A kind of extrusion foaming thermoplastic polyurethane elastomer particle and preparation method thereof

A thermoplastic polyurethane, extrusion foaming technology, used in the field of foam materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

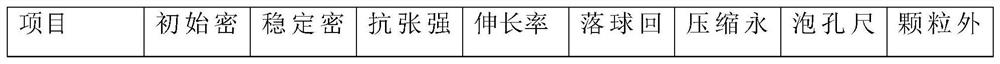

Embodiment 1

[0092] (1) According to mass percentage, 90% of thermoplastic polyether polyurethane (8190RV), 9.4% of polybutylene terephthalate (1200-211L), 0.5% of compatibilizer EPDM-G-MAH and 0.1 % of talcum powder mixed evenly. the mixed composition in the Melt blending is carried out in a co-rotating twin-screw extruder, and the blending temperature is 175-235°C. After underwater granulation and drying, thermoplastic polyurethane blended alloy particles are obtained;

[0093] (2) Put the obtained thermoplastic polyurethane blended gold particles into foaming extrusion equipment, and the material is melted and plasticized in the extrusion equipment to obtain a thermoplastic polyurethane blended gold melt, and the melting temperature is 160-200° C.;

[0094] (3) supercritical carbon dioxide is injected into the blended alloy melt, the pressure of supercritical carbon dioxide is 10MPa, and the consumption is 5% of the blended alloy melt quality;

[0095] (4) Expanded particles are obt...

Embodiment 2

[0098] (1) According to mass percentage, 82.8% of thermoplastic polyether polyurethane (8190RV), 15% of polybutylene terephthalate (1100-211MD), 2% of compatibilizer POE-G-MAH and 0.2 % of nanometer calcium carbonate (NPCC-201, D50=10nm) is mixed evenly. the mixed composition in the Melt blending is carried out in a co-rotating twin-screw extruder, and the blending temperature is 175-235°C. After underwater granulation and drying, thermoplastic polyurethane blended alloy particles are obtained;

[0099] (2) Put the obtained thermoplastic polyurethane blended gold particles into foaming extrusion equipment, and the material is melted and plasticized in the extrusion equipment to obtain a thermoplastic polyurethane blended gold melt, and the melting temperature is 170-220° C.;

[0100] (3) supercritical carbon dioxide is injected into the blended alloy melt, the pressure of supercritical carbon dioxide is 15MPa, and the consumption is 10% of the blended alloy melt quality;

...

Embodiment 3

[0104] (1) According to the mass percentage, 87.5% of thermoplastic polyether polyurethane (8185RV), 2% of thermoplastic polyester elastomer ( 7246), 10% compatibilizer HDPE-G-MAH and 0.5% talcum powder are mixed evenly. the mixed composition in the The melt blending is carried out in a co-rotating twin-screw extruder, and the blending temperature is 175-230°C. After underwater granulation and drying, thermoplastic polyurethane blended alloy particles are obtained;

[0105] (2) Put the obtained thermoplastic polyurethane blended gold particles into foaming extrusion equipment, and the material is melted and plasticized in the extrusion equipment to obtain a thermoplastic polyurethane blended gold melt, and the melting temperature is 160-200° C.;

[0106] (3) supercritical carbon dioxide is injected into the blended alloy melt, the pressure of supercritical carbon dioxide is 25MPa, and the consumption is 15% of the blended alloy melt quality;

[0107] (4) Expanded particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com