A kind of high modulus polypropylene/cage silsesquioxane micro-foaming composite material and preparation method thereof

A technology of silsesquioxane and composite materials, which is applied in the field of high modulus polypropylene/cage silsesquioxane micro-foaming composite materials and its preparation, and can solve the problems of co-foaming and affecting the performance of polypropylene micro-foaming , cell collapse and other problems, to achieve the effect of improving melt strength, improving compatibility and enhancing interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a preparation method of high modulus polypropylene / cage silsesquioxane micro-foaming composite material, comprising the following steps:

[0029] (1) Stir vinyl cage silsesquioxane, alkyl acrylate and emulsifier evenly under water-containing conditions, then stir at 80-90°C for 1-3 hours, then add the initiator dropwise into the reaction system, And heat and reflux at 80-90°C for 12-36h, then cool to room temperature, and adjust the pH of the solution to 7-8 with alkaline substances, then vacuum-dry, crush and sieve to obtain modified vinyl cage silsesquioxane alkyl;

[0030] (2) After mixing the modified vinyl cage silsesquioxane, polypropylene, antioxidant, lubricant, and additives evenly, they are put into a twin-screw extruder, melt-extruded, and granulated to obtain a polymer Acrylic composite materials;

[0031] (3) The polypropylene composite material and foaming agent are uniformly mixed, then added to an injection molding m...

