Preparation method of plugging material of coal mine gas drainage drilling hole

A technique for draining drilling and plugging materials, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., and can solve the problems of poor water resistance and corrosion resistance in coal mine gas drainage drilling and plugging construction quality , the cells are not uniform and dense enough to achieve the effects of wide application range, short production cycle and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

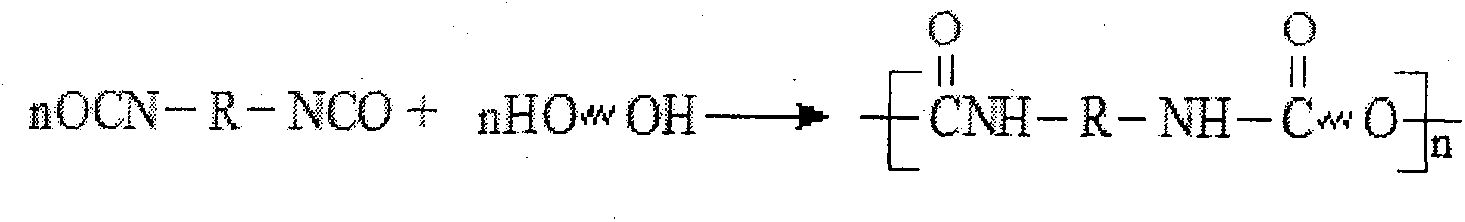

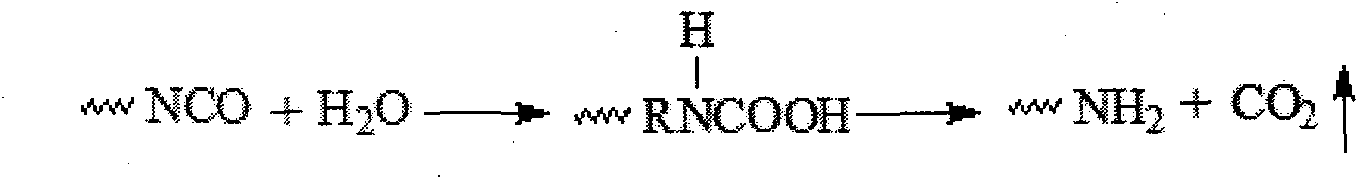

Method used

Image

Examples

Embodiment 1

[0035] The specific steps of a preparation method of a coal mine gas drainage drilling plugging material are as follows:

[0036] (1) material preparation

[0037] Prepare black material and white material separately (all solid reagents need to be dried) and set aside. which is

[0038] The components and mass percentages of the black material are:

[0039] Diphenylmethane diisocyanate (MDI) 60%

[0040] Polymethylene polyphenylisocyanate (PAPI) 40%

[0041] The components and mass percentages of the white material are:

