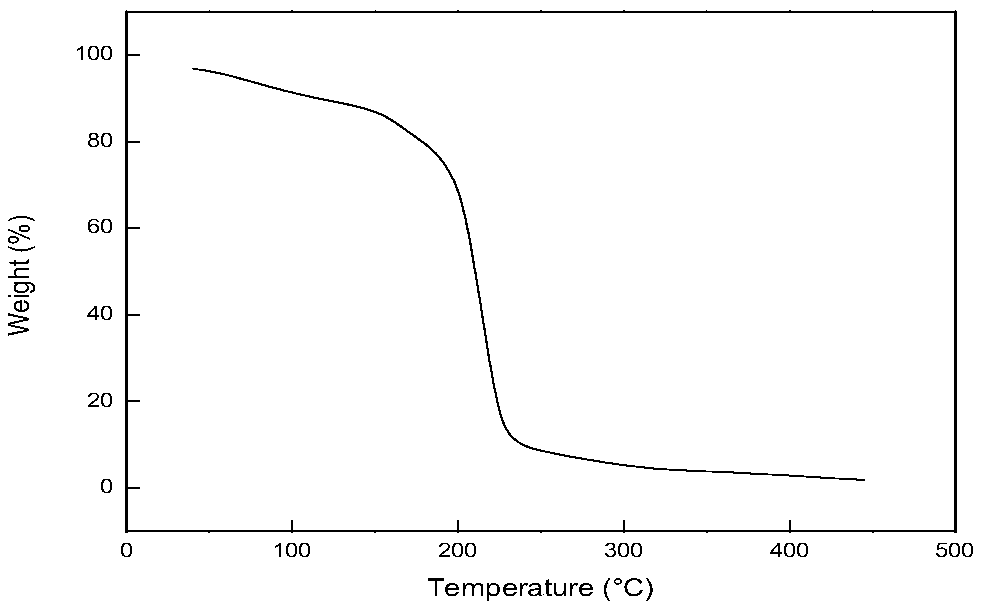

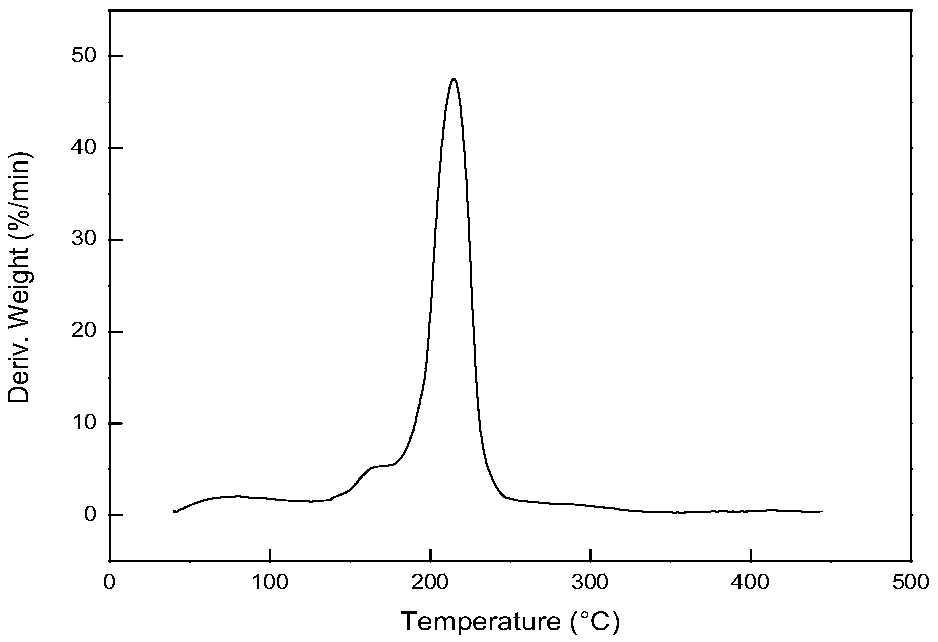

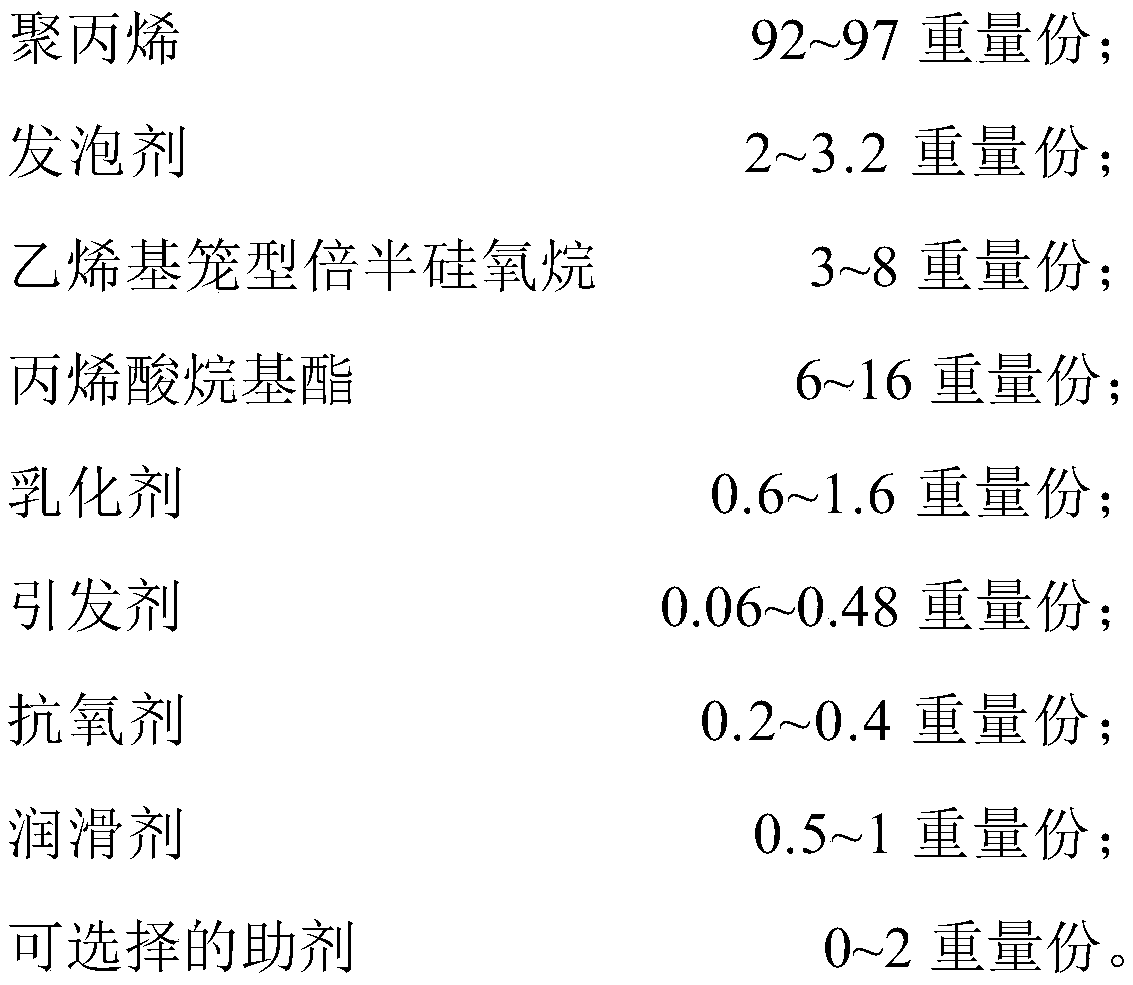

A kind of high modulus polypropylene/cage silsesquioxane micro-foaming composite material and preparation method thereof

