Preparation method of double-surface foamed high-wrinkle-resistance polyurethane leather

A technology of polyurethane leather and polyurethane, which is applied in the direction of textiles and papermaking, can solve the problems of non-environmental protection, low hydrolysis resistance, and poor air permeability of products, and achieve diversified appearance styles and effects, superior scratch resistance and wear resistance, The effect of high hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

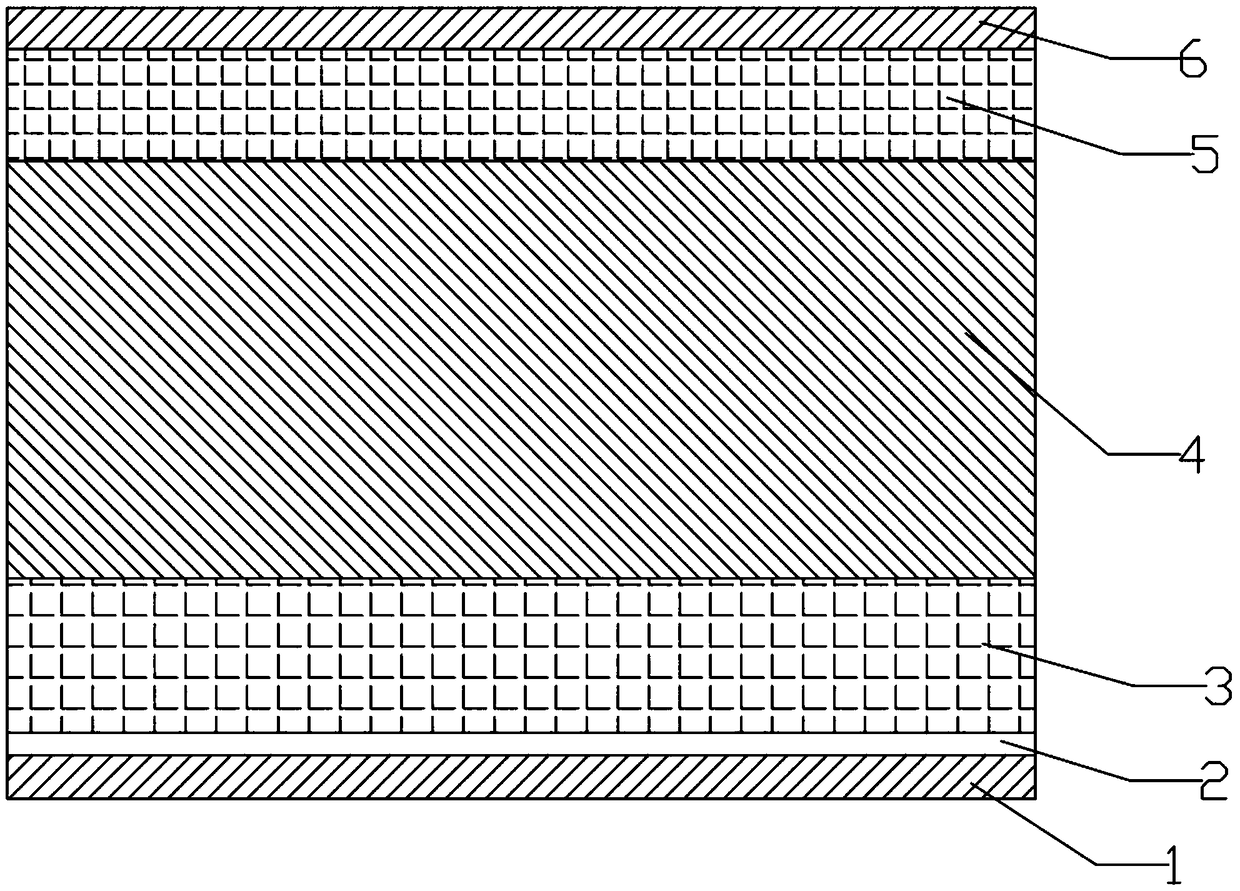

[0070] A double-sided foamed high-wrinkle-resistant ester polyurethane leather, a first polyurethane surface layer 1, an adhesive layer 2, a first polyurethane foam layer 3, a base fabric layer 4, a second polyurethane foam layer 5, and a second polyurethane surface Layer 6; the base fabric layer is formed after the base fabric is impregnated with polyurethane impregnating slurry.

Embodiment 2

[0072] A method for preparing double-sided foamed high-wrinkle-resistant polyurethane leather, comprising the steps of:

[0073] Arranging the bottom in the polyurethane impregnated slurry, and then extruding through extrusion rollers, the distance between the extrusion rollers being 0.3-0.6mm, to obtain the bottom cloth layer;

[0074] Squeegee-coat the first polyurethane foam slurry on the base cloth layer obtained in step (1), then place it in a coagulation tank filled with dimethylformamide-water system to solidify, and then wash it in multiple washing tanks, and then carry out Drying, the temperature of the oven used in the drying is controlled at 100-180°C to obtain a wet-process semi-finished product of the base cloth layer + the first polyurethane foam layer;

[0075] Unwind the release paper, coat the first polyurethane surface layer slurry on the surface of the release paper, the coating thickness is 0.1-0.25mm, dry and cool, the oven temperature used is 60 ° C ~ 150...

Embodiment 3

[0090] A double-sided foamed high anti-wrinkle polyurethane leather, the first polyurethane surface layer, the adhesive layer, the first polyurethane foam layer, the base cloth layer, the second polyurethane foam layer, and the second polyurethane surface layer; the base cloth The layer is formed after the base fabric is impregnated with polyurethane impregnating slurry.

[0091] The polyurethane impregnating slurry includes the following raw materials in parts by weight: 100 parts of polyurethane resin, 1200 parts of dimethylformamide, and 1 part of wet color paste; the viscosity of the polyurethane impregnating slurry is 1000 cps / 25°C;

[0092] The first polyurethane foam layer includes the following raw materials in parts by weight: 100 parts of polyurethane resin, 80 parts of dimethylformamide, 40 parts of calcium carbonate, 0.1 part of defoamer, 0.5 part of washing aid, 1 part of wet color paste parts; after the raw materials of the first polyurethane foam layer are mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com