Aluminum plastic composite plate having honeycomb structure

A technology of aluminum-plastic composite panel and honeycomb structure, applied in the field of panels, can solve the problems of high processing requirements of honeycomb core, loss of honeycomb panel performance, limitation of panel strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

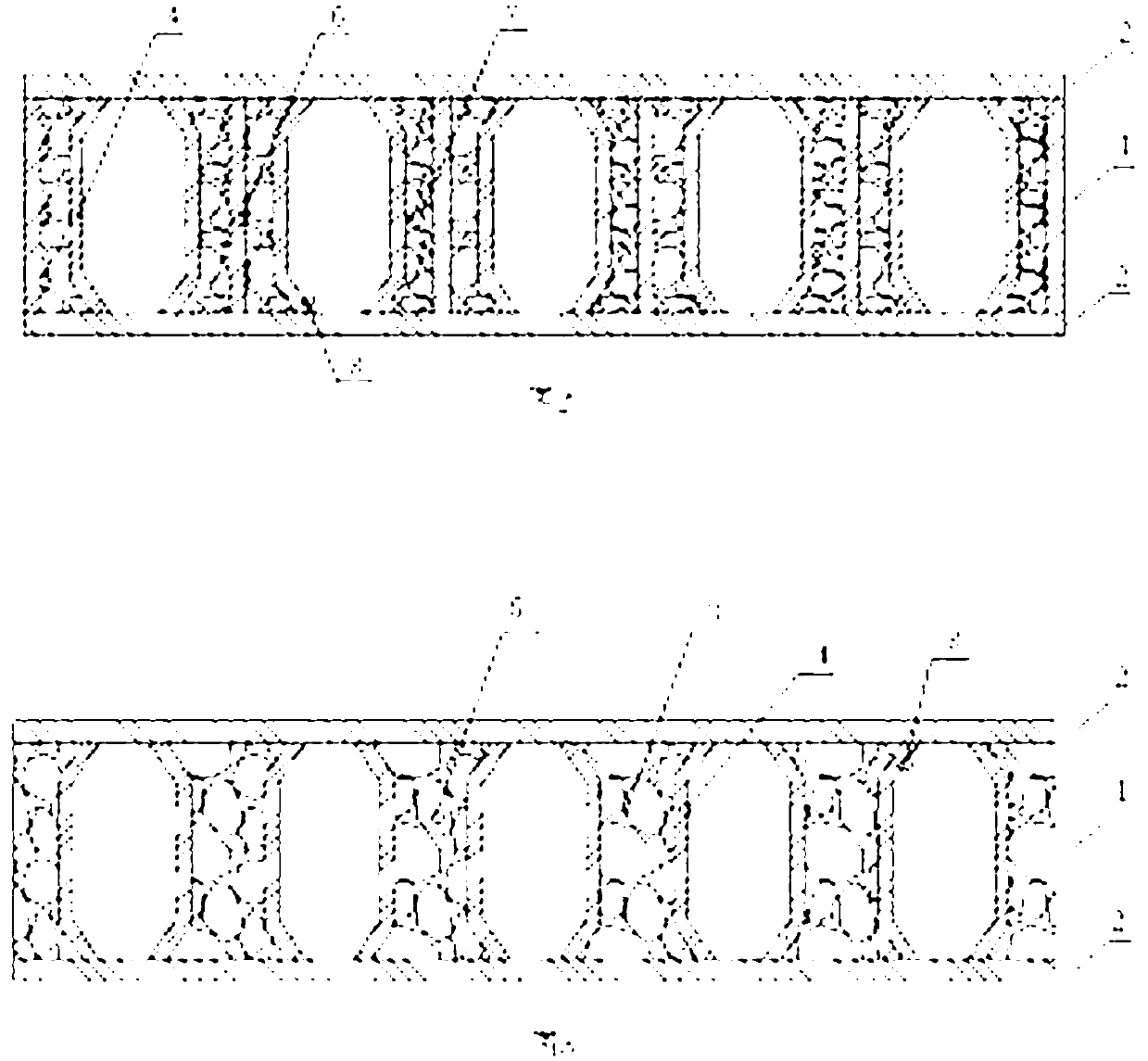

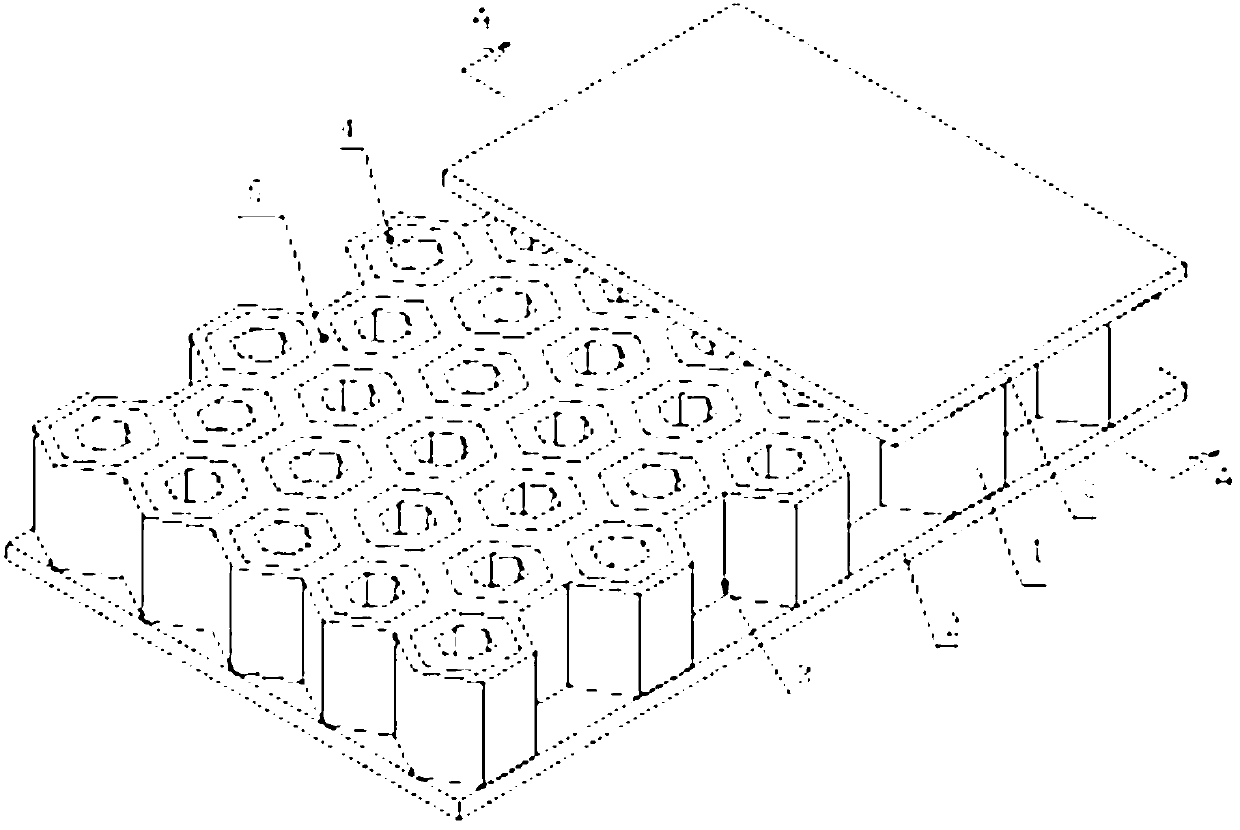

[0019] Embodiment one, such as figure 1 and figure 2 As shown, the aluminum-plastic composite panel adopts a three-layer structure, and a core material 1 is sandwiched between two aluminum panels 2. The core material 1 is a single-layer honeycomb structure, and regular hexagonal honeycombs arranged at even intervals are distributed on it. hole, the core material 1 is composed of a whole piece of honeycomb frame 3 and a shaping cylinder 4, the honeycomb frame 3 is composed of an ordinary aluminum honeycomb core 6 and a plastic wall tube 7, and the plastic wall tube 7 is closely bonded to the aluminum honeycomb core On the inner wall of each honeycomb hole of 6, all the plastic wall tubes 7 constitute the plastic thick wall 5 of the honeycomb frame 3, and the upper and lower ports form a cylindrical shaped tube 4 with inwardly inclined and contracted edges 8. Fit on the inner wall of each plastic wall cylinder 7, the plastic wall cylinder 7 fills the gap between the honeycomb ...

Embodiment 2

[0020] Embodiment two, such as figure 1 and image 3 As shown, the aluminum-plastic composite panel also adopts a three-layer structure, and a core material 1 is sandwiched between two aluminum panels 2. The core material 1 is a single-layer honeycomb structure, which is composed of a whole honeycomb frame 3 and a shaping cylinder 4. Regular hexagonal honeycomb holes arranged at even intervals are distributed on the frame 3, and the shaping cylinder 4 is embedded in each honeycomb hole, and the shaping cylinder 4 is a regular hexagonal cylindrical structure, and the upper and lower ports are formed with an inward inclination Shrinking edge 8, the difference between this example and Example 1 is that the honeycomb frame 3 is served by a monolithic plastic core plate with regular hexagonal honeycomb holes at uniform intervals, and the plastic thick wall is between each honeycomb hole. 5. The shaping cylinder 4 is embedded in each honeycomb hole, and the height of the shaping cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com