Preparation method for foamed yarns

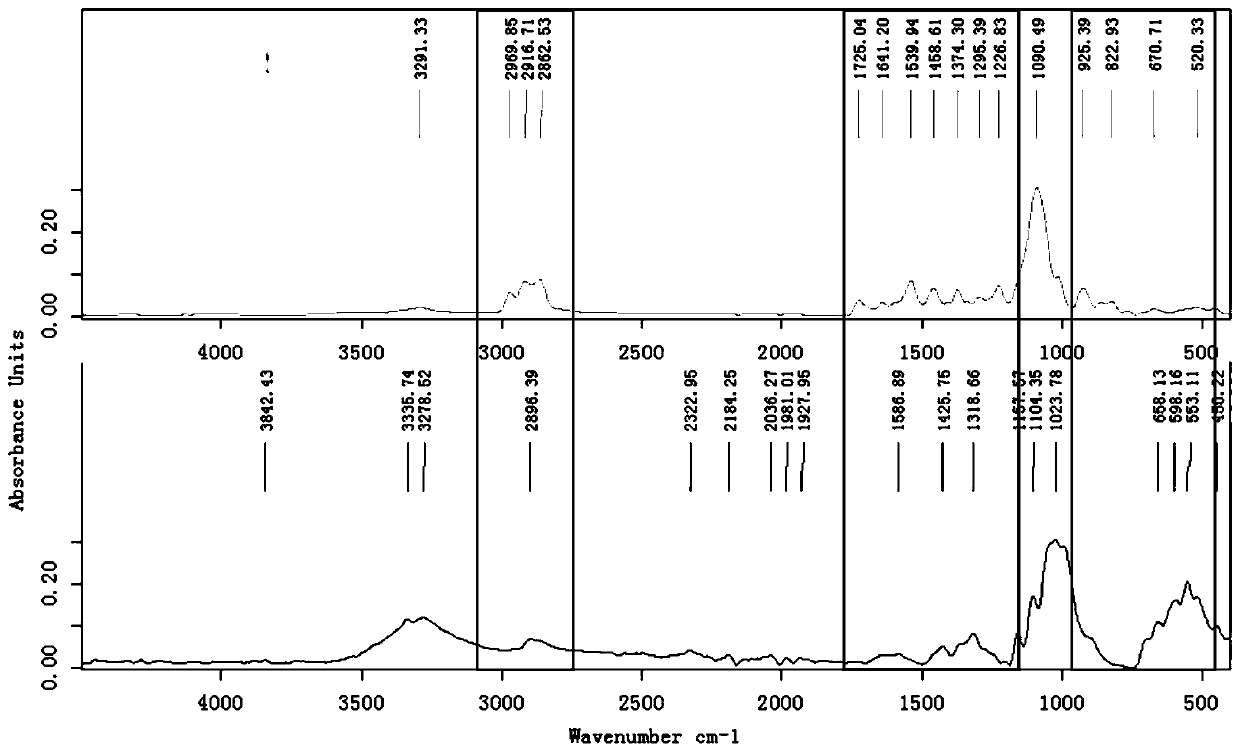

A foam and yarn technology, which is applied in the field of foam yarn preparation, can solve the problems that the appearance and performance of the core-spun yarn are not significantly improved, the combination method and preparation process need to be studied, and the application of yarn has not been reported, etc., to achieve strong plasticity , Short time consumption, uniform and dense cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present embodiment provides a kind of preparation method of foam yarn, comprises the steps:

[0036] (1) Preparation of main ingredients

[0037] Put the mixed solution of polyether polyol and isocyanate in the mixing tank, add tin catalyst and stir to obtain the main material; wherein, the mass ratio of polyether polyol to isocyanate is 30:70; the tin catalyst The mass fraction of the catalyst is 1.5%; the stirring temperature is 60° C., the stirring speed is 1000 r / min, and the stirring time is 6 min.

[0038] (2) Preparation of additives

[0039] Mix polyether polyol, amine catalyst, blowing agent, foam stabilizer, after stirring uniformly, obtain auxiliary agent; Wherein, the mass fraction of described polyether polyol is 66%; The mass fraction of described amine catalyst is 0.9%; the mass fraction of the foaming agent is 10.9%; the mass fraction of the foam stabilizer is 0.7%; the stirring temperature is 60° C., the stirring speed is 1000 r / min, and the stirr...

Embodiment 2~5

[0048] Embodiments 2-5 provide a kind of preparation method of foamed yarn, compared with embodiment 1, the difference is that polyether polyol, isocyanate, tin catalyst, amine catalyst, blowing agent and homogenizer in the raw material are changed. The mass fraction of foaming agent; Wherein polyether polyol is divided into two parts and adds in step (1) and step (2) respectively, and its specific consumption and the contrast with embodiment 1 are as shown in table 1.

[0049] The foamed yarn raw material mass fraction of table 1 embodiment 1~5

[0050]

[0051]

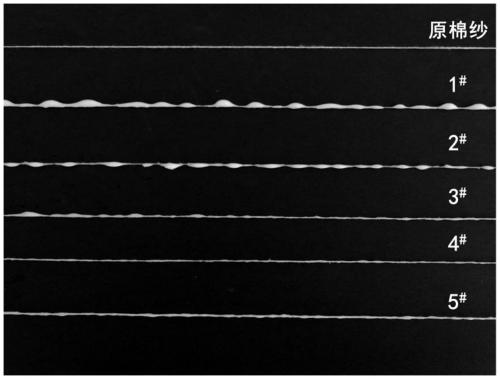

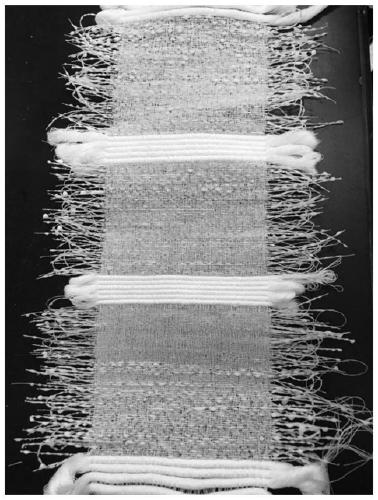

[0052] The foamed yarn appearance of the embodiment 1~5 prepared by the raw material mass fraction shown in table 1 is as follows figure 2 shown. Depend on figure 2 It can be seen that compared with the original cotton yarn, the surface of the foam yarn is covered with foam, and the degree of foaming of the foam yarn prepared according to different raw material mass fractions is different, so the size and ...

Embodiment 6~12

[0055] Embodiments 6-12 provide a preparation method of foamed yarn. Compared with Example 1, the difference is that the parameters of the stirring process, its specific parameter settings, and the elongation at break and breaking strength of the foamed yarn produced are changed. As shown in table 2.

[0056] The mechanical property comparison of the foamed yarn of table 2 embodiment 6~12 and embodiment 1

[0057]

[0058] According to the data shown in table 2, compare examples 6 and 7, embodiment 8 and 1, embodiment 9 and 10, embodiment 11 and 12 successively, it can be seen that when the stirring temperature is constant, with stirring speed and stirring time The elongation at break and the breaking strength of the foamed yarn produced showed a trend of decreasing first and then increasing. When the stirring speed reached 1000r / min and the stirring time was 6min, the effect of increasing the stirring speed and the stirring time on the foamed yarn The improvement of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com