TOFD detection verification method of large-scale spiral case welding seam

A verification method, a spiral technique, applied in the direction of measuring devices, analysis of solids using sonic/ultrasonic/infrasonic waves, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

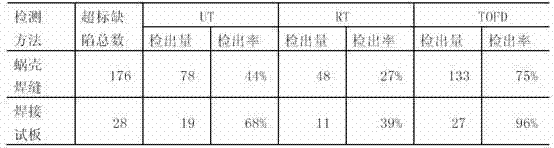

[0017] The present invention can be applied in the TOFD inspection process of the spiral shell weld seam of the important pressure part on the large-scale power station generator set and the RT, UT comparison test process, and is extended to the verification comparison test of the TOFD method replacing RT in large spherical tanks and thick-walled pressure vessels In work, the TOFD method has fast detection speed, low overall cost, and no radiation hazards to the human body and the surrounding environment. It can save costs for the owner to a large extent, and has a great application prospect. The large-scale spiral shell weld TOFD detection process and the RT, UT comparative test method include the following four steps:

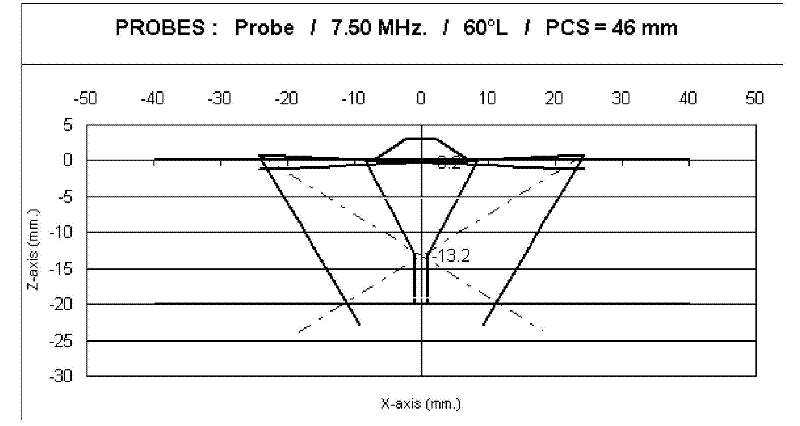

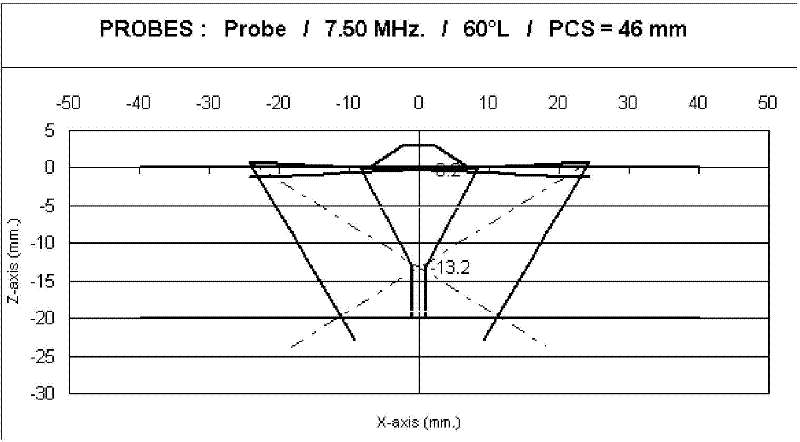

[0018] Make samples, determine acceptance criteria for volute defects and TOFD detection process parameters

[0019] The welding seam structure of the volute is relatively complex, and TOFD technology is applied for the first time, so a large number of compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com