Embodiment 1

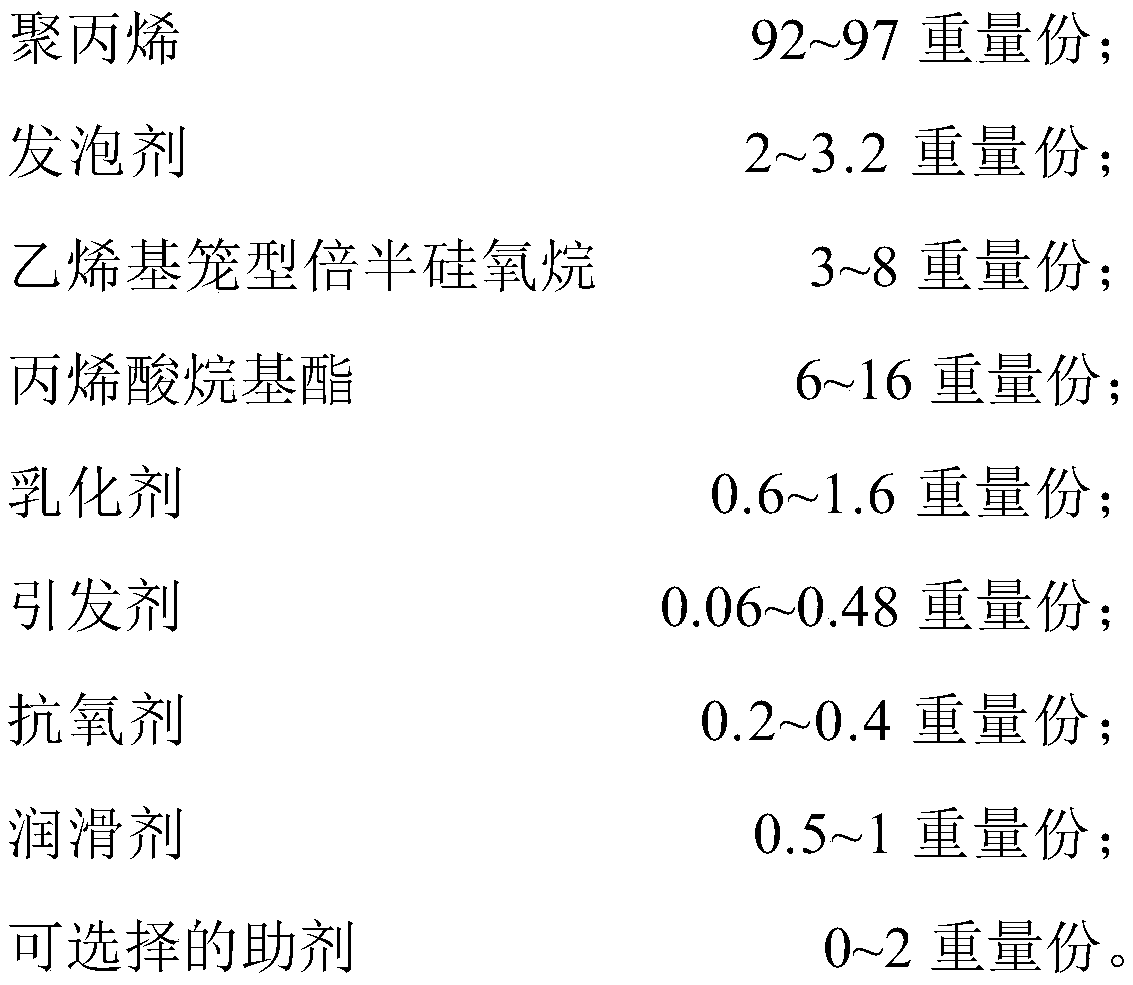

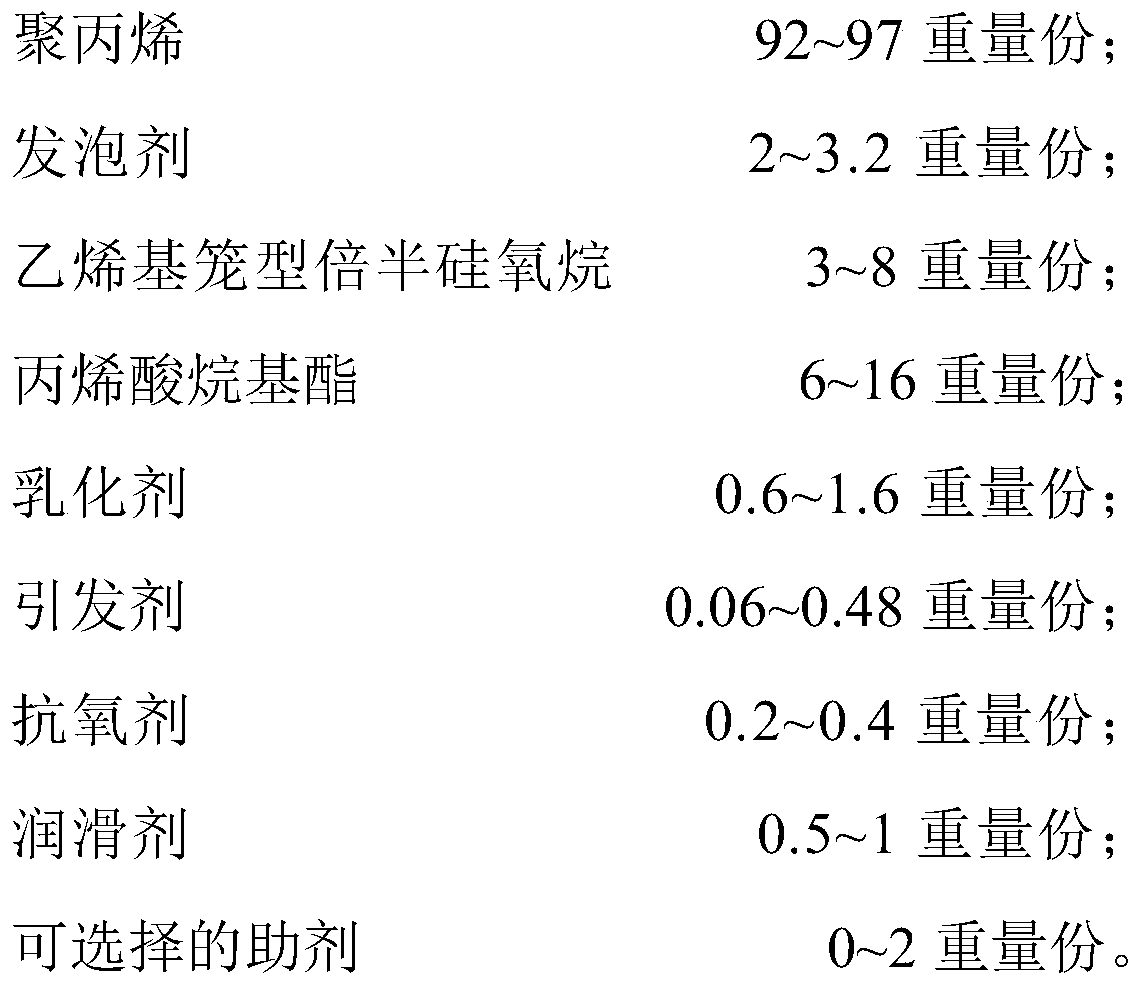

[0038] A high modulus polypropylene / cage silsesquioxane microfoam composite made from:

[0039]

[0040]

[0041] The preparation method of described high modulus polypropylene / cage silsesquioxane micro-foaming composite material is as follows:

[0042] (1) Stir 3 parts by weight of vinyl cage silsesquioxane, 6 parts by weight of lauryl methacrylate and 0.6 part by weight of sodium dodecyl sulfonate in 90.88 parts by weight of deionized water, and then Stir at 80°C for 1h, then add 0.06 parts by weight of ammonium persulfate dropwise to the reaction system, and heat to reflux at 80-90°C for 12h, then cool to room temperature, and neutralize to pH 7 with 5% NaOH solution, then Vacuum-dried at 50°C for 12 hours, and then crushed through a 1000-mesh sieve to obtain modified vinyl cage silsesquioxane;

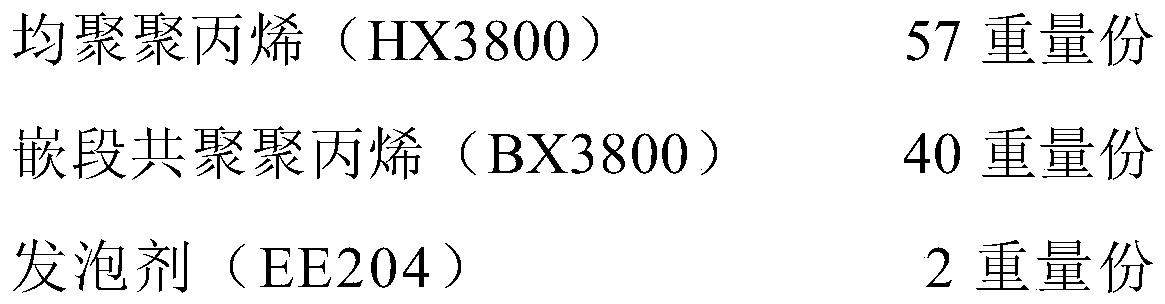

[0043] (2) Modified vinyl cage silsesquioxane, 57 parts by weight homopolypropylene (HX3800), 40 parts by weight block copolymerized polypropylene (BX3800), 0.1 parts by wei...

Embodiment 2

[0046] A high modulus polypropylene / cage silsesquioxane microfoam composite made from:

[0047]

[0048]

[0049] The preparation method of described high modulus polypropylene / cage silsesquioxane micro-foaming composite material is as follows:

[0050] (1) 5 parts by weight of vinyl cage silsesquioxane, 10 parts by weight of dodecyl methacrylate and 1 part by weight of sodium dodecylbenzenesulfonate are stirred in 83.7 parts by weight of deionized water, and then Stir at 80°C for 3h, then add 0.3 parts by weight of potassium persulfate dropwise to the reaction system, and heat to reflux at 80°C for 24h, then cool to room temperature, and neutralize to pH 7.2 with 5% NaOH solution, then Vacuum drying at 70°C for 12 hours, and then crushed through a 1000-mesh sieve to obtain modified vinyl cage silsesquioxane;

[0051] (2) Modified vinyl cage silsesquioxane, 55 parts by weight homopolypropylene (HX3800), 40 parts by weight random copolymerized polypropylene (R370Y), 0.2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com