Coating for offshore steel structure buildings and preparation method thereof

A technology for steel structures and buildings, applied in anti-corrosion coatings, rubber derivative coatings, coatings, etc., can solve the problems of easy peeling of coatings, high cost, corrosion of steel components, etc. Corrosion properties, the effect of enhancing the fire resistance limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

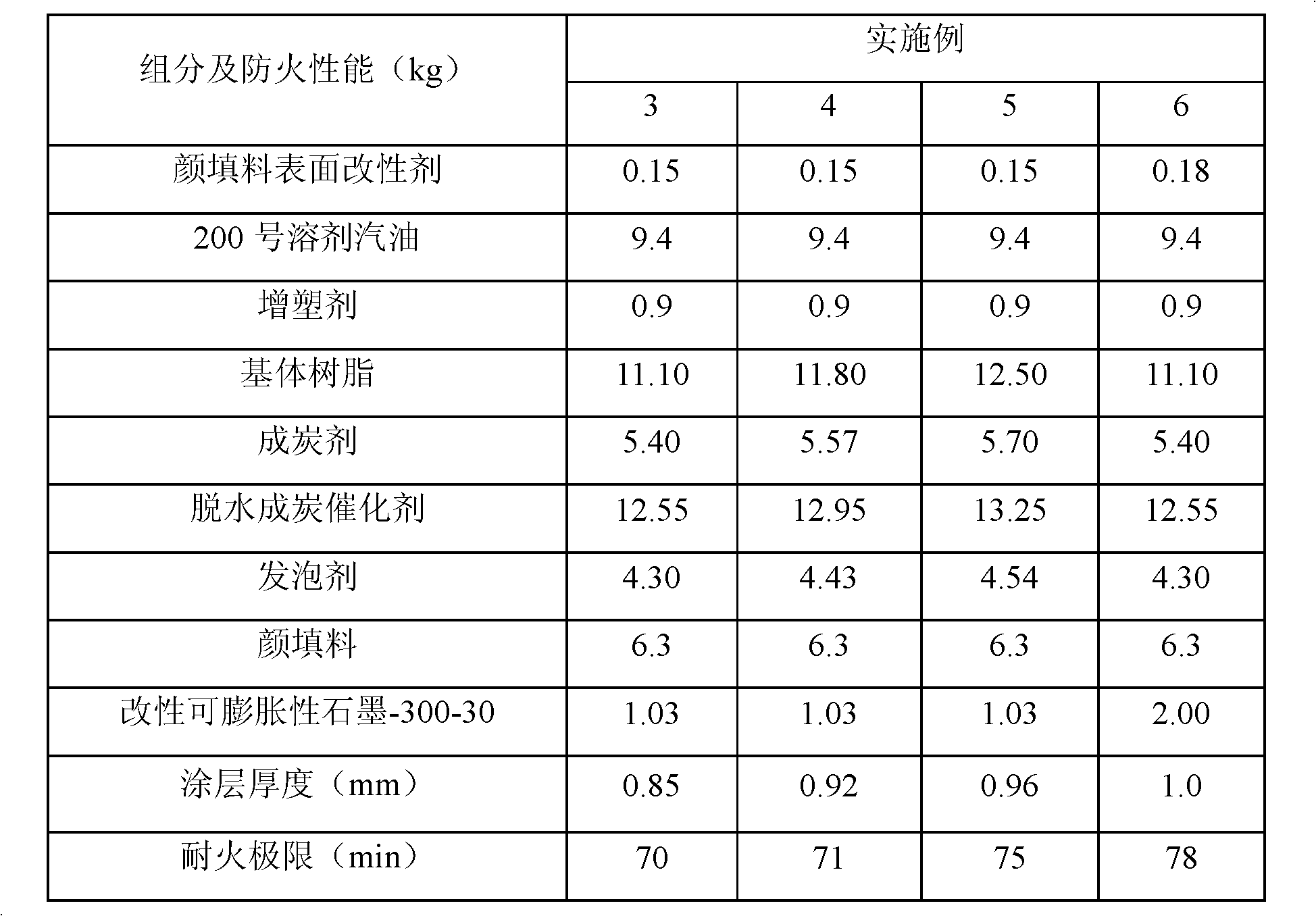

Examples

Embodiment 1

[0038] Step 1: Preparation of Modified Acrylic Resin

[0039] According to the method disclosed in Chinese patent CN101570587A, add 80% of the total dose of 12kg ethyl acetate and 6kg methanol mixed solvent in the reaction kettle, and when heating to 50-60°C while stirring, add 3.55kg of styrene, 1.52 kg of methyltriethoxysiloxane and 51 g of benzoyl peroxide. After reacting for 40 minutes, 4.57 kg of ethyl acrylate, 0.51 kg of perfluoroalkyl butyl acrylate, 51 g of benzoyl peroxide and the remaining mixed solvent were added dropwise within 2.5 hours. Add 51g of ammonium persulfate 20min after the dropwise addition, heat up to 75-80°C, react for 7h, cool down to room temperature and discharge to obtain F 5 Si 15 Modified acrylic resin, the whole reaction process adopts nitrogen protection.

[0040] Step 2: Preparation of Modified Amino Resin

[0041] According to the method disclosed in the Chinese patent CN200510085694.4, 10 kg of clay and 500 kg of deionized water were s...

Embodiment 2

[0051] Step 1: Preparation of Modified Acrylic Resin

[0052] Synthesize modified acrylic resin according to the method disclosed in Chinese patent CN101570587A. Add 80% of the total dose of 12kg ethyl acetate and 6kg methanol mixed solvent into the reaction kettle, and when heating to 50-60°C while stirring, add 3.55kg of styrene, 0.51kg of methyltriethoxy silicone and 51g of benzoyl peroxide. After 40 minutes, 4.57 kg of ethyl acrylate, 1.52 kg of perfluoroalkyl butyl acrylate, 51 g of benzoyl peroxide and the remaining mixed solvent were added dropwise within 2.5 hours. Add 51g of ammonium persulfate 20 minutes after the dropwise addition, raise the temperature to 75-80°C, react for 6-8 hours, cool down to room temperature and discharge to obtain F 15 Si 5 Modified acrylic resin, the whole reaction process adopts nitrogen protection.

[0053] Steps 2-3: Modified amino resin, the preparation of modified expandable graphite is the same as in Example 1.

[0054] Step 4: P...

Embodiment 3

[0057] Step 1: Preparation of Modified Acrylic Resin

[0058]Synthesize modified acrylic resin according to the method disclosed in Chinese patent CN101570587A. Add 80% of the total dose of 12kg ethyl acetate and 6kg methanol mixed solvent into the reaction kettle, and when heating to 50-60°C while stirring, add 3.55kg of styrene, 1.01kg of methyltriethoxy silicone and 51g of benzoyl peroxide. After 40 min, 4.57 kg of ethyl acrylate, 1.01 kg of perfluoroalkyl butyl acrylate, 51 g of benzoyl peroxide and the remaining mixed solvent were added dropwise within 1.5 h. Add 51g of ammonium persulfate 20 minutes after the dropwise addition, raise the temperature to 75-80°C, react for 6-8 hours, cool down to room temperature and discharge to obtain F 10 Si 10 Modified acrylic resin, the whole reaction process adopts nitrogen protection.

[0059] Step 2: Preparation of Modified Amino Resin

[0060] Prepared according to the method disclosed in Chinese patent ZL200510085694.4. Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com