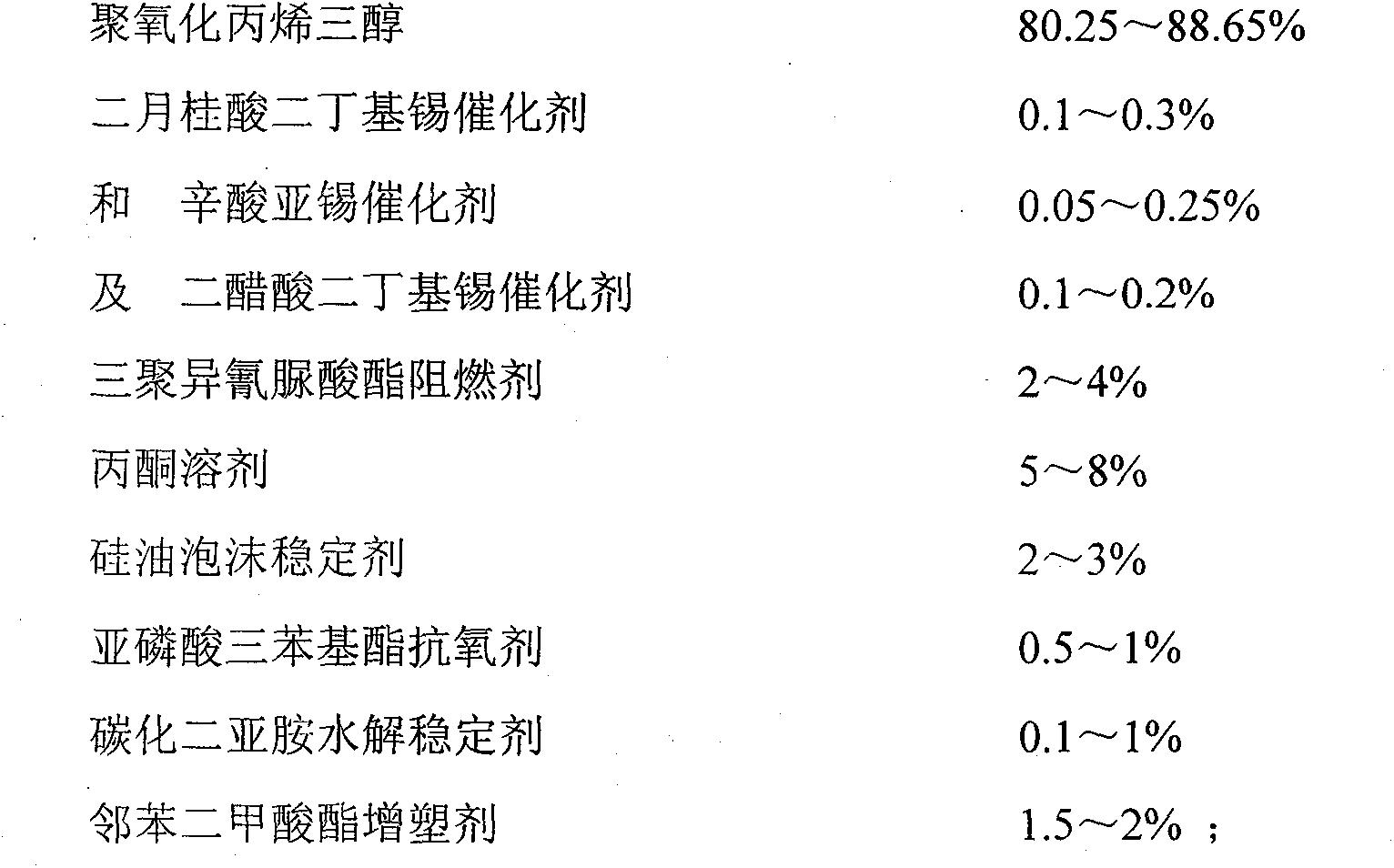

[0042]

[0043] (2) Preparation of white material solution

[0044] After the first step (1) is completed, according to the mass (g) of the white material prepared in the first step: the ratio of the volume (m1) of water is 1:0.04, under the condition of 60 rpm , water was added into the white material, and the stirring was continued for 5 minutes to prepare the white material solution.

[0045] (3) Preparation of rigid polyurethane foam

[0046] A...

Embodiment 2

[0048] A method for preparing coal mine gas drainage drilling plugging material, its specific steps are the same as those in Embodiment 1, wherein:

[0049] In step (1),

[0050] Components of black material and their mass percentages:

[0051] Diphenylmethane diisocyanate (MDI) 80%

[0052] Polymethylene polyphenyl isocyanate (PAPI) 20%

[0053] The composition and mass percentage of white material:

[0054]

[0055]

[0056] In the (2) step, the mass (g) of the white material prepared in the (1) step: the ratio of the volume (ml) of water is 1: 0.06, the rotating speed is 70 rpm, and stirred for 10 min.

[0057] In the (3) step, the black material that the (1) step is ready: the quality of the white material of the white material solution that (2) step makes is the ratio of 1: 1.2, and temperature is 25 ℃, and the rotating speed is 80 revs / Minute, stir for 30s, and let the mixture stand for 7.5min.

Embodiment 3

[0059]A method for preparing coal mine gas drainage drilling plugging material, its specific steps are the same as those in Embodiment 1, wherein:

[0060] In step (1),

[0061] Components of black material and their mass percentages:

[0062] Diphenylmethane diisocyanate (MDI) 100%

[0063] Polymethylene polyphenylisocyanate (PAPI) 0%

[0064] The composition and mass percentage of white material:

[0065]

[0066] In the (2) step, the mass (g) of the white material prepared in the (1) step: the ratio of the volume (ml) of water is 1: 0.08, the rotating speed is 80 rpm, and stirred for 15 min.

[0067] In the (3) step, the black material prepared in the (1) step: the quality of the white material of the white material solution prepared in the (2) step is a ratio of 1: 1.3, the temperature is 40°C, and the rotating speed is 100 rpm Divide, stir for 35s, and let the mixture stand for 10min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com