Water-based UV-Monocoat colored coating for plastic base material and construction process

A colored coating, water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of difficult coating, poor adhesion, slow drying, etc., to achieve convenient construction, excellent adhesion, and strong metallic feeling of the coating film Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

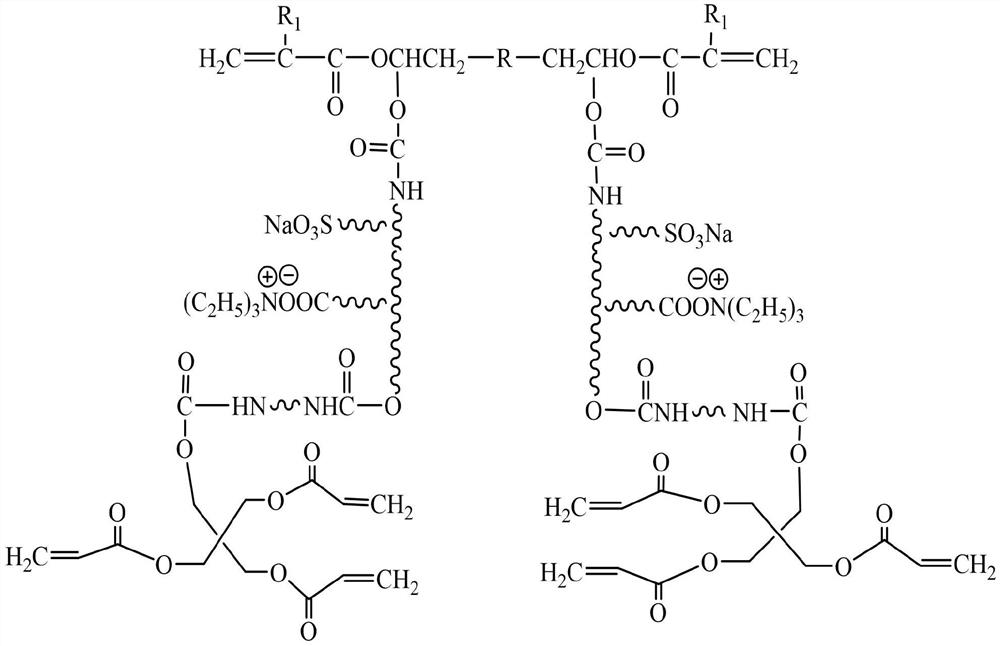

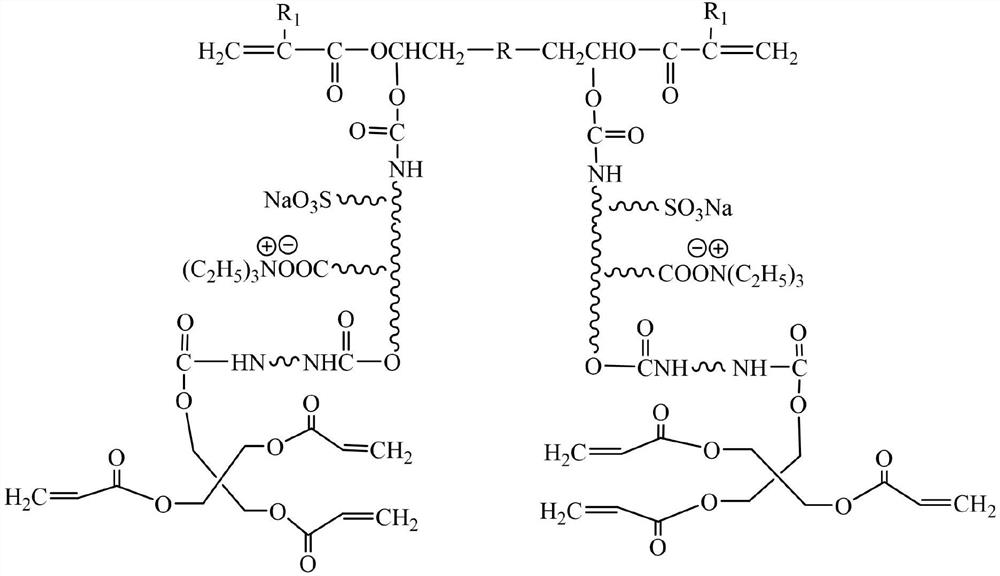

[0061] A kind of UV-Monocoat water-based UV resin A, its preparation steps are as follows:

