Patents

Literature

45 results about "Lateral wave" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

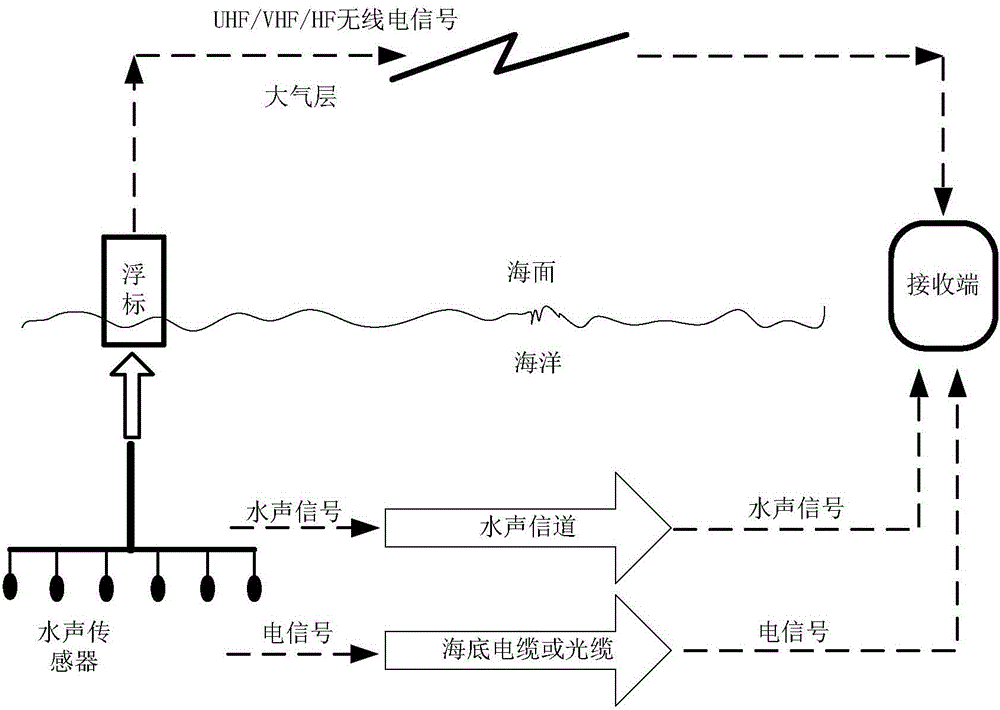

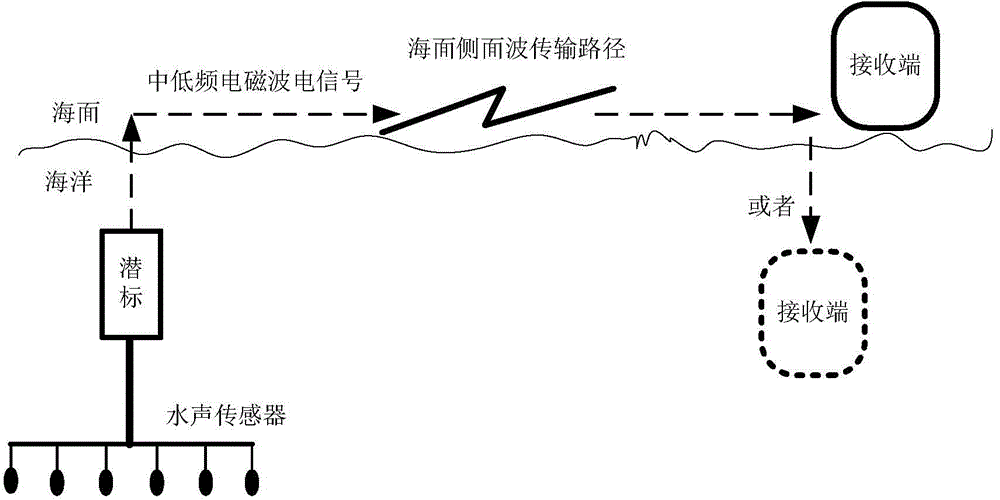

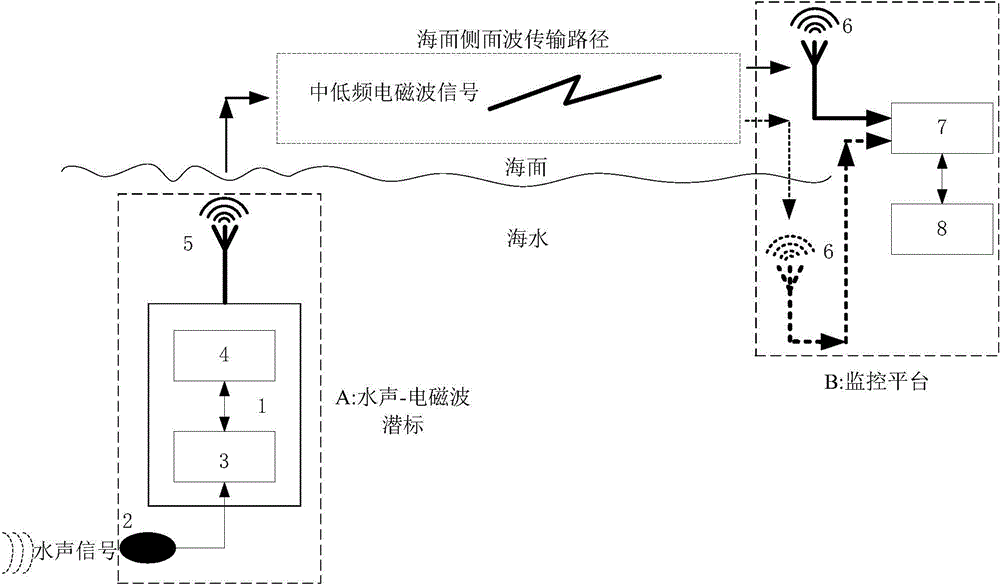

Electromagnetic wave transmission system crossing seawater-air interface and method thereof

ActiveCN104618032AAvoid inconvenienceAvoid instabilityFree-space transmissionControl signalElectromagnetic wave transmission

The invention relates to an electromagnetic wave transmission system crossing seawater-air interface and a method thereof; the system comprises one or more underwater sound-electromagnetic wave subsurface buoys and a monitor platform; the underwater sound-electromagnetic wave subsurface buoys convert underwater sound signals of underwater device received by underwater sound sensors into electromagnetic signals at first; the electromagnetic signals are mainly received by being transmitted to the monitor platform via a lateral wave propagation path of the electromagnetic wave in a medium having a smaller conductivity; in return, the electromagnetic wave control signals transmitted by the monitor platform are transmitted to the underwater sound-electromagnetic wave subsurface buoys via similar links.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

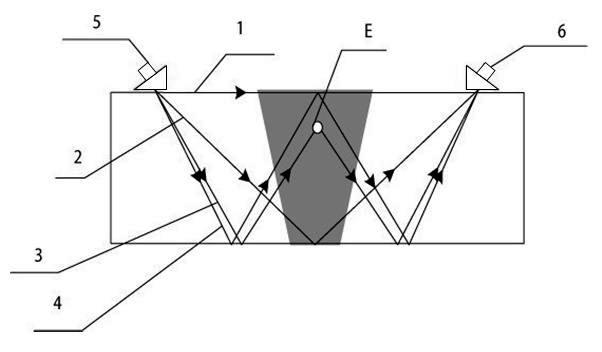

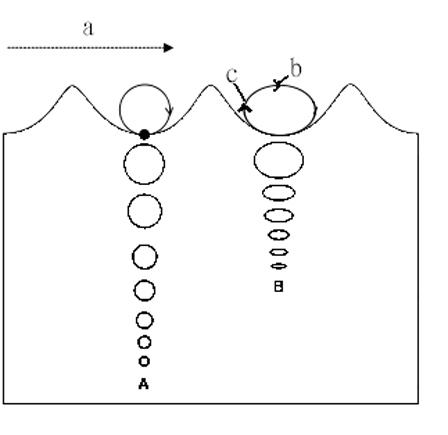

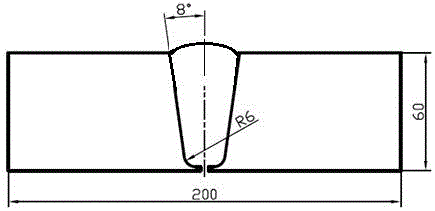

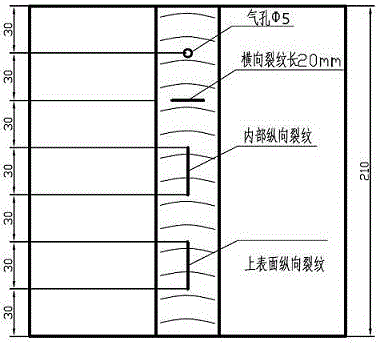

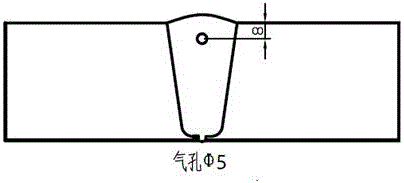

Near-surface defect recognition method based on ultrasonic TOFD

InactiveCN101839895AEasy to detectShort timeAnalysing solids using sonic/ultrasonic/infrasonic wavesLongitudinal waveComputer science

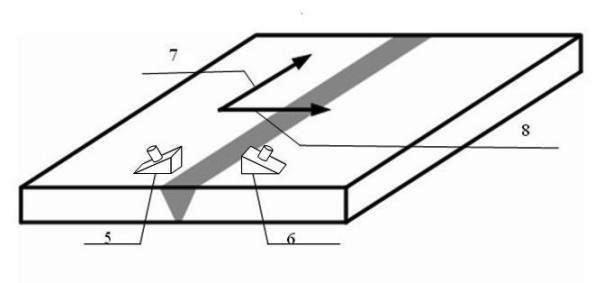

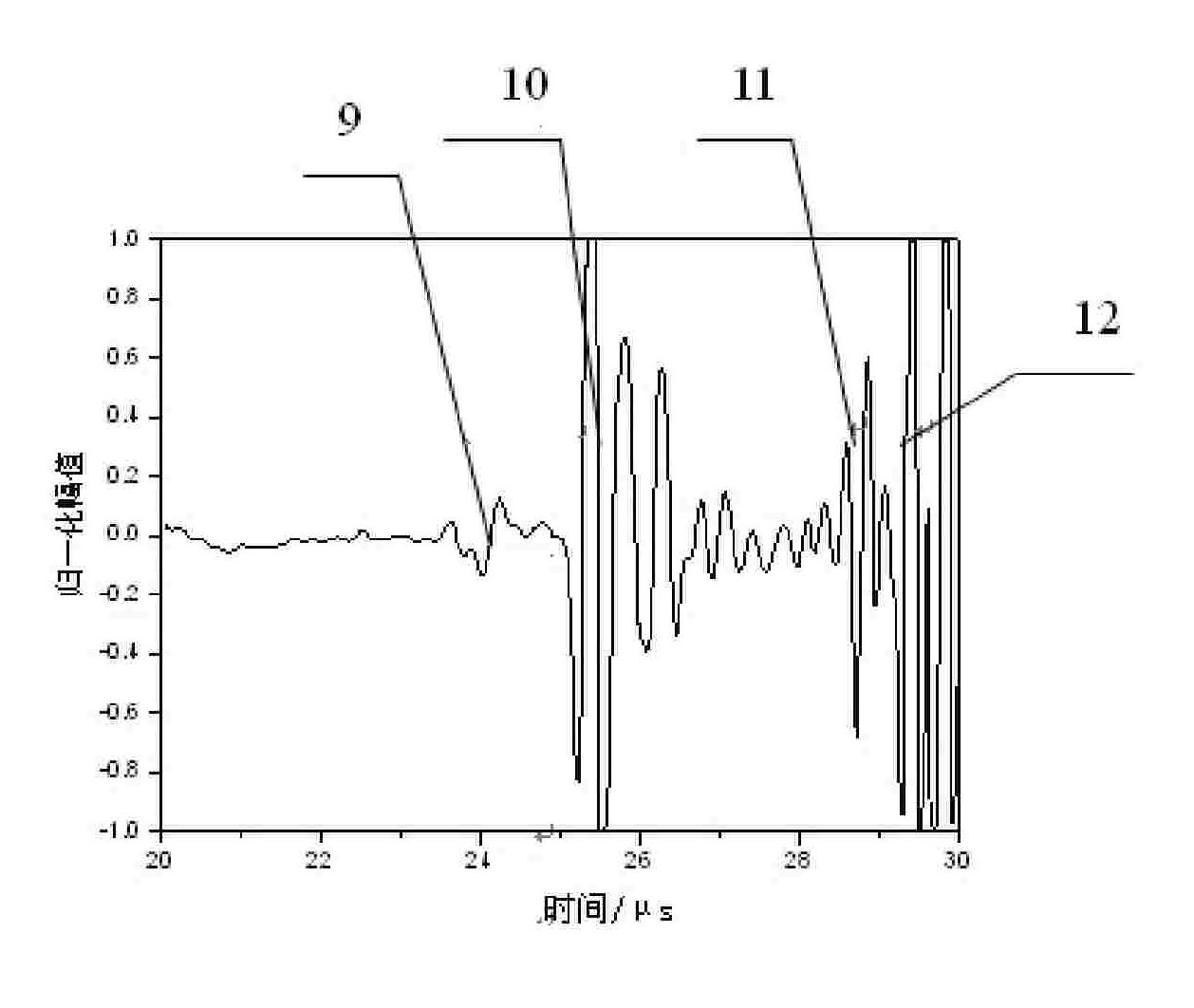

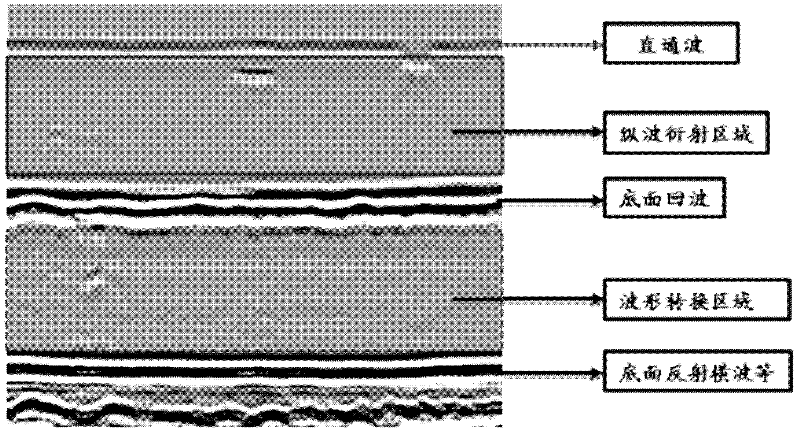

The invention relates to a near-surface defect recognition method based on ultrasonic TOFD, belonging to the field of ultrasonic nondestructive detection. The invention solves the problems that the prior ultrasonic TOFD detection technology is not sensitive to surface and near-surface defects, auxiliary detection devices are required by the existing hardware technology, the data processing process through the existing software technology is complex, the time is long, the suppression to lateral waves is not full and the near-surface defect signals are damaged. The process of the method comprises selecting probe spacing according to the thickness of an object to be detected and the angle of probes to enable a longitudinal wave main axis acoustic beam transmitted by a transmitting probe to be received by another probe after the acoustic beam is propagated along a W-shaped acoustic path in the object to be detected. By adopting the selected probe spacing, A scanning is conducted to the object to be detected, D scanning and B scanning are conducted to the object to be detected according to the obtained A scanning signals to respectively obtain D scanning images and B scanning images, and thereby the defect recognition is realized and the length and the buried depth of the defects are obtained. The method can be widely used in the filed of ultrasonic nondestructive detection.

Owner:HARBIN INST OF TECH

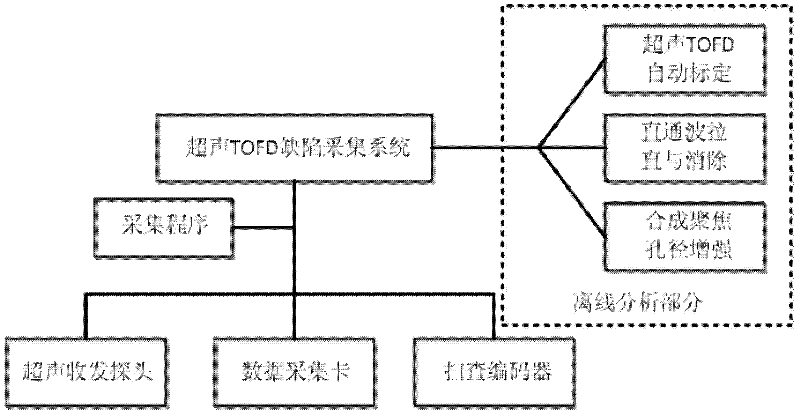

Ultrasonic time of flight diffraction (TOFD)-based offline defect judgment method

InactiveCN102393422APrecise positioningProcessing detected response signalSonificationImaging processing

The invention discloses an ultrasonic time of flight diffraction (TOFD)-based offline defect judgment method, which is characterized by comprising the following steps of: 1, scanning a body to be detected by using an ultrasonic detector to acquire lateral waves, bottom echoes and A scanning signals of the body to be detected, and synthesizing to obtain a B / D scanned picture; 2, accurately positioning the lateral waves and the bottom echoes by using an image processing and lateral peak search combined method to complete computer calibration of an ultrasonic atlas so as to obtain a plate thickness value of the body to be detected; 3, straightening and eliminating lateral waves with overlapped near surface defects by using peak calibration and a difference algorithm; and 4, performing wave beam sharpening and image enhancement treatment on a B scanned picture by using a synthetic aperture convergence technology to obtain an accurate position of a weld defect. By the method, near surface and internal defects can be effectively identified and accurately positioned, and the method can be widely applied to the field of ultrasonic nondestructive detection.

Owner:JIANGSU SUPERVISION & INSPECTION INST FOR PROD QUALITY

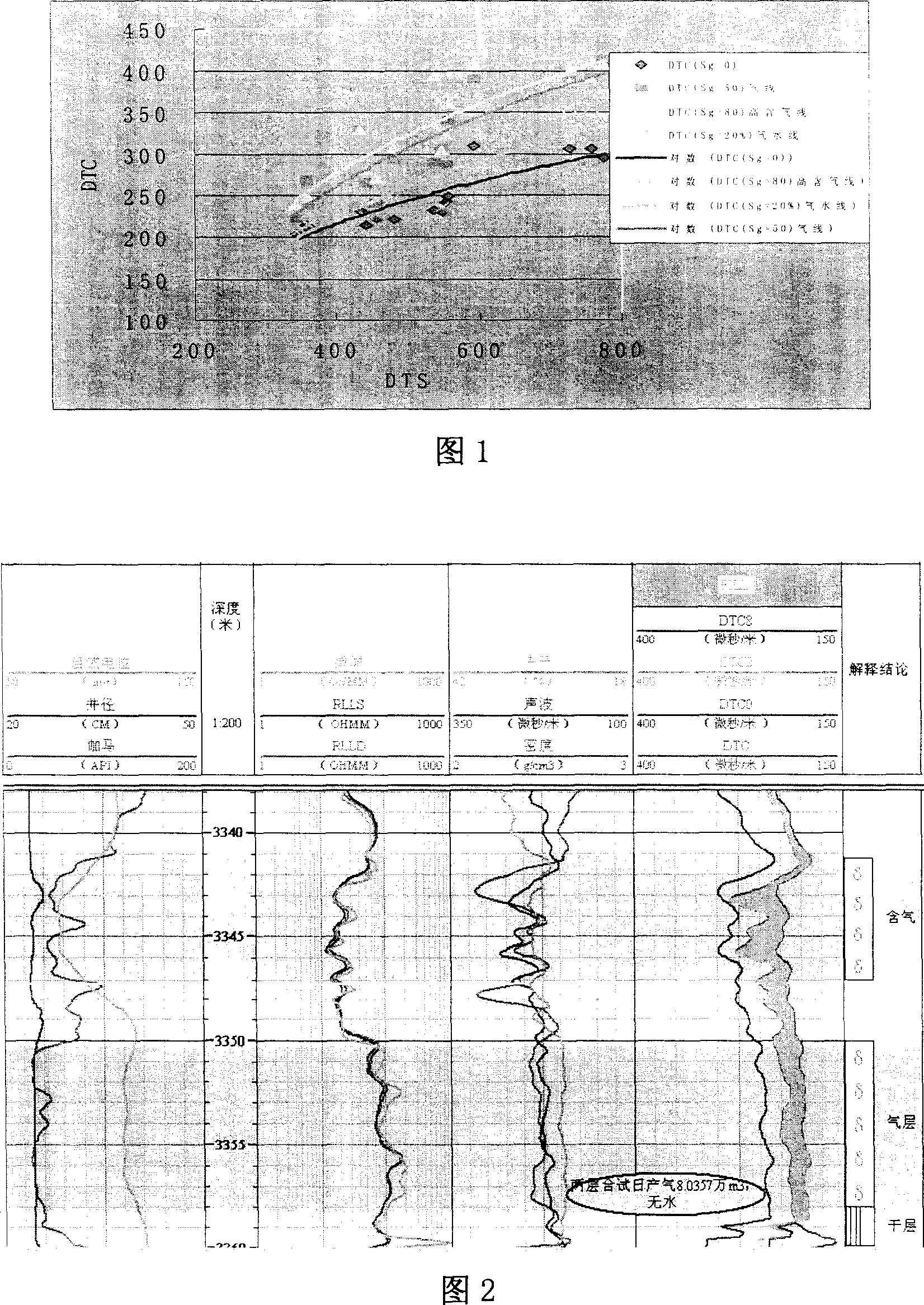

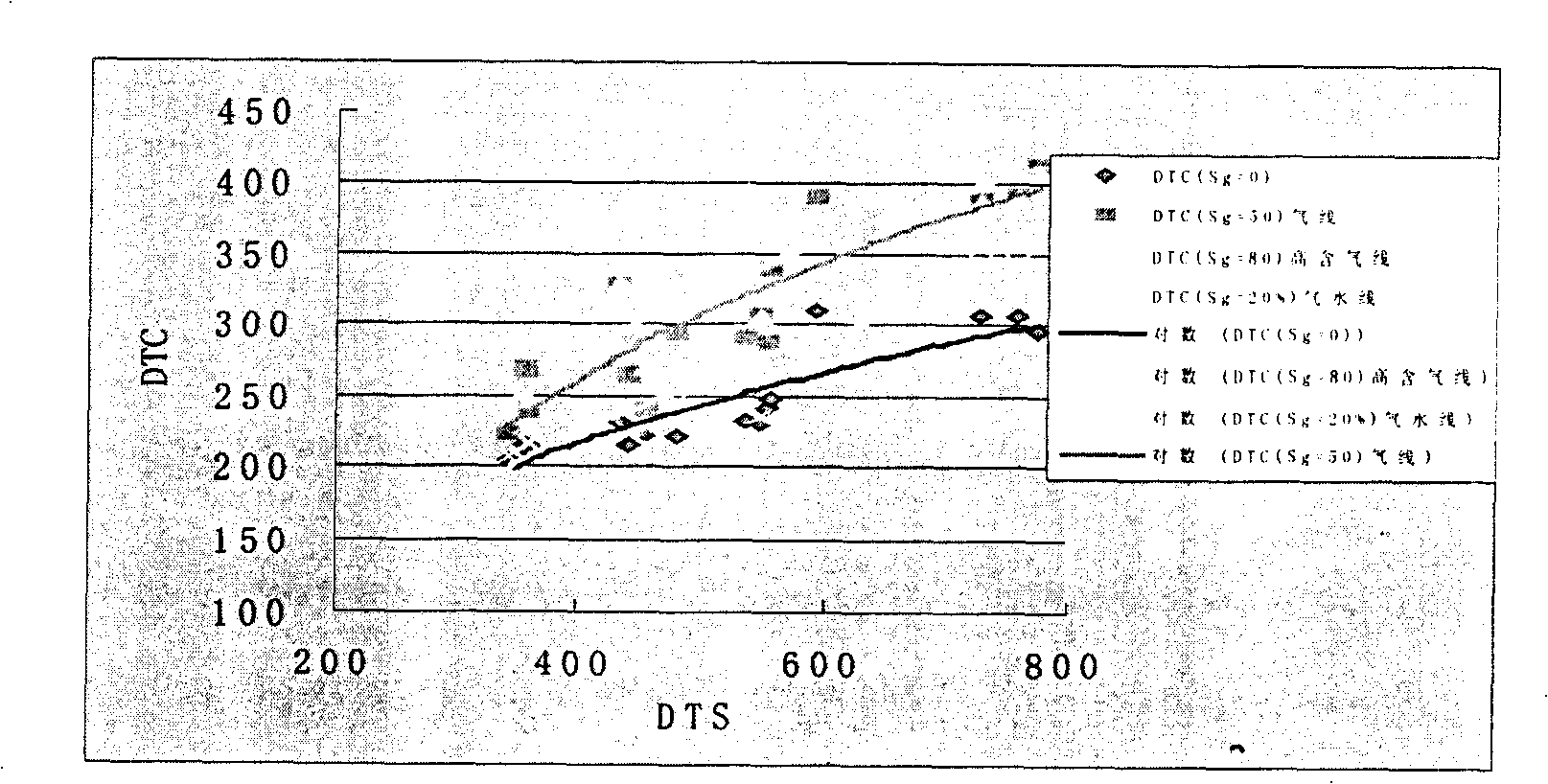

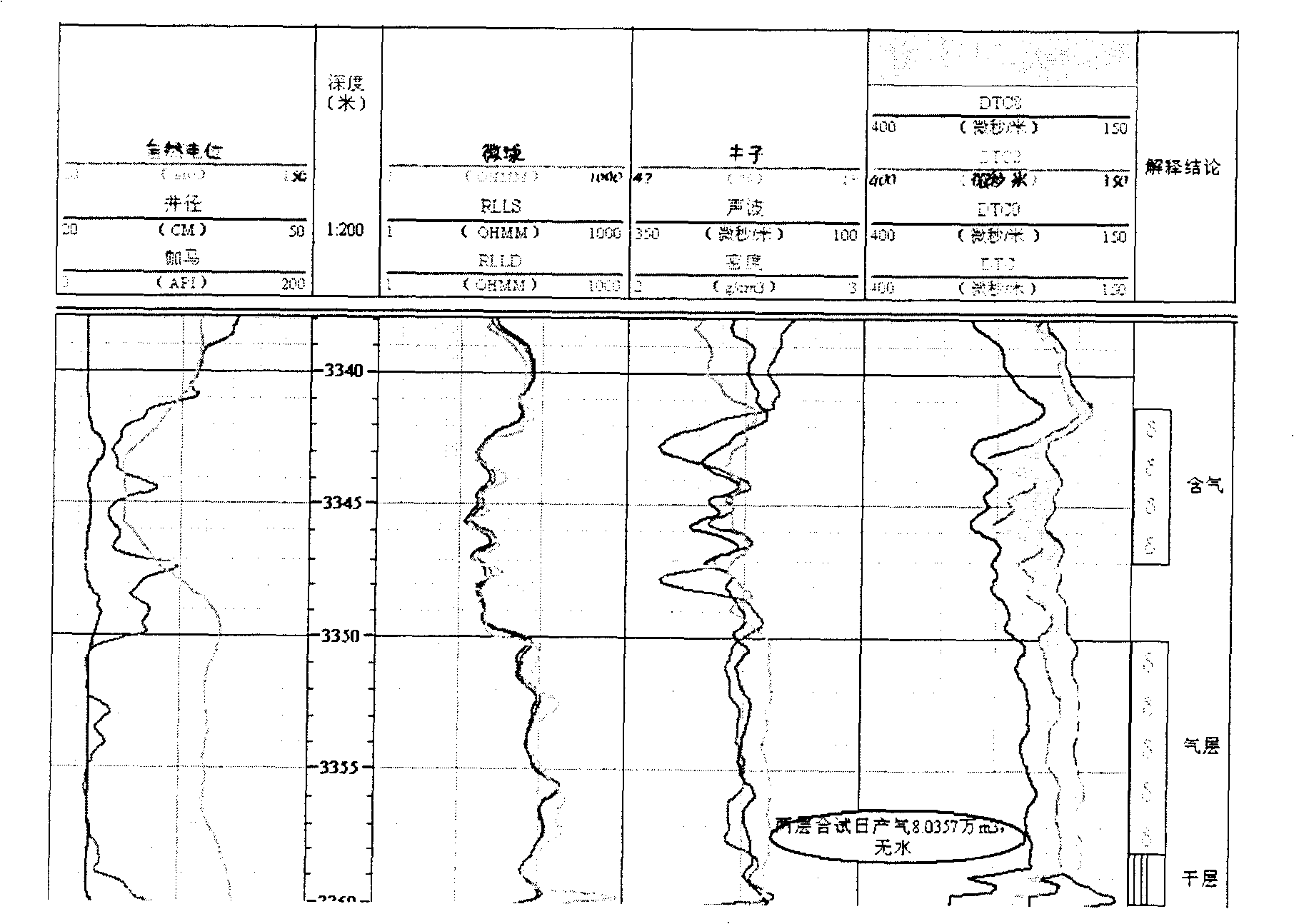

Method for determining air layer using acoustic wave split-double pole transverse wave well-logging data

