Spiral welded pipe weld seam probe frame

A technology of spiral welded pipe and probe holder, which is applied in the direction of material analysis using sound wave/ultrasonic wave/infrasonic wave, solid state analysis using sound wave/ultrasonic wave/infrasonic wave, measuring device, etc. Eliminate and other problems to achieve the effect of improving defect detection rate, reducing flaw detection error, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

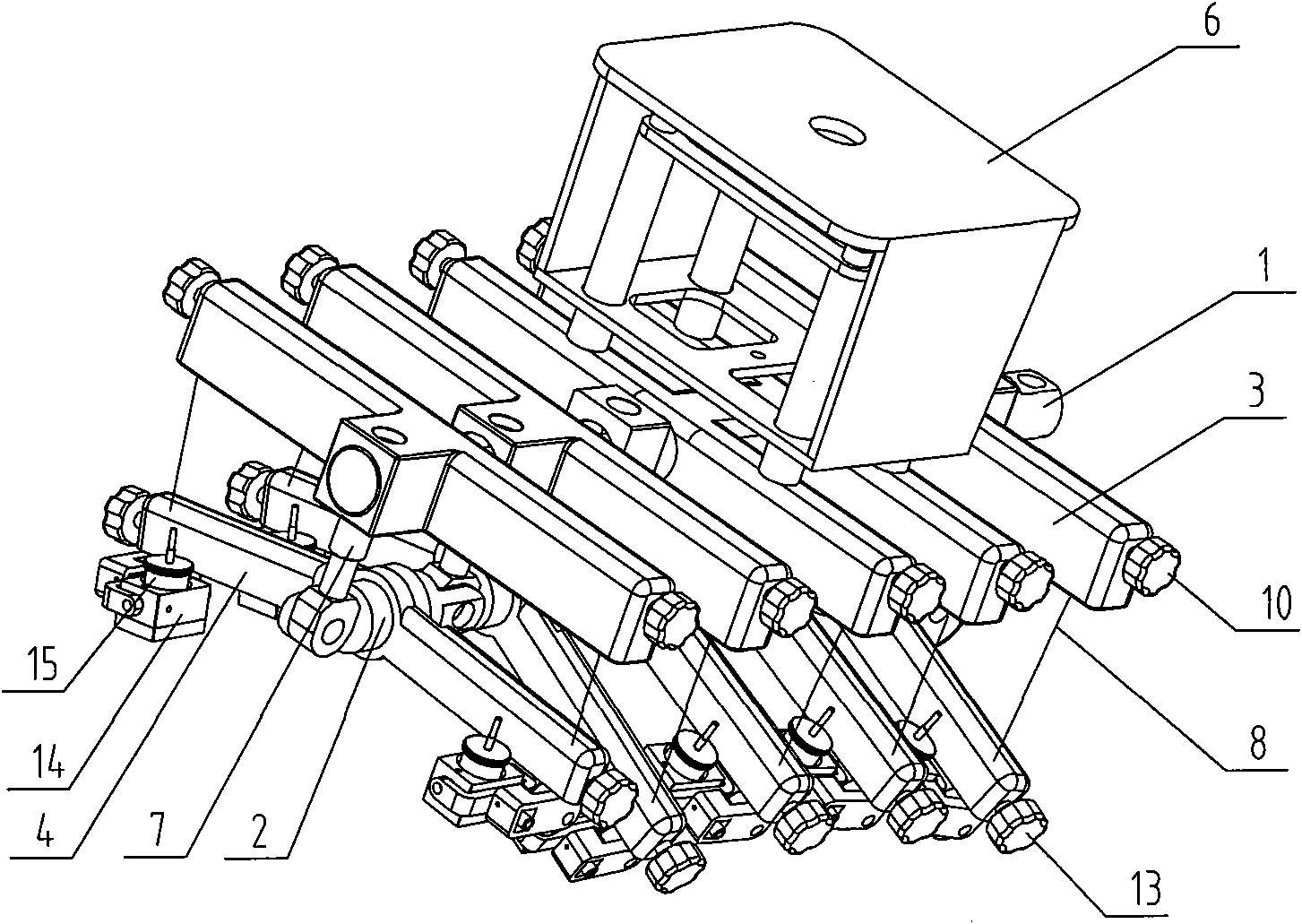

