Quick detection method for LTPS-IGZO glass substrate broken hole

A technology for glass substrates and detection methods, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of long detection time, low efficiency, and large subjective influence, and achieve low calculation time and defect detection. High-yield, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The accompanying drawings are for illustrative purposes only, and should not be construed as limiting the patent. The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

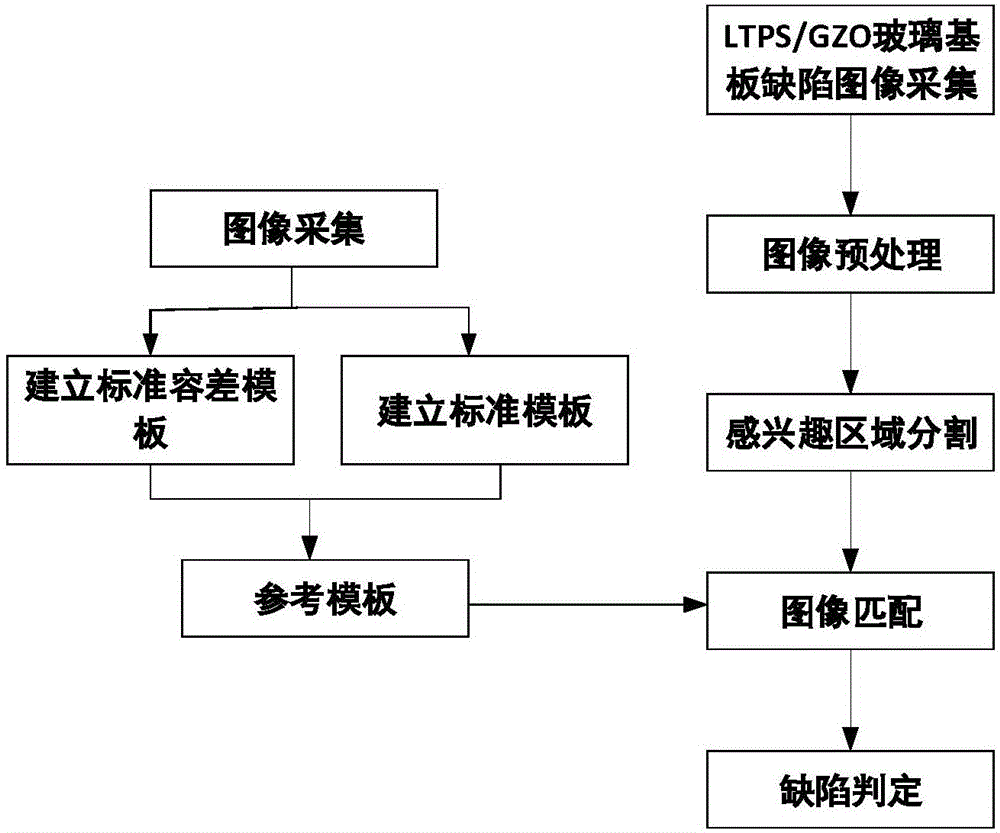

[0036] The invention provides a rapid detection method for holes in LTPS / IGZO glass substrates, see figure 1 , which includes the following steps:

[0037] Step 1: Image preprocessing. Due to the influence of mechanical vibration, shooting angle, optical distortion, etc., it is necessary to perform operations such as optical distortion processing, system vibration processing, image dynamic alignment, and sample plane correction on the collected images;

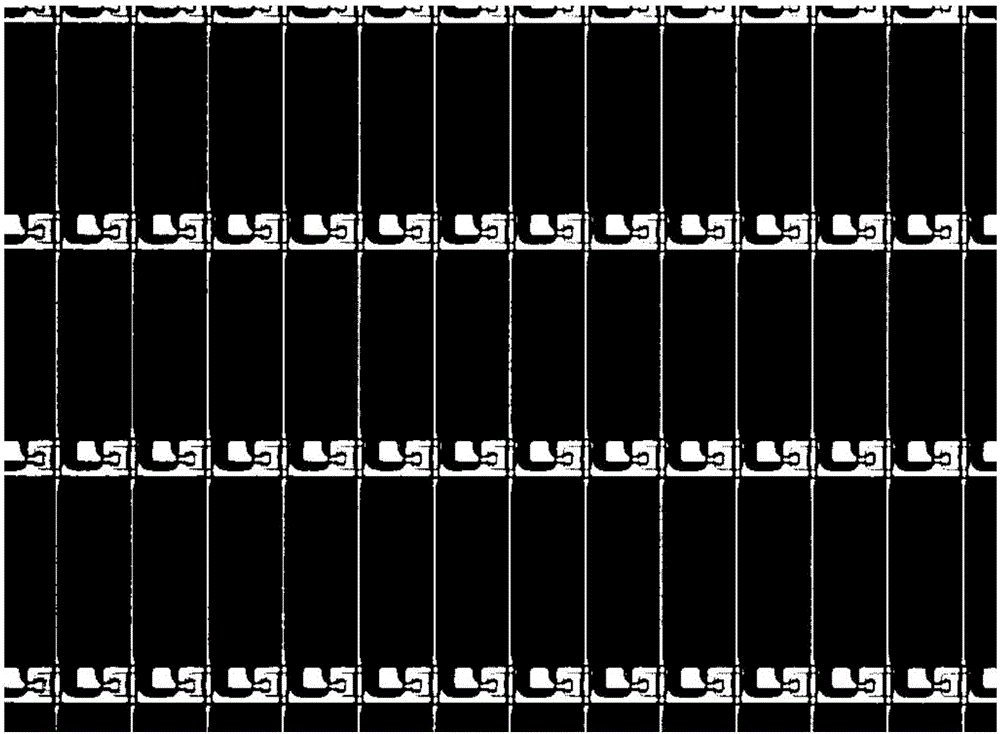

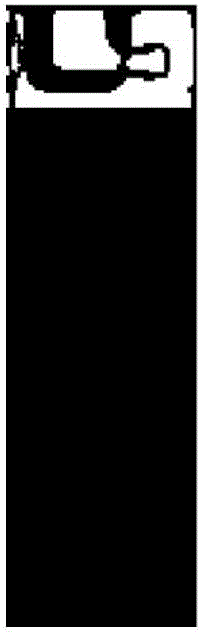

[0038] Step 2: Segment the region of interest, use the window cutting method to segment the preprocessed image. Such as figure 2 As shown, the input LPTS / IGZO glass substrate image is a large-capacity periodic complex image, which needs to be divided into small-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com