ActiveCN101000378AImprove abilitiesSeismic signal processingSeismology for water-loggingLongitudinal waveWell logging

A method of utilizing full wave column and dipolar lateral wave well-logging data to confirm gas layer includes setting up lateral-longitudinal wave conversion cross map of various gas saturation degree at gas reservoir in exploration area according to known rock physical character, utilizing acoustic wave data lateral wave time difference to confirm longitudinal wave time difference at various gas saturation degree, measuring longitudinal wave time difference and using various gas saturation degrees in said cross map to confirm gas situation in reservoir.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for accurately quantifying flaw height of girth welding seam in submarine pipeline

InactiveCN104359976ASolve the problem of low pass rateAccurate defect height quantitative accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesOcean bottomChannel parameter

A method for accurately quantifying the flaw height of a girth welding seam in a submarine pipeline comprises the following inspection steps: (1) setting the depths of focuses of a diffractive ultrasonic emission probe and a diffractive ultrasonic receiving probe at a position of 2 / 3T of the wall thickness of the welding seam; (2) calculating the probe center distance; (3) performing sound velocity measurement, wedge delay calibrations, and detection system calibrations on sound velocity probes separately on a submarine pipeline sound velocity test block; (4) importing the ultrasonic time-of-flight diffraction channel parameter into the embedded flaw position of the girth welding seam in the submarine pipeline; (5) finding lateral wave signals and bottom surface reflected wave signals, and finding upper tip diffraction signals and lower tip diffraction signals from the embedded flaw; (6) comparing the wall thickness parameter of the girth welding seam of the submarine pipeline with the phase variation of the ultrasonic time-of-flight diffraction; (7) accurately quantifying the height of the embedded flaw; (8) carrying out comparative analysis on the macroscopic flaw section height and the height quantified by adopting the ultrasonic time-of-flight diffraction technology. The method has the advantages that the problem of low qualification rate of welding seams can be solved, the welding quality of the submarine pipeline can be ensured, and the submarine pipeline laying efficiency can be improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

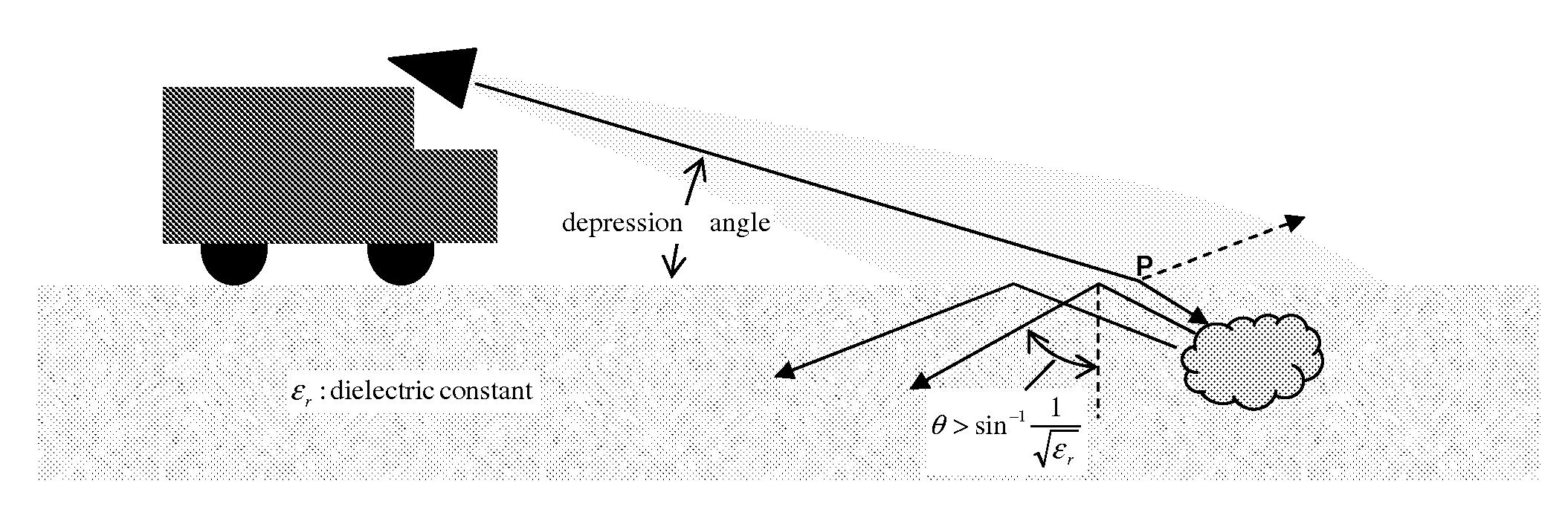

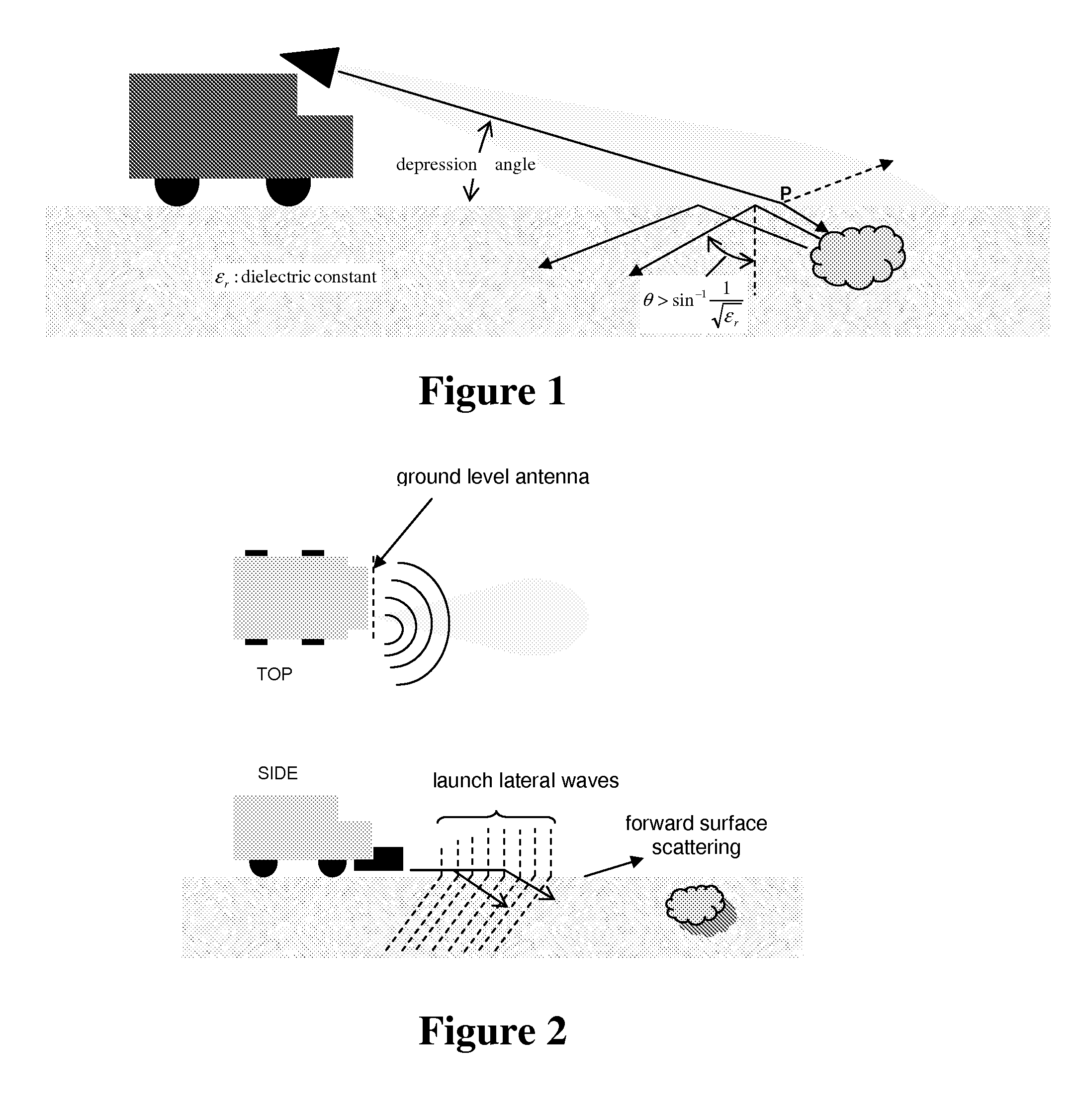

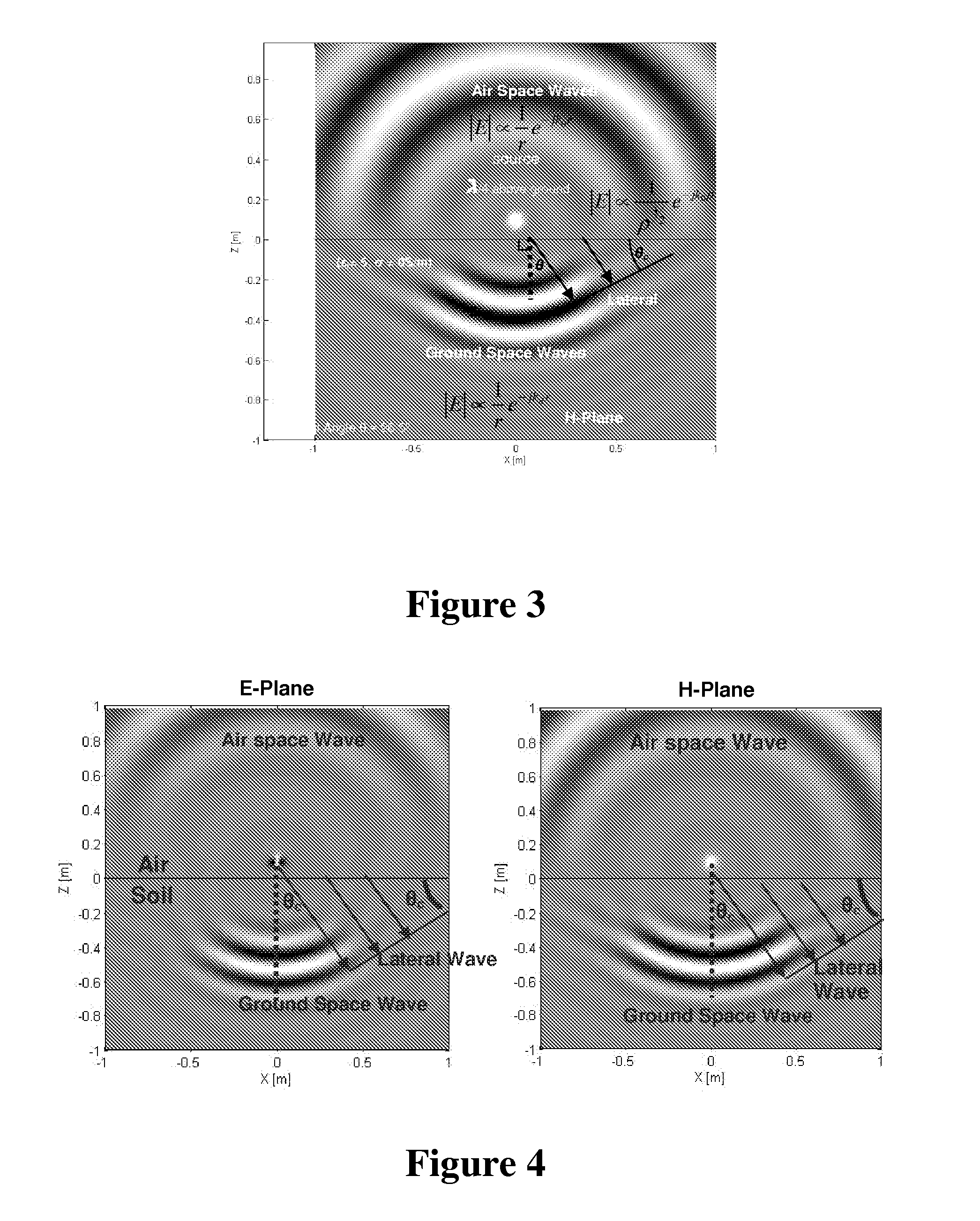

Lateral wave radar system for forward detection

A forward-looking radar system adapted to detect and identify buried or near surface objects from a moving ground vehicle has been developed. The system incorporates a radar detection system and in one embodiment is mounted on a ground vehicle. The system is adapted to differentiate common roadway clutter from objects of interest.

Owner:THE OHIO STATE UNIV RES FOUND

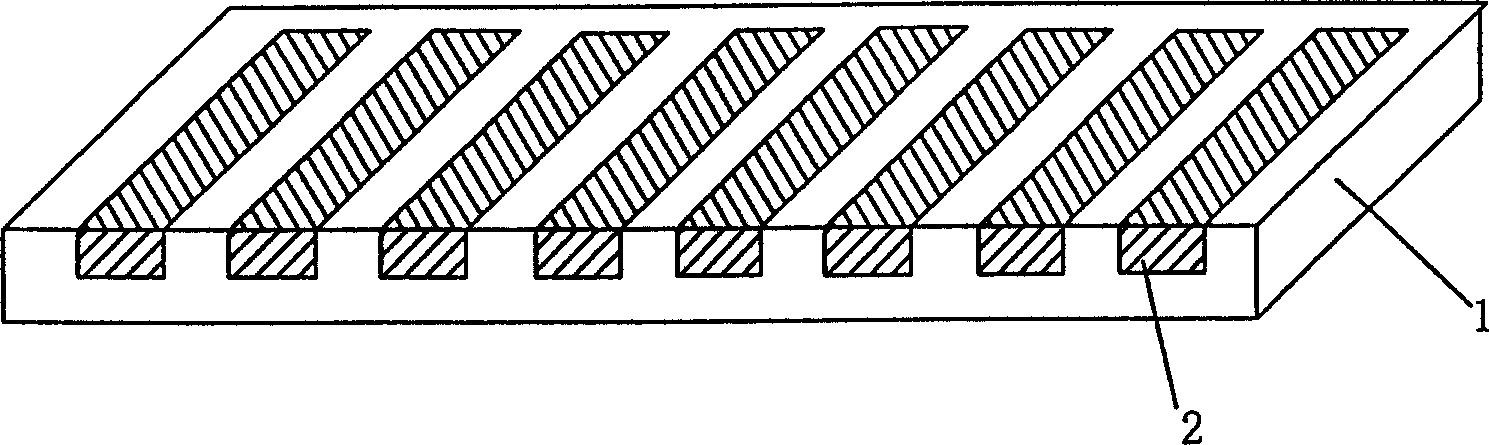

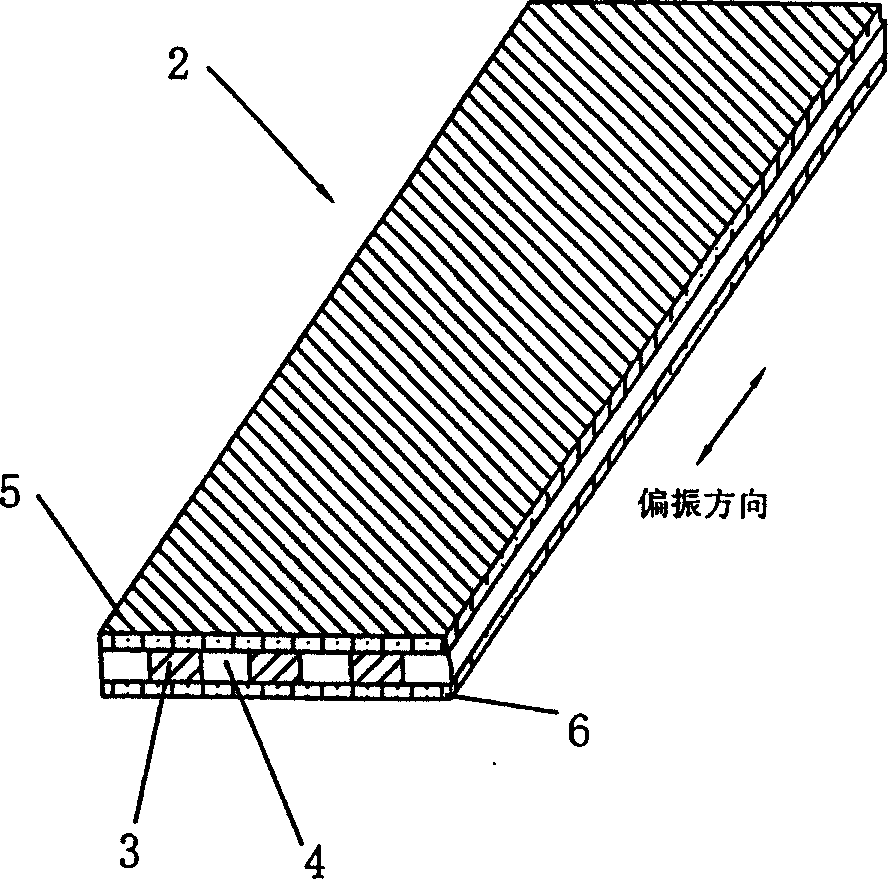

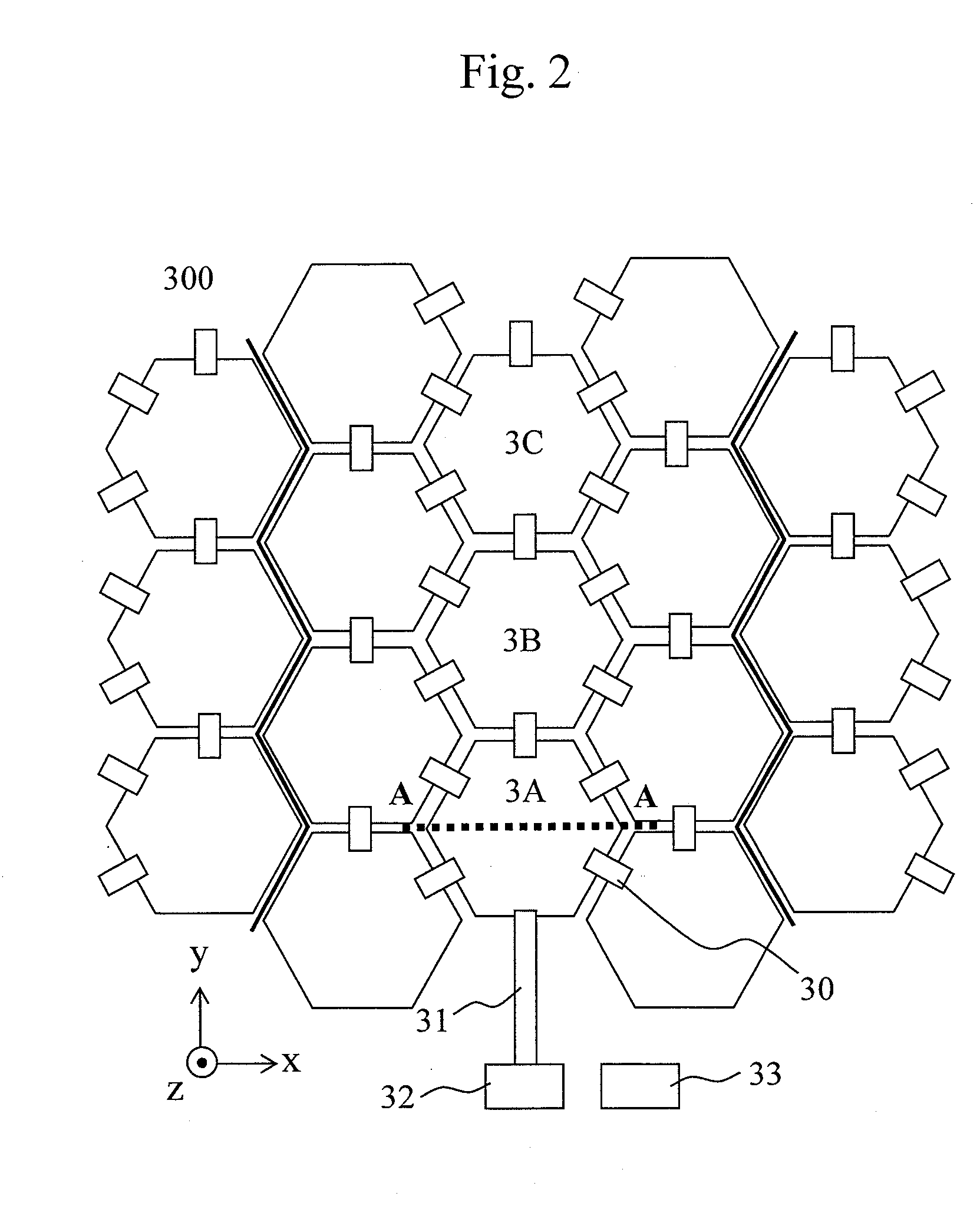

Phased array probe for scanning imager

InactiveCN1530650AAvoid lostAvoid interferenceMaterial analysis using sonic/ultrasonic/infrasonic wavesTransducerPhase control

The phase array probe comprises array formed by transducer unit which is presented in form of rectangular solid, composed of piezoelectric block and non-piezoelectric block as well as covered with top electrode and bottom electrode at its top and bottom surface. The piezoelectric block and non-piezoelectric block are stagger-placed along width direction of the transducer unit so that the probe not noly can be used to realize beam electronic scanning with vertical-pure lateral wave for solid material by utilizing electronic phase control technique but also can be used to carry on detection for liquid sandwich and zero gap desplicing in spliced boundary.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

