Transverse wave detection method for defects of spiral weld steel pipe body and flaw detection apparatus used in same

A technology of spiral welding seam and detection method, which is applied in the direction of measuring device, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves, etc. The outer wall of the steel pipe cannot guarantee the bridging and other problems, so as to achieve the effect of good bridging, reducing flaw detection error and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

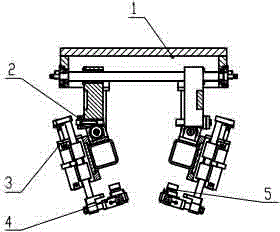

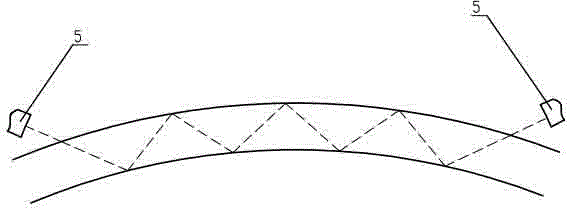

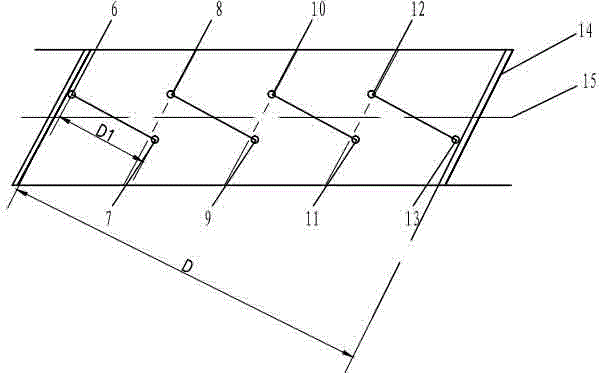

[0027] According to attached figure 1 It can be seen that the present invention specifically relates to a shear wave detection method and flaw detection device for spiral welded steel pipe body defects. The detection method uses a shear wave probe and a special layout method to realize the detection of steel pipe body defects with spiral welds.

[0028] The detection method in the present invention includes the following steps: first, more than one set of shear wave probes are arranged between two adjacent welds on the surface of the steel pipe body, and one set of shear wave probes includes a transmitting probe and a receiving probe, wherein the transmitting probe is used to transmit shear waves , the receiving probe is used to receive the shear wave emitted by the transmitting probe, the connection line between the transmitting probe and the receiving probe in each group of shear wave probes is perpendicular to the weld seam, and the direction of the transmitting probe and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com