Microcurrent heating composite and heating toilet seat

A composite material and micro-current technology, used in heating element materials, electric heating devices, ohmic resistance heating, etc., can solve the problems of inconvenient power access, endanger personal safety, and temperature control failure in the toilet seat, and avoid short-circuit or leakage. Injury to the human body, avoid rewiring, the effect of small working current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

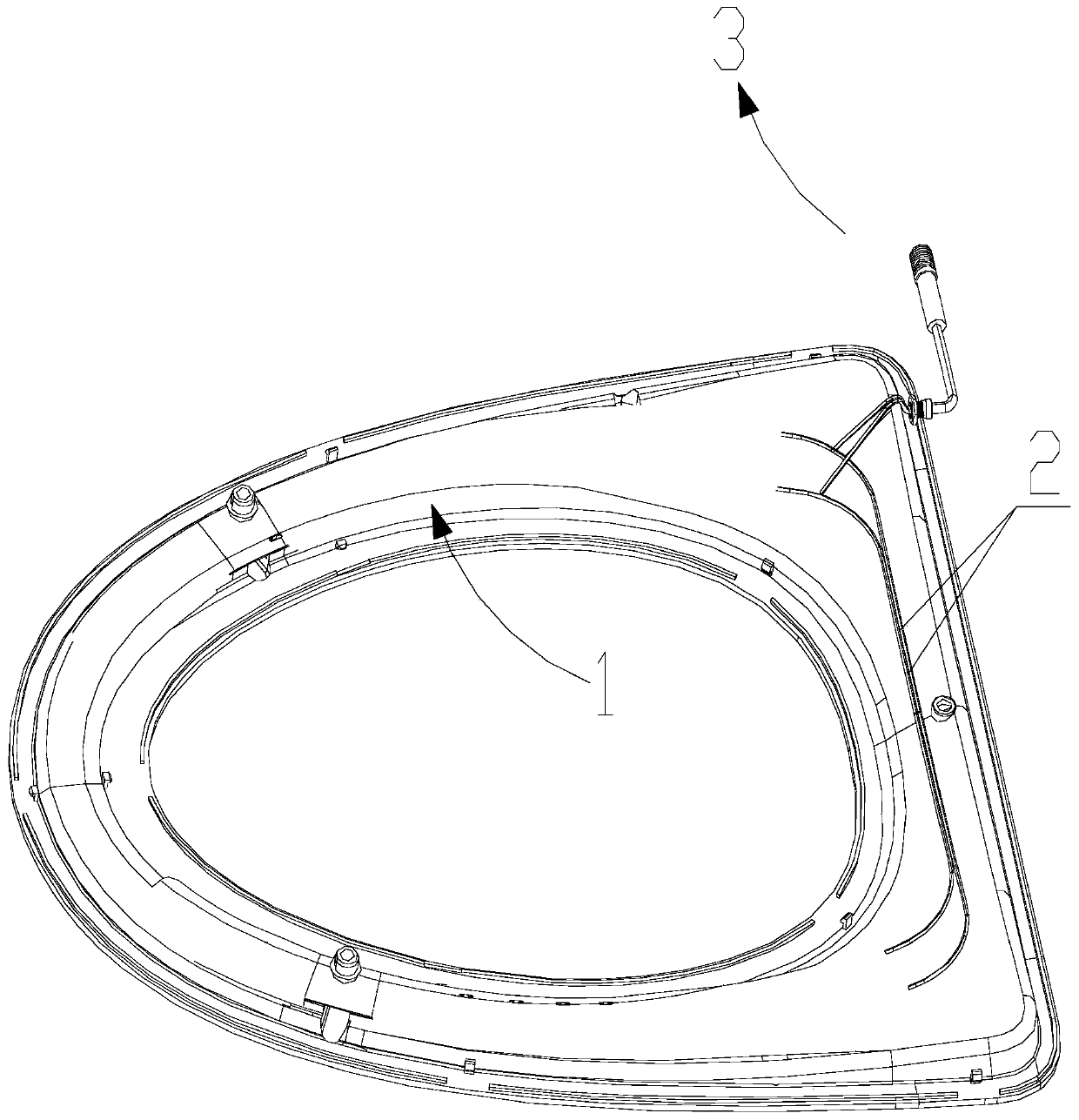

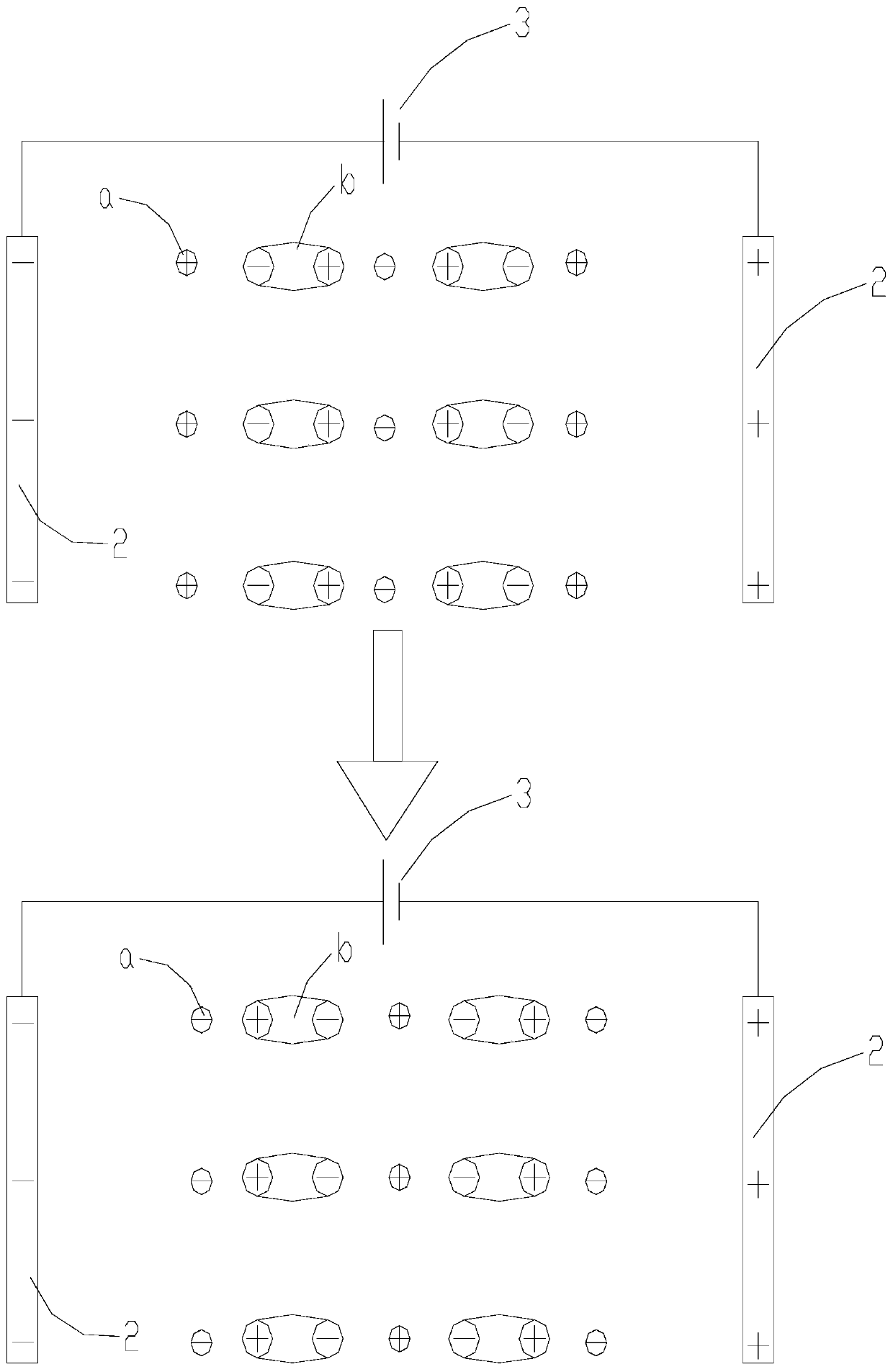

[0020] figure 1 A heating toilet seat according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a main body 1 formed by exothermic material.

[0021] In this embodiment, the heating material is a micro-current heating composite material.

[0022] The main body 1 is provided with at least one pair of mutually separated electrodes 2 .

[0023] The electrodes 2 are pre-embedded inside the main body 1 when the main body 1 is injection molded.

[0024] The electrodes 2 are made of metal conductors, and the two electrodes 2 are respectively connected to the positive and negative poles of the external DC power supply 3 .

[0025] The external DC power supply 3 forms a current loop in the main body 1 through the two electrodes 2 , and when the current passes through the main body 1 , the main body 1 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com