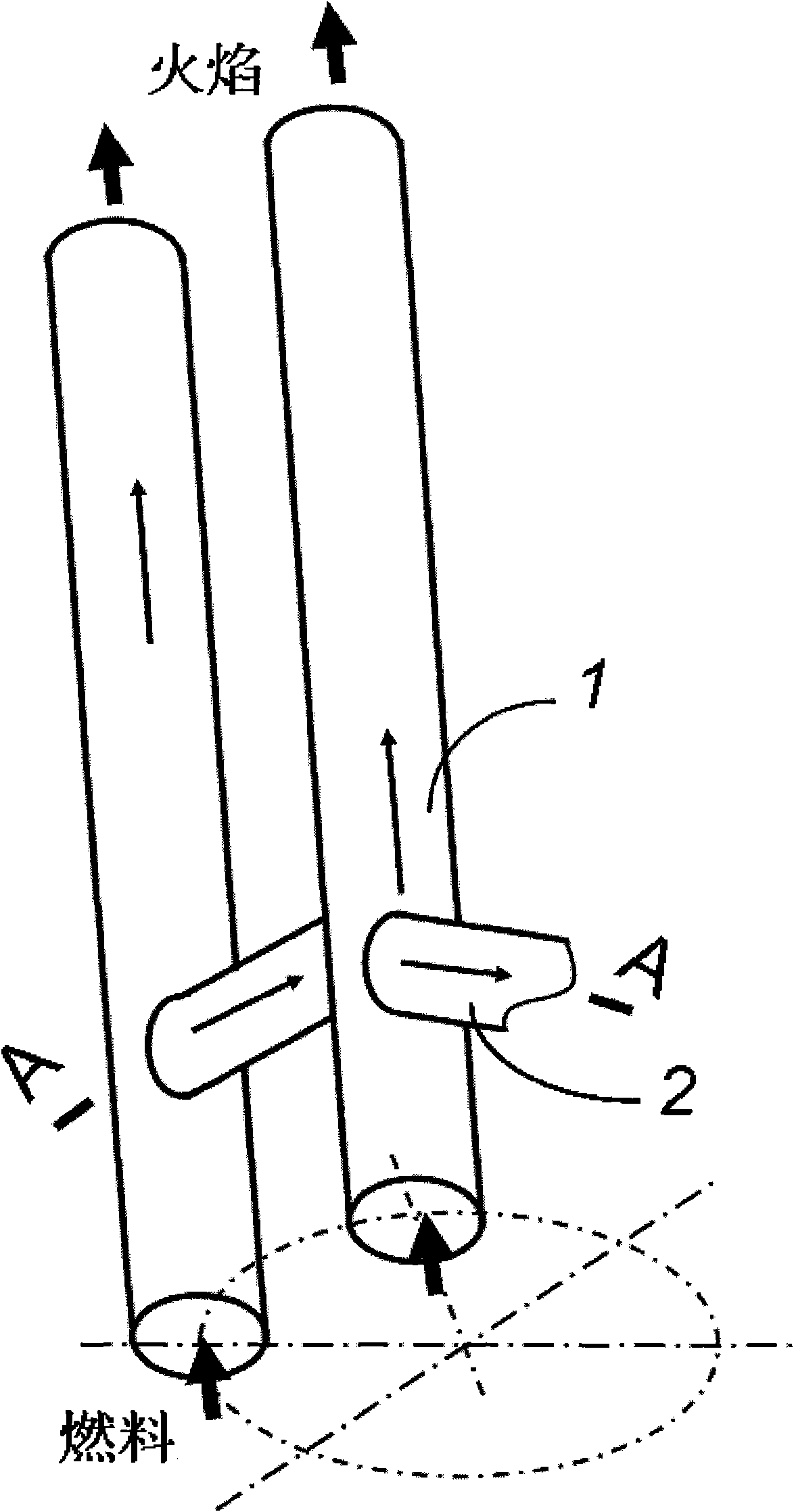

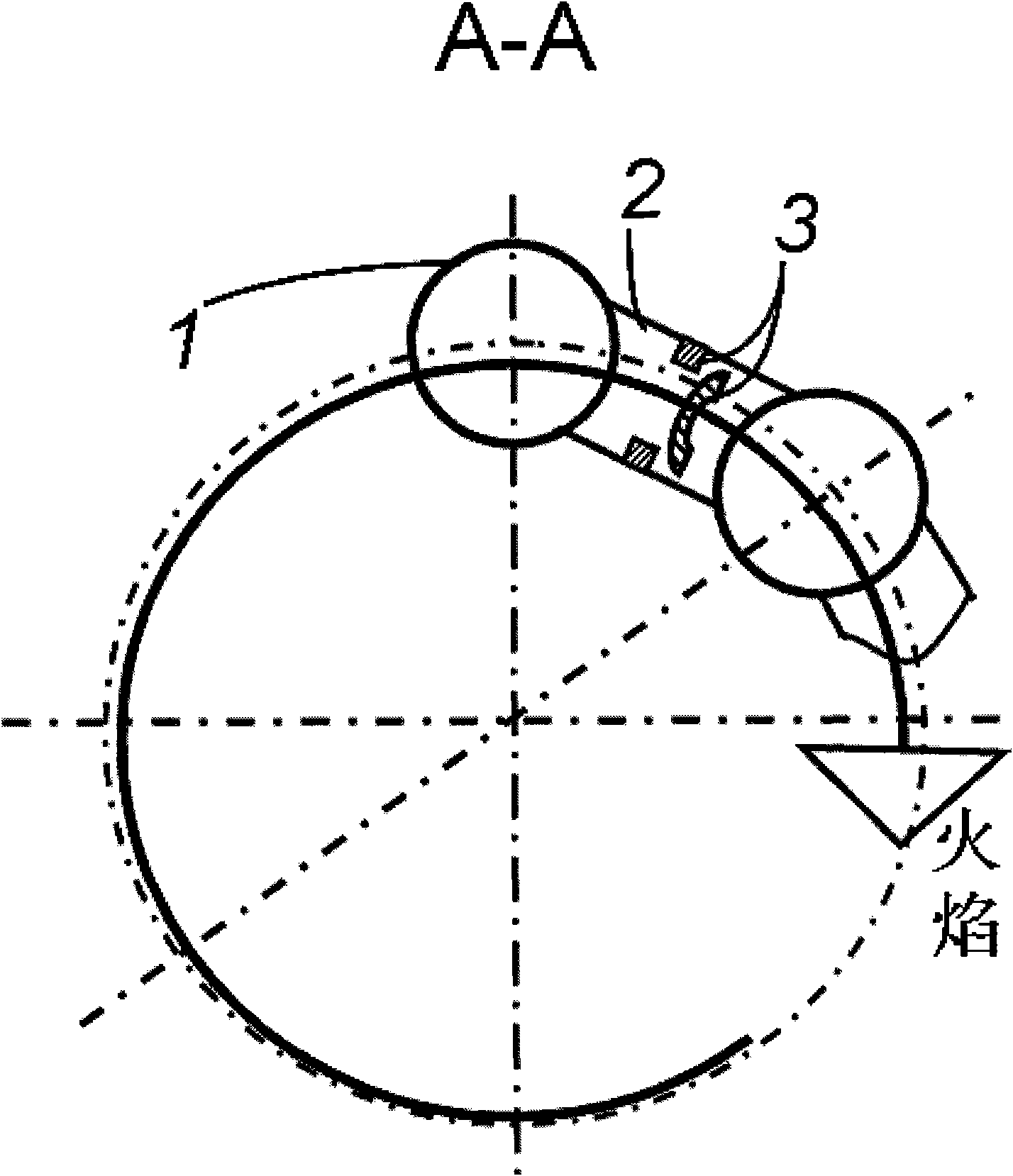

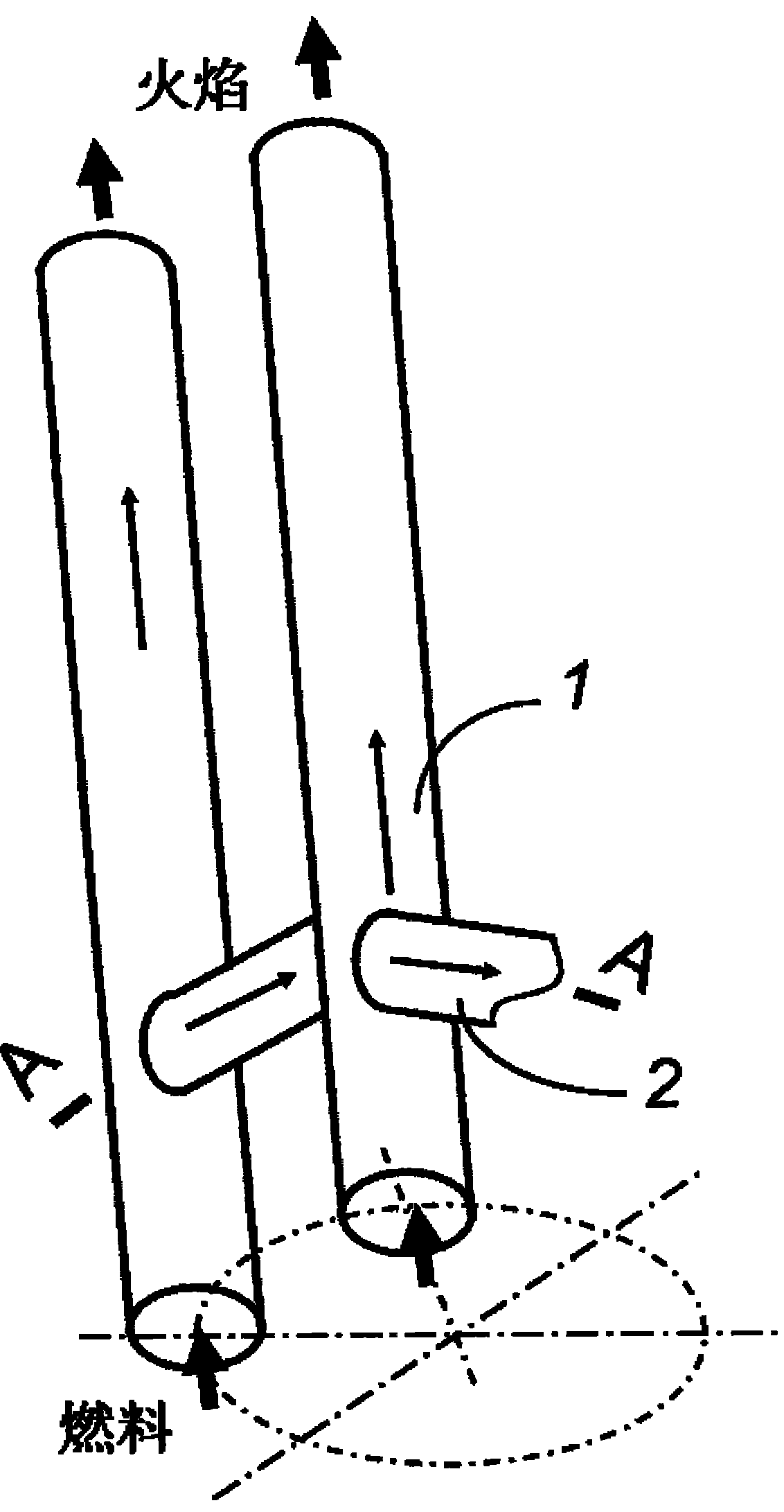

Multi-tube detonation lateral wave ignition device

InactiveCN101858278AChange relatively independent featuresIgnition continues uninterruptedIntermittent jet plantsRocket engine plantsCombustionHigh energy

The invention relates to a multi-tube detonation lateral wave ignition device comprising a plurality of parallel detonation tubes, lateral flame tubes and flame check valve assemblies, wherein the lateral flame tubes are connected with the adjacent detonation tubes and form lateral flame channels of which the tails and the heads are communicated in a system, and the flame check valve assemblies are arranged in the lateral flame tubes. Not only flames in the upstream detonation tubes move to the exit of a spray tube, the branches of the flames also enter the lateral flame tubes, and lateral combustion waves in the tubes move to the adjacent downstream detonation tubes by the flame check valve assemblies to ignite premixed fuels in the downstream detonation tubes to realize combustion; the process is circulated in cycles among the detonation tubes to realize the deflagration to detonation transition (DDT) process of the ignition self-sustaining of a detonation tube system. The invention has simple structure, can meet the demands of high frequency and high-energy ignition and overcome the difficulties of continuous ignition and deflagration to detonation transition. The invention can be used as the ignition realizing mode of a multi-tube pulse detonation engine.

Owner:SHANGHAI UNIV

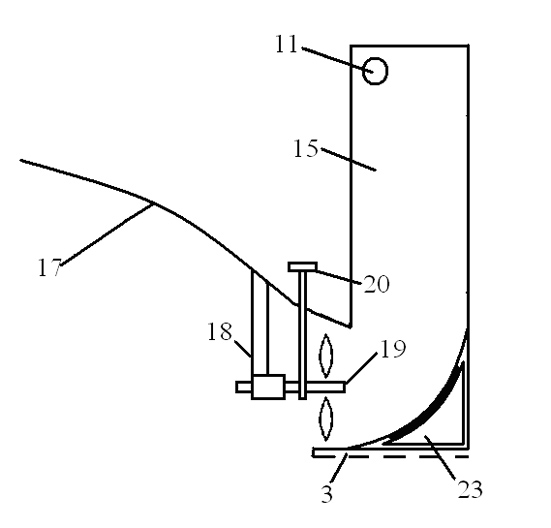

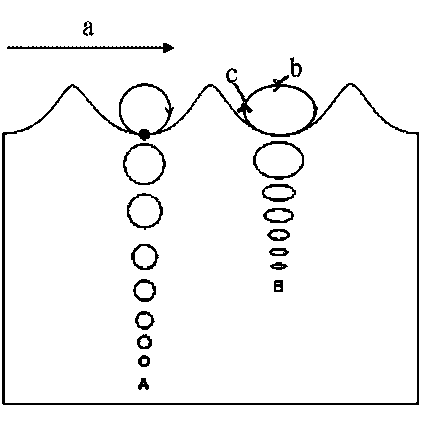

Efficient power generation device using wave energy

InactiveCN101984250AImprove energy utilizationSeawater treatmentWater/sewage treatment bu osmosis/dialysisElectricityEngineering

The invention relates to an efficient power generation device using wave energy, comprising a left side board, a right side board, a middle board, an inner top board and a first cavity. The upper parts of the left side board and the right side board are respectively sealed and connected with the inner top board, and the lower parts of the left side board and the right side board are respectively sealed and connected with the middle board. The left side board, the right side board, the middle board and the inner top board form a first side opening. One end of the first side opening faces the movement direction of the waves, the other end of the first side opening is sealed and connected with the first cavity, and the inner of a structure which is formed by the communication of the first side opening and the first cavity is provided with a structure capable of generating electricity by using the lateral waves. The efficient power generation device using the wave energy has the advantages that the kinetic energy, potential energy and lateral impact force of the waves are fully utilized, and the using efficiency of the waves is high.

Owner:陈鹤

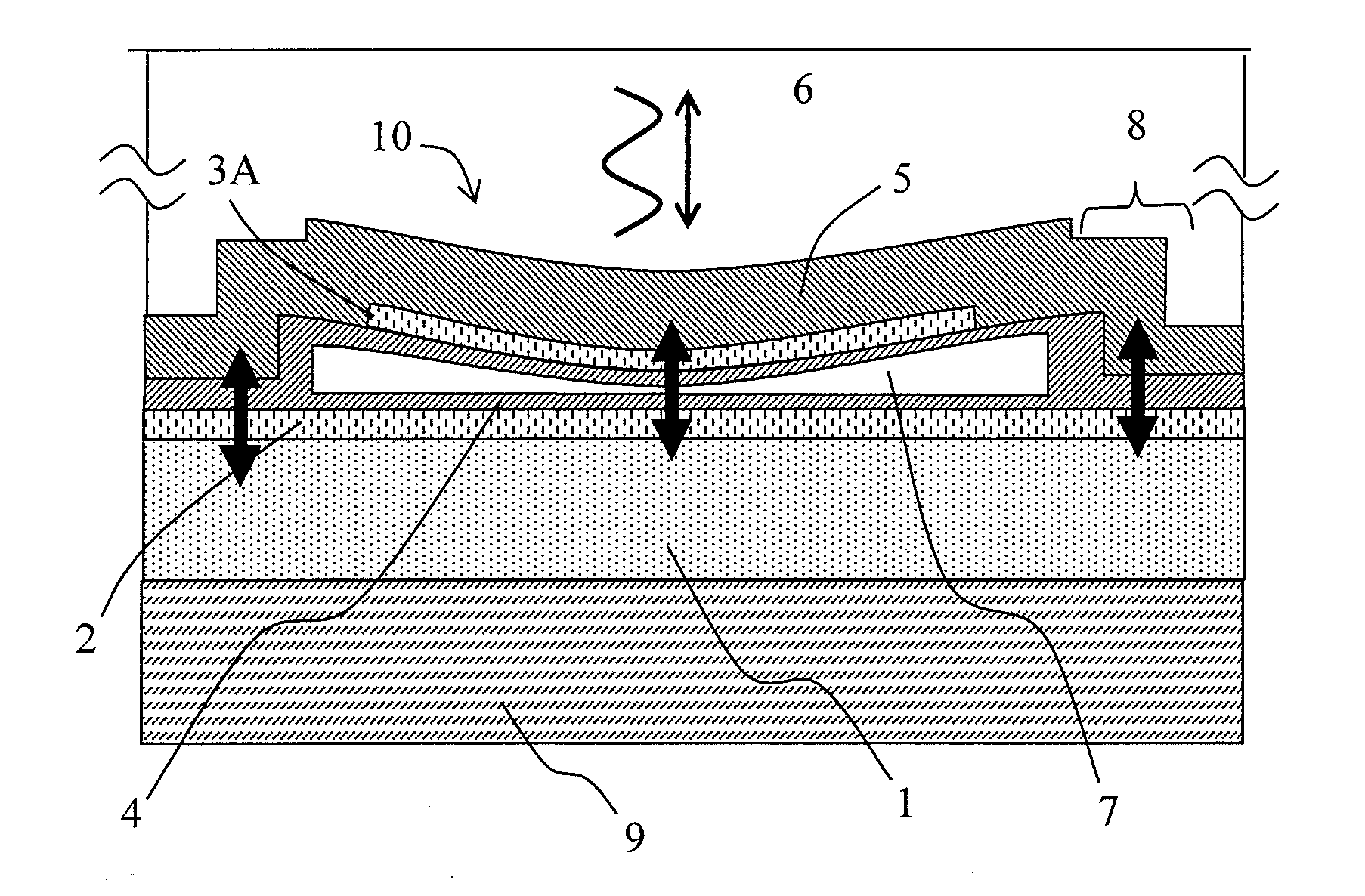

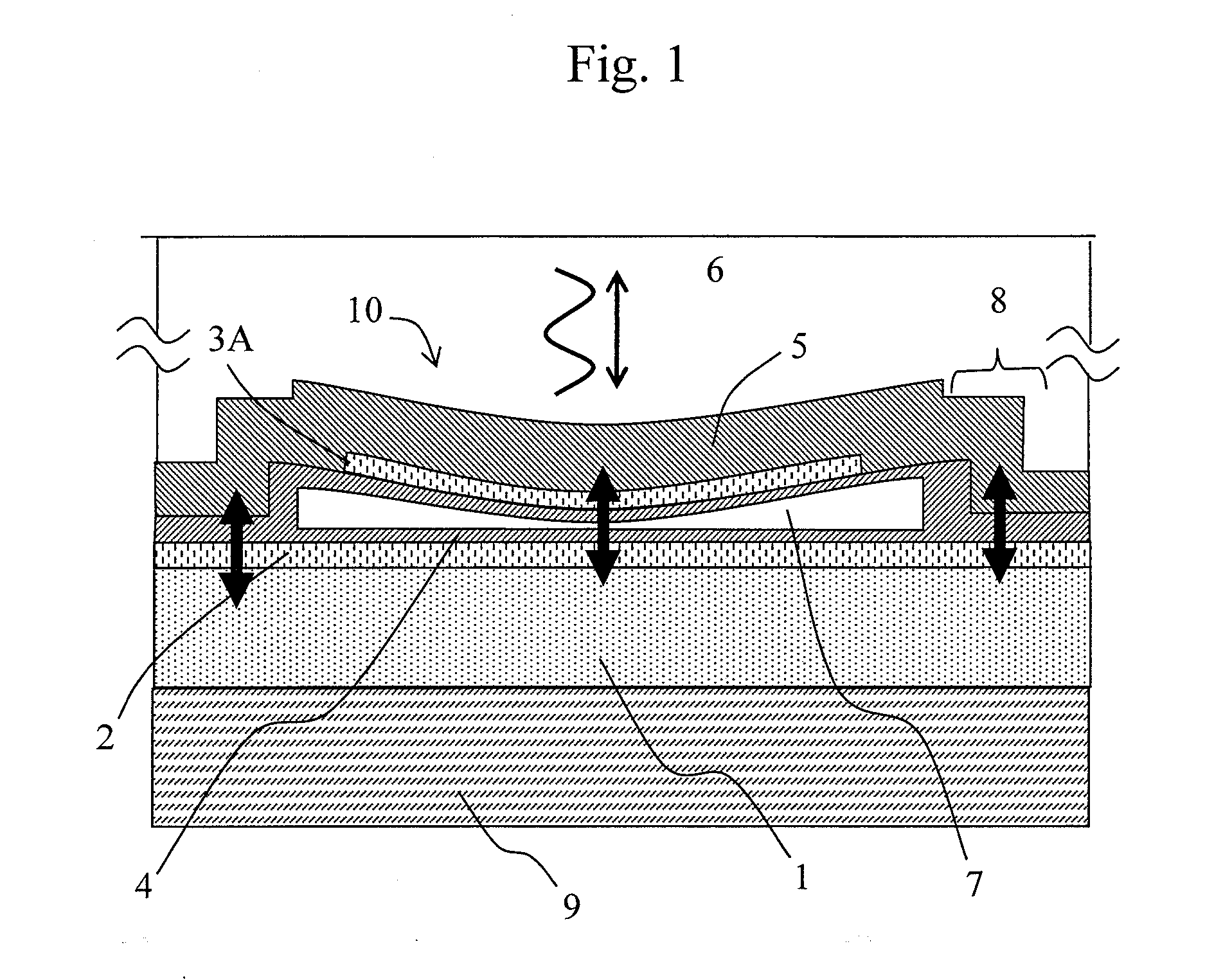

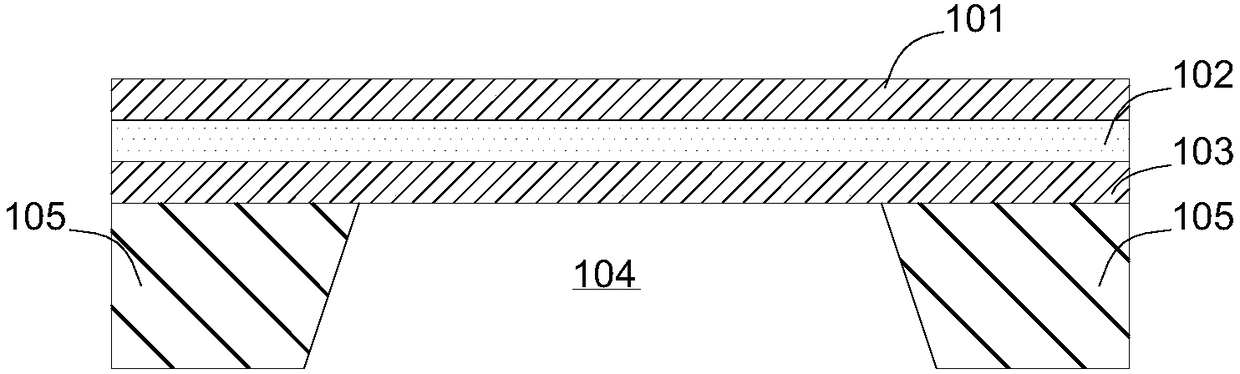

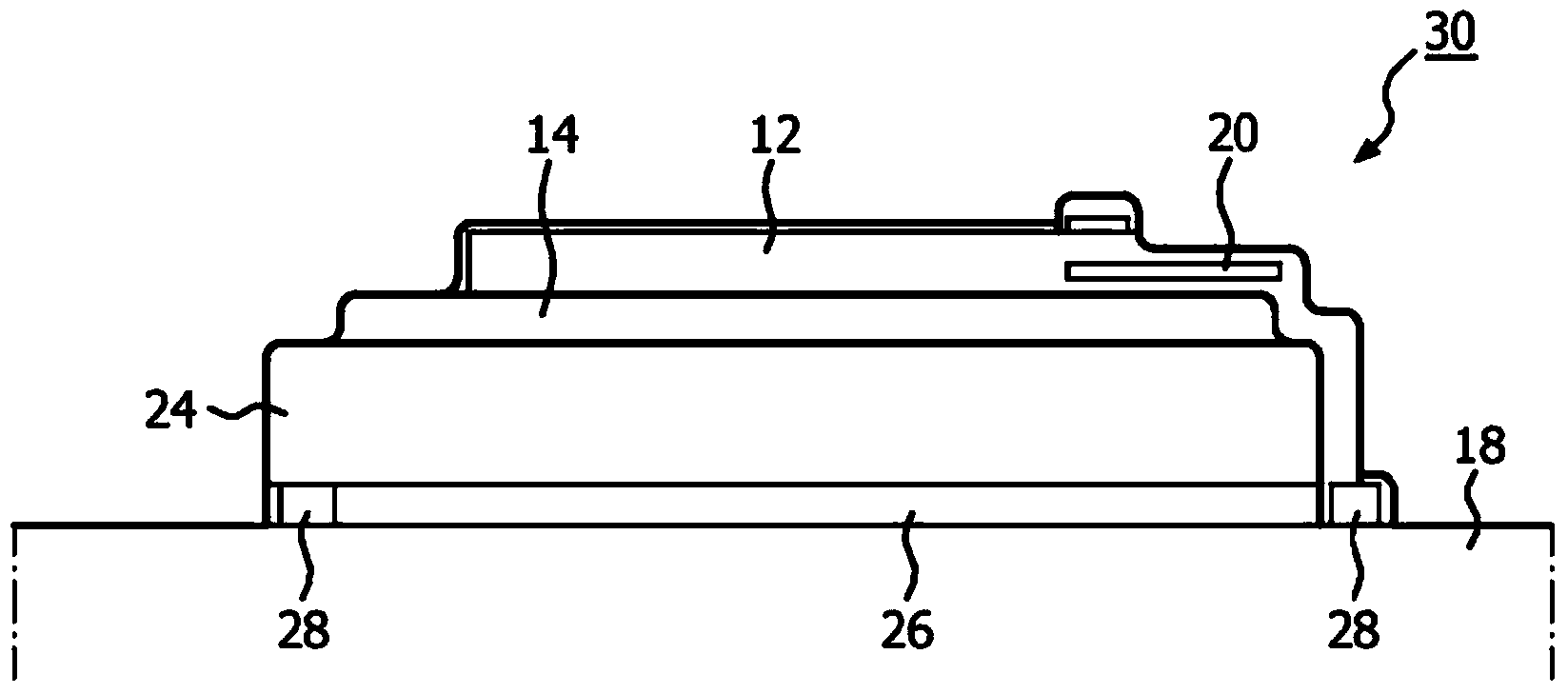

Ultrasonic probe and ultrasonic imaging apparatus

ActiveUS20120038242A1Suppress undesired response componentAvoid artifactsUltrasonic/sonic/infrasonic diagnosticsMechanical vibrations separationUltrasonic imagingUltrasound probe

Artifacts due to lateral wave that occurs in a substrate of a Capacitive Micro-machined Ultrasonic Transducer is reduced. The substrate thickness of the ultrasonic transducer is set in an optimum range to efficiently radiate the energy of lateral wave in the sensitive band 91 of the ultrasonic transducer to the outside so that the lateral wave is attenuated thereby reducing the artifacts in ultrasonic imaging.

