Ultrasonic phased array weld defect detection method based on oblique incidence

An ultrasonic phased array and defect detection technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measurement devices. It can solve signal synthesis related calculations without research and imaging effects. , large amount of calculation and other issues, to achieve the effect of improving the defect detection rate, increasing the coverage of the beam, and improving the imaging resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

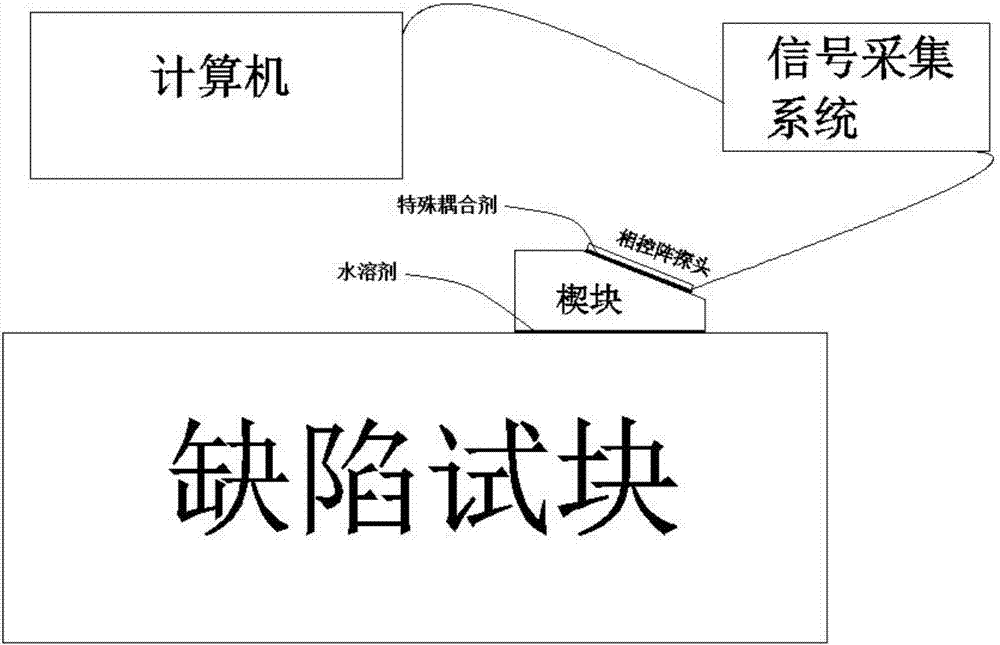

[0034] The present invention provides an ultrasonic phased array weld defect detection method based on oblique incidence, the structural diagram is as follows figure 1 , the ultrasonic phased array includes an ultrasonic phased array signal acquisition system, a phased array ultrasonic transducer probe, a plexiglass wedge with a certain inclination angle, a water solvent connecting the plexiglass wedge and the surface of the test block, a connecting phase The special couplant for the array ultrasonic transducer probe and the plexiglass wedge and the software for calculating the data of the ultrasonic phased array signal acquisition system; the specific implementation steps are as follows:

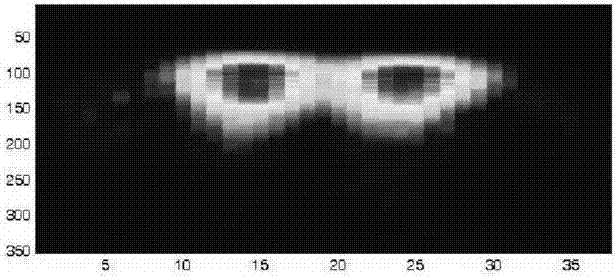

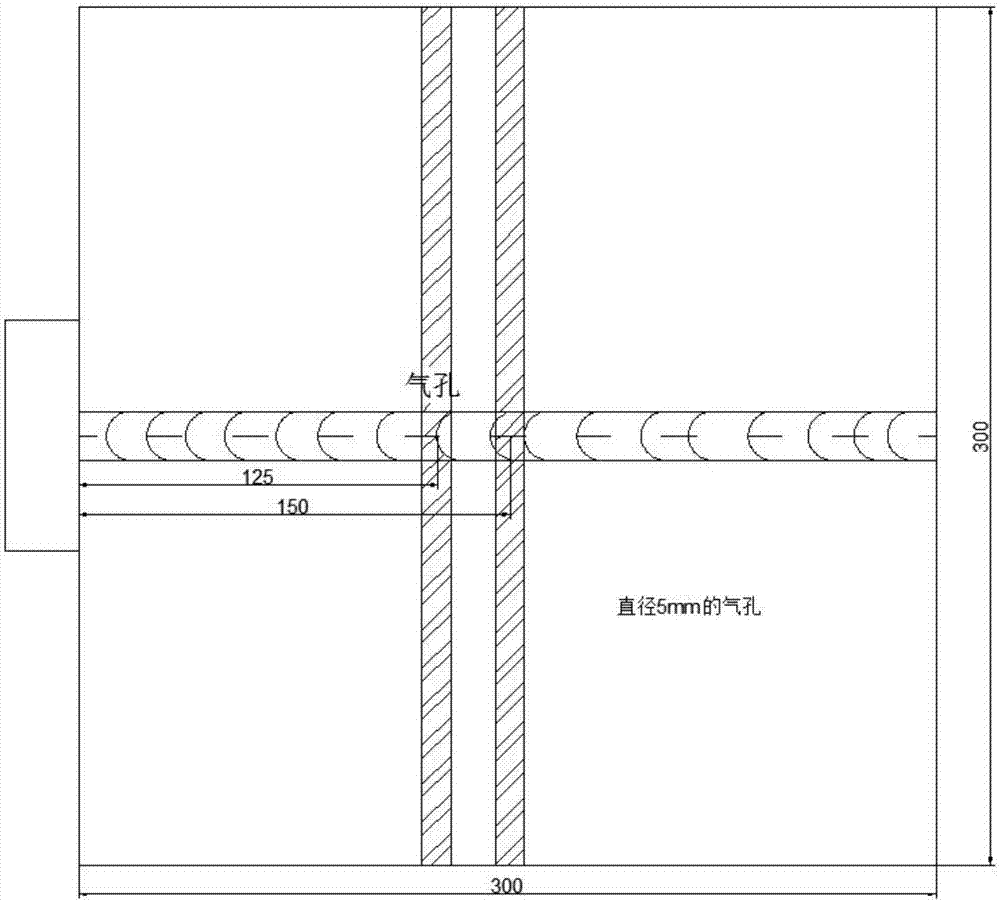

[0035] (a) Select an ordinary carbon steel plate with a length, height and width of 300*300*20mm as a test block. In this carbon steel plate, the shear wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com