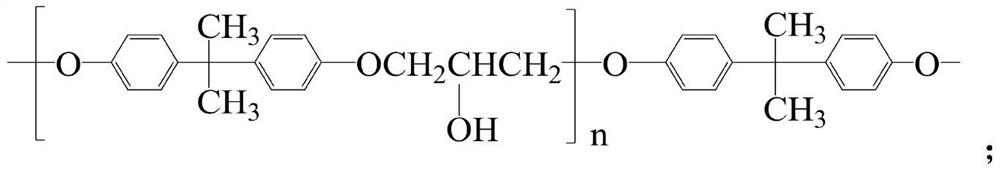

[0062] a) Preparation of epoxy acrylate E44A: add 0.1mol bisphenol A epoxy resin E-44 to a four-necked flask equipped with a reflux condenser, thermometer, dropping funnel and stirrer, and wait until the temperature rises to 80°C Slowly add dropwise a mixture of 0.2mol acrylic acid, 1.5 parts N,N-dimethylaniline and 0.2 parts p-hydroxyanisole. After the dropwise addition, slowly raise the temperature to 85-90°C, keep the temperature for 3 hours, and then every 40 minutes

[0063] Sampling and detecting the acid value of the system, when the detected acid value is lower than 5mgKOH / g, the reaction is stopped to obtain epoxy acrylate E44A;

[0064] b), preparation of polyurethane prepolymer: add 0.2mol polyether glycol sulfonate SPPG, 0.1mol polyester in advance dehydration treatment in the four-neck flask equipped with reflux condenser, thermometer, dropping funnel and stirrer Dihydric...

Embodiment 2

[0070] A kind of UV-Monocoat water-based UV resin B, its preparation steps are as follows:

[0071] a) Preparation of epoxy acrylate E44A: add 0.1mol bisphenol A epoxy resin E-44 to a four-necked flask equipped with a reflux condenser, thermometer, dropping funnel and stirrer, and wait until the temperature rises to 80°C Slowly add dropwise a mixture of 0.2mol acrylic acid, 1.5 parts N,N-dimethylaniline and 0.2 parts p-hydroxyanisole. After the dropwise addition, slowly raise the temperature to 85-90°C, keep the temperature for 3 hours, and then every 40 minutes

[0072] Sampling and detecting the acid value of the system, when the detected acid value is lower than 5mgKOH / g, the reaction is stopped to obtain epoxy acrylate E44A;

[0073] b), preparation of polyurethane prepolymer: add 0.2mol polyether glycol sulfonate SPPG, 0.12mol polyester of pre-dehydration treatment in the four-neck flask equipped with reflux condenser, thermometer, dropping funnel and stirrer Dihydric al...

Embodiment 3

[0079] A water-based UV-Monocoat silver-white paint for plastic substrates: by weight, it consists of: 60.0 parts of water-based UV resin A, 5.0 parts of 8 μm water-based aluminum silver paste, 2.0 parts of 10 μm water-based aluminum silver paste, and 0.2 parts of Tego 270 , Tego 41000.2 parts, diethylene glycol ethyl ether 3.0 parts, silver row additive 2.4 parts, 1173+TPO 2.0 parts, leveling agent 0.4 parts, matting agent 1.6 parts, pH regulator 0.2 parts, BYK-3720 1.5 parts, increase Thickener 0.3 parts, deionized water 21.2 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com