Owner:FUJIFILM HEALTHCARE CORP

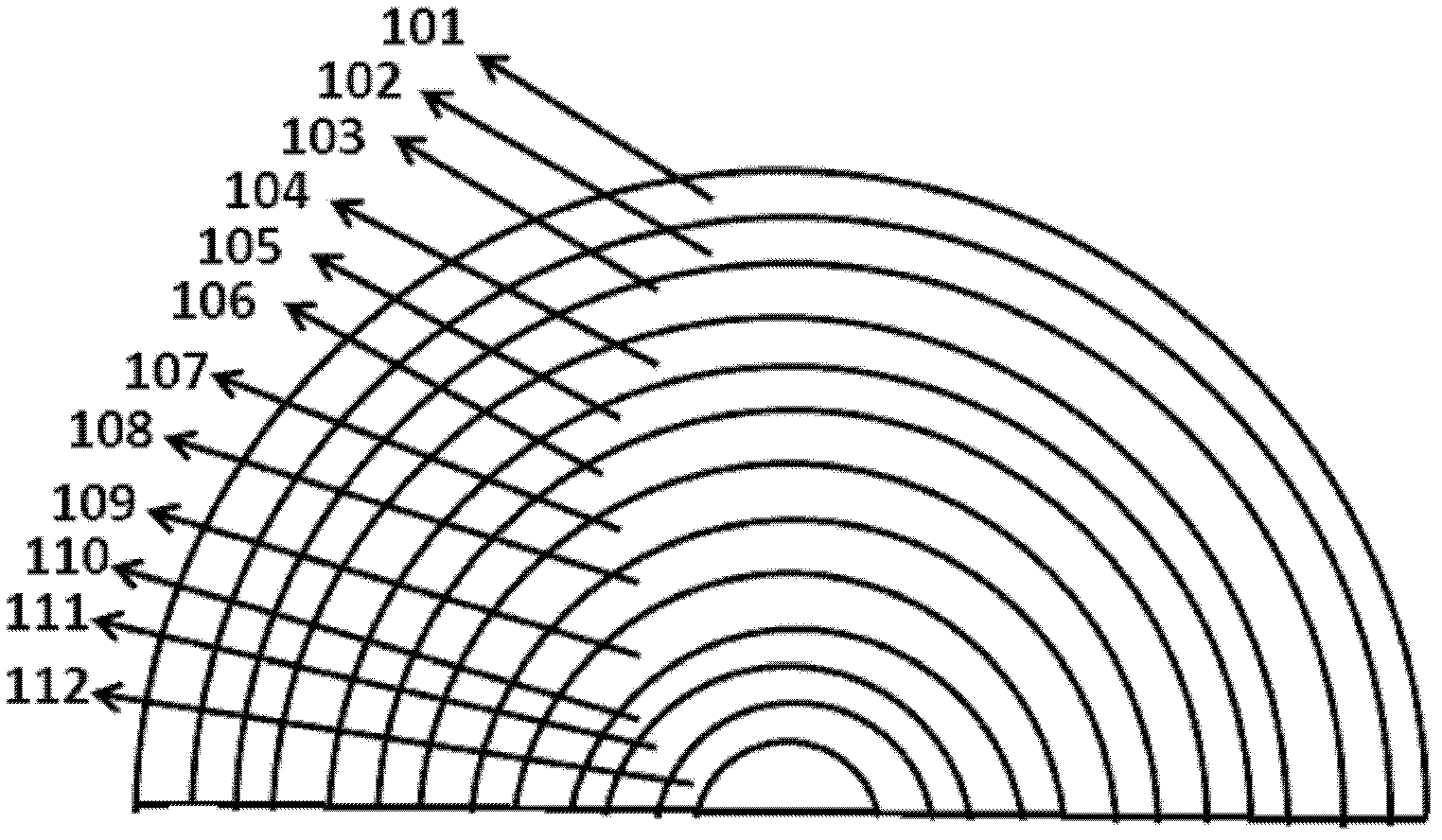

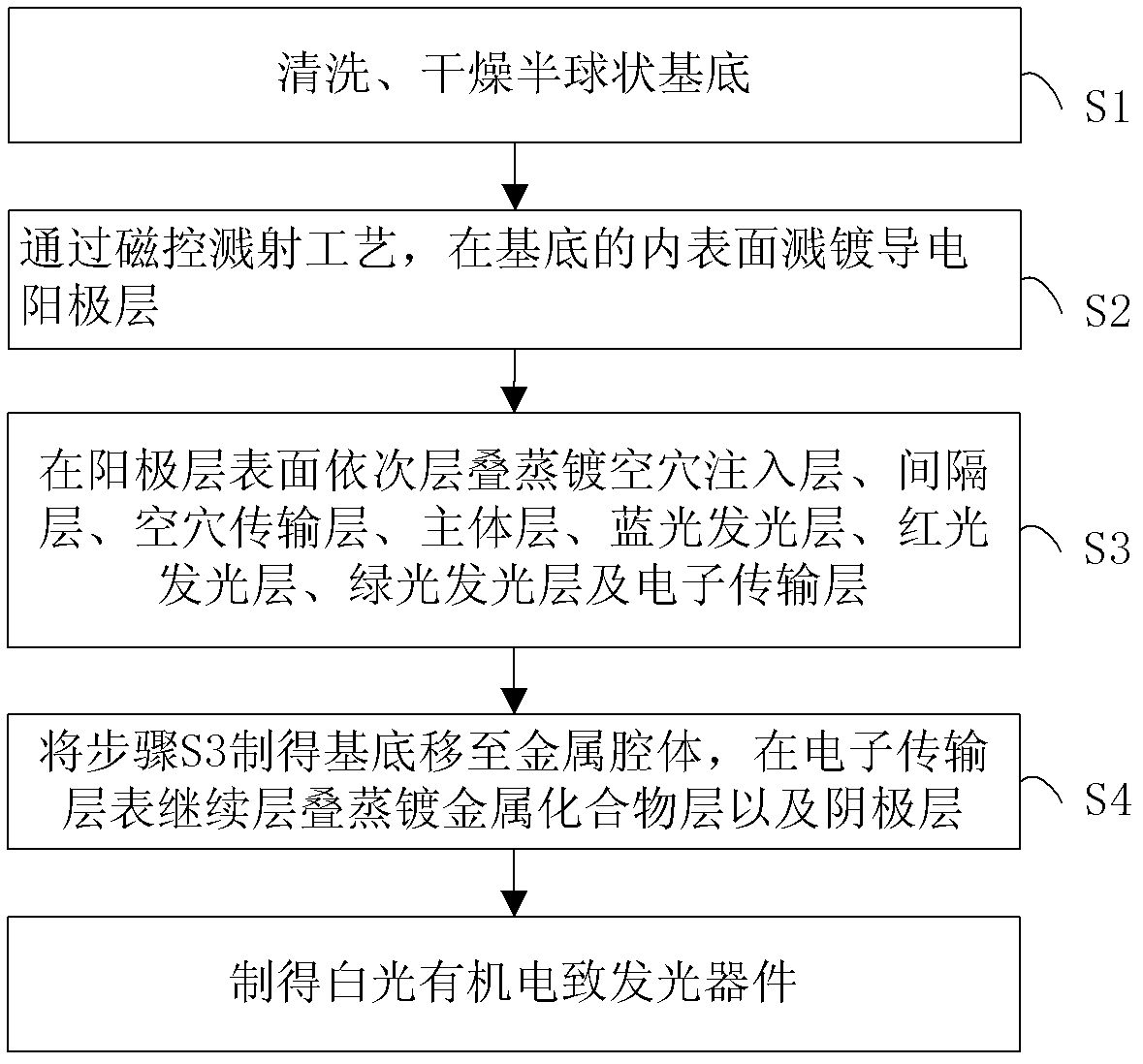

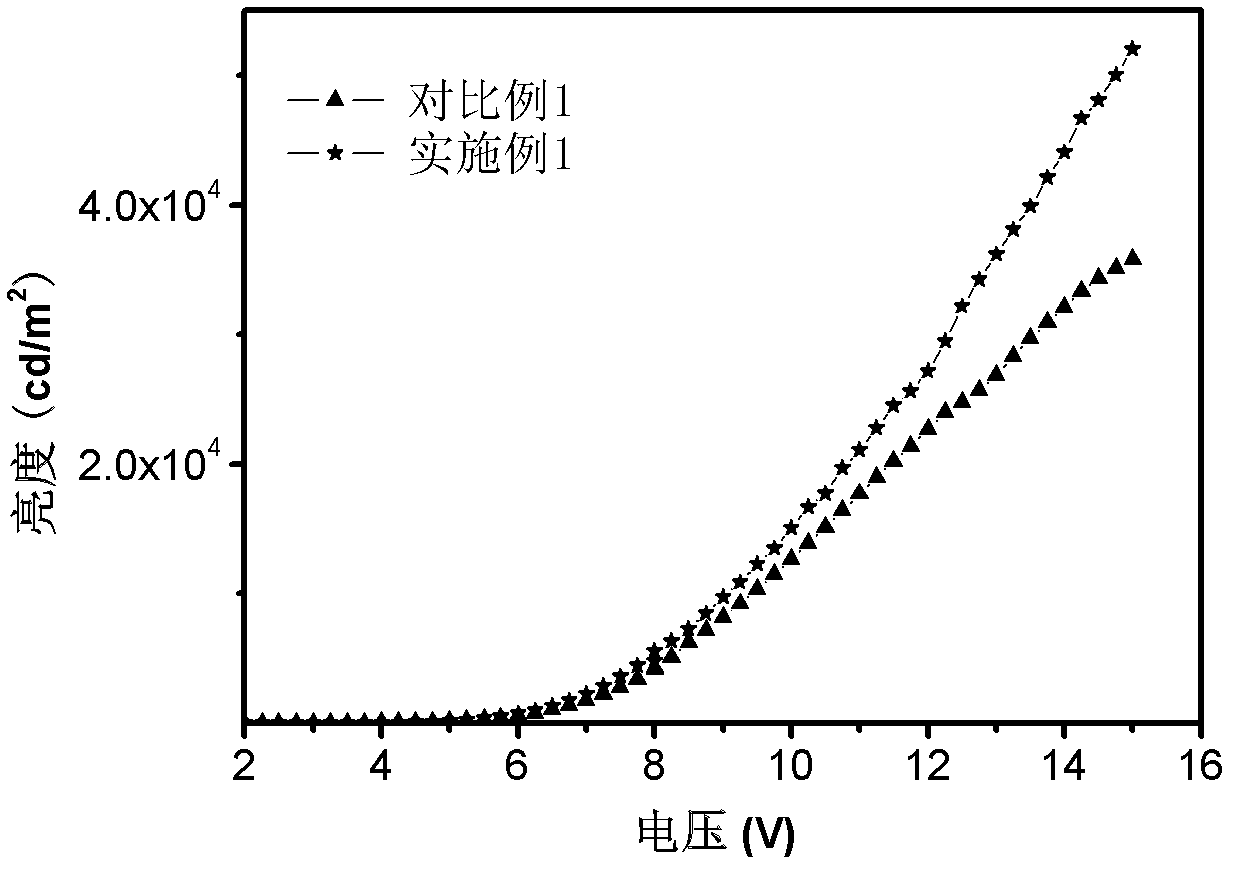

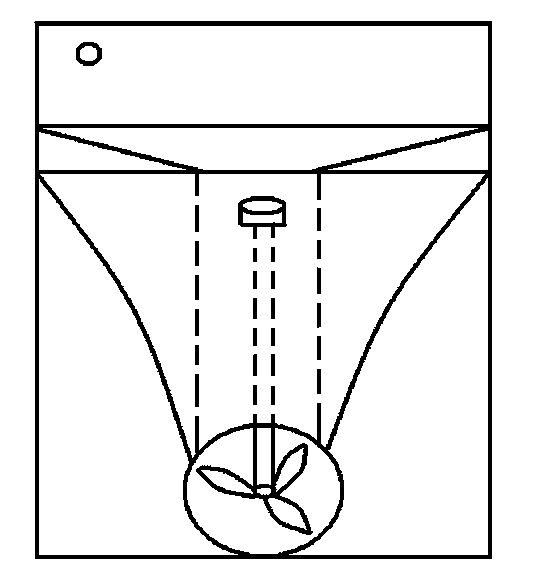

Undoped efficient white organic emitting device and preparation method thereof

InactiveCN103165815AReduce the starting voltageImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingTotal internal reflectionHole injection layer

The invention belongs to the field of photoelectric devices, and discloses an undoped efficient white organic emitting device and a preparation method thereof. The undoped efficient white organic emitting device comprises a hemispherical shell-shaped base, wherein a positive pole layer, a hole injection layer, a spacer layer, a hole transfer layer, a main body layer, a blue light luminous layer, a red light luminous layer, a green light luminous layer, an electron transfer layer, a metallic compound layer and a negative pole layer are stacked on the inner surface of the hemispherical shell-shaped base in sequence. Due to the fact that the undoped efficient white organic emitting device is hemispherical, total internal reflection loss caused by the difference between the refractive index of the luminous layers and the refractive index of the air is refracted out through a curved surface, loss caused by the lateral waves of an organic layer can be captured, and thus luminous efficiency is improved greatly.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

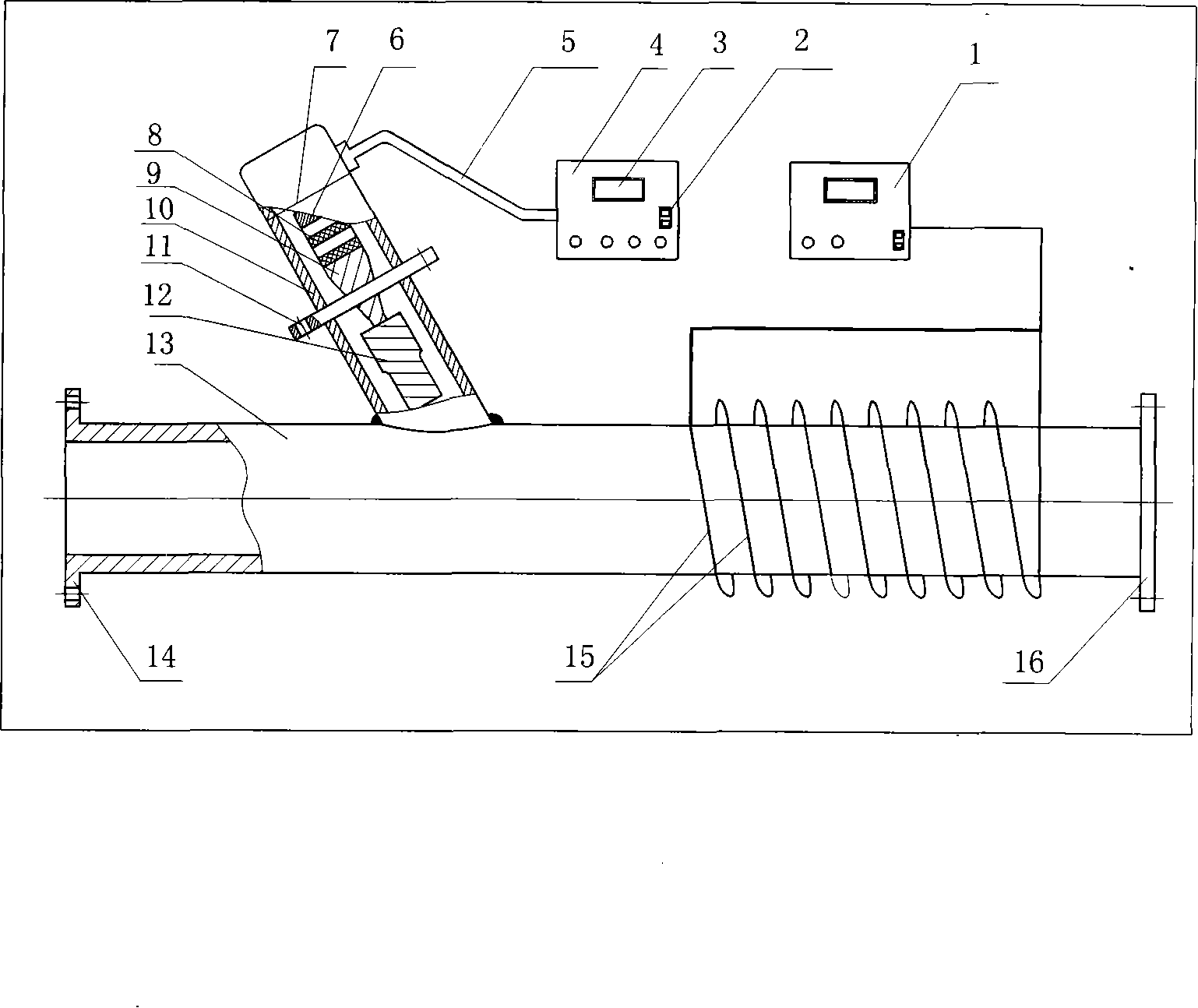

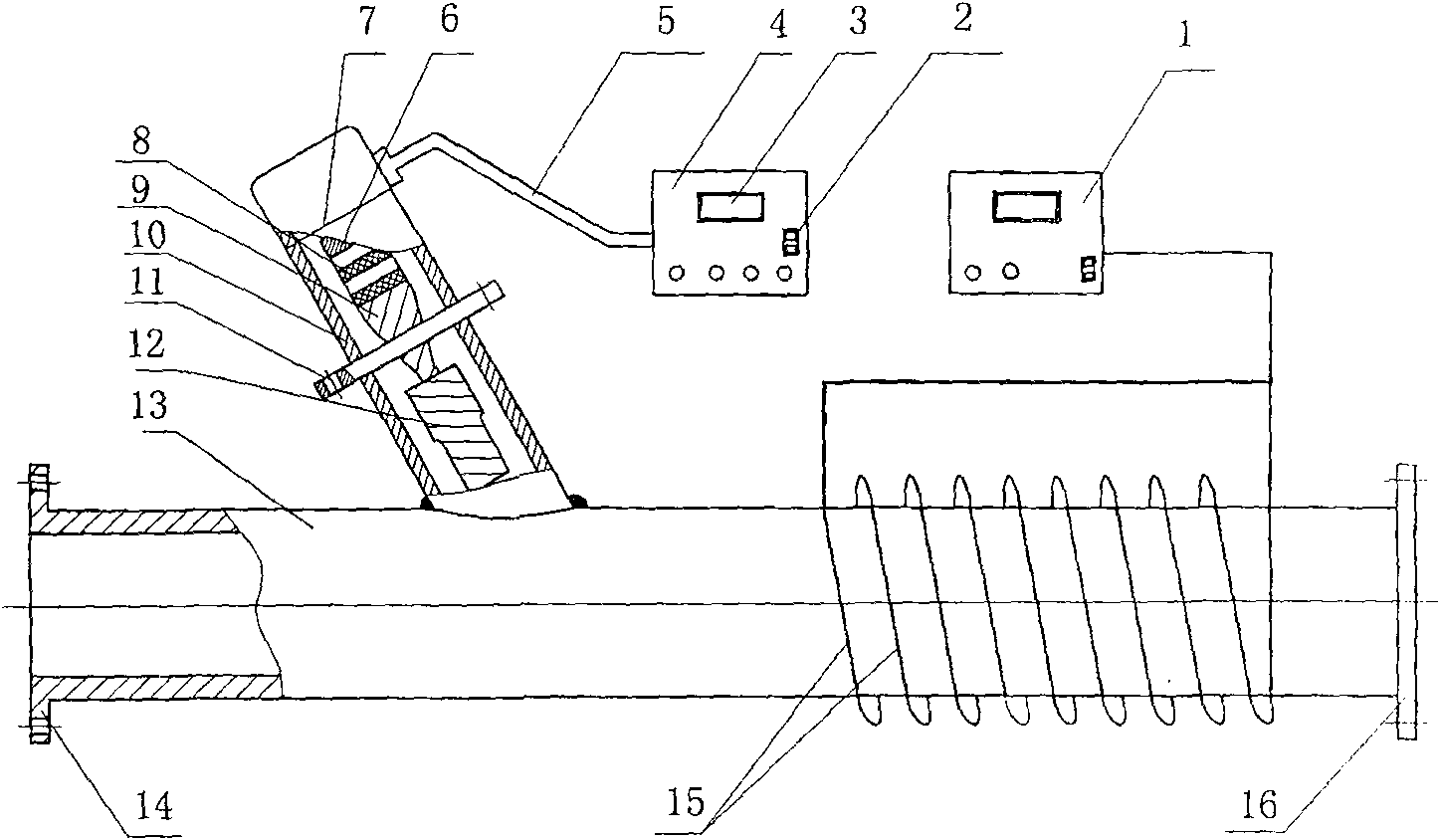

Remote digital type ultrasound wave/frequency conversion antiscaling descaling equipment

InactiveCN101108383AHelp clearReduce oxidation corrosionWater/sewage treatment with mechanical oscillationsMechanical vibrations separationCavitationTransformer

A long distance digital supersonic wave / variable frequency antiscale and descale equipment is provided, which is composed of an inductance power, a digital module, a digital crystal displayer, a supersonic power, a cable conductor, a transducer, a protecting cover, a ring piezoelectricity ceramic plate, a metal amplitude transformer, an engine body, a flange, a metal energy collecting block, a pipeline, a pipeline front flange, a rear flange, an inductance coil. Wherein, the supersonic wave engine and the pipeline have an ideal inclined angle range of 30 to 60 degree and are welded on the pipeline, the communication of the supersonic wave and the flow direction are same. As that, the invention in not only helpful to the communication of the supersonic wave and is not easy to produce standing wave and rejection wave, but also reduces the repeat shocking to the pipeline of the cavitation effect of the supersonic wave, thus prolonging the service life of the pipeline. A twist wire connected with multicircuit or variable frequency circuit board is winded on the industrial pipeline. The invention uses the cavitation effect of the supersonic wave to work on the dirt on the inner wall of the pipeline in lateral wave and vertical wave, which realizes the descaling of equipment, and the long and short distance in the pipeline, and procede variable frequency antiscale and descale to the pipeline fluid in distance by using variable frequency magnetic field. The equipment can remove furr in advance, but also can prevent forming dirt, which can make the longer pipeline provided with no furr producing condition, ensures the whole pipeline smooth. The invention saves water resource, improves equipment efficiency, reduces the maintaining cost and prolongs the service life of the equipment, which can realize digital controlling and automatic protection functions.

Owner:刘利华

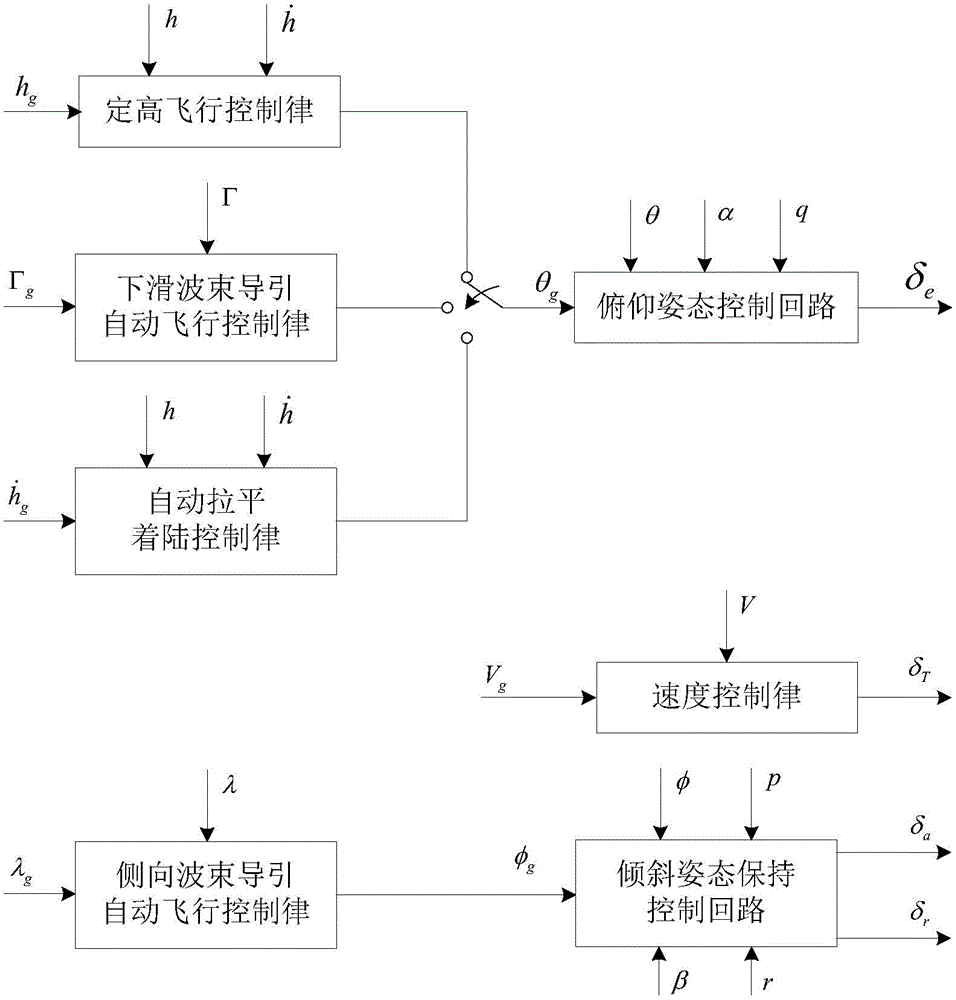

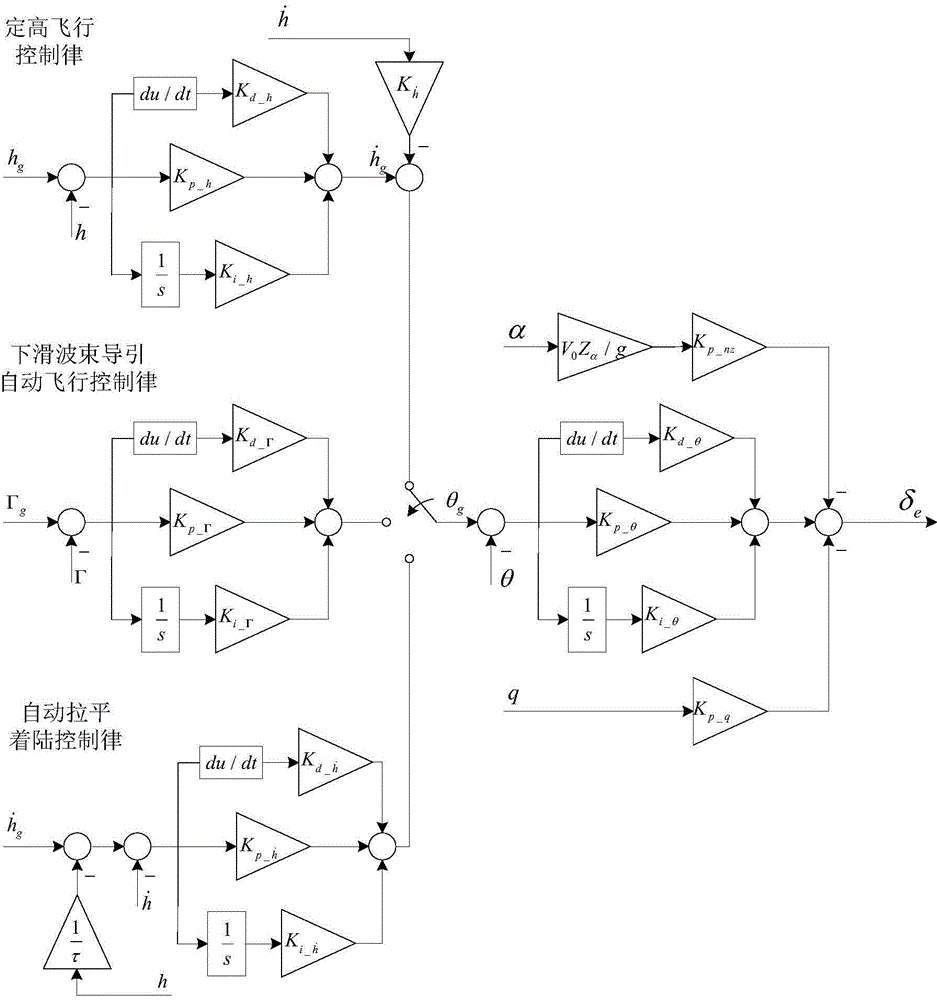

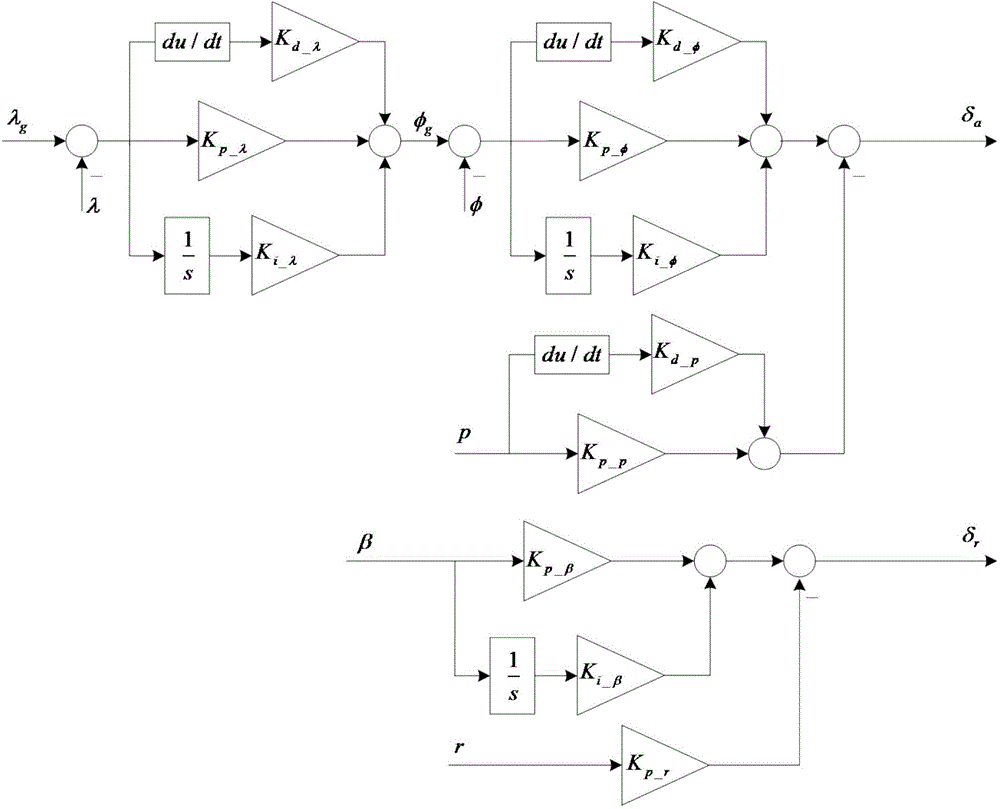

Corporate aircraft descending and landing control method

InactiveCN104656661AMeet the speed requirementsAdaptive controlPosition/course control in three dimensionsGuidance controlControl system

The invention discloses a corporate aircraft descending and landing control method. The corporate aircraft descending and landing control method is characterized in that a gliding wave beam guidance control system, a lateral wave beam guidance control system and a speed keeping control system are included, wherein the gliding wave beam guidance control system takes a pitch attitude control loop as an inner loop, selects a corresponding control law as an outer loop according to three stages in the corporate aircraft descending and landing process and realizes that a corporate aircraft accurately tracks and keeps a predetermined flight trajectory under the guidance of a gliding wave beam; the lateral wave beam guidance control system takes an inclined posture keeping control loop as an inner loop, takes a lateral wave beam guidance automatic flight control law as an outer loop, takes deviation angles of a radio wave beam and other intensity lines as controlled volumes of the system and realizes the accurate control of a lateral motion trajectory and a course in the landing process; the speed keeping control system controls the speed of the corporate aircraft and meets the requirements for speed in the corporate aircraft descending and landing process. According to the corporate aircraft descending and landing control method, that the corporate aircraft can accurately track and keep the predetermined flight trajectory under the guidance of the gliding wave beam and a lateral wave beam is ensured, and safe descending and landing of the corporate aircraft is ensured.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Film bulk acoustic wave resonator

ActiveCN108134589AWeaken energyReduce reflected energyImpedence networksUltrasound attenuationThin-film bulk acoustic resonator

The present invention provides a film bulk acoustic wave resonator. The film bulk acoustic wave resonator comprises a substrate, a bottom electrode, a piezoelectric layer and a top electrode which arearranged in order from bottom to top. A reflection interface is arranged between the substrate and the bottom electrode, and in the bottom electrode, the piezoelectric layer and the top electrode, atleast one layer is different from the other layers in shape. On the premise that process layers are not extra added, a bump or a deformed block is added to regulate the shape of the top electrode, the piezoelectric layer or the bottom electrode to perform energy attenuation of lateral waves, reduce the reflection energy of the lateral waves and improve a Q value.

