Device for disposing harmful gases

A harmful gas and deflection device technology, which is applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of restarting, continuous operation of the flame root repeatedly extinguishing obstacles, interruption of the combustion process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

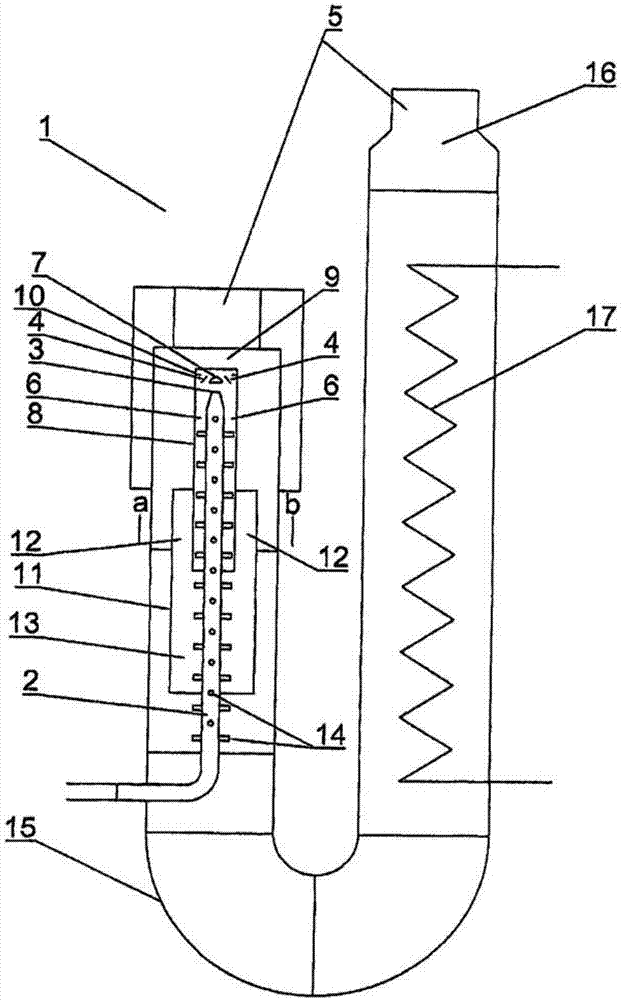

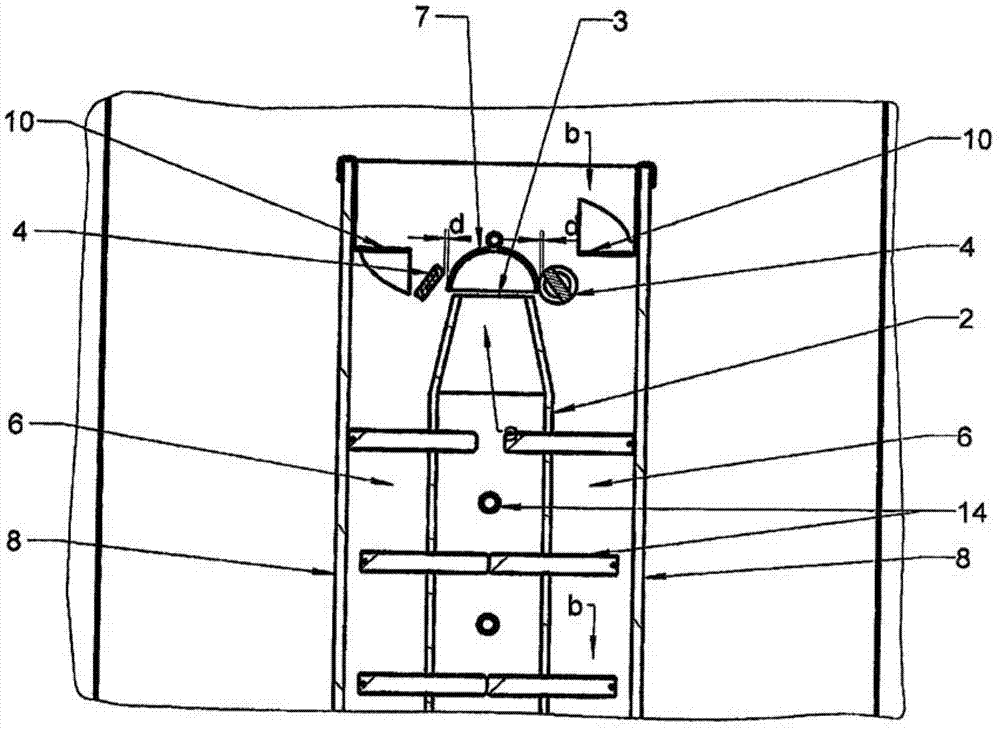

[0042] figure 1 with figure 2 An exemplary embodiment of a device 1 according to the invention for removing harmful gases, which are produced, for example, during the production of semiconductor materials, is shown. Hazardous gases of this type mainly include hydrogen and ammonia as process gases and other gases, especially metal-organic compounds that are incorporated into the process gas in smaller quantities. Furthermore, the process gas can additionally be mixed with nitrogen.

[0043] According to the invention, the conversion of the noxious gases into reaction gases which are subsequently combusted with air supply takes place by thermal cracking, wherein the heat generated during the combustion of the reaction gases is advantageously used for pyrolytic cracking of the noxious gases.

[0044] According to the invention, the device 1 has a heatable pyrolysis tube 2 through which harmful gases flow for thermal cracking. If harmful gases such as ammonia (NH 3 ), then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com