Melting and spinning device and melting and spinning method

A technology for melting spinnerets and nozzles, which is applied in the field of medical materials, and can solve the problems of inability to uniformly decompose and absorb the entire graft fixer, inability to support vessels such as blood vessels, and uneven strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The melt-spinning device of the present invention and the method of melt-spinning a biodegradable polymer material using the melt-spinning device will be described in more detail below.

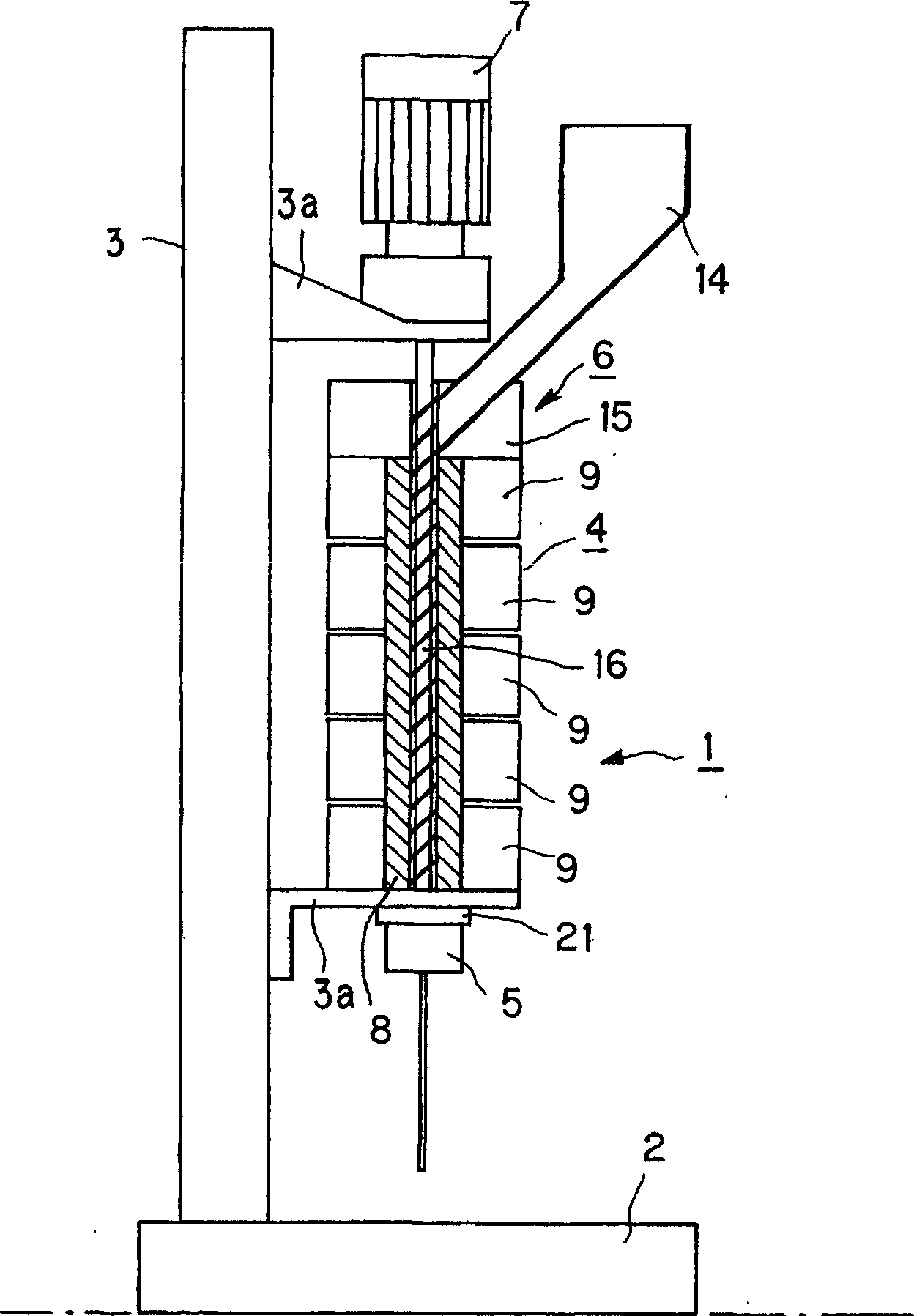

[0030] Melt spinning device of the present invention, such as figure 1 Shown is a vertical melt-spinning device in which the melt-spinner is installed vertically.