Owner:WUHAN YANXI MICRO COMPONENTS CO LTD

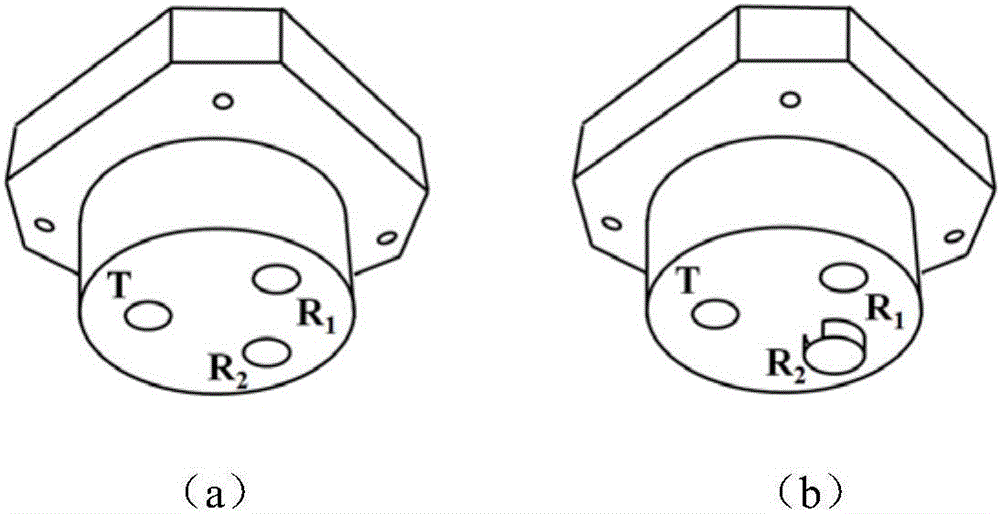

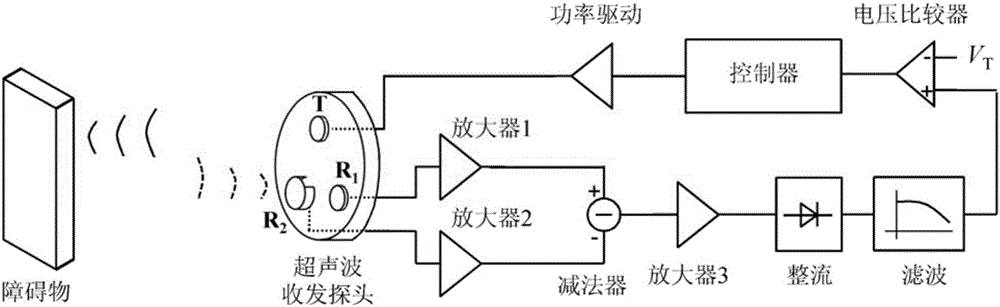

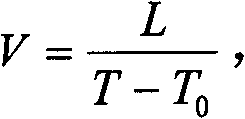

Non-blind area ultrasonic distance measurement probe and distance measurement method

PendingCN106483526AEliminates the effects of crosstalk thru wavesSimple structureAcoustic wave reradiationTransmitterUltrasound

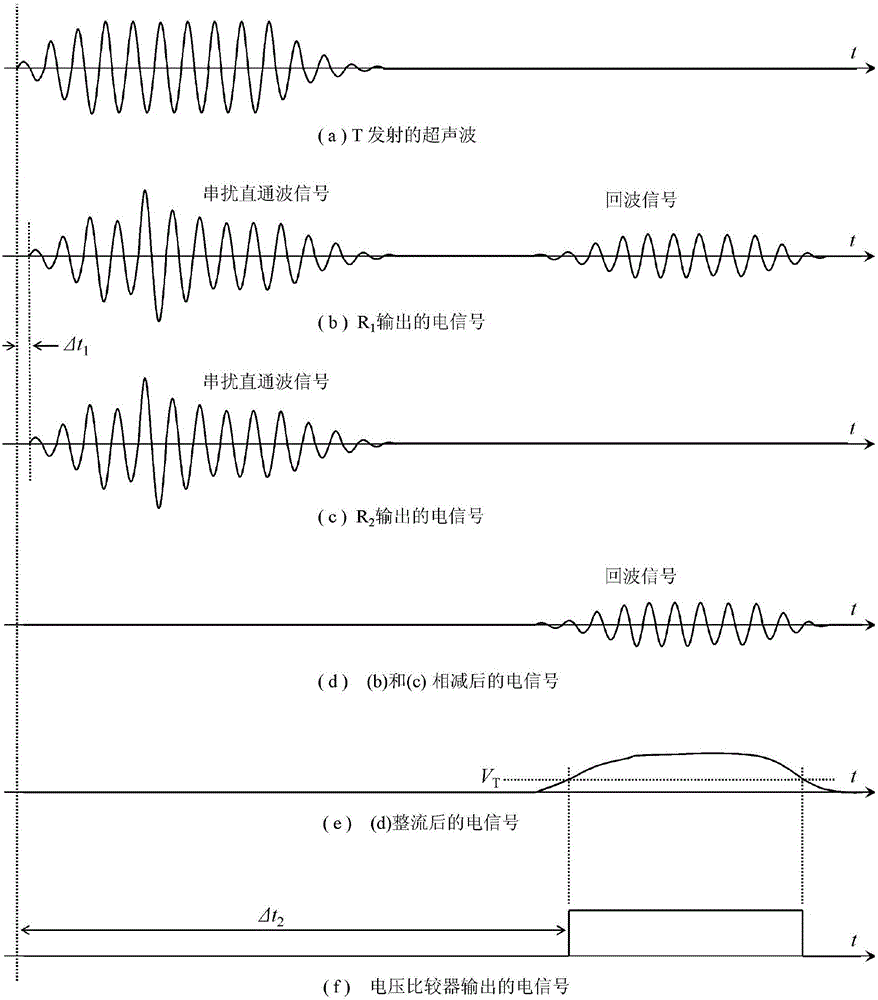

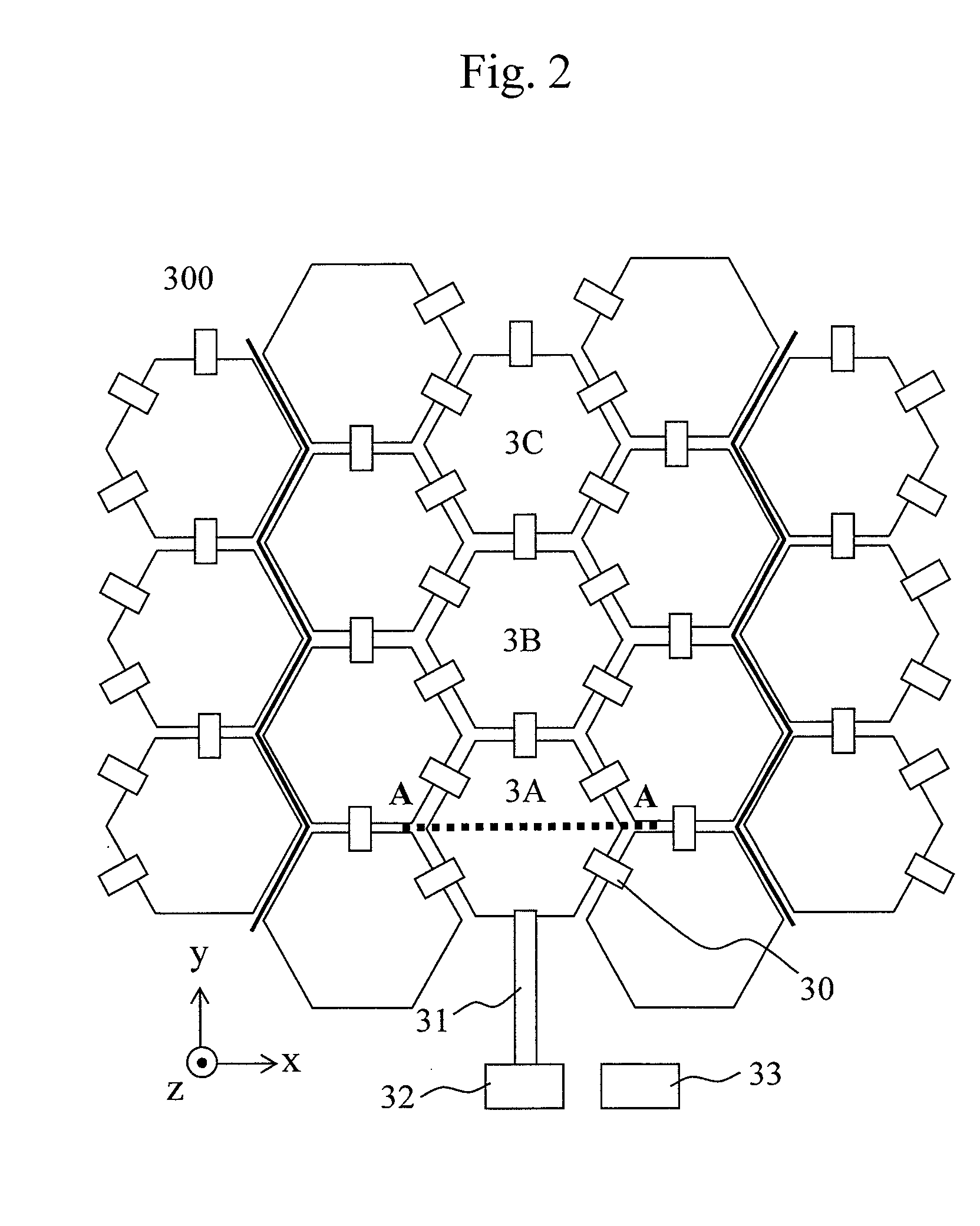

The present invention discloses a non-blind area ultrasonic distance measurement probe and distance measurement method. The probe includes an ultrasonic transmitter T, a first ultrasonic receiver R1 and a second ultrasonic receiver R2 which are located on the same plane; a distance from the first ultrasonic receiver R1 to the ultrasonic transmitter T is equal to a distance from the second ultrasonic receiver R2 to the ultrasonic transmitter T; the first ultrasonic receiver R1 and the second ultrasonic receiver R2 are located at the same side of the ultrasonic transmitter T; the second ultrasonic receiver R2 is covered with a container with a groove formed at the side surface of the container, so that echoes can be isolated; the direction of the groove of the container direclty faces the ultrasonic transmitter T; and the first ultrasonic receiver R1 and the second ultrasonic receiver R2 can be simultaneously subjected to the influence of crosstalk lateral waves of the ultrasonic transmitter T in an equal-amplitude manner. The influence of the crosstalk lateral waves is eliminated through an anti-phase superposition method, and therefore, non-blind area ultrasonic distance measurement can be realized. The non-blind area ultrasonic distance measurement probe and distance measurement method have the advantages of simple structure, easiness in implementation and excellent effects.

Owner:杭州立方控股股份有限公司

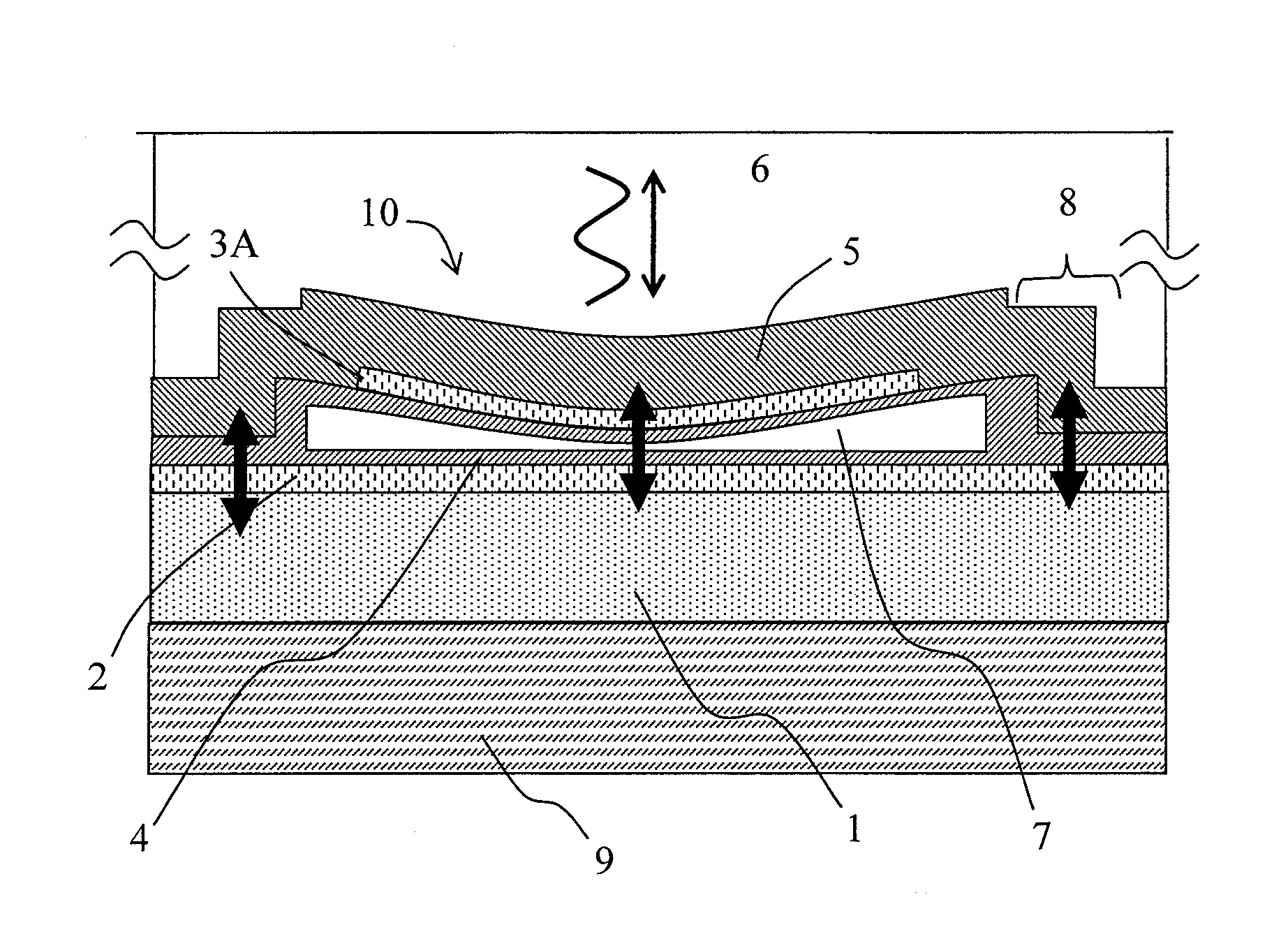

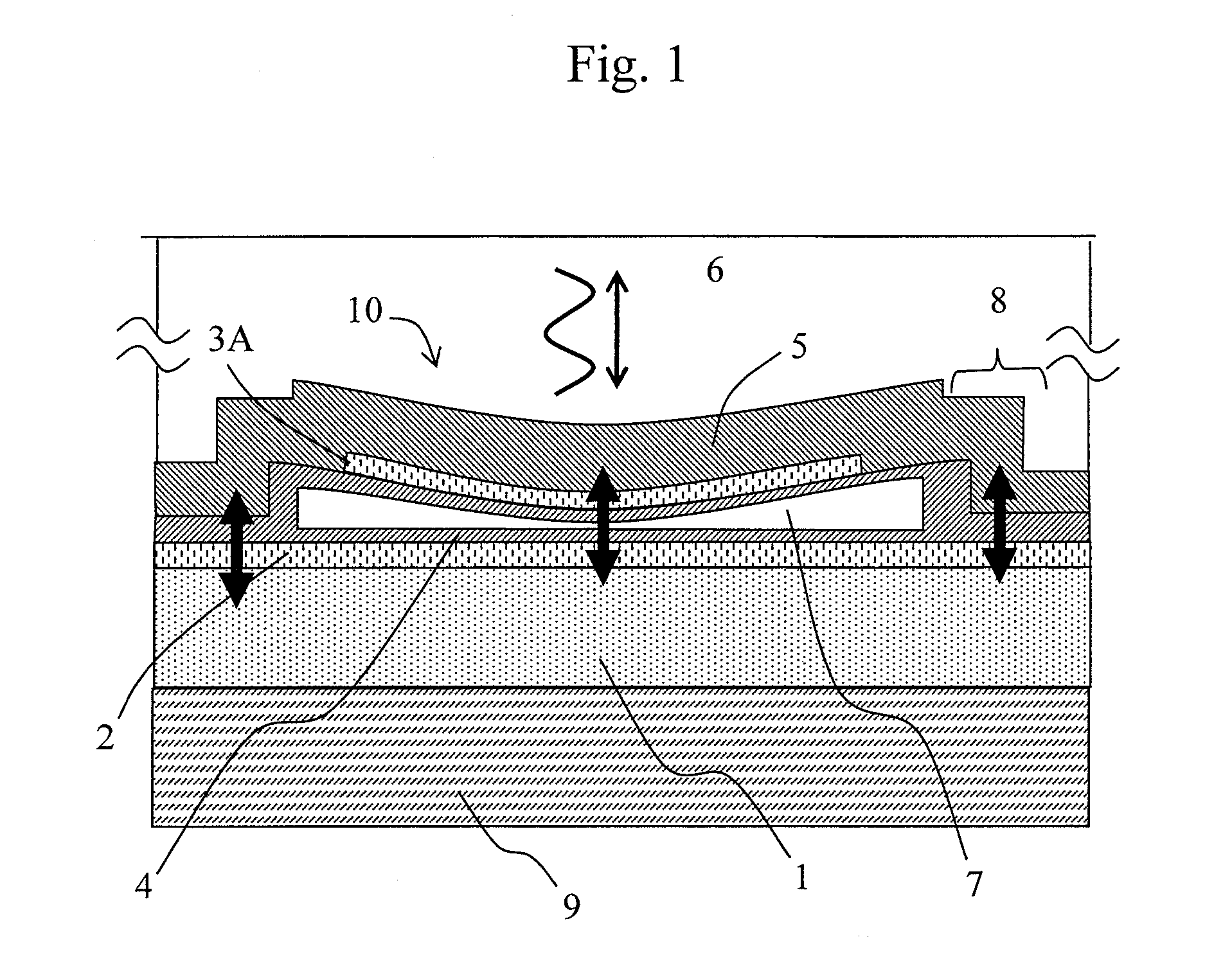

Ultrasonic probe and ultrasonic imaging apparatus

ActiveUS8760974B2Suppress undesired response componentsAvoid artifactsUltrasonic/sonic/infrasonic diagnosticsMechanical vibrations separationSonificationUltrasonic imaging

Artifacts due to lateral wave that occurs in a substrate of a Capacitive Micro-machined Ultrasonic Transducer is reduced. The substrate thickness of the ultrasonic transducer is set in an optimum range to efficiently radiate the energy of lateral wave in the sensitive band 91 of the ultrasonic transducer to the outside so that the lateral wave is attenuated thereby reducing the artifacts in ultrasonic imaging.

Owner:FUJIFILM HEALTHCARE CORP

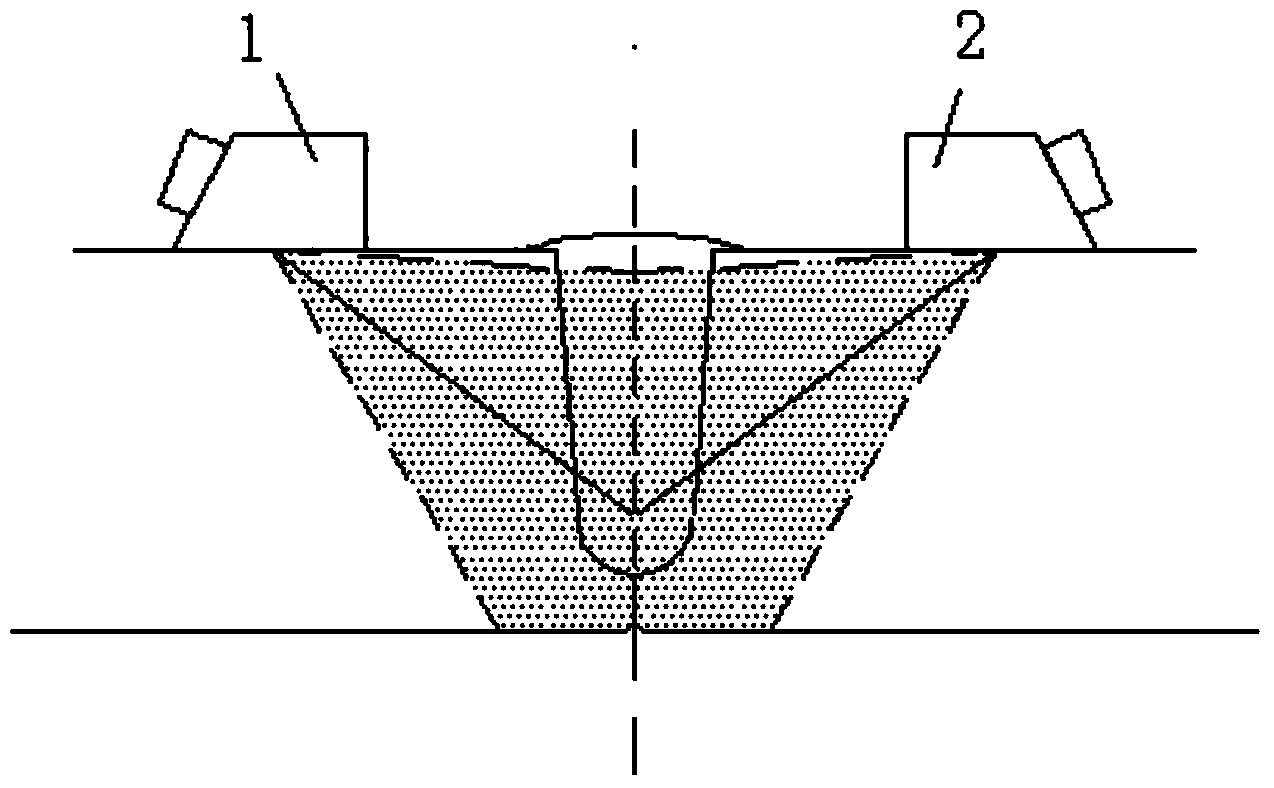

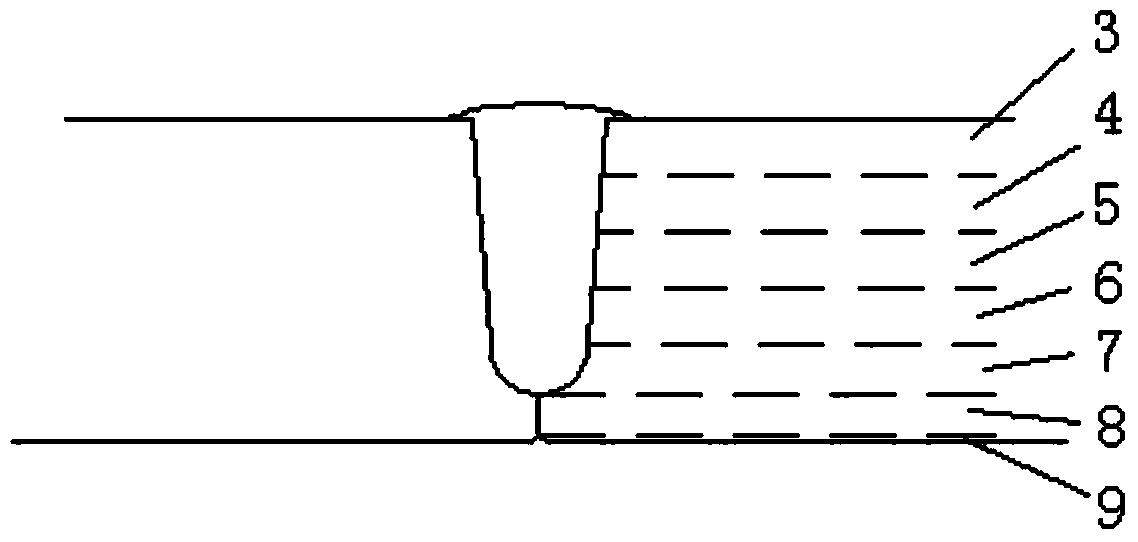

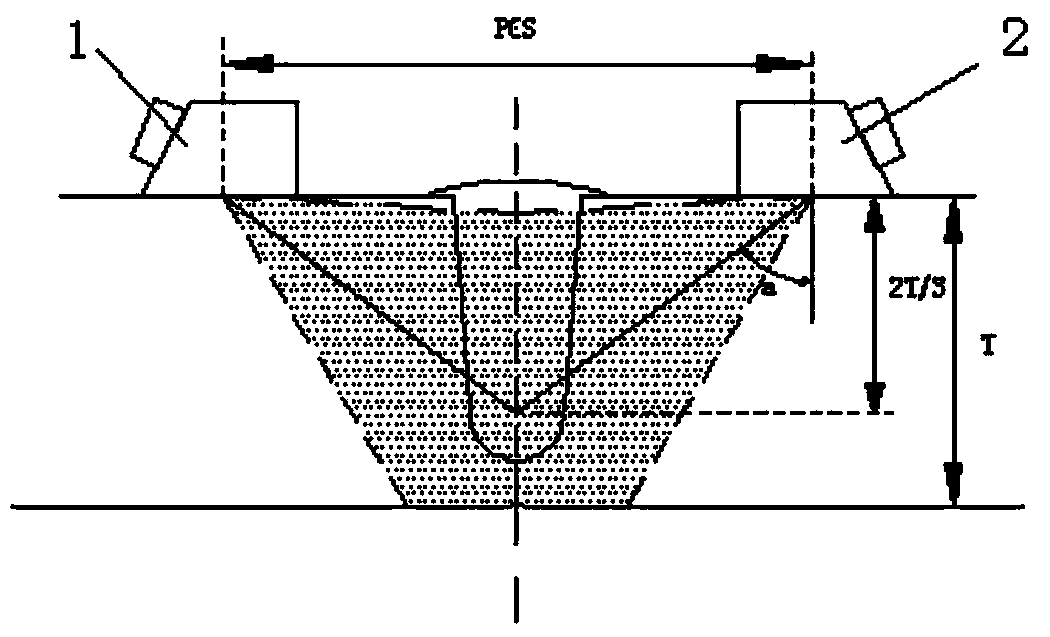

Ultrasonic detection method for thick-walled tube girth weld surface defect diffraction time difference

ActiveCN105717197AReduce energy lossImprove defect detection rateAnalysing solids using sonic/ultrasonic/infrasonic wavesDetection rateLateral wave

The invention provides an ultrasonic detection method for the thick-walled tube girth weld surface defect diffraction time difference. The method includes the steps that firstly, a reference block weld is detected, and arranged simulated defects are verified to be detected; then two transverse wave angle probes, namely, the transmitting probe (1) and the receiving probe (2) are symmetrically placed on the outer surfaces of base metal on the two sides of a detected thick-walled tube girth weld (3), the center distance between the probes is adjusted to be proper to adjust lateral waves to 40% to 80% of the full screen height, and the detected thick-walled tube girth weld is detected in a non-parallel scanning mode. The 65-degree transverse wave angle probes are adopted for detection, compared with an existing detection method, energy loss of the probes is small, and detection sensitivity is greatly improved. The detection rate of defects such as round air holes and transverse cracks with dot-shaped defect characteristics can be remarkably improved, wherein the defects are formed on the surface layer of the weld. The detection method cannot be disturbed by various deformation waves of bottom waves.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO +1

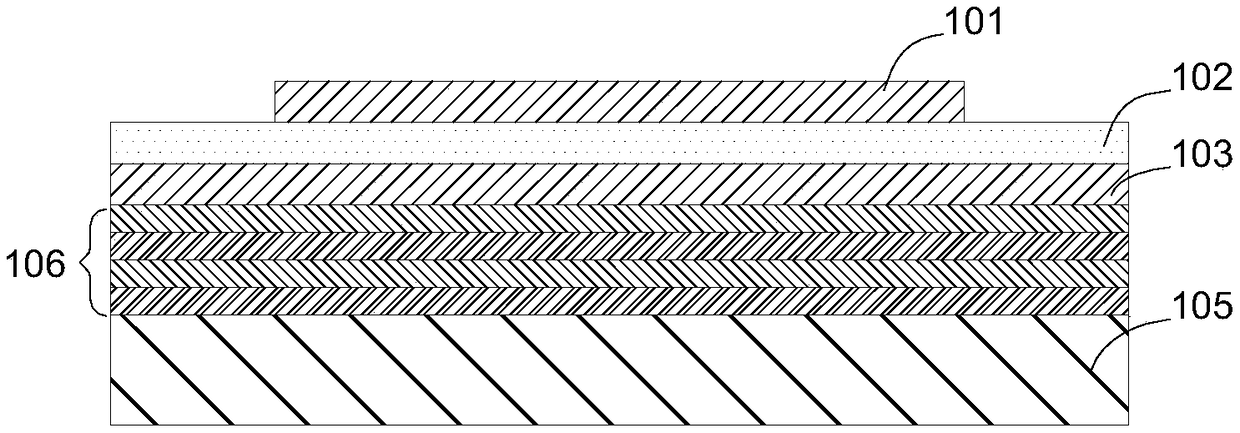

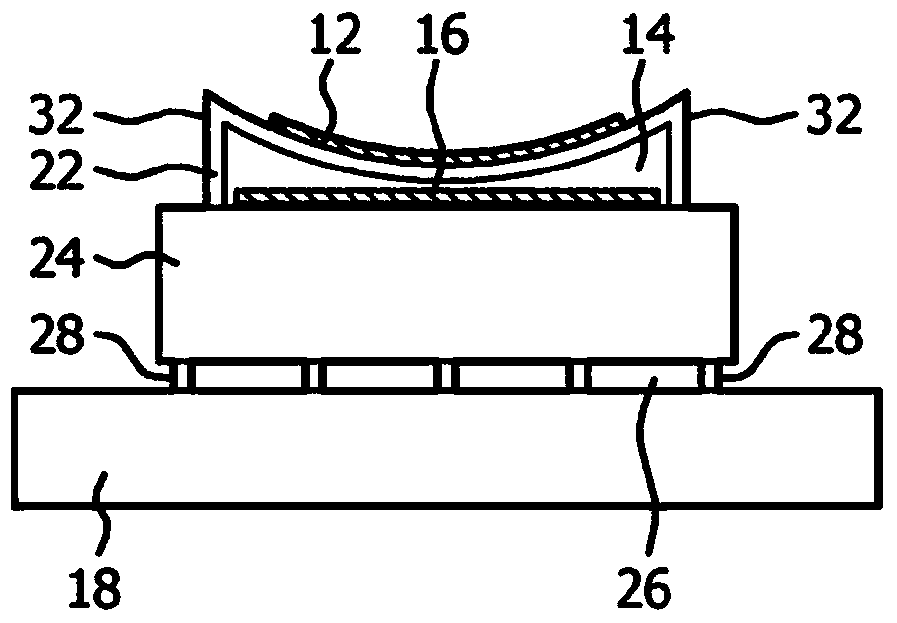

Ultrasonic cmut with suppressed acoustic coupling to the substrate

ActiveCN103501922AUltrasonic/sonic/infrasonic diagnosticsSubsonic/sonic/ultrasonic wave measurementAcoustic energyClassical mechanics

An array of cMUT cells are formed on individually isolated massive plates on a substrate. The mass of each plate provides an inertial force in opposition to the force and motion of transmission by the cell which reduces the resultant translation of motion in the plate. The reduction in motion results in less coupling of acoustic energy into the substrate and contamination of the signals of adjacent cMUT cells by lateral waves. The unwanted wave coupling into the substrate can be further damped by compliant or sparse periodic mounting of the massive plates on the substrate.