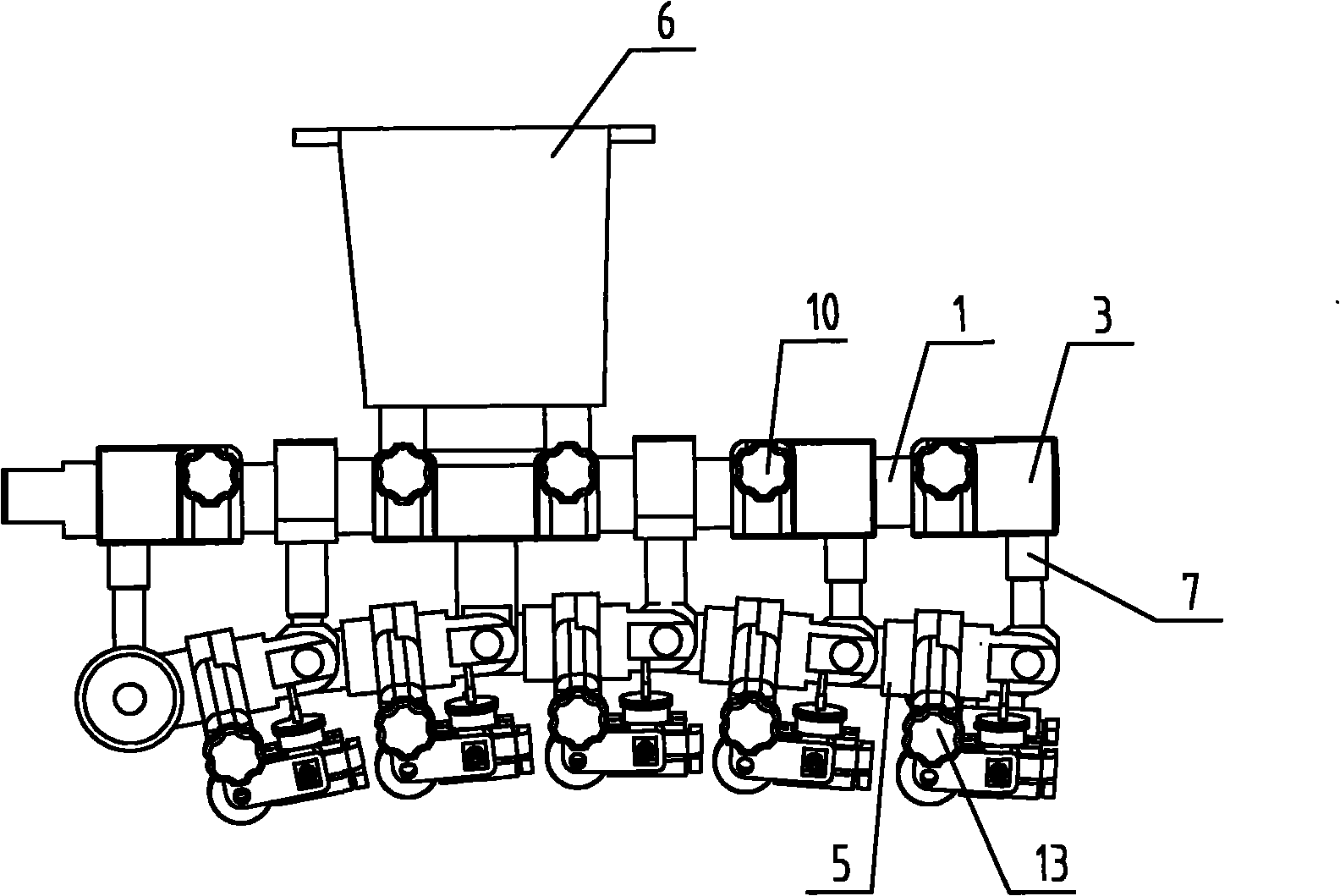

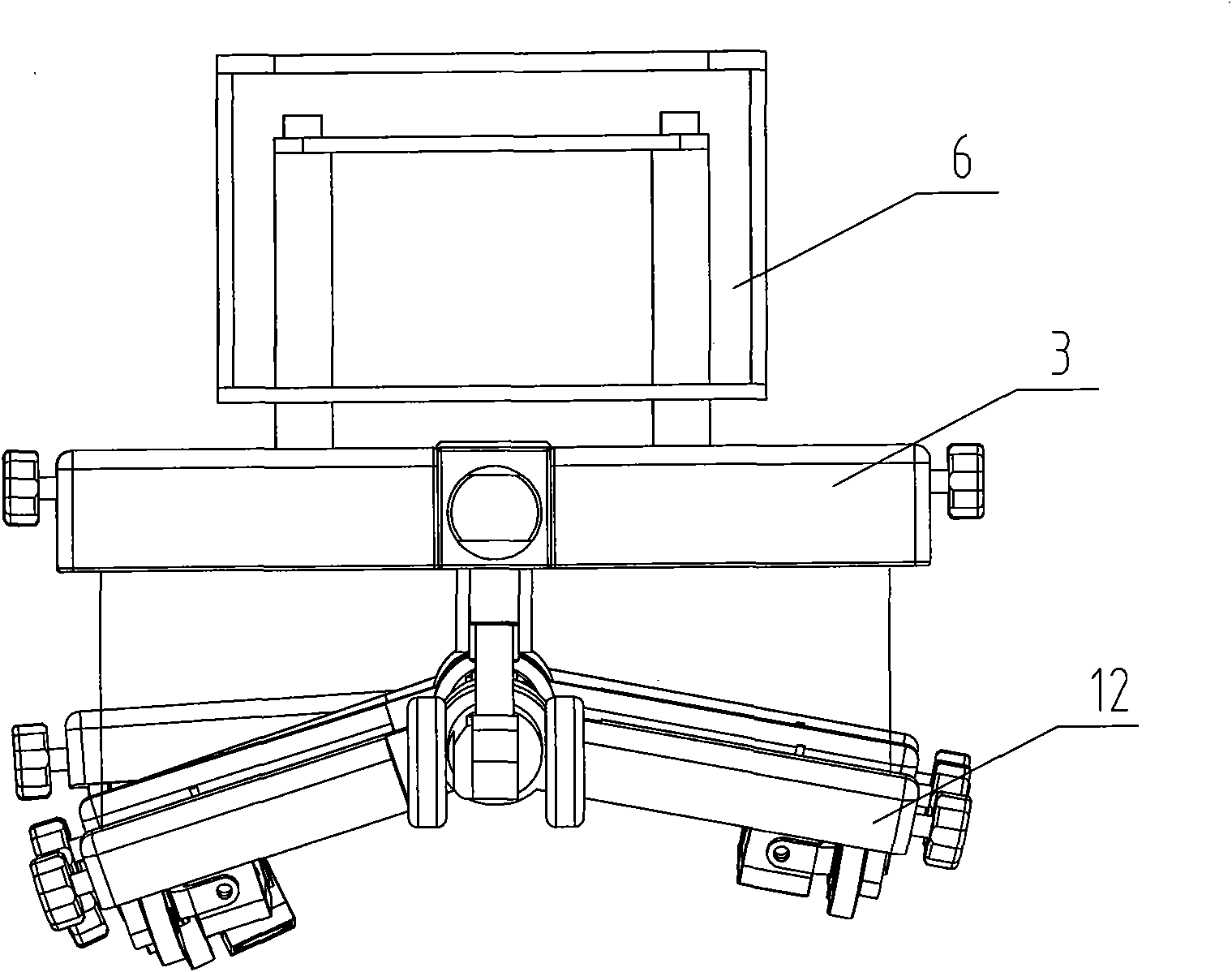

[0016] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a spiral welded pipe weld probe frame, comprising a rigid main shaft 1, a flexible main shaft 2, a fixed wing 3, and a swinging wing 4, the rigid main shaft 1 and the flexible main shaft 2 are arranged in parallel up and down, and a plurality of fixed wings 3 are arranged in series Connected to the rigid main shaft 1, the flexible main shaft 2 is composed of a plurality of main shaft joints 5 connected end to end. The radian of the flexible main shaft 2 is manually adjusted by the arc adjusting screw 7, the adjustment range is large, and the adjustment is flexible. The swing wing 4 is arranged under the fixed wing 3, which is beneficial to ensure the correct shape of the adjustment. Stable, the end of the swinging wing 4 is connected with the end of the fixed wing 3 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com