The invention relates to the field of polymer technology, in particular to a high-modulus polypropylene / polyhedral oligomeric silsesquioxane microcellular foaming composite material and a preparationmethod thereof. The high-modulus polypropylene / polyhedral oligomeric silsesquioxane microcellular foaming composite material is prepared from a raw composition, wherein the raw composition is preparedfrom the following components in parts by weight: 92 to 97 parts of polypropylene, 2 to 3.2 parts of foaming agent, 3 to 8 parts of vinyl polyhedral oligomeric silsesquioxane, 6 to 16 parts of alkylester acrylate, 0.6 to 1.6 parts of emulsifying agent, 0.06 to 0.48 part of initiator, 0.2 to 0.4 part of antioxidant, 0.5 to 1 part of lubricating agent and 0 to 2 parts of optional assistant. The polypropylene / polyhedral oligomeric silsesquioxane composite material disclosed by the invention has the characteristics of small cell diameter and superior mechanical property, and has a wide application prospect in the field of automobile weight reduction.

Owner:ORINKO NEW MATERIAL CO LTD

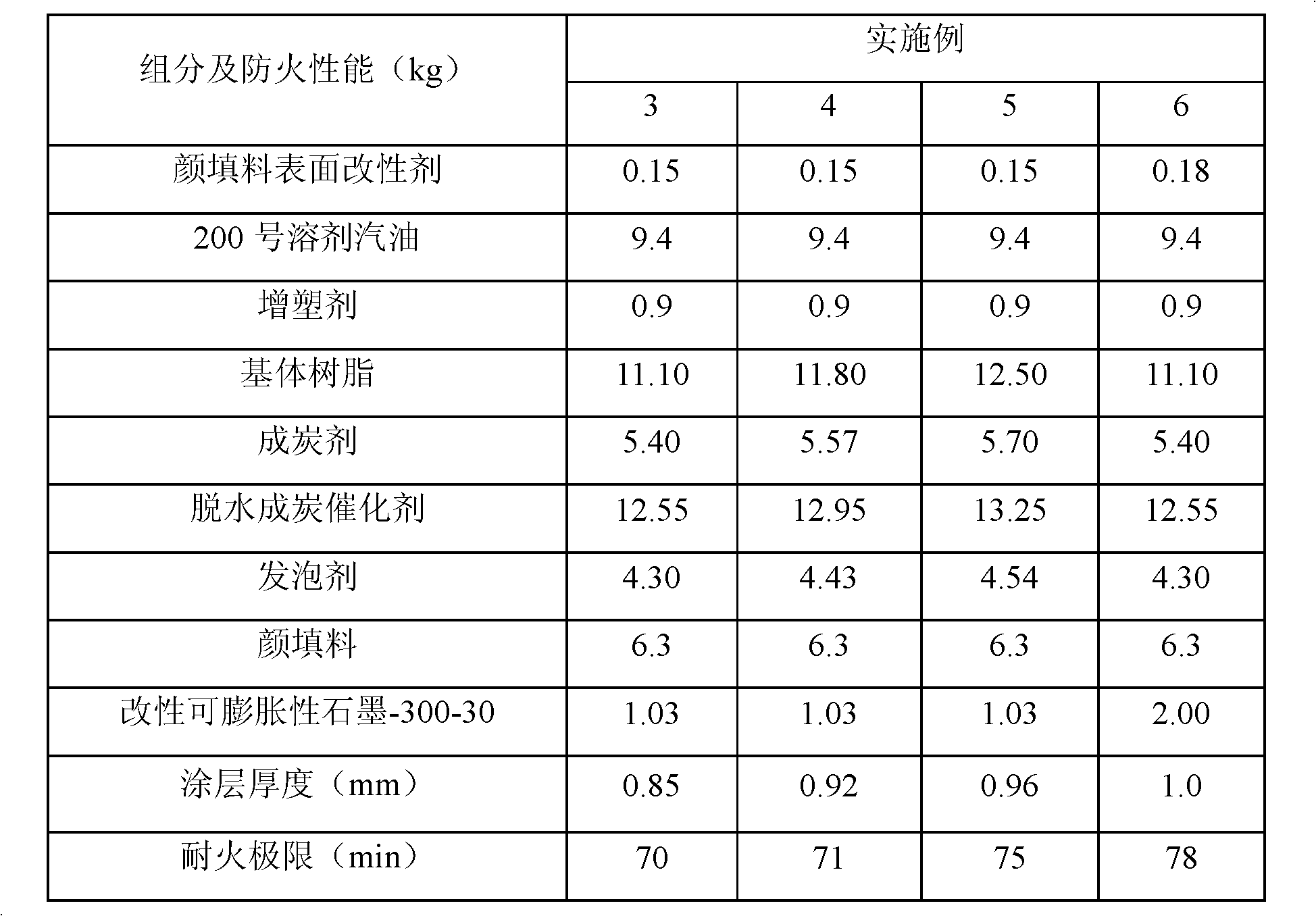

Coating for offshore steel structure buildings and preparation method thereof

ActiveCN102604503BEasy reunionGood dispersionRubber derivative coatingsAnti-corrosive paintsFoaming agentFire protection

Owner:XIAMEN UNIV

Microporous PVC foam and preparation method thereof

ActiveCN111592728ADense and uniform cellsHigh compressive and tensile strengthIsocyanateFlame resistance

The invention belongs to the technical field of PVC foam, and particularly relates to microporous PVC foam and a preparation method thereof. The microporous PVC foam includes following raw materials;95-100 parts of polyvinyl chloride resin, 20-35 parts of small molecular alcohol, 40-75 parts of isocyanate, 20-30 parts of anhydride, 6-8 parts of a foaming agent, 3-7 parts of a heat stabilizer, 1-3.5 parts of melamine cyanurate