Owner:KONINKLJIJKE PHILIPS NV

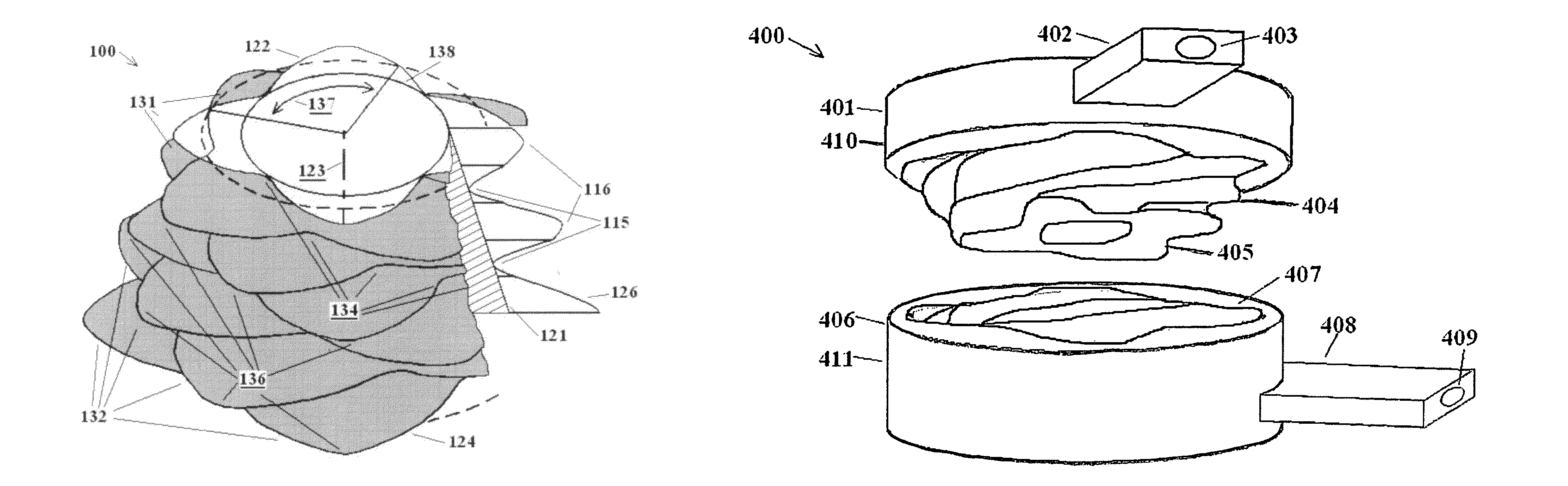

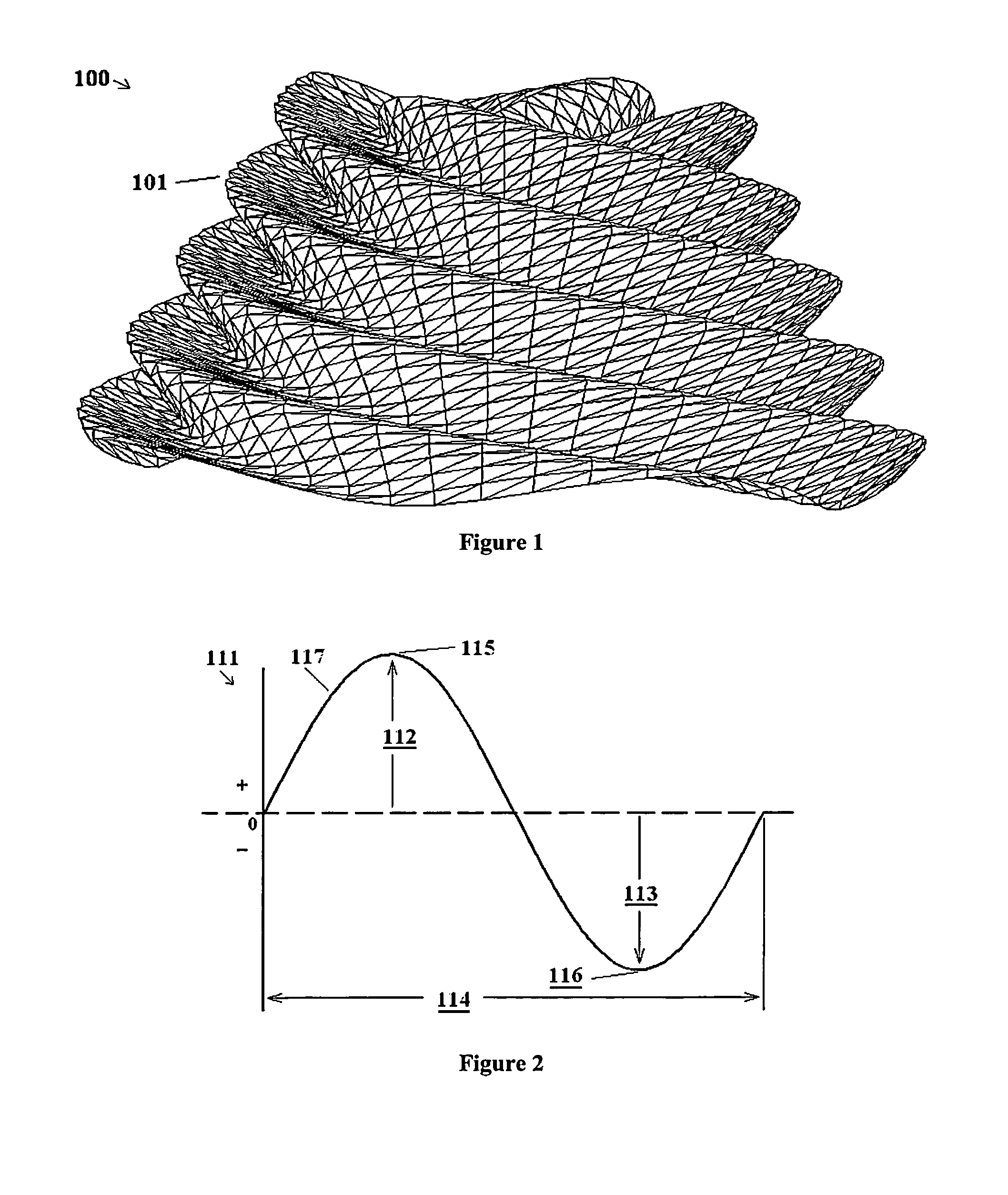

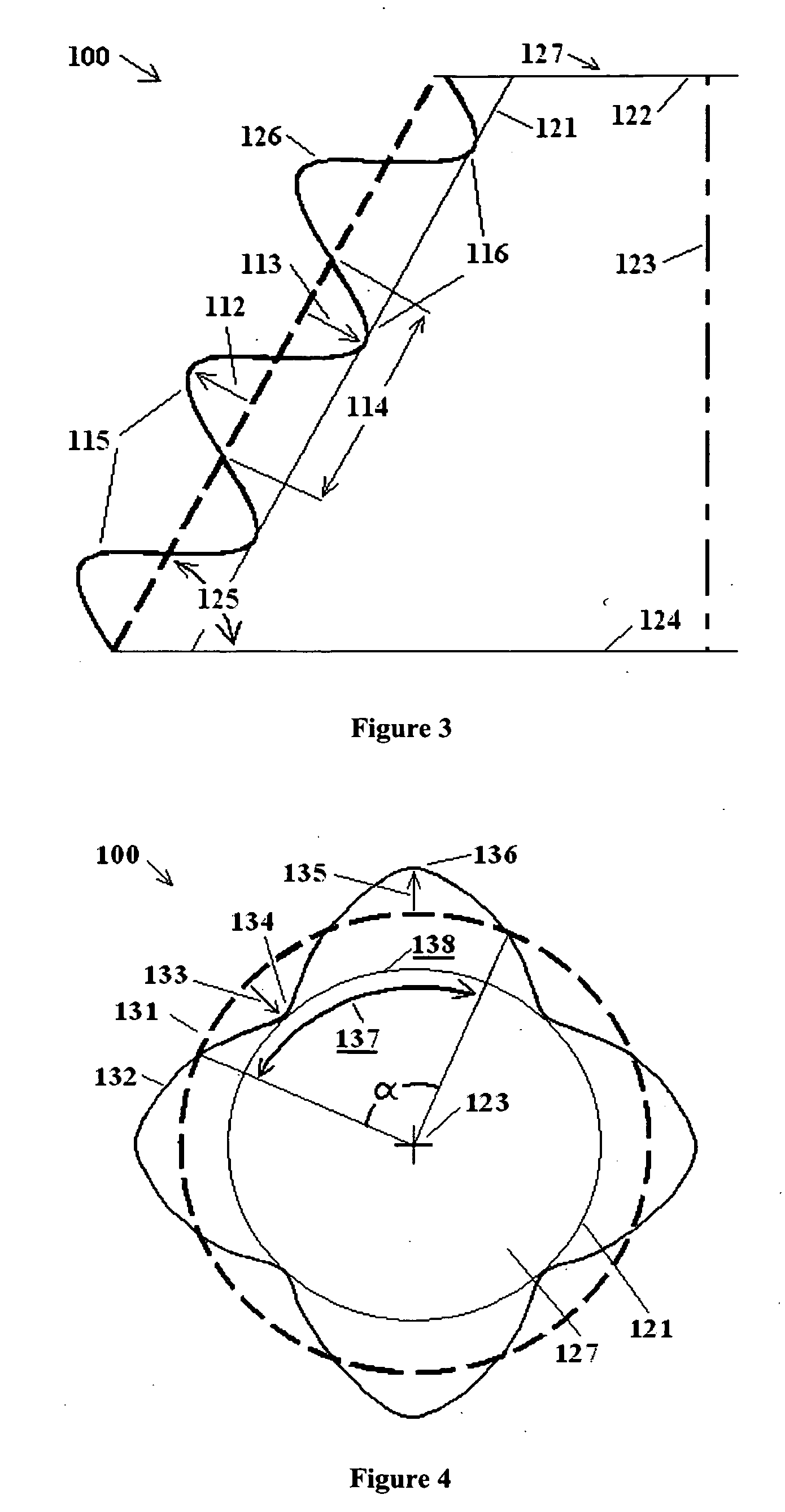

Threaded fastener and fastener system

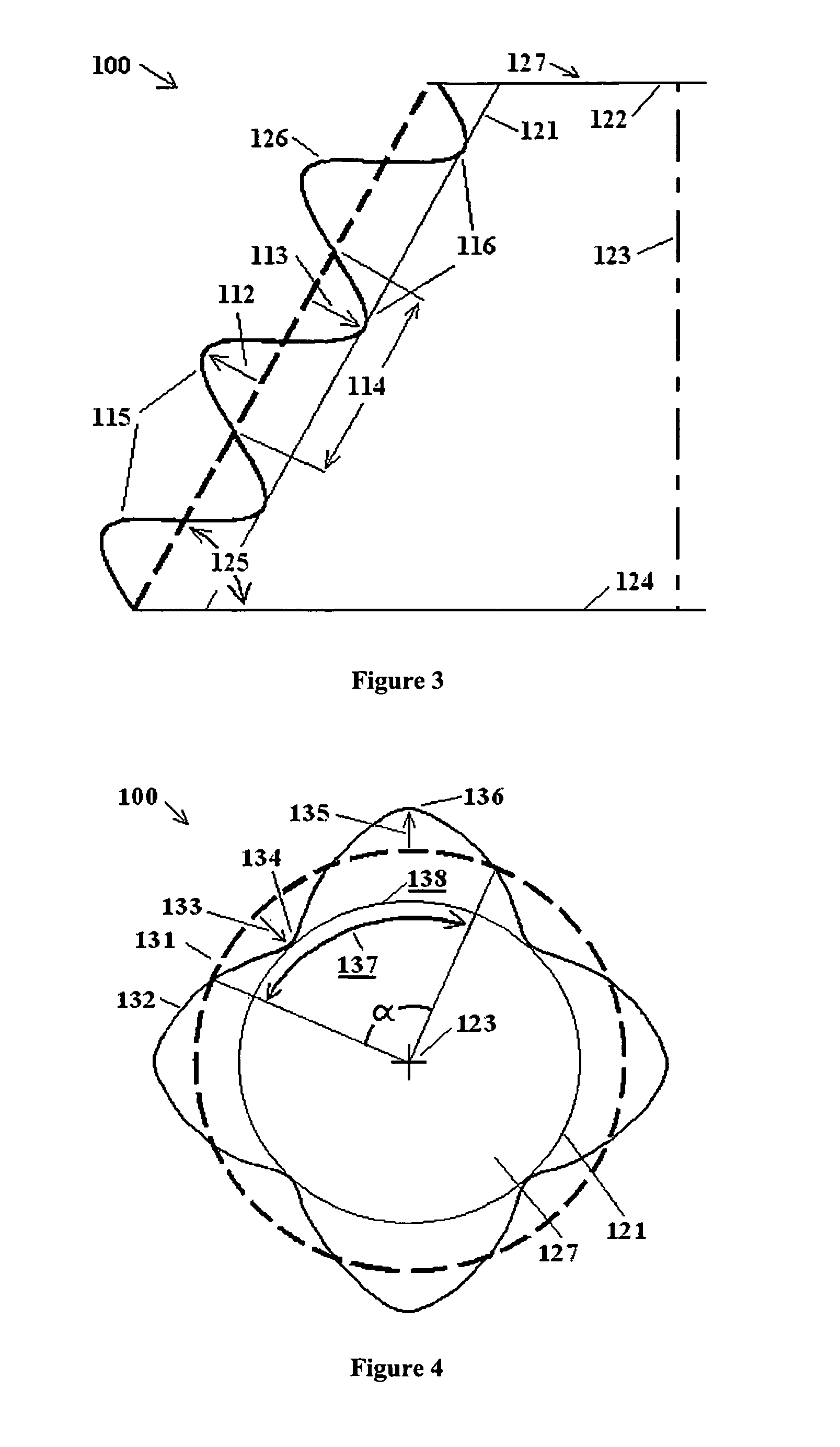

A wave threaded fastener and system. A wave thread extends from the outer surface of the body and is made up of a profile wave and a lateral wave. The profile wave includes a plurality of profile crests and profile roots defining a plurality of profile thread widths. The lateral wave includes at least one lateral crest and at least one lateral root defining at least one wave period. Each wave period forms a period arc having a period arc angle and the sum of all period arc angles about the lateral wave equals three hundred and sixty degrees. Each of the profile crests and roots are aligned with corresponding lateral crests and roots and the wave thread travels one profile thread width per each period arc traveled.

Owner:VAN COR DALE E

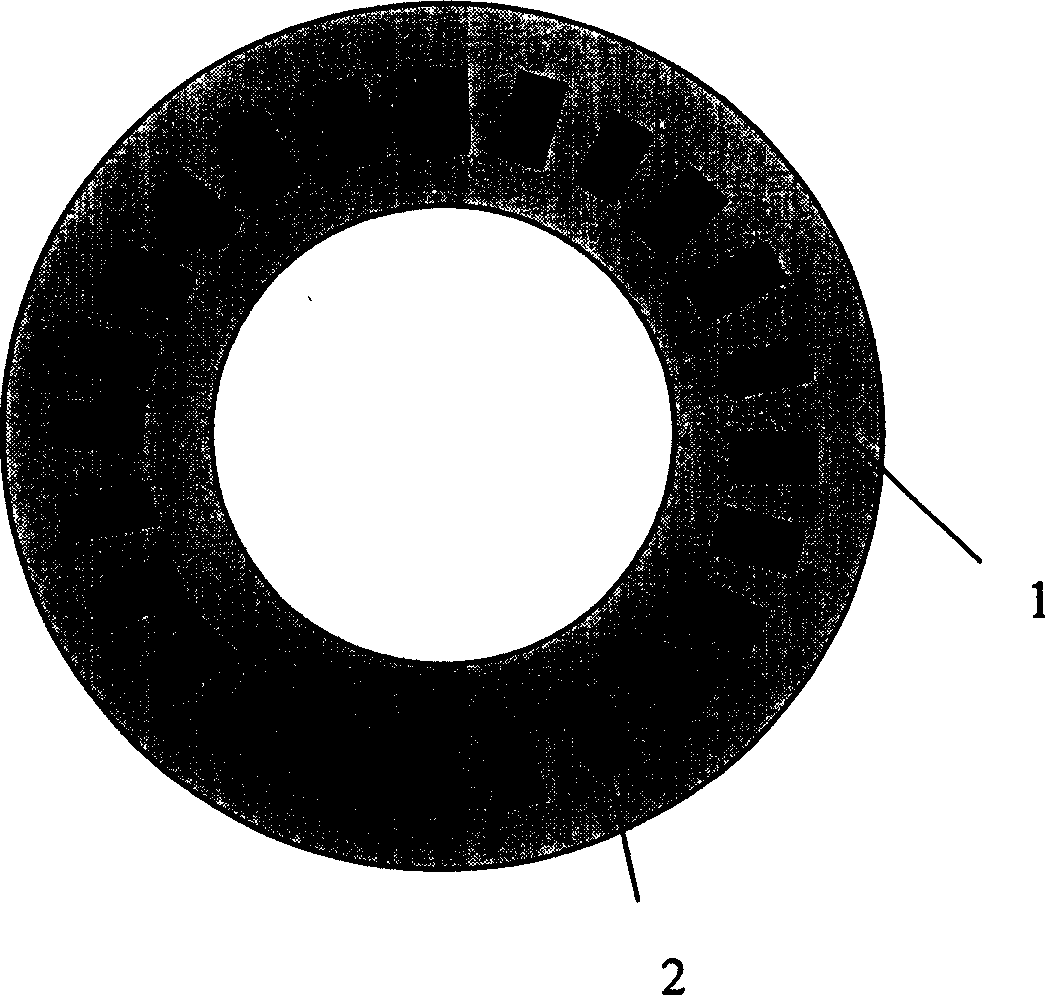

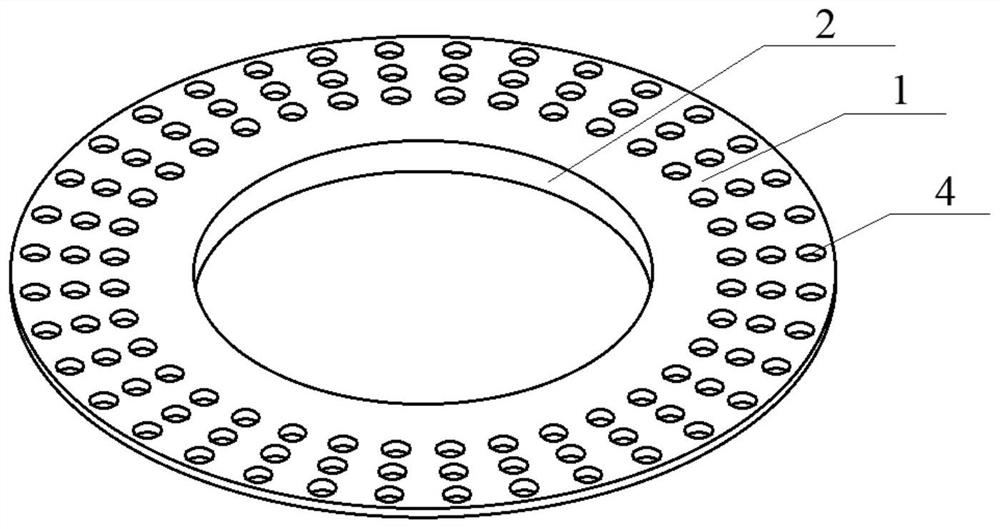

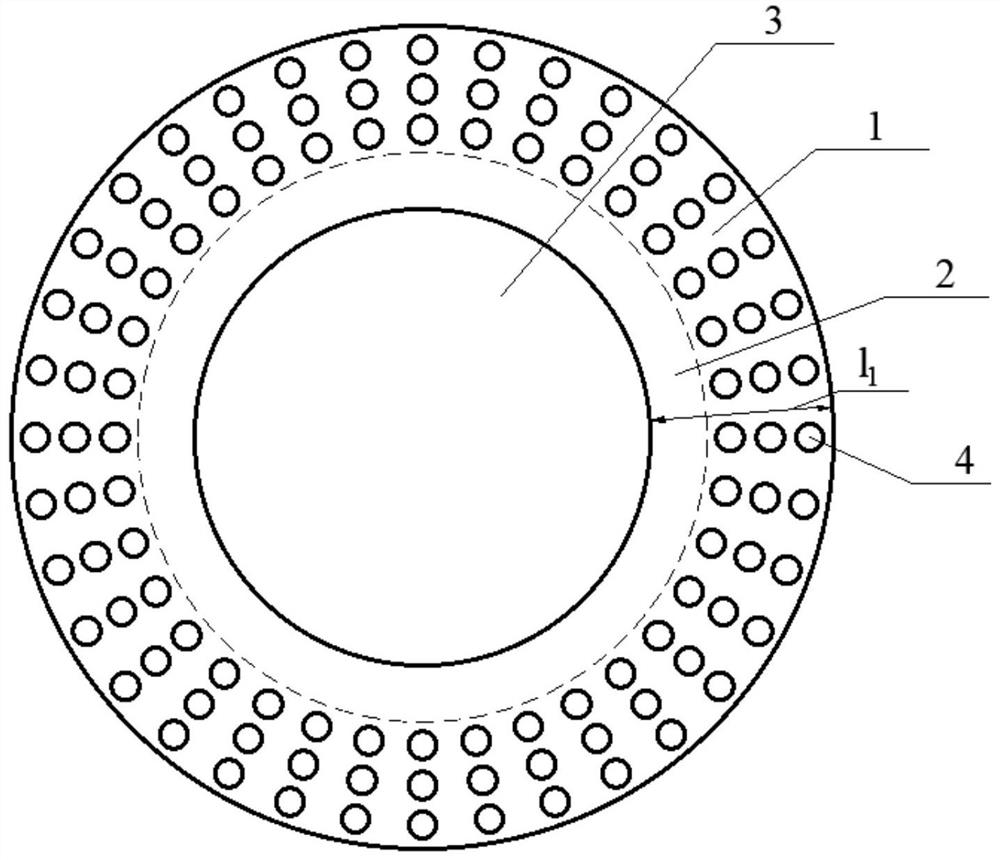

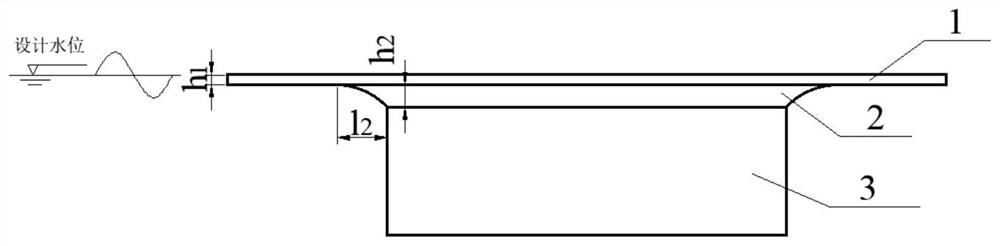

Wave-dissipating and load-reducing protection device for sea-crossing bridge high pile cap foundation

ActiveCN114197401AImproved lateral wave loadsChange wave formClimate change adaptationProtective foundationPile capWave form

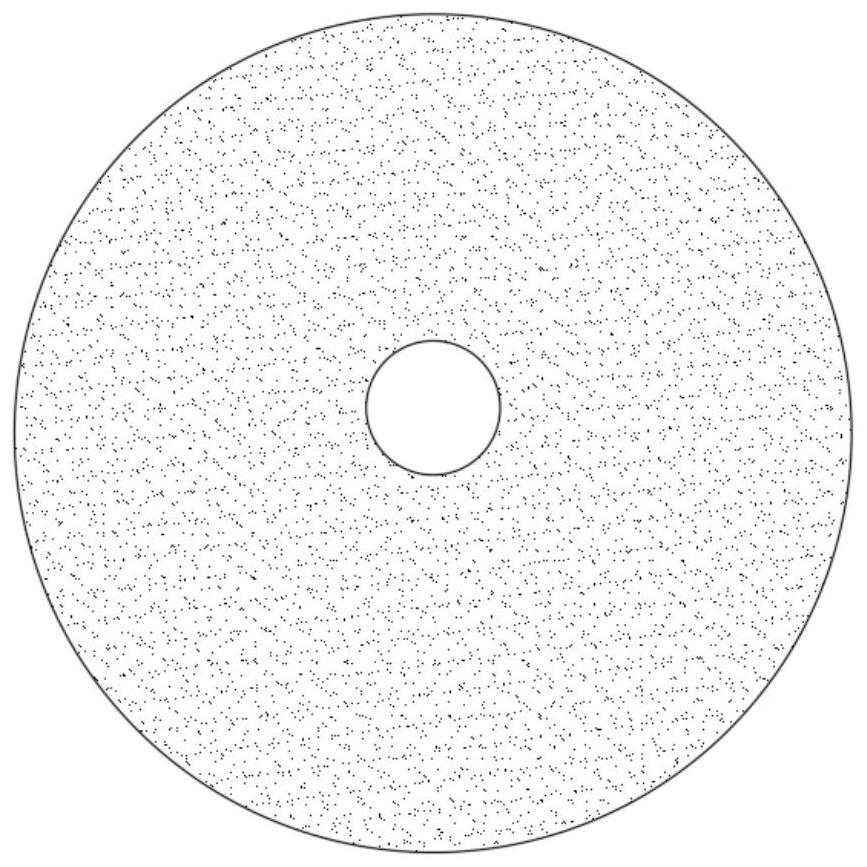

The invention discloses a wave-dissipating and load-reducing protection device for a sea-crossing bridge high pile cap foundation, which comprises an annular protection plate and a supporting part, a plurality of uniformly distributed through holes are formed in the annular protection plate, and the through hole rate of the through holes in the annular protection plate is 35%-55%; the annular protective plate is vertically and fixedly connected to the outer surface of the high pile cap, the top face of the annular protective plate is flush with the designed water level, the thickness of the annular protective plate is 1 / 8-1 / 5 of the designed wave height, and the length of the annular protective plate is 1 / 20-1 / 10 of the designed wave length; one end of the supporting component is connected with the lower surface of the ring type protection plate, and the other end of the supporting component is connected with the high pile cap. According to the invention, the perforated ring-type protective plates and the supporting parts can be utilized to obviously improve the lateral wave load of the high-rise pile cap from the three mechanisms of inhibiting the climbing of surface waves, changing the wave form and increasing the energy dissipation of the wave, a certain ship collision prevention capability is provided for the high-rise pile cap foundation of a sea-crossing bridge, and technical support is provided for sea-crossing traffic engineering.

