A kind of blowing agent synergistic auxiliary agent

A technology of foaming agent and auxiliary agent, applied in the field of sheet product processing, can solve the problems of unevenness, non-dense cells, affecting product quality, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

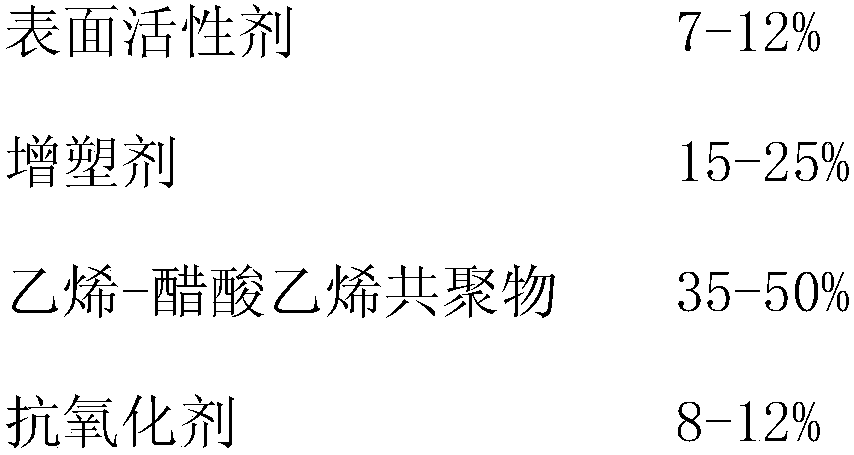

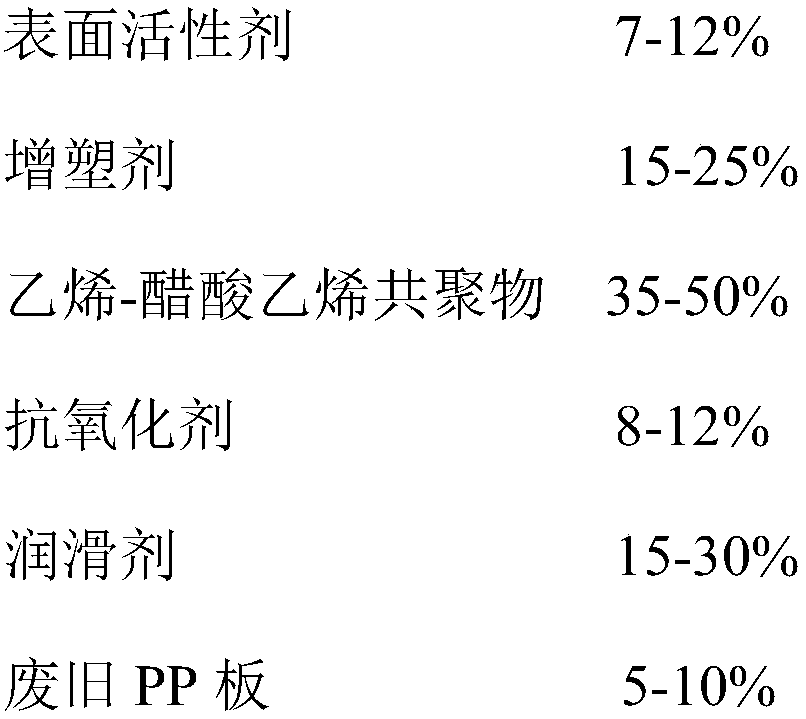

[0017] A kind of blowing agent synergistic auxiliary agent, synergistic auxiliary agent is made up of the raw material of following mass percent: quaternary ammonium compound 7%; Diisobutyl phthalate 25%; Ethylene-vinyl acetate copolymer 40%; Di-tert-butyl 8% p-cresol; 15% carboxylic acid; 5% waste PP board; among them, the content of ethyl acetate in ethylene-vinyl acetate copolymer is 5-15%; waste PP board is used waste.

[0018] In the present invention, because the formula product reduces the AC foaming temperature and stability, increases fluidity, and reduces the internal heat generated by material friction, thereby greatly reducing the extrusion molding temperature, it can absorb a large amount of heat in a short time, which belongs to endothermic Type additives solve the problem of non-densification and inhomogeneity, making the foamed cells dense and uniform.

Embodiment 2

[0020] A kind of blowing agent synergistic auxiliary agent, synergistic auxiliary agent is made up of the raw material of following mass percent: Sodium dodecylbenzene sulfonate 7%; Phthalic acid diester 25%; Ethylene-vinyl acetate copolymer 40%; Butylated hydroxyanisole 8%; fatty acid amide 15%; waste PP board 5%; wherein, the content of ethyl acetate in ethylene-vinyl acetate copolymer is 5-15%; waste PP board is used waste.

[0021] In the present invention, because the formula product reduces the AC foaming temperature and stability, increases fluidity, and reduces the internal heat generated by material friction, thereby greatly reducing the extrusion molding temperature, it can absorb a large amount of heat in a short time, which belongs to endothermic Type additives solve the problem of non-densification and inhomogeneity, making the foamed cells dense and uniform.

Embodiment 3

[0023] A foaming agent synergist, the synergist is composed of the following raw materials in mass percentage: 7% sodium dodecylbenzenesulfonate; 25% dibutyl phthalate; 40% ethylene-vinyl acetate copolymer; Tert-butyl hydroxyanisole 8%; polyester 15%; waste PP board 5%; wherein, the content of ethyl acetate in ethylene-vinyl acetate copolymer is 5-15%; waste PP board is used waste.

[0024] In the present invention, because the formula product reduces the AC foaming temperature and stability, increases fluidity, and reduces the internal heat generated by material friction, thereby greatly reducing the extrusion molding temperature, it can absorb a large amount of heat in a short time, which belongs to endothermic Type additives solve the problem of non-densification and inhomogeneity, making the foamed cells dense and uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com