and 0.5-1.5 parts of a phosphorus-based flame retardant. The microporous PVC foam is compact and uniform in foam holes, high in compression strength and tensile strength, and very good in flame retardance; the preparation method is simple and controllable in process, beneficial to construction, easy to operate, high in production efficiency and suitable for industrial production.

Owner:东营瑞致新材料有限公司

A common extruder extrudes TPE material and method for foaming floating cables

ActiveCN107057380BImprove structural stabilityGood dispersionClimate change adaptationInsulated cablesElastomerPolypropylene

The invention relates to a TPE (Thermoplastic Elastomer) material for a foamed floating cable extruded by a common extruder and a method. According to the technical scheme, the TPE material comprises at least one of ultra-high molecular weight SEBS and ultra-high molecular weight SEEPS, 10-100 parts of long chain branch olefin polymers, 20-50 parts of white oil, 20-160 parts of reinforced resins, 5-30 parts of maleic anhydride grafted polypropylene, 5-30 parts of nano-clay, 10-40 parts of aids, and 20-200 parts of a TPE base material foamed water master batch. The material has the beneficial effects that by utilizing the low temperature sensitive and strain hardening phenomena of long chain branch olefin polymers and the characteristics of low melt viscosity and high melt strength of ultra-high molecular weight elastomers, the foamed melt has good foam structure stability at a certain temperature, the dependence on equipment and processing parameters is reduced, the product processing stability is improved, and the production cost is reduced; and moreover, foaming extrusion of the common extruder can be realized, the foaming agent is uniformly dispersed, the foaming process is stable, foam is uniform and dense, and the foamed product is fine, smooth and soft in surface, high in strength and high in weather resistance.