Owner:SOUTHWEST JIAOTONG UNIV

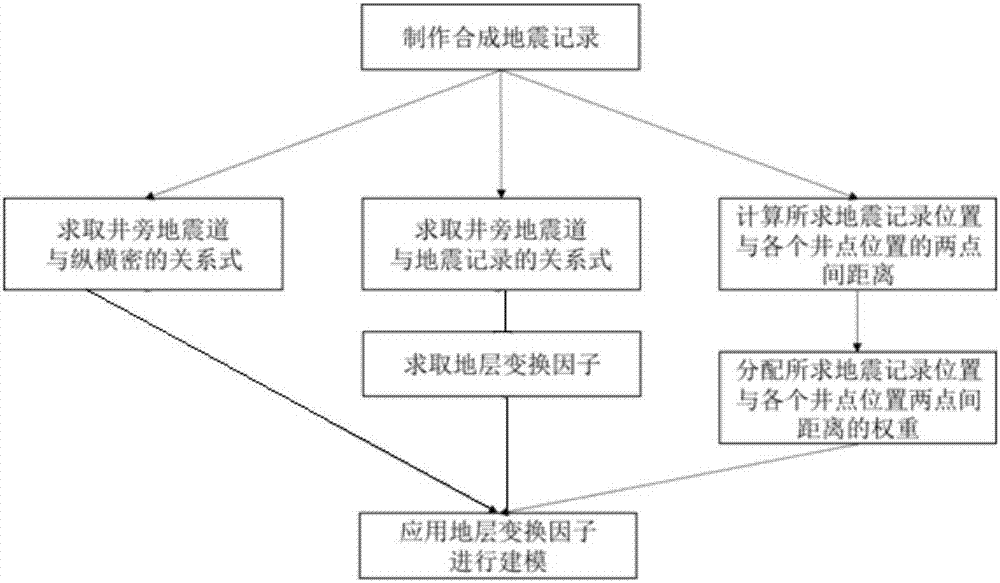

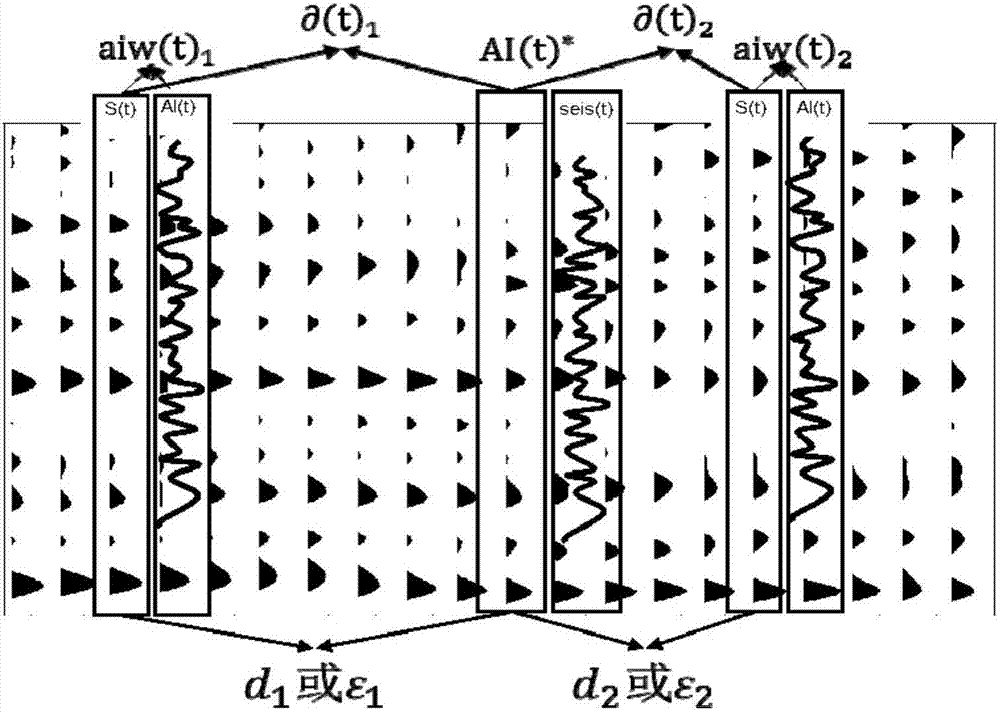

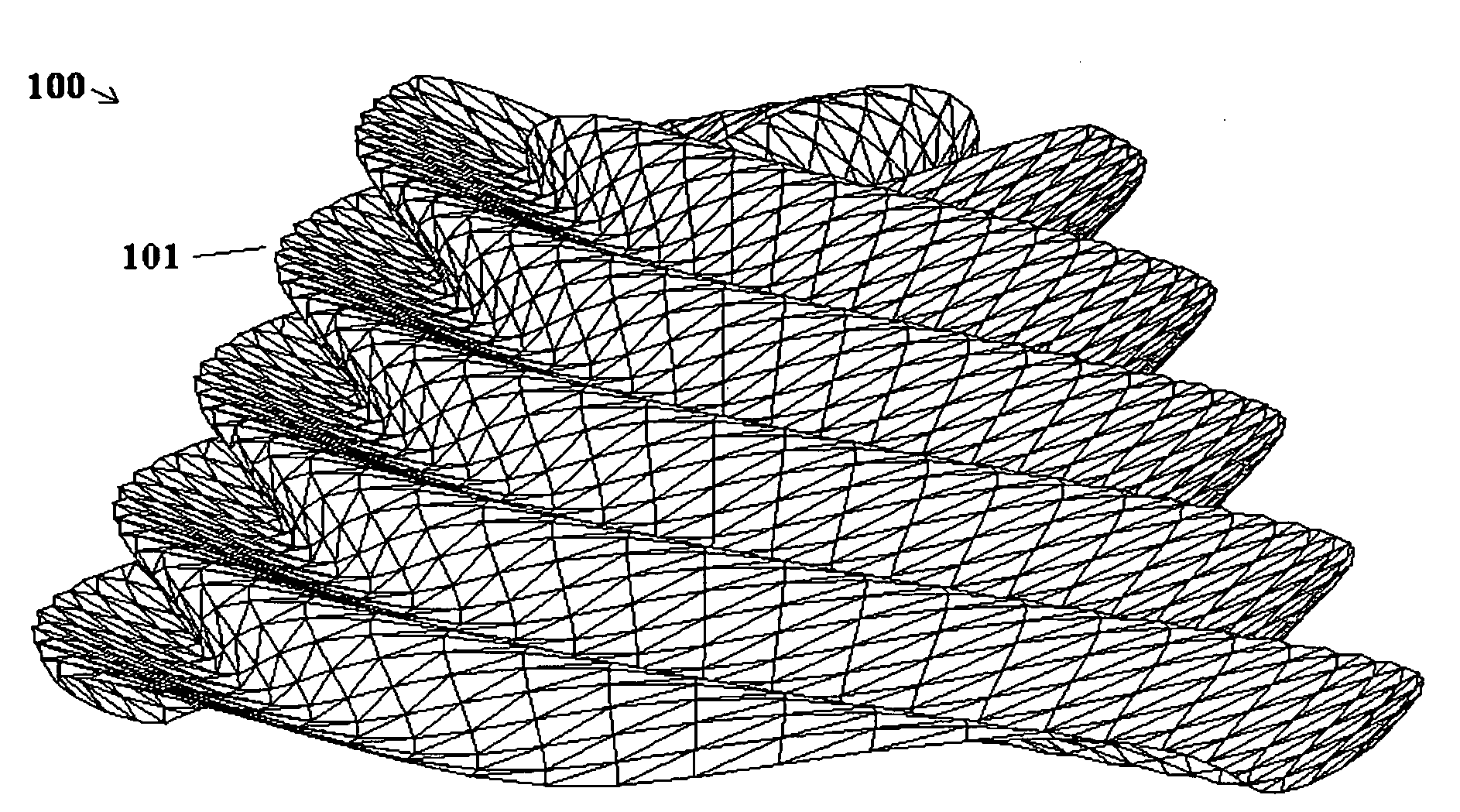

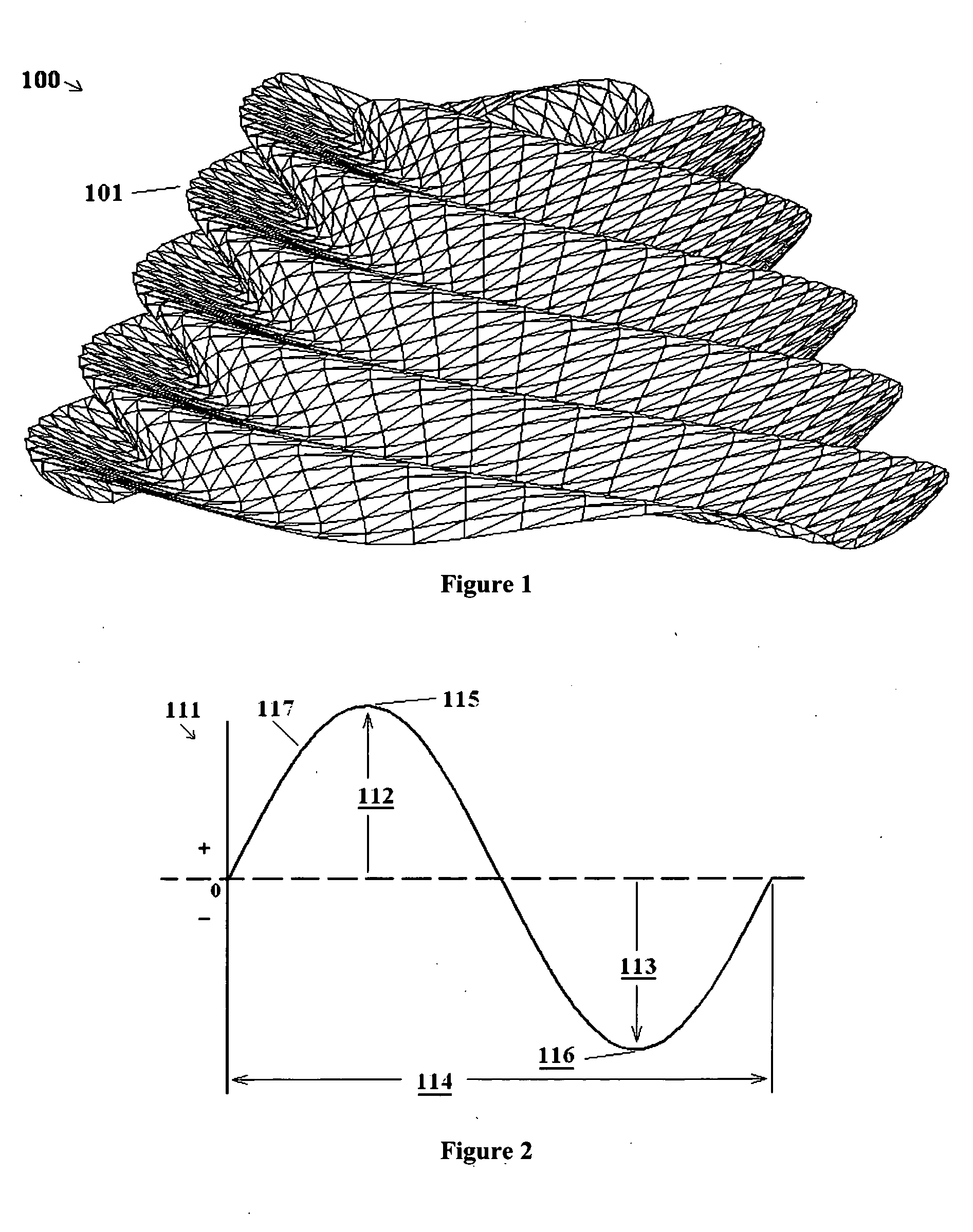

Method for establishing initial model based on multi-well stratum conformation factors

ActiveCN107272056AMeet actual needsGeomodellingSeismic signal processingGeomorphologyWeight coefficient

The invention provides a method for establishing an initial model based on multi-well stratum conformation factors. The method includes the steps of making synthesized earthquake record for each well, extracting wavelets, and calibrating layer position, solving the matching factors between well side seismic channel and logging longitudinal wave impedance, lateral wave impedance and density, obtaining stratum conformation factors, calculating the point to point distance between the earthquake record position to be solved and the positions of various well points, distributing the weight of point to point distance between the earthquake record position to be solved and the positions of various well points, applying the obtained matching factors, the stratum conformation factors and the weight coefficient to each earthquake record, and establishing the initial model of the earthquake record. Through the method, the initial model that is accurate and can satisfies the needs of real work areas can be established when the work areas are large, the number of wells is great, and the structural change of the work area is great.

Owner:CHINA PETROLEUM & CHEM CORP +1

Threaded fastener and fastener system

A wave threaded fastener and system. A wave thread extends from the outer surface of the body and is made up of a profile wave and a lateral wave. The profile wave includes a plurality of profile crests and profile roots defining a plurality of profile thread widths. The lateral wave includes at least one lateral crest and at least one lateral root defining at least one wave period. Each wave period forms a period arc having a period arc angle and the sum of all period arc angles about the lateral Wave equals three hundred and sixty degrees. Each of the profile crests and roots are aligned with corresponding lateral crests and roots and the wave thread travels one profile thread width per each period arc traveled.

Owner:VAN COR DALE E

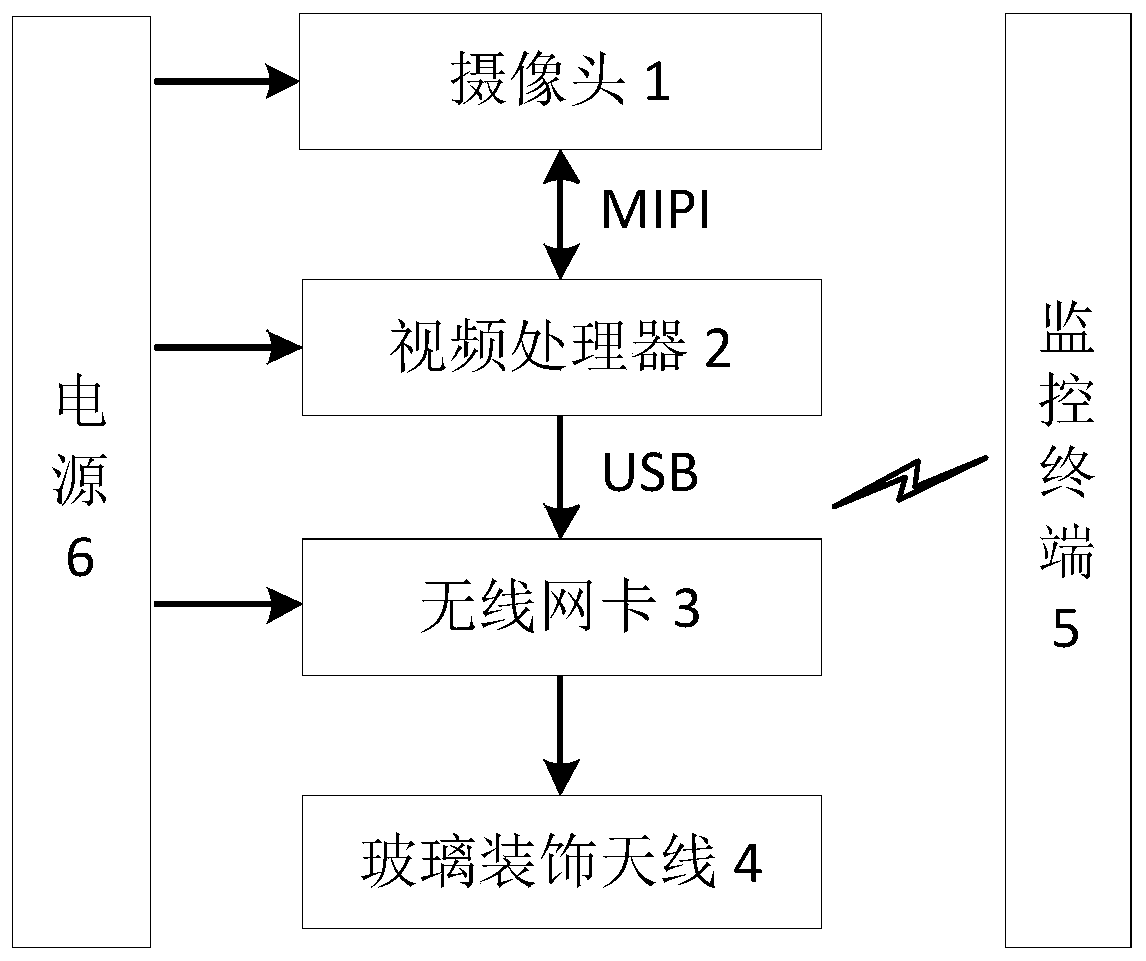

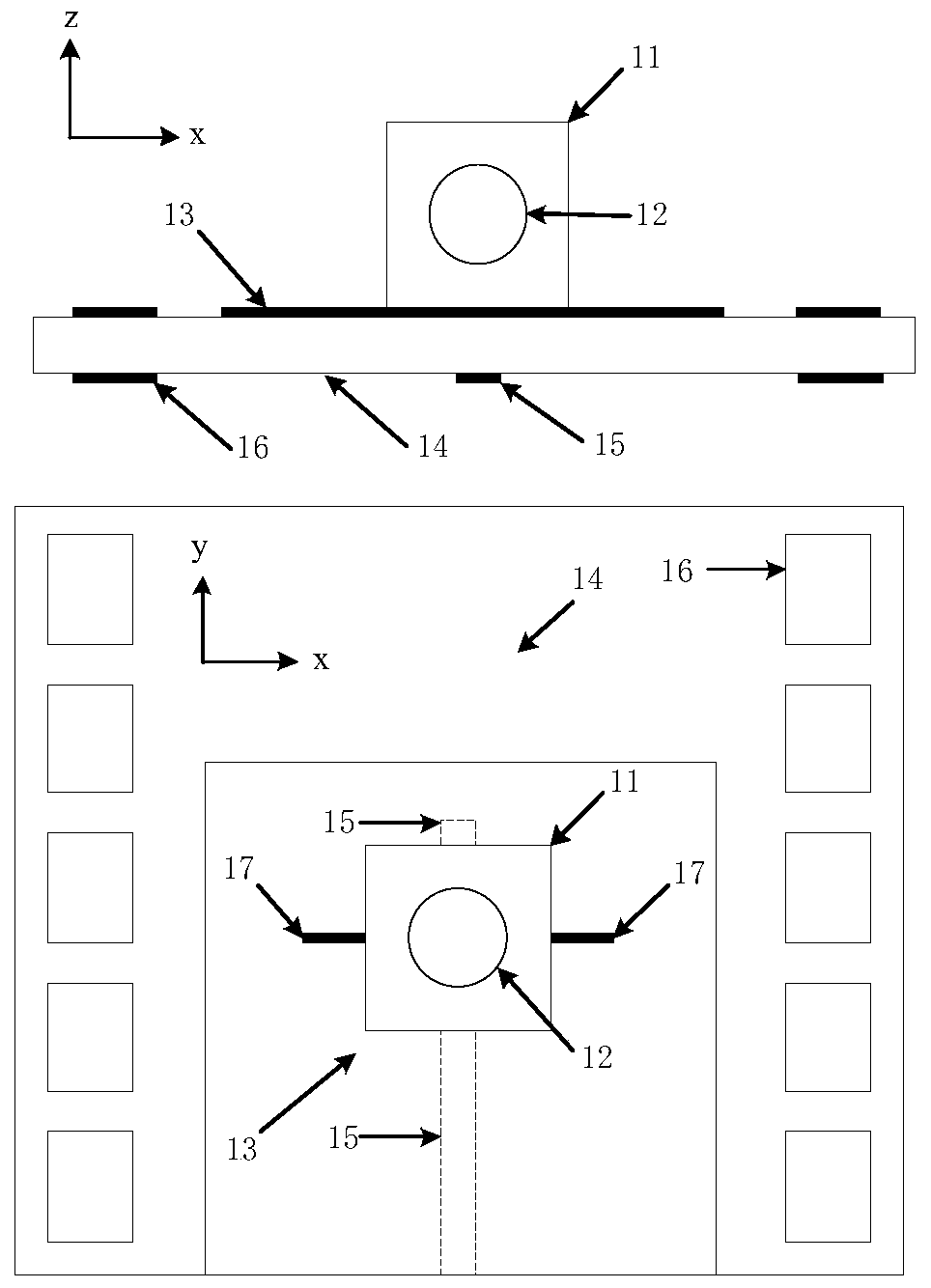

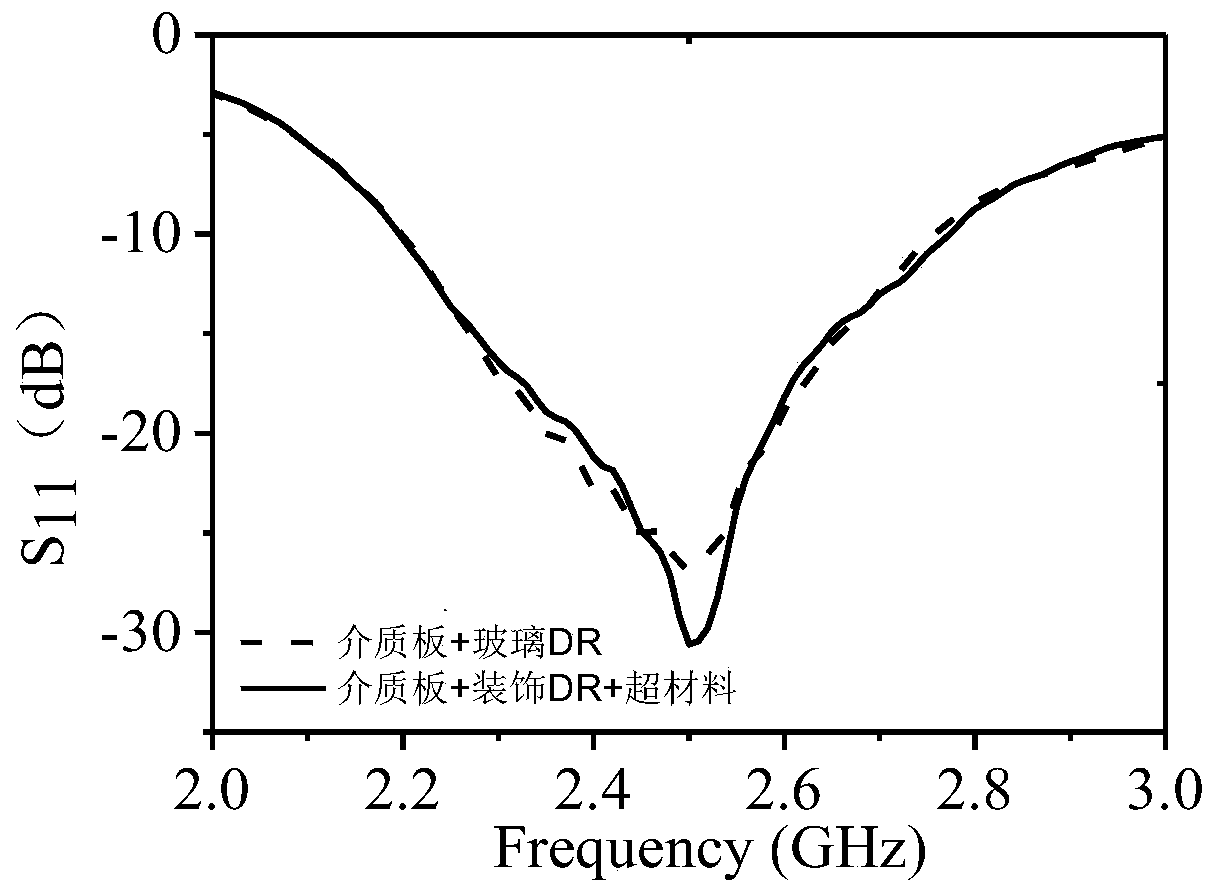

Wireless high-definition video monitoring system based on glass decorative antenna

ActiveCN109904616AImprove coding efficiencyReduce bit rateAntenna earthingsAntennas earthing switches associationVideo monitoringDielectric resonator antenna

The invention discloses a wireless high-definition video monitoring system based on a glass decorative antenna. The glass decorative antenna is a dielectric resonator antenna, and comprises a dielectric resonator, a dielectric substrate, a ground plane, metamaterial unit arrays, a microstrip line and a slot, wherein the ground plane is arranged in the middle of the upper surface of the dielectricsubstrate, the two sides of the ground plane on the upper surface of the dielectric substrate are respectively distributed with a column of metamaterial unit arrays, the microstrip line is arranged inthe middle of the lower surface of the dielectric substrate, the two sides of the microstrip line on the lower surface of the dielectric substrate are respectively distributed with a column of metamaterial unit arrays, a rectangular slot is formed in the middle of the ground plane on the dielectric substrate, and the dielectric resonator is arranged above the slot. The decorative antenna of the invention adopts the mode of loading metamaterial units on the side edge, the internal surface wave of the dielectric plate and the lateral wave of the dielectric resonator are suppressed, and the antenna gain is increased from 5.65dBi to 8.2dBi without sacrificing the impedance bandwidth performance of the antenna. The scheme of the invention has the characteristics of high gain and low profile.

