Flange surface defect detection method, system and equipment

A defect detection, flange surface technology, applied in neural learning methods, image data processing, instruments, etc., can solve problems such as difficulty in achieving accuracy and robustness, limited machine learning representation learning ability, and different defect shapes. To achieve the effect of improving robustness, improving detection accuracy and efficiency, and reducing false detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solution and advantages of the present invention more clear and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and technical solutions.

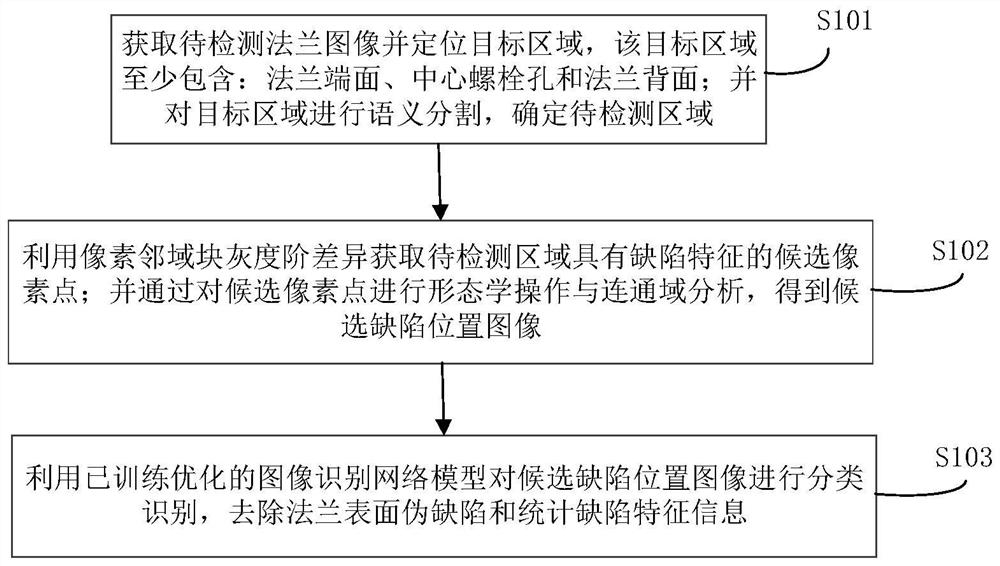

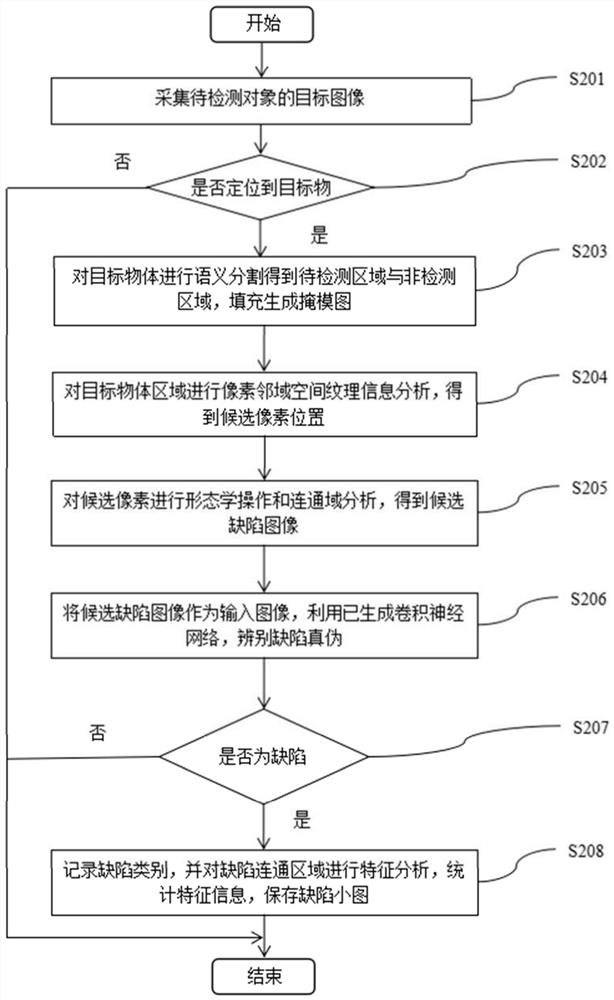

[0038] Embodiment of the present invention, see figure 1 As shown, a flange surface defect detection method is provided, including the following content:

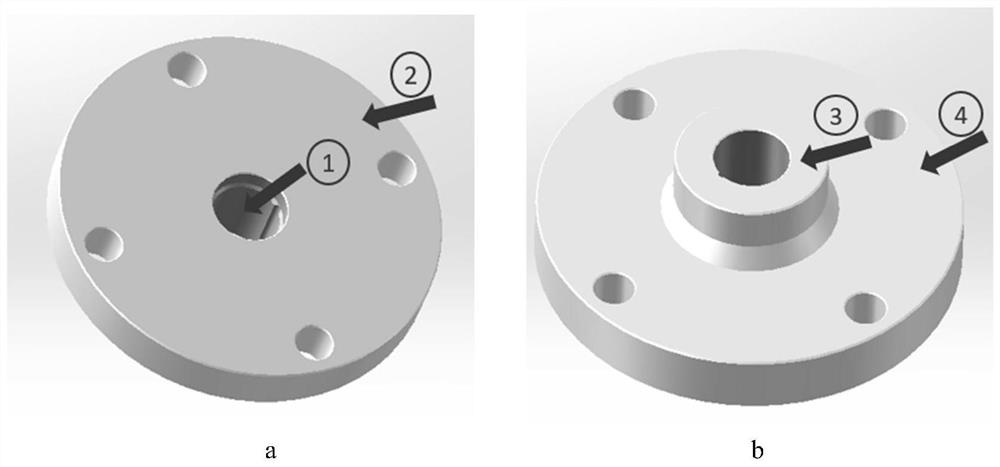

[0039] S101. Acquire the image of the flange to be detected and locate the target area, the target area at least includes: the flange end face, the central bolt hole and the back of the flange; and perform semantic segmentation on the target area to determine the area to be detected;

[0040] S102. Obtain candidate pixel points with defect characteristics in the area to be detected by using the gray scale difference of neighboring pixels; obtain candidate defect position images by performing morphological operations and connected domain analysis on the candidate pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com