Double-layer symmetrical differential plane eddy current detection sensor

A symmetrical differential and eddy current detection technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., to achieve the effect of increasing lift-off height and sensitivity, improving defect detection rate, and reducing electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

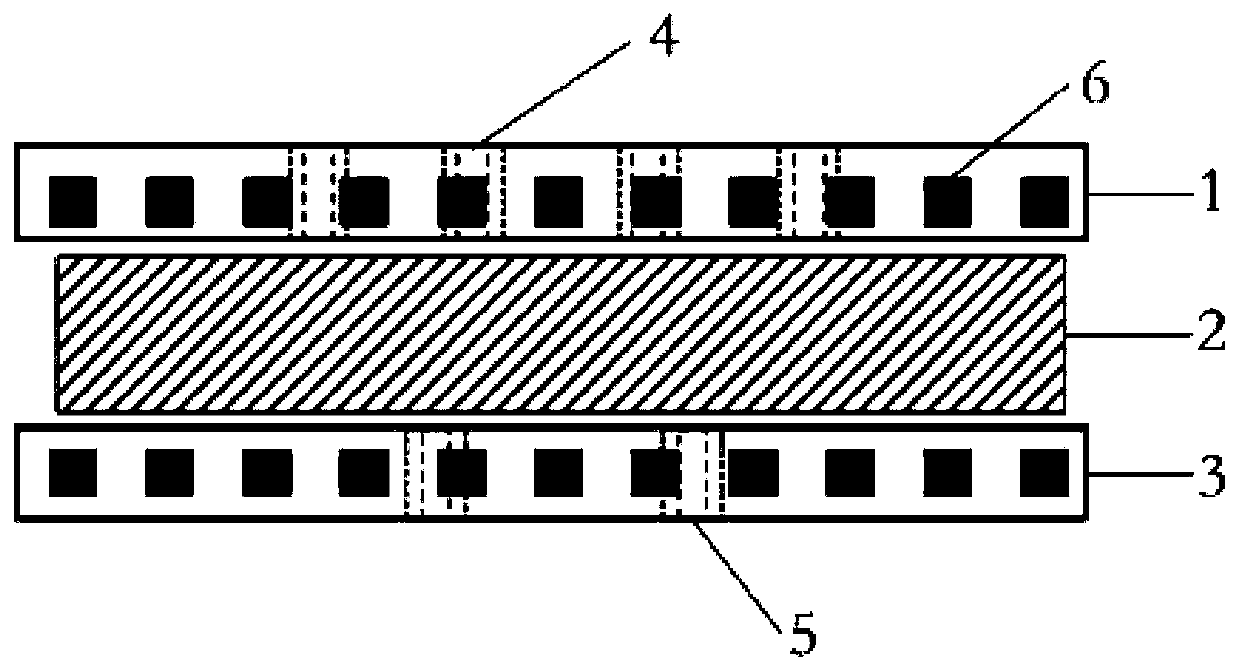

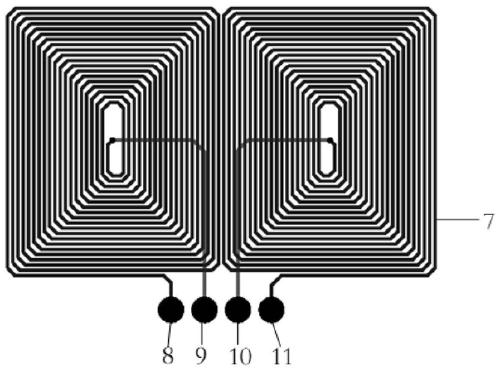

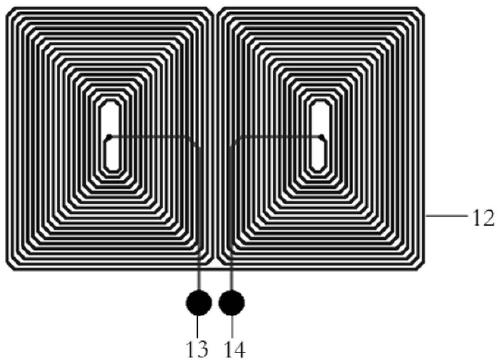

[0035] In order to better illustrate the technical effects of the present invention, specific experiments are used to verify the optimal coupling distance, and different thicknesses of insulating covering layers are used for experimental comparison. Figure 5 It is the actual image of the planar eddy current detection sensor with double-layer symmetrical difference in this embodiment. Such as Figure 5 As shown, the parameters of each component of the multi-layer electromagnetic shielding pulse far-field eddy current detection sensor in this embodiment are as follows:

[0036] The excitation coil 7 is made of PCB immersion gold technology, placed on the upper layer of the sensor, and the total length of a single coil is l 1 =24mm, width is w 1 =30mm, wire diameter is d 11 =10mil, line spacing is d 12 =10mil, the number of turns is n 1 =20, the distance between the exciting coils is r 1 = 2.5mm, the thickness of the copper layer is 2 oz, and the thickness of the excitatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com