Owner:XI AN JIAOTONG UNIV

Method for determining air layer using acoustic wave split-double pole transverse wave well-logging data

ActiveCN100429529CImprove abilitiesSeismic signal processingSeismology for water-loggingFull waveLongitudinal wave

A method of utilizing full wave column and dipolar lateral wave well-logging data to confirm gas layer includes setting up lateral-longitudinal wave conversion cross map of various gas saturation degree at gas reservoir in exploration area according to known rock physical character, utilizing acoustic wave data lateral wave time difference to confirm longitudinal wave time difference at various gas saturation degree, measuring longitudinal wave time difference and using various gas saturation degrees in said cross map to confirm gas situation in reservoir.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Remote digital type ultrasound wave/frequency conversion antiscaling descaling equipment

InactiveCN100579670CHelp clearReduce oxidation corrosionWater/sewage treatment with mechanical oscillationsMechanical vibrations separationCavitationShortest distance

Owner:刘利华

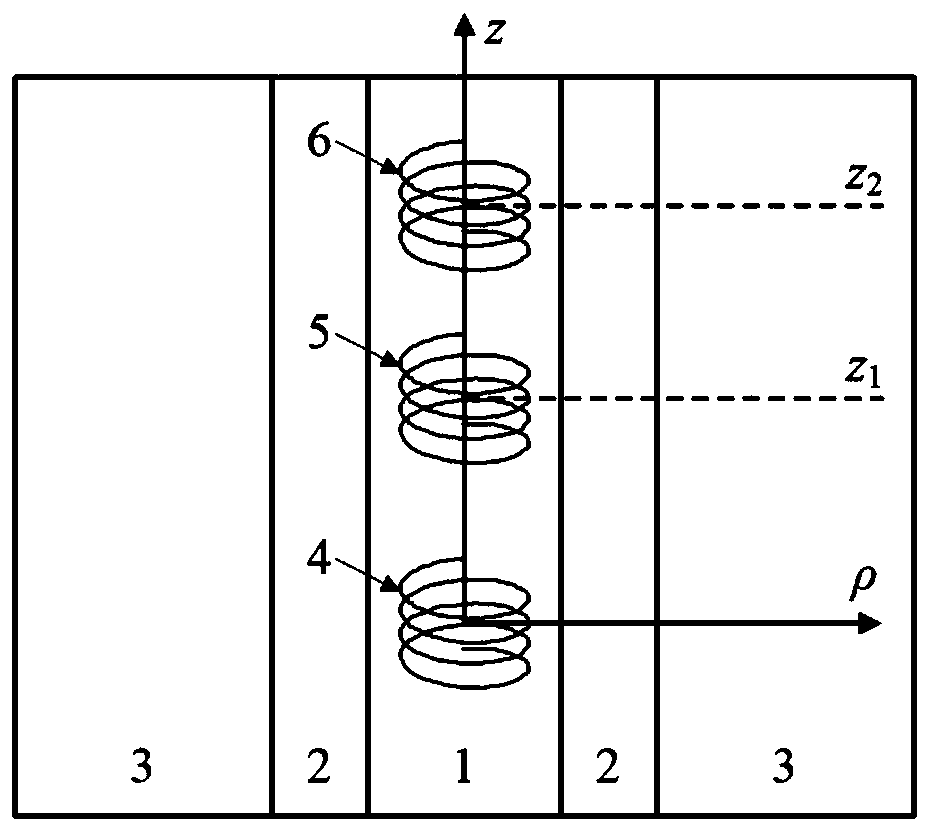

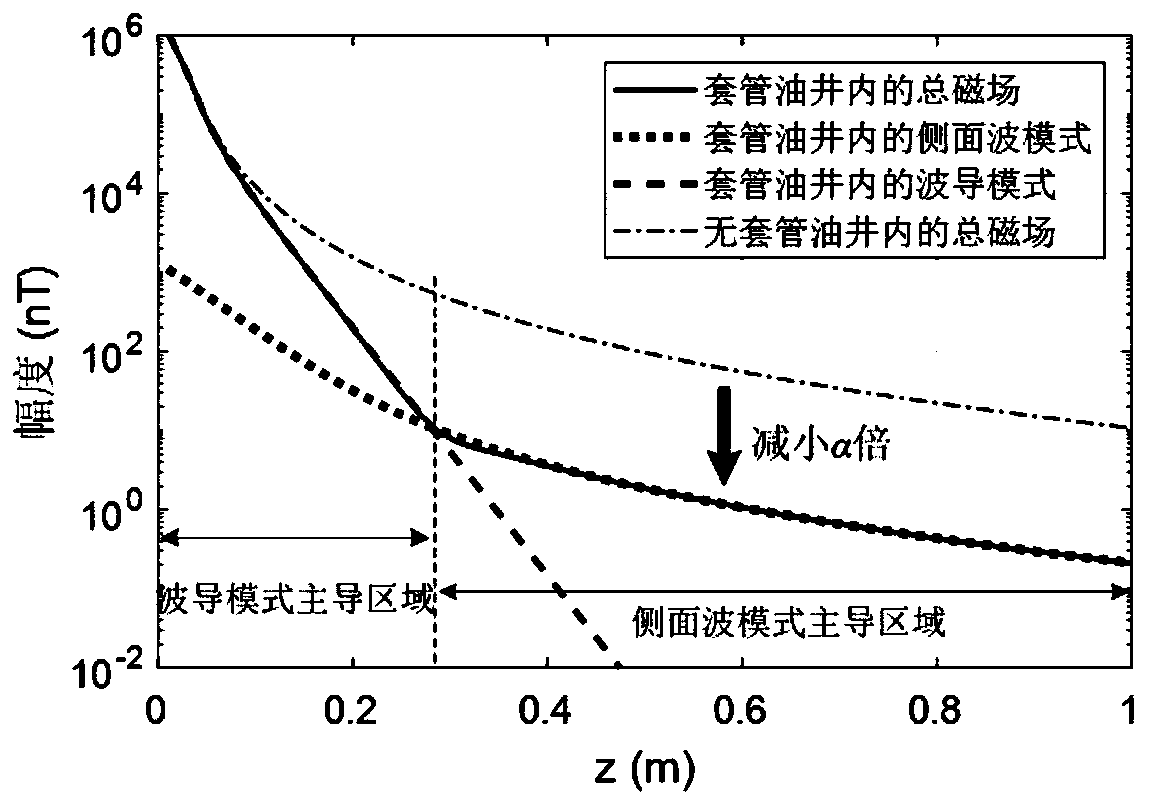

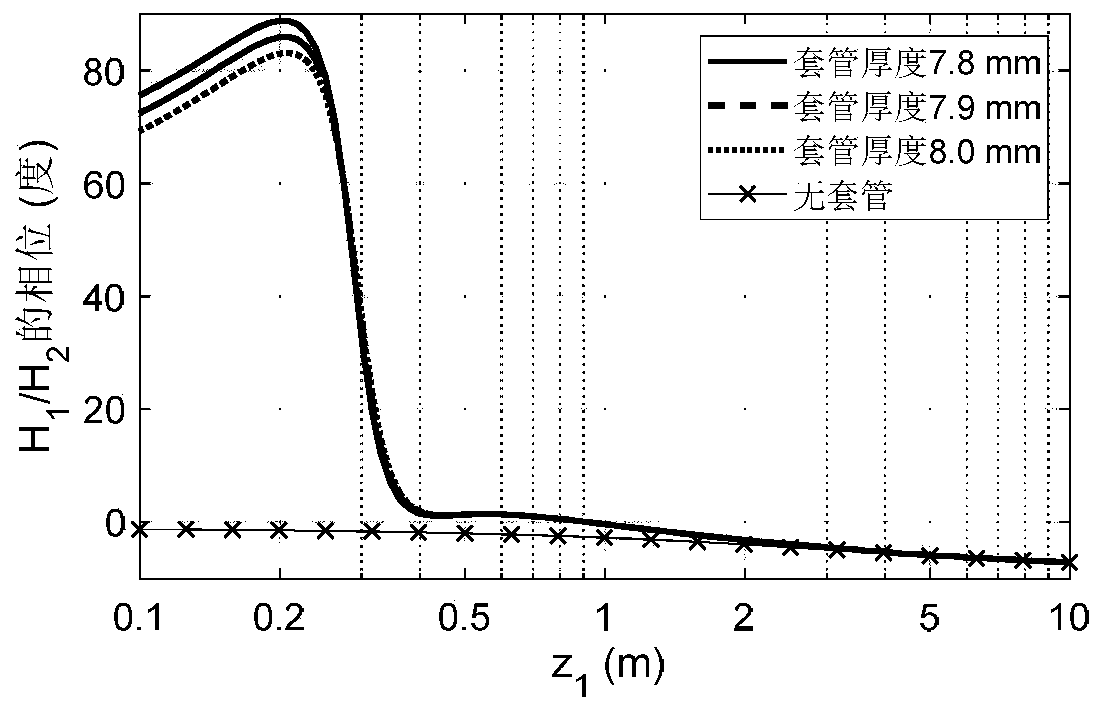

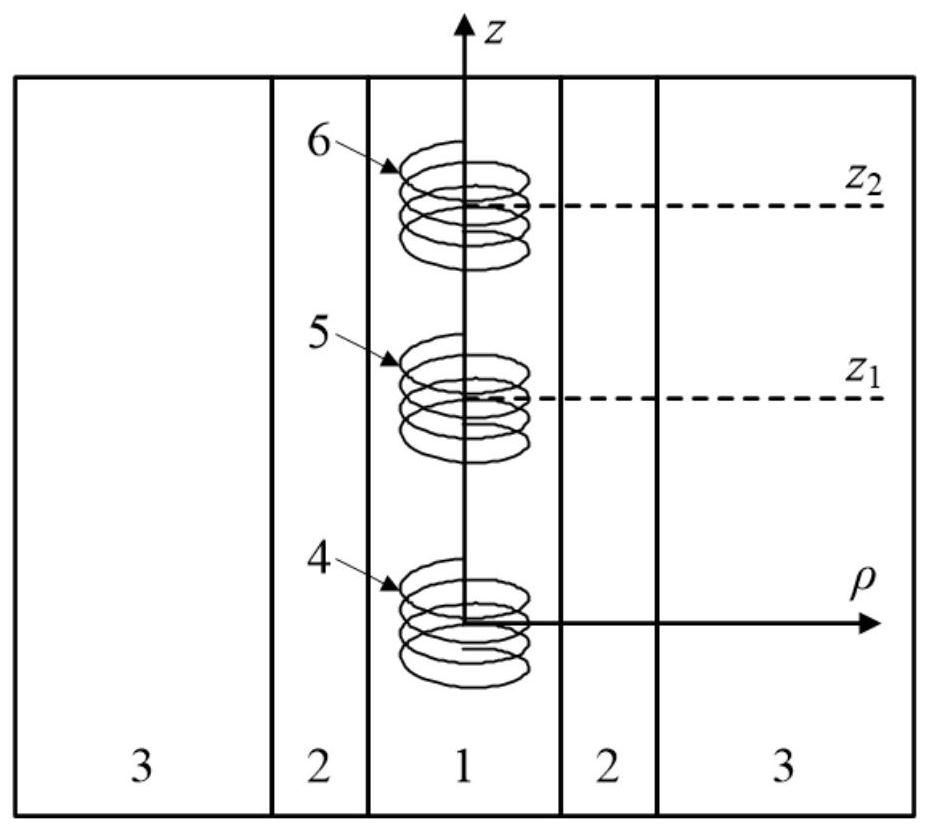

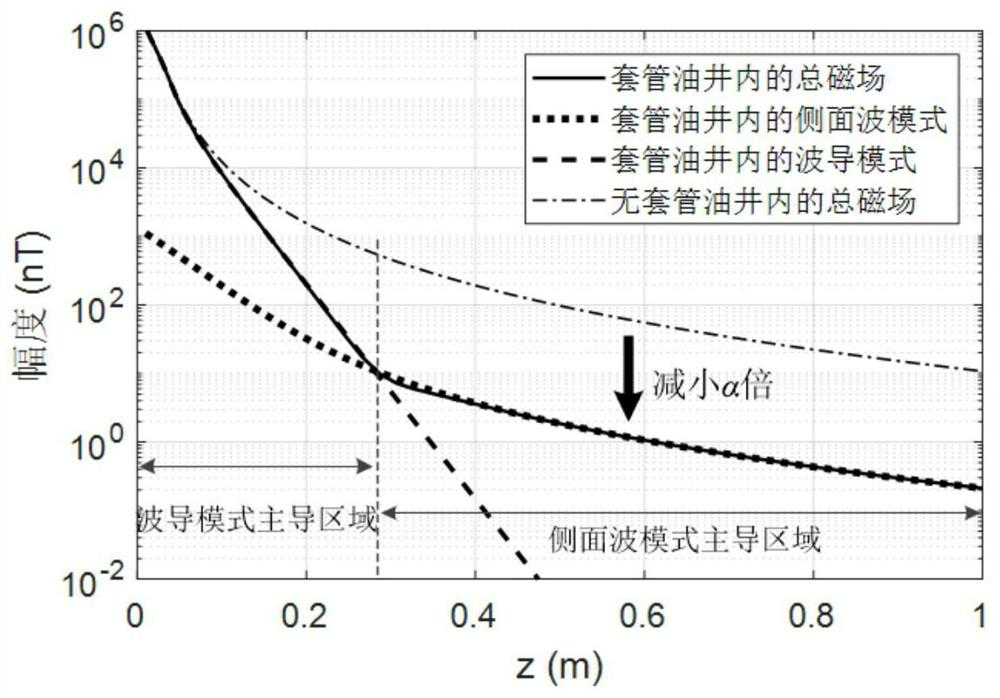

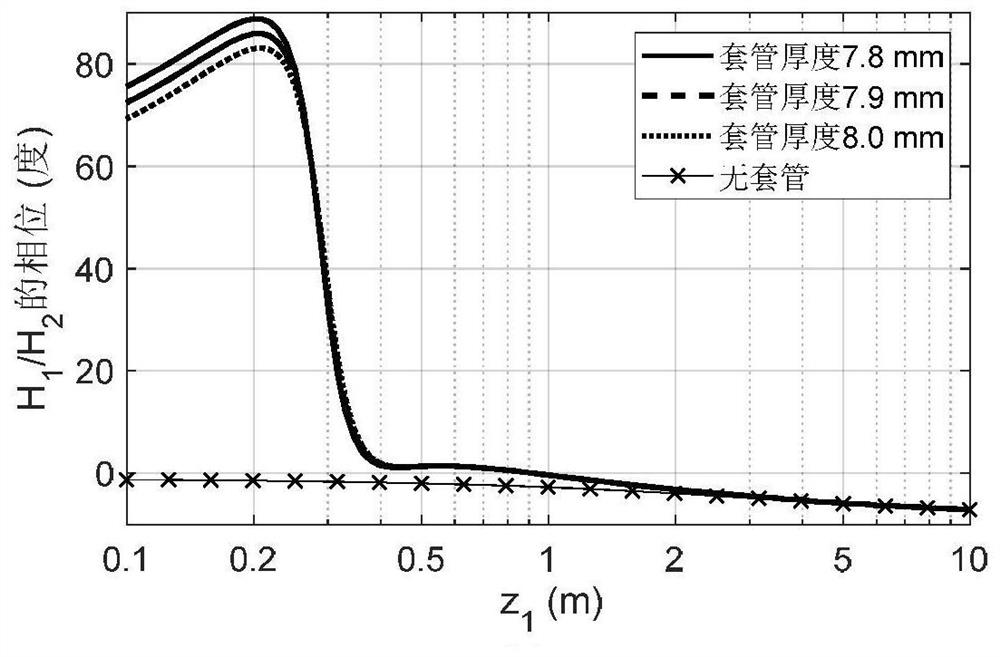

Casing-through induction logging method based on lateral wave detection

The invention discloses a casing-through induction logging method based on lateral wave detection. The casing-through induction logging method comprises the following steps of arranging a detection device in a cased well, wherein the detection device comprises a transmitting coil, two main receiving coils and two compensation receiving coils, the two main receiving coils, the two compensation receiving coils and the transmitting coil are respectively arranged in the cased well vertically and coaxially; exciting the transmitting coil by sine wave currents to generate induction electromagnetic fields inside and outside the cased well; using the main receiving coils to measure magnetic fields of a plurality of different positions inside the cased well; collecting the ratio of the magnetic field measurement results of the two main receiving coils at different axial positions in the cased well; and inputting the ratio into an inversion model of the transmitting coil in a caseless well to obtain the formation conductivity. According to the casing-through induction logging method based on lateral wave detection, the measuring coils does not need to contact the inner wall of a casting, sothat the problems of poor measuring effect and the like caused by poor contact under the condition of serious casting corrosion of a casting-through logging instrument based on the electrode method are solved.

Owner:ZHEJIANG UNIV

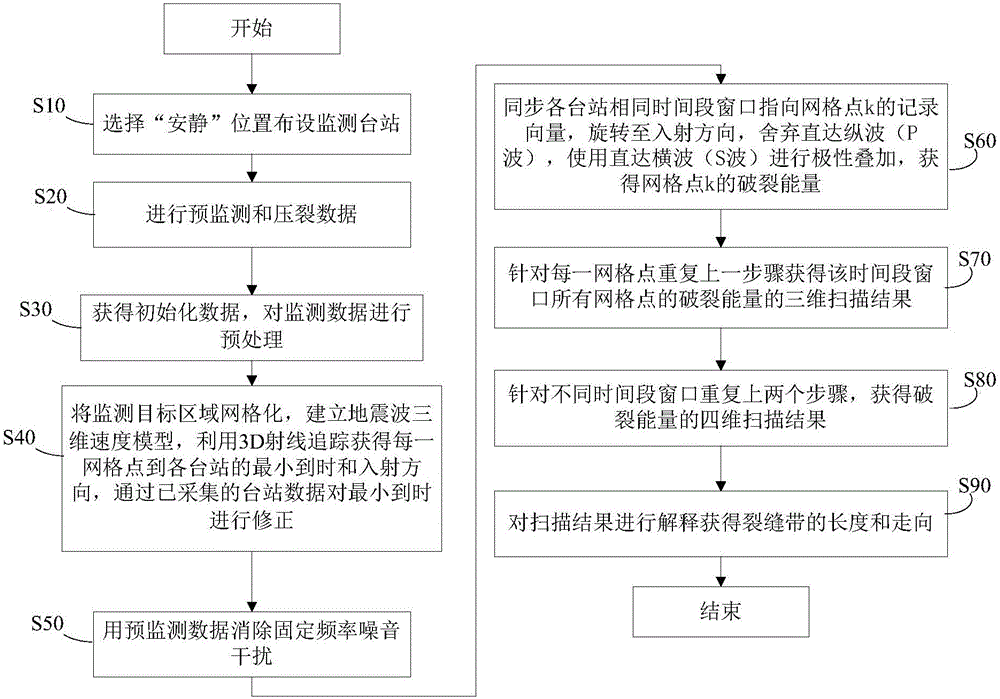

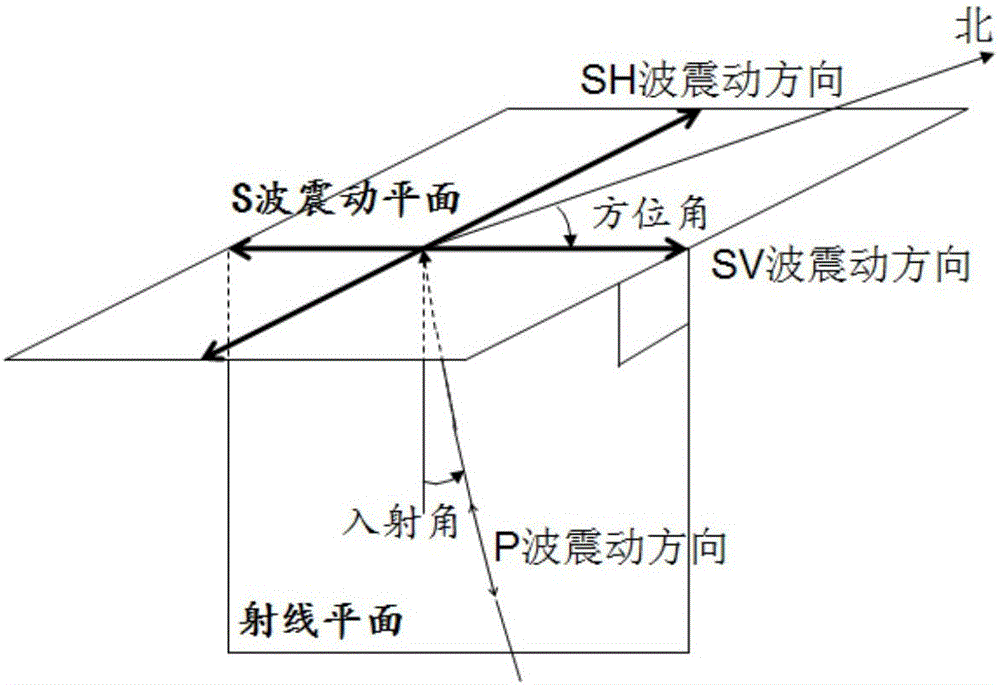

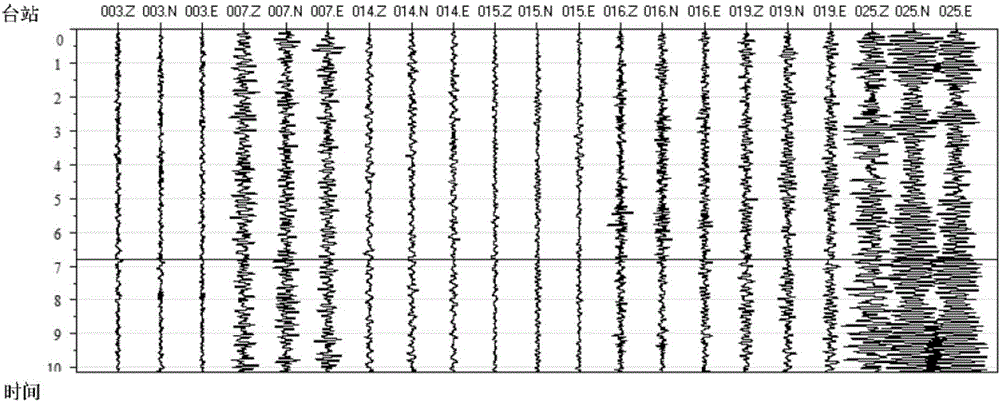

Micro-fracture vector scanning method

The invention discloses a micro-fracture vector scanning method, and the method comprises the following steps: (1), obtaining initialization data, and carrying out the preprocessing of micro-fracture monitoring data; (2), carrying out the gridding of a monitoring region, and building a seismic three-dimensional speed model; (3), synchronizing record vectors of all stations towards a grid point k in the same time period window, carrying out polarity superposing, abandoning a nonstop longitudinal wave (P wave) during vector polarity superposing, and employing a nonstop lateral wave (S wave) for weighted polarity superposing; (4), repeatedly carrying out the step (3) for each grid point, and obtaining a three-dimensional scanning result of fracture energy of all grid points in the time period window; (5), repeatedly carrying out the steps (3) and (4) in different time period windows, and obtaining four-dimensional scanning distribution of the fracture energy of a monitoring target region. The method can effectively inhibit noises, enhances useful signals, and achieves the effective positioning of an underground fracture point through scanning underground fracture energy.

Owner:北京京援伟达技术有限公司

A through-casing induction logging method based on lateral wave detection

The invention discloses a casing-through induction logging method based on lateral wave detection. The casing-through induction logging method comprises the following steps of arranging a detection device in a cased well, wherein the detection device comprises a transmitting coil, two main receiving coils and two compensation receiving coils, the two main receiving coils, the two compensation receiving coils and the transmitting coil are respectively arranged in the cased well vertically and coaxially; exciting the transmitting coil by sine wave currents to generate induction electromagnetic fields inside and outside the cased well; using the main receiving coils to measure magnetic fields of a plurality of different positions inside the cased well; collecting the ratio of the magnetic field measurement results of the two main receiving coils at different axial positions in the cased well; and inputting the ratio into an inversion model of the transmitting coil in a caseless well to obtain the formation conductivity. According to the casing-through induction logging method based on lateral wave detection, the measuring coils does not need to contact the inner wall of a casting, sothat the problems of poor measuring effect and the like caused by poor contact under the condition of serious casting corrosion of a casting-through logging instrument based on the electrode method are solved.

Owner:ZHEJIANG UNIV

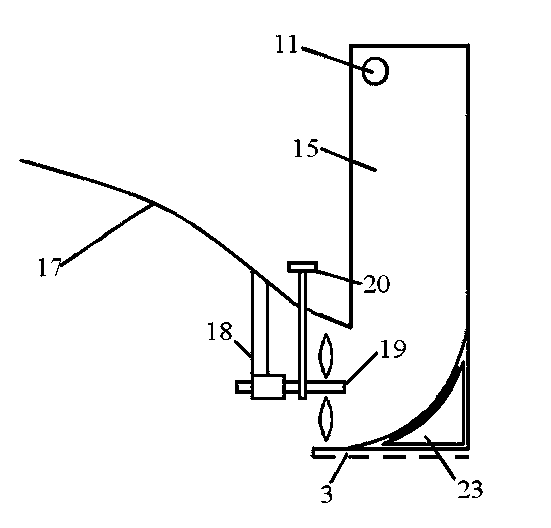

Efficient power generation device using wave energy

InactiveCN101984250BSeawater treatmentWater/sewage treatment bu osmosis/dialysisSea wavesEngineering

A high-efficiency power generation device using wave energy comprises a left side board (2), a right side board (1), a middle board (3), an inner upper board (17) and a first chamber (15). Upper parts of the left side board (2) and the right side board (1) are respectively connected to the inner upper board (17) in a sealed manner, and lower parts of the left side board (2) and the right side board (1) are respectively connected to the middle board (3) in a sealed manner. The left side board (2), the right side board (1), the middle board (3) and the inner upper board (17) form a first side opening (13). One end of the first side opening (13) faces a movement direction of waves, the other end of the first side opening (13) is connected to the first chamber (15) in a sealed manner, and a structure capable of generating electricity by using lateral waves is disposed in a space formed by communicating the first side opening (13) and the first chamber (15). The device can fully utilize the kinetic energy, potential energy and lateral impact force of the waves, thereby achieving high utilization efficiency of the waves.

Owner:陈鹤

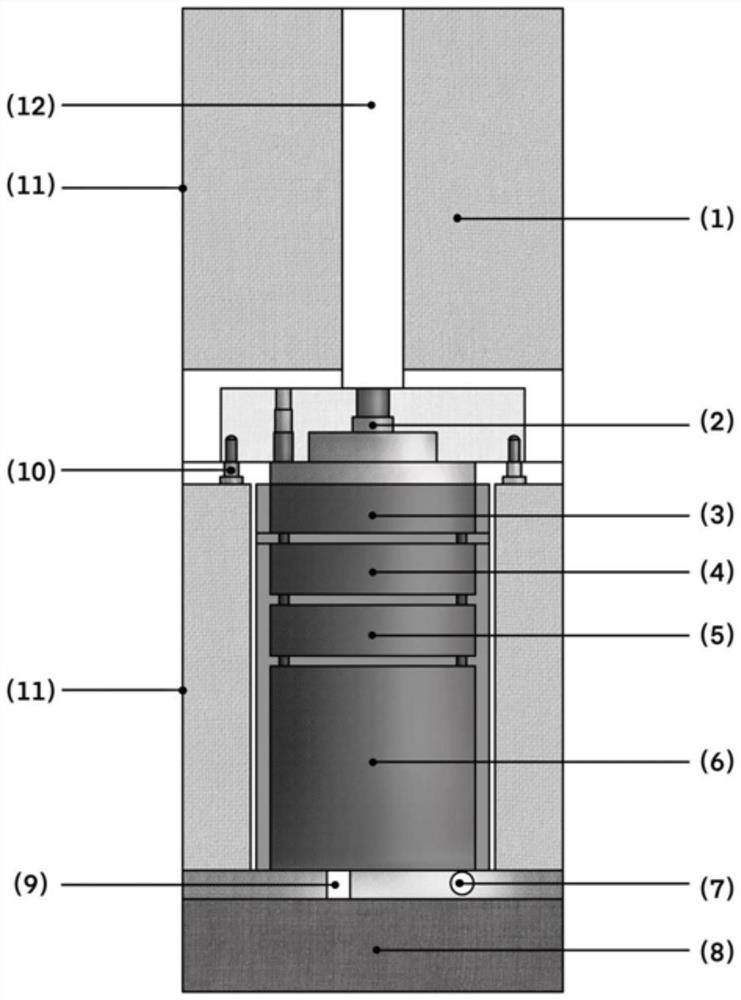

Tubular close-range shock wave tester

PendingCN114674477AModule voltage is stableWon't saveMeasurement of explosion forceEngineeringStress sensors

The invention aims to provide a tubular close-range shock wave tester which can be used for field data testing of various engineering constructions and blasting tests, and provides accurate shock wave parameters for research of ammunition shock wave damage capability and feasibility analysis of various engineering blasting safety assessment. The device specifically comprises a composite cushioning material (1), a pressure sensor (2), a supporting beam (3), a signal processor (4), an information memory (5), a power supply device (6), a start button (7), a device base (8), a switch (9), a connecting bolt (10), a metal shell (11) and a tubular receiver (12). The whole device is wrapped by a metal shell, a built-in cushioning material has high resistance to interference factors such as clutters, lateral waves and electromagnetic waves, and shock wave parameters in a blasting field are measured and stored through an electric measurement method.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com