Environment-friendly light brush plate for urban cleaning vehicle and preparation method of environment-friendly light brush plate

A cleaning vehicle, an environmentally friendly technology, applied in the field of urban cleaning equipment, can solve the problems of affecting the cleaning effect, consuming large materials, and large driving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The preparation of an environmentally friendly lightweight brush plate for urban cleaning vehicles includes the following steps:

[0015] A, get modified polypropylene 3.09kg; Sodium bicarbonate: 0.52kg; Azodicarbonamide 0.68kg; Acid 0.07kg; Paraffin 0.07kg; added to the hopper of extruder A;

[0016] B. Add 78.00kg of PP recycled material; 16.00kg of PE recycled material; 1.50kg of color masterbatch into the hopper of extruder B;

[0017] C. The material is co-extruded to the mold through extruder A and extruder B, and cooled to form the finished product.

[0018] In this embodiment, the modified polypropylene refers to a radiation-modified polypropylene resin, which can be obtained by irradiating polypropylene with a high-energy electron beam generated by an electron accelerator. The high-energy ray absorbed dose during the irradiation process is 15-30 kGy .

Embodiment 2

[0020] In the present embodiment, the preparation of an environmentally friendly light-weight brush plate for an urban cleaning vehicle includes the following steps:

[0021] A, get modified polypropylene 3.09kg; Sodium bicarbonate: 0.52kg; Azodicarbonamide 0.68kg; Acid 0.07kg; Paraffin 0.07kg; added to the hopper of extruder A;

[0022] B. 76.00kg of PP recycled material; 17.50kg of PE recycled material; 2kg of color masterbatch are added to the hopper of extruder B;

[0023] C. The material is co-extruded to the mold through extruder A and extruder B, and cooled to form the finished product.

Embodiment 3

[0025] A, get modified polypropylene 4kg; Sodium bicarbonate: 1kg; Azodicarbonamide 1kg; Four (3,5-di-tert-butyl-4-hydroxyl) phenylpropionate pentaerythritol 0.1kg; ; Paraffin 0.1kg; added to the hopper of extruder A;

[0026] B. 76.00kg of PP recycled material; 15.7kg of PE recycled material; 2kg of color masterbatch are added to the hopper of extruder B;

[0027] C. The material is co-extruded to the mold through extruder A and extruder B, and cooled to form the finished product.

[0028]

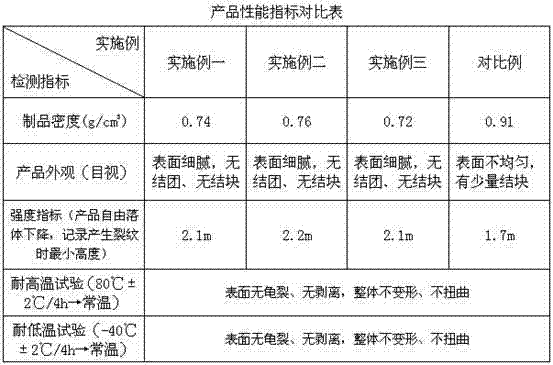

[0029] Analysis of the testing data shows that the brushes prepared in the above examples have low density and light weight characteristics; through visual inspection of the product, the surface is fine and fine, and there is no agglomeration or agglomeration, which proves that it has good uniformity; This product is placed at a high place, and it is free-falling down to the cement floor, gradually raising the height, and recording the minimum height when cracks occur. By comparison, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com