Multi-dimensional probe holder for ultrasonic flaw detection of weld joint on spiral welded pipe

A spiral welded pipe, ultrasonic technology, applied in the direction of material analysis, measuring devices, instruments, etc. using sound waves/ultrasonic waves/infrasonic waves, can solve problems that are difficult to eliminate, increase flaw detection errors, and cannot guarantee complete bridging, etc., to improve defect detection High yield, reduced flaw detection error, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

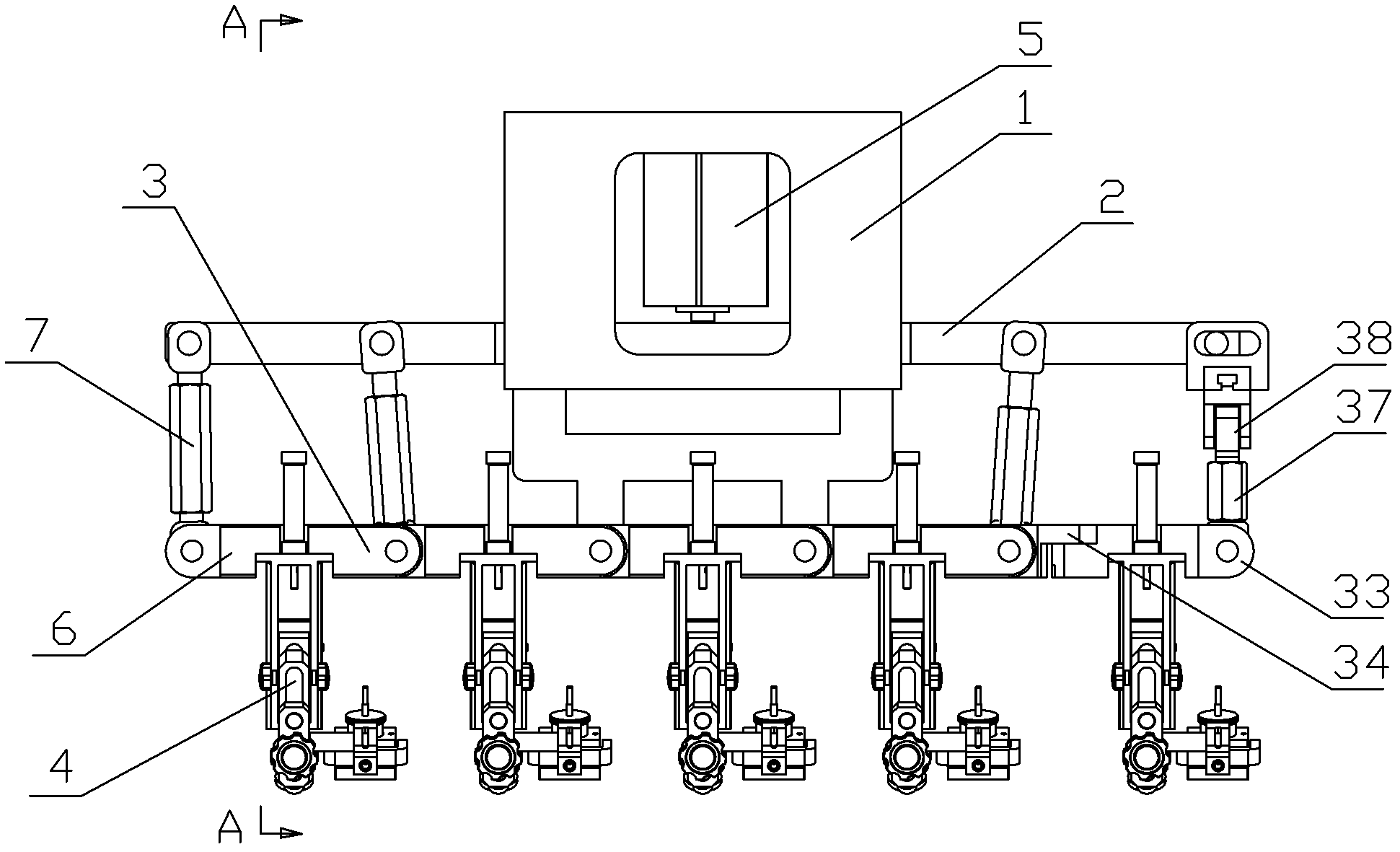

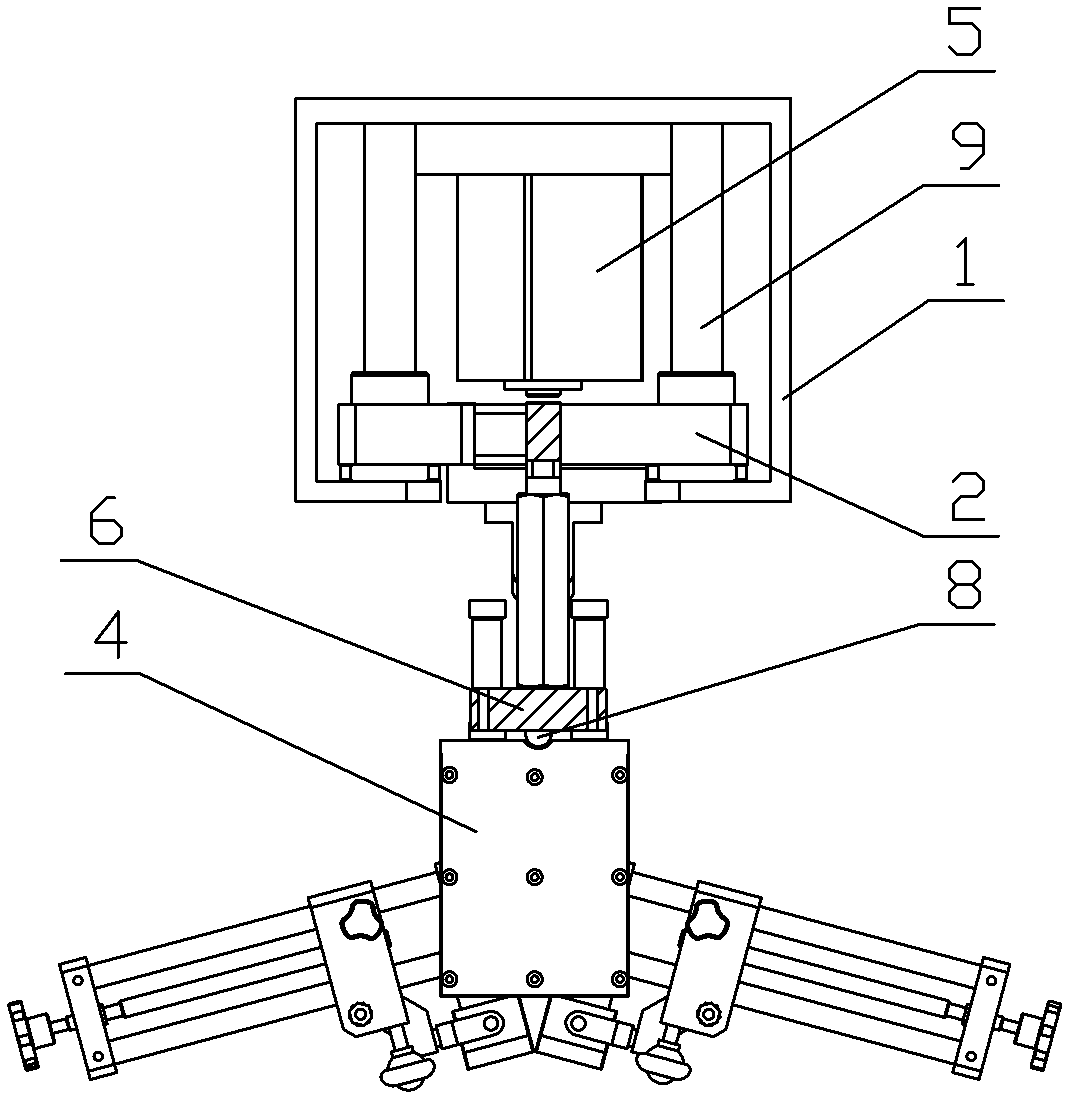

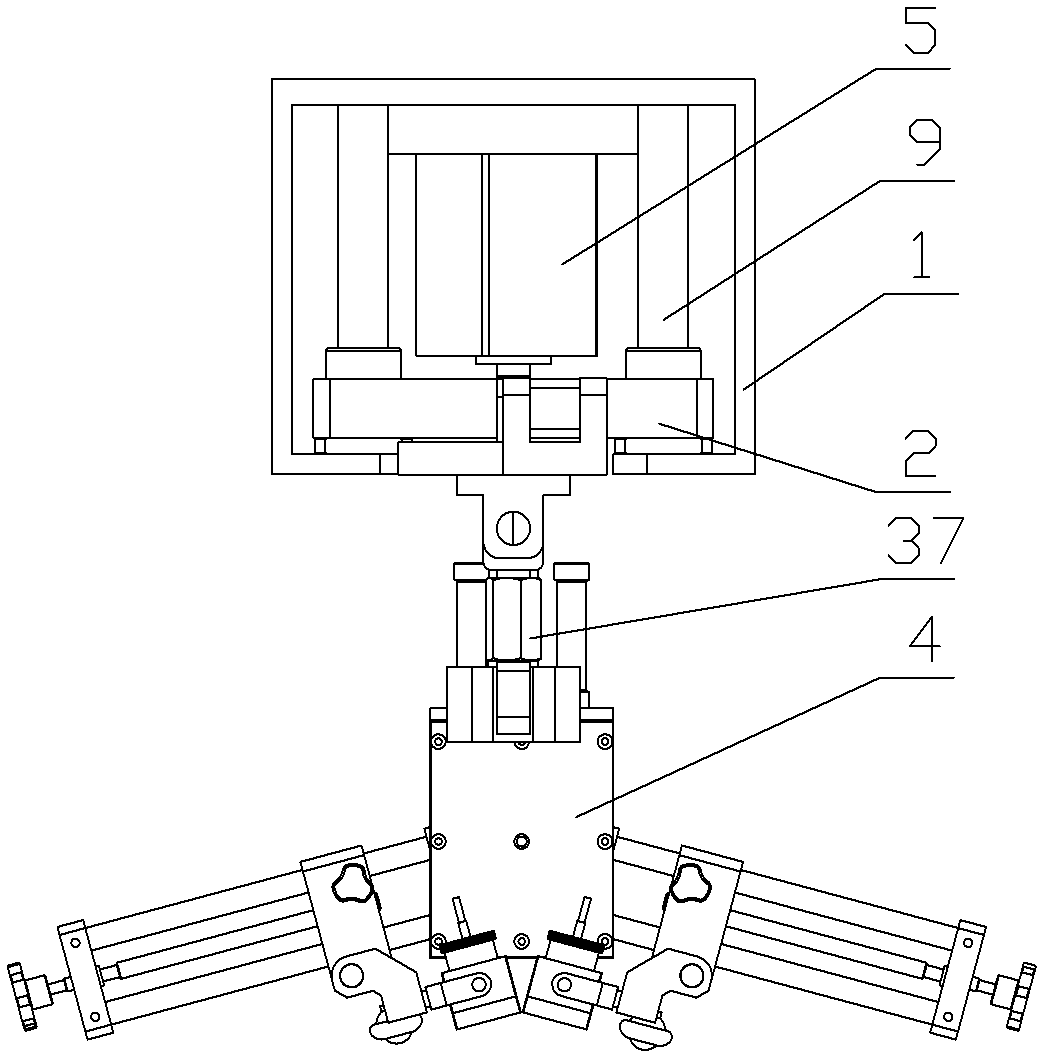

[0018] See figure 1 , figure 2 , image 3 , Figure 4 , is a structural schematic diagram of a multi-dimensional probe frame for ultrasonic flaw detection of a spiral welded pipe weld of the present invention, including a connecting seat 1, a beam 2, a flexible spindle 3 and a probe holder 4, the connecting seat 1 is centrally arranged on the beam 2, and the groove-shaped connecting seat 1 The built-in lifting cylinder 5, the end of the piston rod of the lifting cylinder 5 is connected with the crossbeam 2, the flexible main shaft 3 is formed by five-section main shaft joints 6 in sequence, the flexible main shaft 3 is set under the crossbeam 2 and connected with the crossbeam 2 through the middle section, and the crossbeam 2 and other spindle joints of the flexible spindle 3 are also provided with an adjusting screw 7, which can adjust the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com