Owner:济南泰瑞丰高分子新材料有限公司

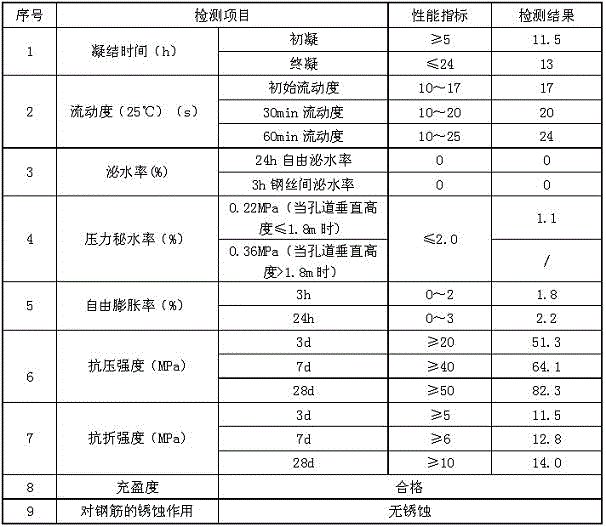

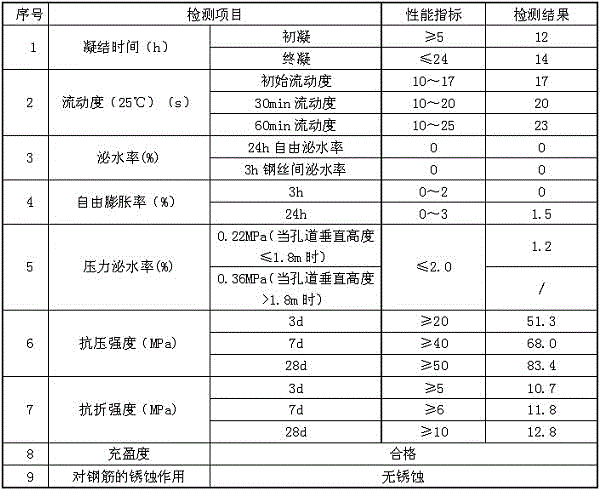

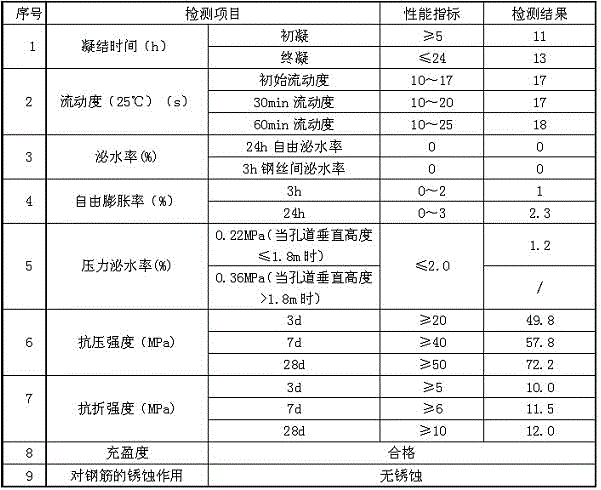

A post-tensioned prestressed pipeline grouting agent

The invention relates to a post-tensioned pre-stressing pipeline grouting agent, which is obtained by uniformly stirring the following raw materials according to weight percentage with rotating speed of no lower than 1000r / min: 4.7-5.1% of water reducing component, 0.3-0.5% of plastic expansion component, 28.2-30.1% of middle- to late-stage swelling component, 0.1-0.2% of stabilization component, 0.3-0.5% of delayed coagulation component, 0.3-0.5% of defoaming component, 43.0-47.1% of ultrafine active mineral admixture material and 18.9-20.4% of sulphoaluminate cement. The post-tensioned pre-stressing pipeline grouting agent has good performance, can satisfy requirement of industrialized production and can satisfy requirement of on-site construction preparation, construction operation is simple, and the grouting agent is especially suitable for post-tensioned pre-stressing pipeline grouting construction of large-scale engineering such as road, bridge and nuclear power station.

