Carbon-series modified high-conductivity foaming ethylene propylene diene monomer

An EPDM rubber, high conductivity technology, applied in the field of rubber, can solve the problems of inability to replace EPDM materials, weak ability to improve electrical conductivity, high material hardness, etc., and achieve good processing safety and electrical conductivity The effect of improving and good process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

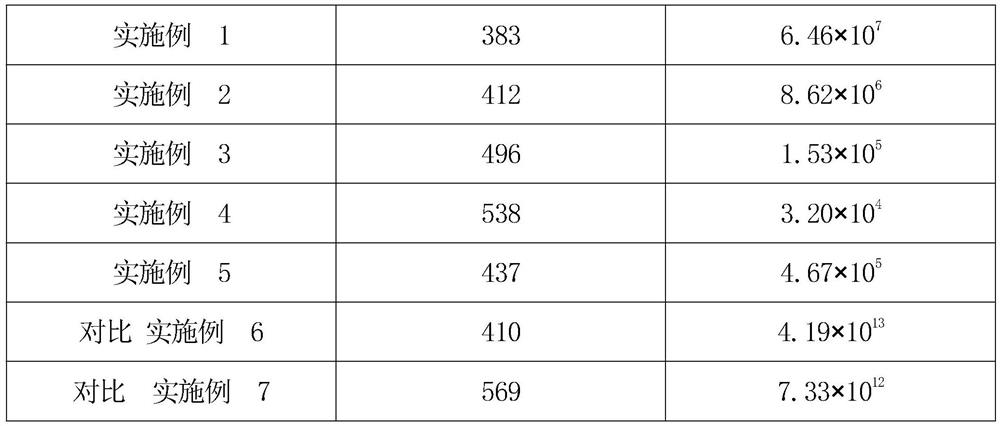

Embodiment 1

[0026] A carbon-based modified highly conductive foamed EPDM rubber

[0027] Raw materials in parts by weight include: 4045100 parts of EPDM rubber, 5 parts of zinc oxide, 1 part of stearic acid, 12 parts of N774 carbon black, 18 parts of conductive carbon black, 20 parts of light calcium carbonate, and 15 parts of paraffin oil , 1.2 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1.2 parts of zinc dibutyldithiocarbamate, 0.3 parts of tetramethylthiuram disulfide, 0.3 parts of pentamethylenethiuram tetrasulfide 0.5 parts of sulfur, 1 part of 4,4'-oxobisbenzenesulfonyl hydrazide, 1.5 parts of azodicarbonamide, 2.5 parts of microsphere foaming agent, 4.4 parts of single-walled carbon nanotubes, and 0.6 parts of graphene oxide .

Embodiment 2

[0029] A carbon-based modified highly conductive foamed EPDM rubber

[0030] Raw materials in parts by weight include: EPDM rubber 4045100 parts, zinc oxide 6 parts, stearic acid 2 parts, N774 carbon black 16 parts, conductive carbon black 24 parts, light calcium cholate 25 parts, paraffin oil 20 parts 1.4 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1.4 parts of zinc dibutyldithiocarbamate, 0.35 parts of tetramethylthiuram disulfide, pentamethylenethiuram tetrasulfide 0.35 parts, 0.7 parts of sulfur, 1 part of 4,4'-oxobisbenzenesulfonyl hydrazide, 1.5 parts of azodicarbonamide, 2.5 parts of microsphere foaming agent, 7 parts of single-walled carbon nanotubes, 1 part of graphene oxide share.

Embodiment 3

[0032] A carbon-based modified highly conductive foamed EPDM rubber

[0033] Raw materials in parts by weight include: EPDM rubber 4045100 parts, zinc oxide 8 parts, stearic acid 3 parts, N774 carbon black 20 parts, conductive carbon black 30 parts, light calcium carbonate 35 parts, paraffin oil 30 parts , 2.2 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 2.2 parts of zinc dibutyldithiocarbamate, 0.55 parts of tetramethylthiuram disulfide, 0.55 parts of pentamethylenethiuram tetrasulfide 0.9 parts of sulfur, 1 part of 4,4'-oxobisbenzenesulfonyl hydrazide, 1.5 parts of azodicarbonamide, 2.5 parts of microsphere foaming agent, 10.5 parts of single-walled carbon nanotubes, and 1.5 parts of graphene oxide .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com