Statistical test device and method for verifying safety failure rate of nuclear safety class instrumentation and control platform

A test device and nuclear safety technology, applied in the field of nuclear safety, can solve the problems of high modification cost, low detection rate, and few logical combinations, etc., to achieve the effect of improving defect detection rate, reducing maintenance cost, and improving user confidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

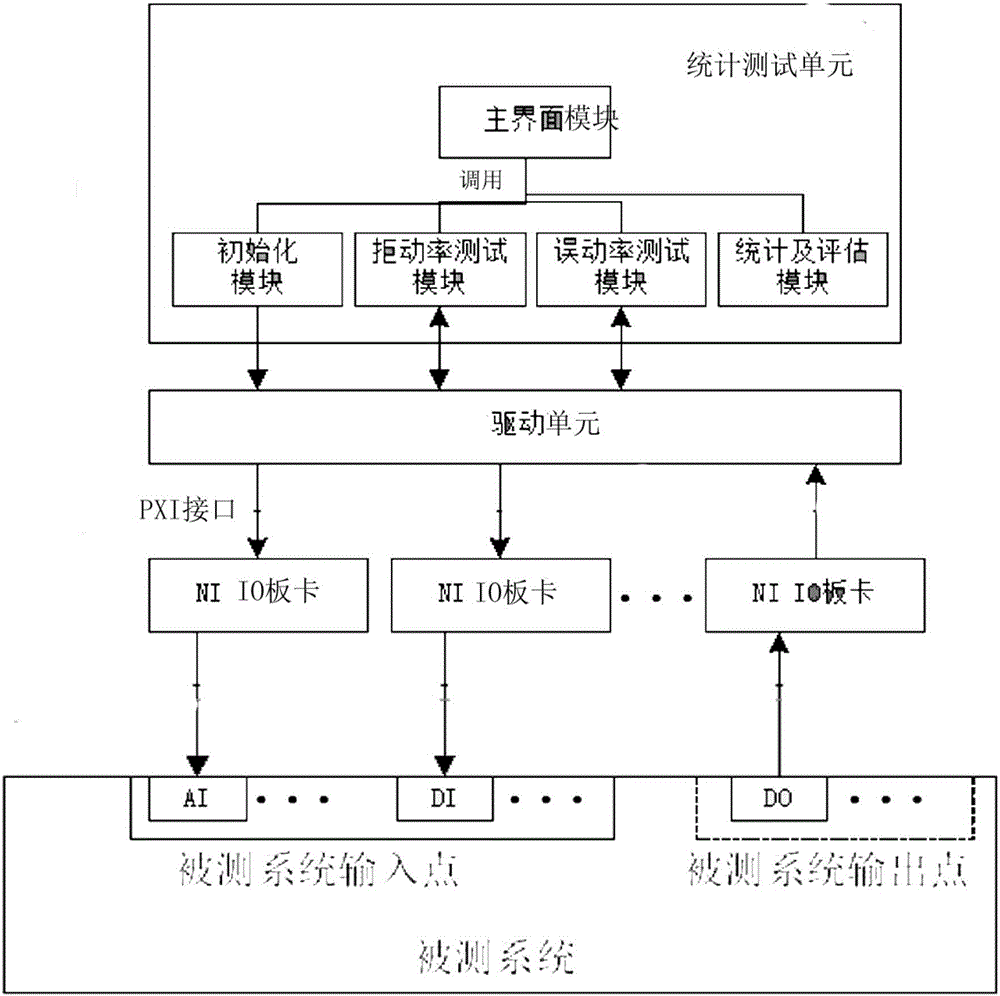

[0035] The invention has been applied in the test of the FirmSys system of the nuclear safety level digital instrument control platform, and is used to verify whether the FirmSys platform can realize the safety failure rate index of the ACPR1000 safety level instrument control system. The hardware platform of the test device adopts NI virtual instrument processing control machine, and the software platform adopts LabVIEW configuration tool.

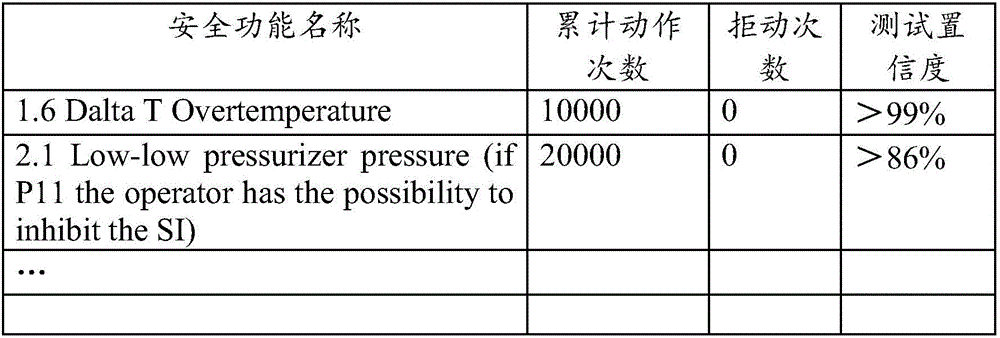

[0036] The ACPR1000 safety-level I&C system architecture includes 4 redundant RPC channels and 2 redundant ESF columns, which are used to realize the safety shutdown function and the special safety facility driving function respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com