Owner:GANSU CHANGLONG HIGHWAY MAINTENANCE TECH RES INST CO LTD

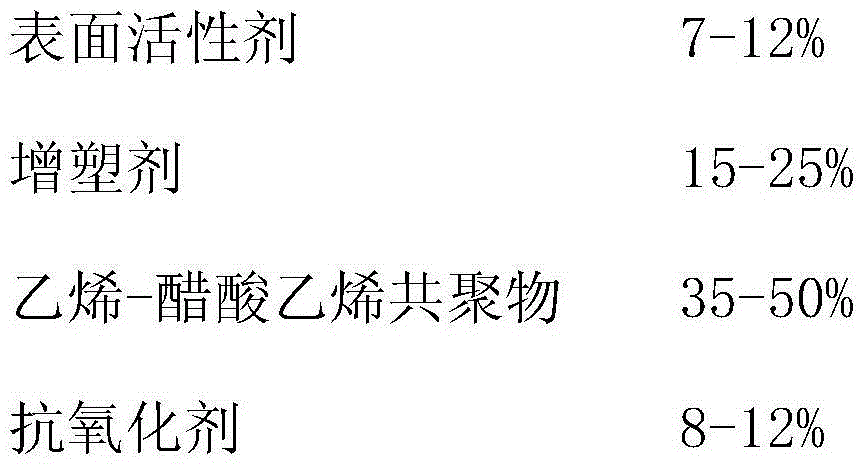

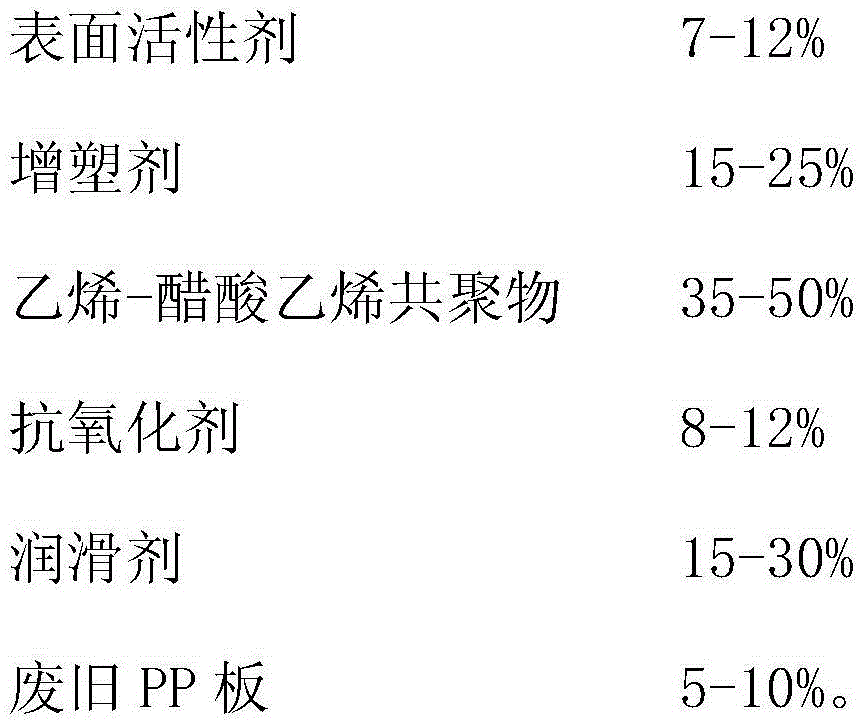

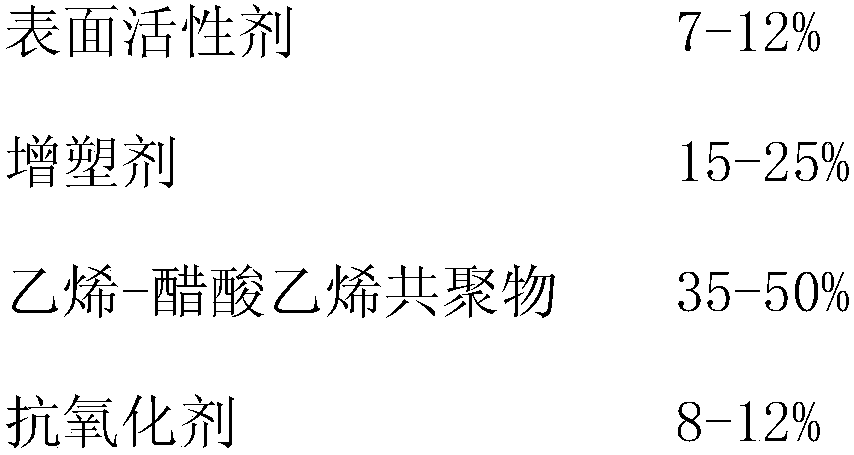

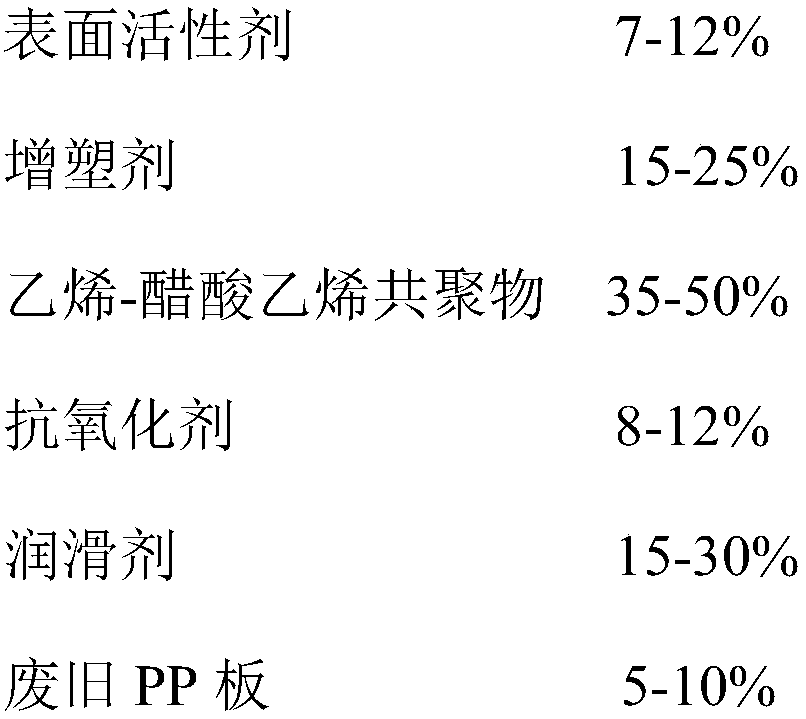

Foaming agent synergistic auxiliary agent

The invention provides a foaming agent synergistic auxiliary agent. The synergistic auxiliary agent consists of the following raw materials in percentage by mass: 7-12% of a surfactant, 15-25% of a plasticizer, 35-50% of an ethylene-vinyl acetate copolymer, 8-12% of an antioxidant, 15-30% of a lubricating agent and 5-10% of a thermosetting resin waste material. Because a formulated product is used for reducing the AC foaming temperature and stability, the foaming agent synergistic auxiliary agent provided by the invention can be used for increasing the fluidity and reducing the internal heat generated by material friction, so that the extrusion molding temperature can be greatly reduced; therefore, the foaming agent synergistic auxiliary agent can be used for absorbing a great number of heat within a short time; the foaming agent synergistic auxiliary agent belongs to a heat-absorbing auxiliary agent, can be used for solving the problems of non-compactness and non-uniformity, and can ensure that foamed cells are compact and uniform.

Owner:安徽恒森新材料有限公司

A kind of blowing agent synergistic auxiliary agent

The invention provides a foaming agent synergistic auxiliary agent. The synergistic auxiliary agent consists of the following raw materials in percentage by mass: 7-12% of a surfactant, 15-25% of a plasticizer, 35-50% of an ethylene-vinyl acetate copolymer, 8-12% of an antioxidant, 15-30% of a lubricating agent and 5-10% of a thermosetting resin waste material. Because a formulated product is used for reducing the AC foaming temperature and stability, the foaming agent synergistic auxiliary agent provided by the invention can be used for increasing the fluidity and reducing the internal heat generated by material friction, so that the extrusion molding temperature can be greatly reduced; therefore, the foaming agent synergistic auxiliary agent can be used for absorbing a great number of heat within a short time; the foaming agent synergistic auxiliary agent belongs to a heat-absorbing auxiliary agent, can be used for solving the problems of non-compactness and non-uniformity, and can ensure that foamed cells are compact and uniform.

