Method for preparing degradable cushioning materials

A buffer material and starch technology, which is applied in the field of preparation of degradable buffer materials, can solve problems such as aloe vera skin powder resource waste, and achieve the effect of solving environmental problems and resource waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

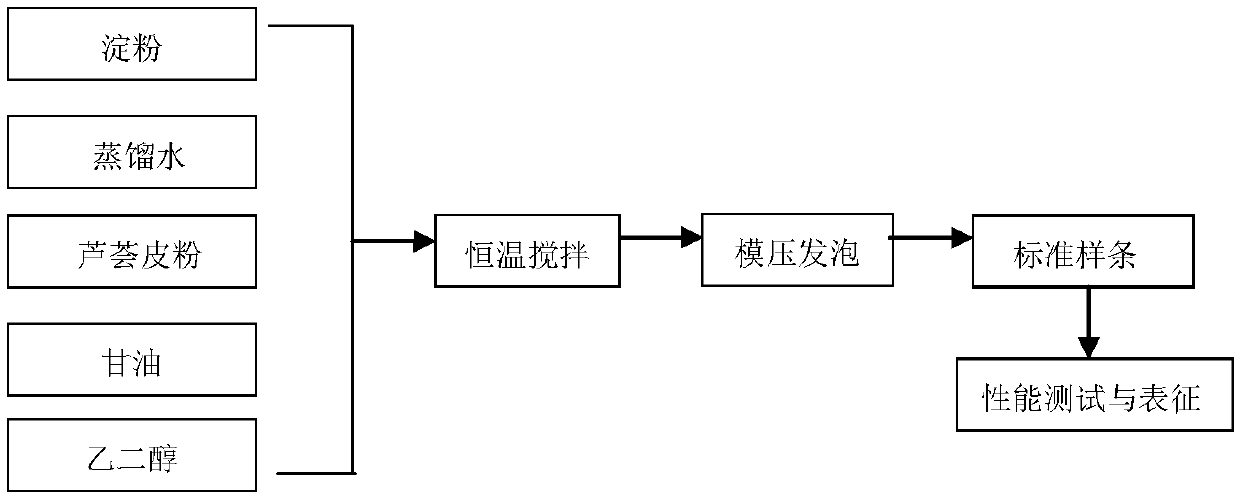

[0026] Using starch as a matrix and untreated aloe bark powder as a filler, a degradable buffer foaming material was prepared. The method was as follows: starch (100 parts) was mixed with an appropriate amount of distilled water (100 parts), and glycerin (7 parts) was added in turn. , ethylene glycol (14 parts), untreated aloe bark powder (20 parts), the mixture is placed in a constant temperature oil bath and stirred at a constant speed, and then molded, and its specific preparation process is as follows:

[0027] The first step: dry the aloe bark powder;

[0028] Step 2: Mix the starch with an appropriate amount of distilled water, and add plasticizer and untreated aloe bark powder in sequence, and place the mixture in a constant temperature oil bath at 65°C and stir for 30 minutes at a constant speed;

[0029] Step 3: Put the prepared mixture into a mold with a fixed shape, and use a flat vulcanizer to foam. The processing temperature of the flat vulcanizer is 150°C, the pr...

Embodiment 2

[0033] With starch as the matrix, aloe bark powder treated with blanching and coupling agent is used as filler to prepare a degradable buffer foaming material. The method is as follows: mix starch (100 parts) with appropriate amount of distilled water (100 parts), and successively Add glycerin (7 parts), ethylene glycol (14 parts), untreated aloe bark powder (20 parts), place the mixture in a constant temperature oil bath and stir at a constant speed, and then carry out compression molding. The specific preparation process is as follows:

[0034] The first step: carry out broom treatment to aloe bark powder, in lye, the lye used is the mass fraction of 12% NaOH solution, soak in 1h, wash to neutrality and then dry, add in dried aloe bark powder Silane coupling agent KH550 (0.2 parts) is evenly dispersed and then dried again;

[0035] The second step: mix the starch with an appropriate amount of distilled water, and add the plasticizer and the treated aloe skin powder in turn, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com