A kind of thermoplastic polymer foam beads and preparation method thereof

A technology of thermoplastic polymers and foamed beads, which is applied in the field of polymer foaming, can solve the problems of uneven cell size, long saturation time, and high production cost of foamed beads, and achieve uniform cell size and apparent appearance. Fewer defects and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

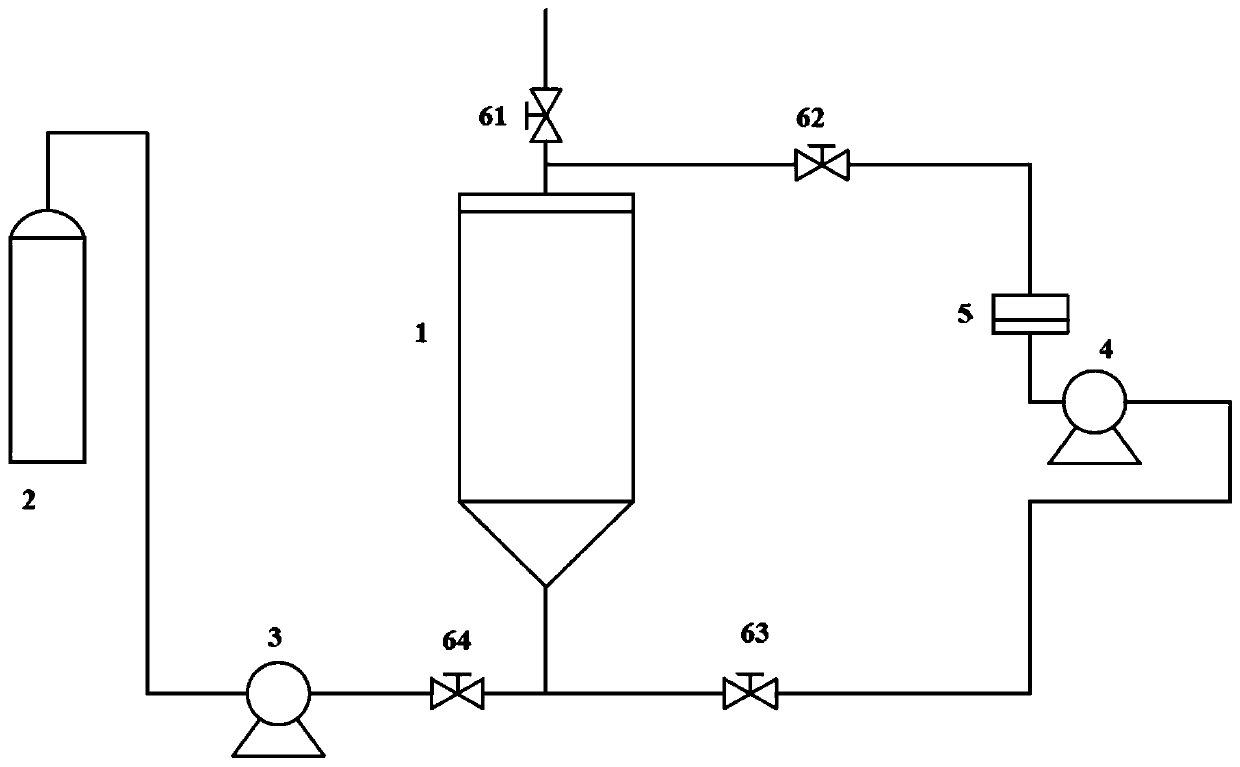

[0037] Such as figure 1 , add average diameter 3.8mm, T to spouted bed 1 m polyethylene beads at 119°C to 35% of the bed volume; start the carbon dioxide injection pump 3, feed carbon dioxide from the carbon dioxide storage tank 2 to replace the air in the system, seal the system and maintain it under a carbon dioxide atmosphere; The bed layer of the moving bed 1 is heated by program temperature control, the heating rate is 5°C / min, and heated to a foaming temperature of 105°C; continue to inject carbon dioxide, control the injection pressure of carbon dioxide to 15MPa, open the valve 64, and make the foaming temperature in the spouted bed 1 The carbon dioxide is in a supercritical state; start the circulation pump 4, open the valve 62 and valve 63, and carry out the carbon dioxide circulation operation through the filter 5, the spray speed is 0.30m / s, keep the spray state for 25min, and make the polyethylene beads reach saturation State: close valve 62, valve 63, and valve 6...

Embodiment 2

[0039] Such as figure 1 , add average diameter 1.8mm, T to the bed layer of spouted bed 1 m Polypropylene beads at 165°C to 40% of the bed volume; start the carbon dioxide injection pump 3, feed carbon dioxide from the carbon dioxide storage tank 2 to replace the air in the system, seal the system and maintain it under a carbon dioxide atmosphere; The bed layer of the moving bed 1 is heated by program temperature control, the heating rate is 5°C / min, and heated to a foaming temperature of 147°C; continue to inject carbon dioxide, control the injection pressure of carbon dioxide to 12MPa, open the valve 64, and make the foaming temperature in the spouted bed 1 When the carbon dioxide is in a supercritical state, start the circulation pump 4, open the valve 62 and valve 63, and carry out the carbon dioxide circulation operation through the filter 5. The spray speed is 0.25m / s, and keep the spray state for 30 minutes to make the polypropylene beads reach saturation State: close ...

Embodiment 3

[0041] Such as figure 1 , add average diameter 3.5mm, T to the bed layer of spouted bed 1 mThermoplastic polyurethane beads at 135°C to 45% of the bed volume; start the carbon dioxide injection pump 3, feed carbon dioxide from the carbon dioxide storage tank 2 to replace the air in the system, seal the system and maintain it under a carbon dioxide atmosphere; The bed layer of the moving bed 1 is heated by program temperature control, the heating rate is 5°C / min, and heated to a foaming temperature of 120°C; continue to inject carbon dioxide, control the injection pressure of carbon dioxide to 15MPa, open the valve 64, and make the foaming temperature in the spouted bed 1 Carbon dioxide is in a supercritical state, start the circulation pump 3, open valve 62 and valve 63 to carry out carbon dioxide circulation operation, the spray speed is 0.42m / s, keep the spray state for 28min, and the thermoplastic polyurethane beads reach a saturated state; close valve 62, valve 63. Valve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com