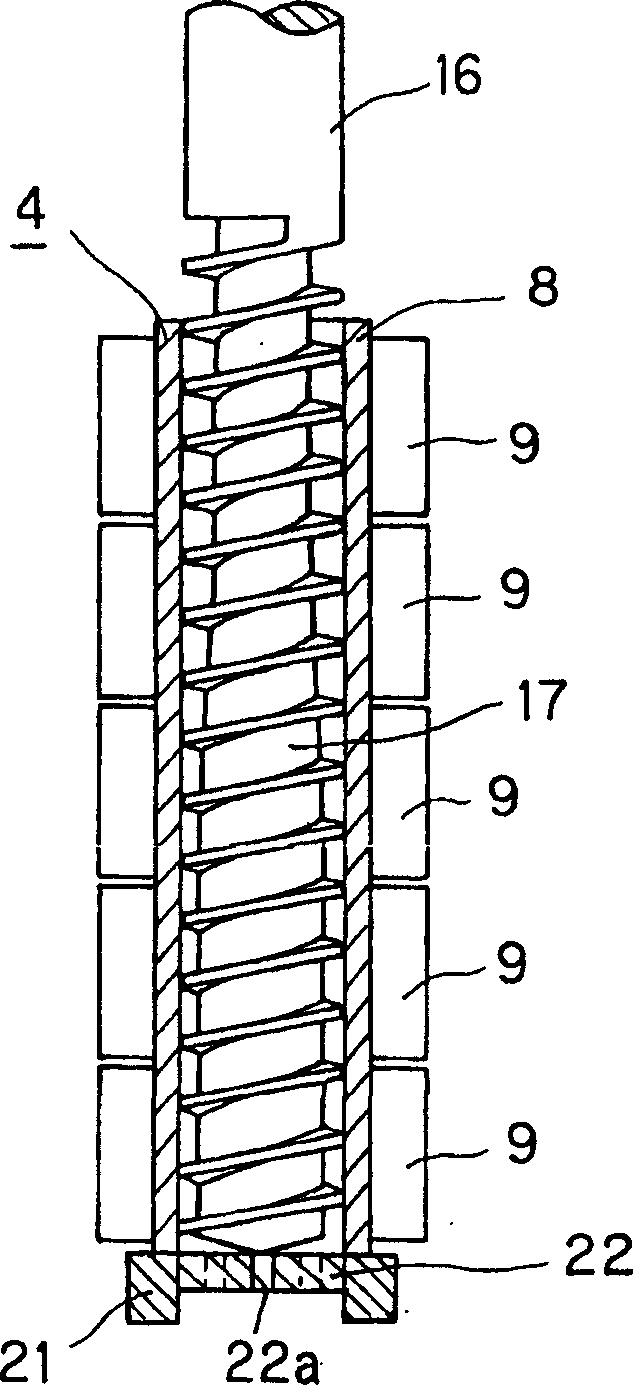

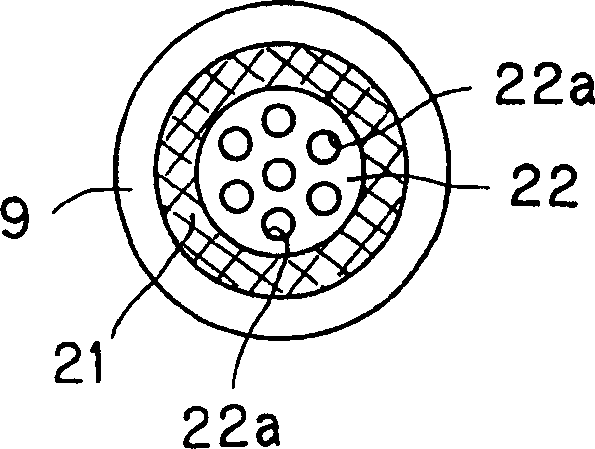

[0031] figure 1 The melt-spinning apparatus shown has a substrate 2 installed horizontally on an installation surface, and a melt-spinner 1 supported by a support member 3 a on a support 3 vertically installed on the above-mentioned substrate 2 . The melt spinning machine 1 is equipped with: a melting mechanism 4 supported in parallel on the vertically arranged pillar 3, a discharge part 5 for ejecting the polymer material melted by the melting mechanism 4, and a supply of the polymer material to the melting mechanism 4. Part 6, and a rotary drive mechanism 7 that rotationally drives the screw 16 constituting the melting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com