Owner:安徽恒森新材料有限公司

Polyethylene composition and expanded beads, method for producing the same, and expanded bead molding

ActiveCN107312233BUniform and dense cellsHigh compressive strengthLinear low-density polyethylenePolymer science

The present invention relates to the field of polymers, and particularly provides a polyethylene composition, a foamed bead and a preparation method thereof, and a foamed bead molding body. The polyethylene composition comprises a component A, a component B, a component C and a cell nucleating agent, wherein the component A is ethylene / alpha-olefin copolymerized linear low-density polyethylene, has the melt index MIA of 0.01-2 g / 10 min, and has the density [rho]A of 0.880-0.936 g / cm<3>, the component B is ethylene / alpha-olefin copolymerized linear low-density polyethylene, has the melt index MIB of 2.1-9.9 g / 10 min, and has the density [rho]B of 0.910-0.930 g / cm<3>, and the component C is ethylene / alpha-olefin copolymerized linear low-density polyethylene, has the melt index MIC of 10-80 g / 10 min, and has the density [rho]C of 0.880-0.930 g / cm<3>. The foamed bead prepared from the polyethylene composition has the uniform and compact cells, and the prepared foamed bead molding body has the high compressive strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of extrusion foaming thermoplastic polyurethane elastomer particle and preparation method thereof

ActiveCN108239386BProduction environmental protectionSimple preparation processPolymer scienceFoaming agent

The invention relates to extruded foamed thermoplastic polyurethane elastomer particles and a preparation method thereof. Comprising the following components by mass percentage, (A) 65-90% thermoplastic polyurethane elastomer, (B) 2-30% thermoplastic resin polymer, (C) 0.5-15% compatibilizer, (D) 0.1 ‑5% foam nucleating agent. The preparation method of the TPU foamed particles comprises: mixing thermoplastic polyurethane elastomer, thermoplastic resin polymer, compatibilizer and foaming nucleating agent uniformly into melt extrusion equipment, obtaining blended gold particles through granulation; Gold particles are put into foaming extrusion equipment, melted and plasticized to obtain a melt, supercritical carbon dioxide is dissolved in the melt, foamed through a die, and expanded particles are obtained by underwater pelletizing. The prepared thermoplastic polyurethane foam particles are stable in size, basically do not shrink, have bright and full surfaces, and uniform cell diameters.

Owner:WANHUA CHEM GRP CO LTD

A kind of biological polyurethane and its preparation method and application

The present invention relates to a kind of biotype polyurethane, and the raw material of described biotype polyurethane comprises 1,3,5-benzenetrimethanol, diisocyanate, hydroxyl-containing amino acid, polyethylene glycol monomethyl ether; Wherein, in the diisocyanate The number of moles of isocyanate groups is greater than the sum of the number of moles of hydroxyl and carboxyl groups in the 1,3,5-benzenetrimethanol, amino acid, and polyethylene glycol monomethyl ether. The present invention also includes the preparation method of the biological polyurethane and its application in the field of polyurethane porous sponge. The advantages of the bio-polyurethane are: (1) high flexibility and good degradability; (2) ideal biocompatibility; (3) the resulting bio-polyurethane is subsequently foamed with water The biological polyurethane porous sponge formed by the reaction has uniform and dense cells, high porosity, and ideal mechanical properties.

Owner:湖北世丰新材料有限公司

Preparation method of plugging material of coal mine gas drainage drilling hole

Owner:CHONGQING UNIV

A kind of thermoplastic polymer foam beads and preparation method thereof

Owner:EAST CHINA UNIV OF SCI & TECH

Material coring device of polyurethane foaming machine

ActiveCN102152436BUniform and dense cellsImprove mold filling qualitySteering wheelPulp and paper industry

The invention discloses a material coring device of a polyurethane foaming machine, comprising the following composing units of: a coring machine, a density meter, an air inlet and a conveying pump component, wherein the density meter and the air inlet are connected with a gas inlet of the coring machine; and the conveying pump component is connected with an input end of the density meter. An output hole of the coring machine and the conveying pump component are respectively and correspondingly communicated with the top end and the bottom part of a polyether polyalcohol material tank; the composing units are connected with one another through a pipeline; and an output end of the density meter is connected with a control unit of the coring machine. The material coring device cores the polyether polyalcohol materials, improves the mold charging quality and the surface quality of the products for producing the self-skinned vehicle steering wheels or polyether self-skinned foam products so that the foam holes of the foam plastic are compact and uniform, and the product quality is greatly improved.

Owner:张家港力勤机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com