Preparation method of biomass-base polyurethane foam material

A biomass polyurethane and foam material technology, applied in the chemical industry, can solve the problems of rarely being effectively utilized, and achieve the effects of large and uneven cells, improved apparent color, and improved thermal properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

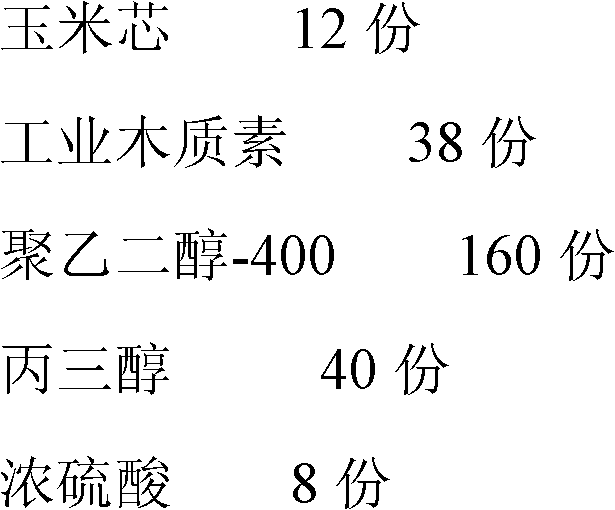

[0031] Take crushed corncobs (which have been crushed through a 20-mesh sieve and dried to constant weight at 105°C) and industrial lignin (dried to constant weight at 105°C), according to the following mass ratio:

[0032]

[0033] Put the three-neck flask with the mixed liquefaction agent and catalyst in the oil bath and heat it. When the mixed liquid in the bottle reaches the predetermined temperature, add the mixture of crushed corncobs and industrial lignin, and stir continuously with a stirrer. When the reaction reaches the predetermined time, the three-neck flask is taken out from the oil bath, and rapidly cooled to room temperature to obtain a biomass liquefaction product, wherein the predetermined temperature is 160° C. and the predetermined time is 150 min.

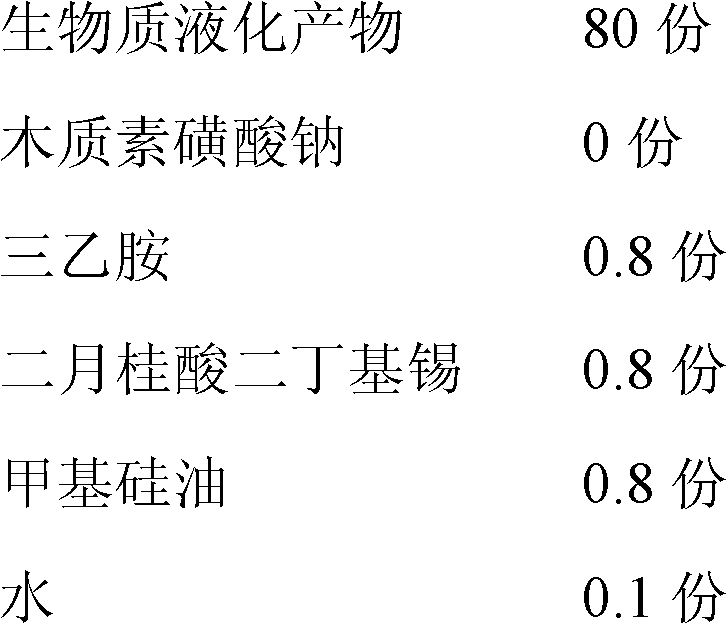

[0034] Take biomass liquefaction products and synthesize polyurethane foam according to the following mass ratio:

[0035] A component:

[0036]

[0037] B component:

[0038] Polymethylene polyphenyl po...

Embodiment 2

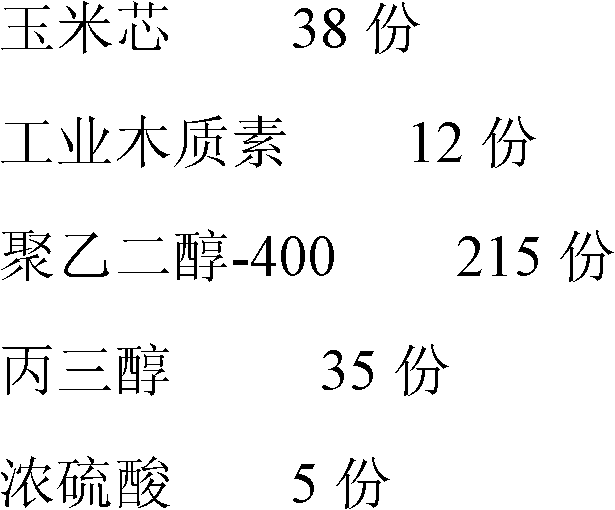

[0043] Take crushed corncobs (which have been crushed through a 20-mesh sieve and dried to constant weight at 105°C) and industrial lignin (dried to constant weight at 105°C), according to the following mass ratio:

[0044]

[0045] For the raw materials used and the liquefaction process, refer to Example 1 to obtain a biomass liquefaction product, wherein the predetermined temperature is 150° C., and the predetermined time is 120 minutes.

[0046] Take biomass liquefaction products and synthesize polyurethane foam according to the following mass ratio:

[0047] A component:

[0048]

[0049]

[0050] B component:

[0051] Polymethylene polyphenyl polyisocyanate (PAPI) 96 parts

[0052] Mix components A and B in a stirring container, stir at 14000 rpm at 30°C for 10s, then pour into a mold, foam naturally for 30s, place at 120°C for 12 hours, and store at room temperature for 12 hours. It is fully matured and shaped.

[0053] The appearance color of the obtained p...

Embodiment 3

[0055] Take crushed corncobs (which have been crushed through a 20-mesh sieve and dried to constant weight at 105°C) and industrial lignin (dried to constant weight at 105°C), according to the following mass ratio:

[0056]

[0057] For the raw materials used and the liquefaction process, refer to Example 1 to obtain a biomass liquefaction product, wherein the predetermined temperature is 200° C. and the predetermined time is 180 minutes.

[0058] Take biomass liquefaction products and synthesize polyurethane foam according to the following mass ratio:

[0059] A component:

[0060]

[0061]

[0062] B component:

[0063] Polymethylene polyphenyl polyisocyanate (PAPI) 60 parts

[0064] Mix components A and B in a stirring container, stir at 10,000 rpm at 30°C for 20s, then pour into a mold, let it foam naturally for 40s, place it at 100°C for 12 hours, and store it at room temperature for 24 hours. It is fully matured and formed.

[0065] The appearance color of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com