Undoped efficient white organic emitting device and preparation method thereof

An electroluminescent device, non-doping technology, applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of inaccurate concentration control, unstable co-evaporation rate, low luminous efficiency, etc., to achieve No angle dependence, improved device luminous efficiency, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

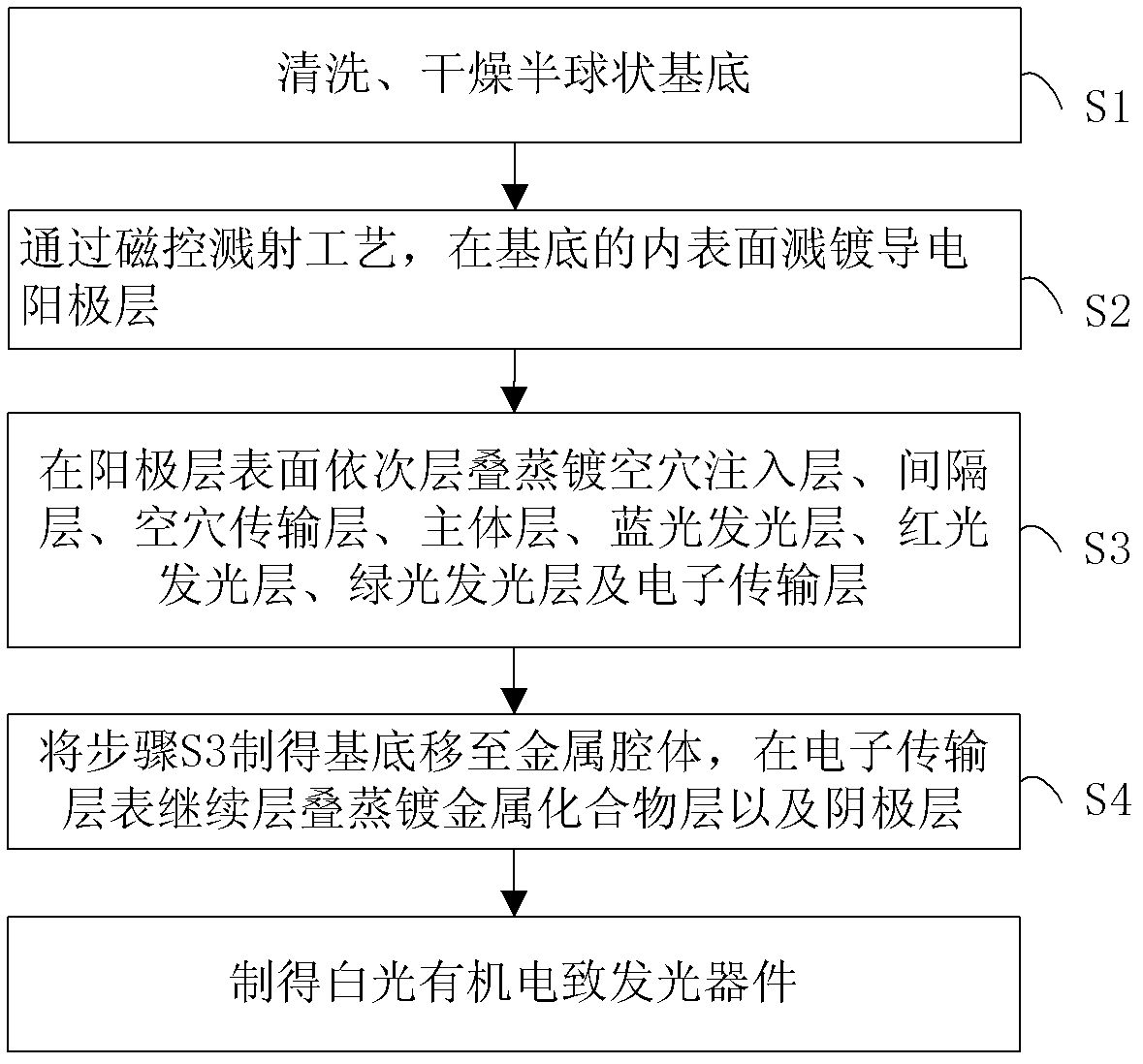

[0044] The preparation method of the above-mentioned non-doped high-efficiency white light organic electroluminescent device, such as figure 2 shown, including the following steps:

[0045] S1. The hemispherical substrate (eg, glass) is ultrasonically cleaned with purified water, acetone, ethanol, etc. for 15 minutes in sequence, and dried after cleaning;

[0046] S2, using the magnetron sputtering process, putting the hemispherical shell-shaped substrate into the vacuum chamber of the magnetron sputtering equipment, and sputtering an anode layer with a thickness of 150 nm on the inner surface of the hemispherical shell-shaped substrate; making the hemispherical shell shaped anode substrate, and then the anode layer was treated with oxygen plasma with a power of 10W for 15min;

[0047] S3. Put the hemispherical shell-shaped anode substrate into the organic vacuum cavity of the evaporation equipment, the hole injection layer, the spacer layer, the hole transport layer, the ma...

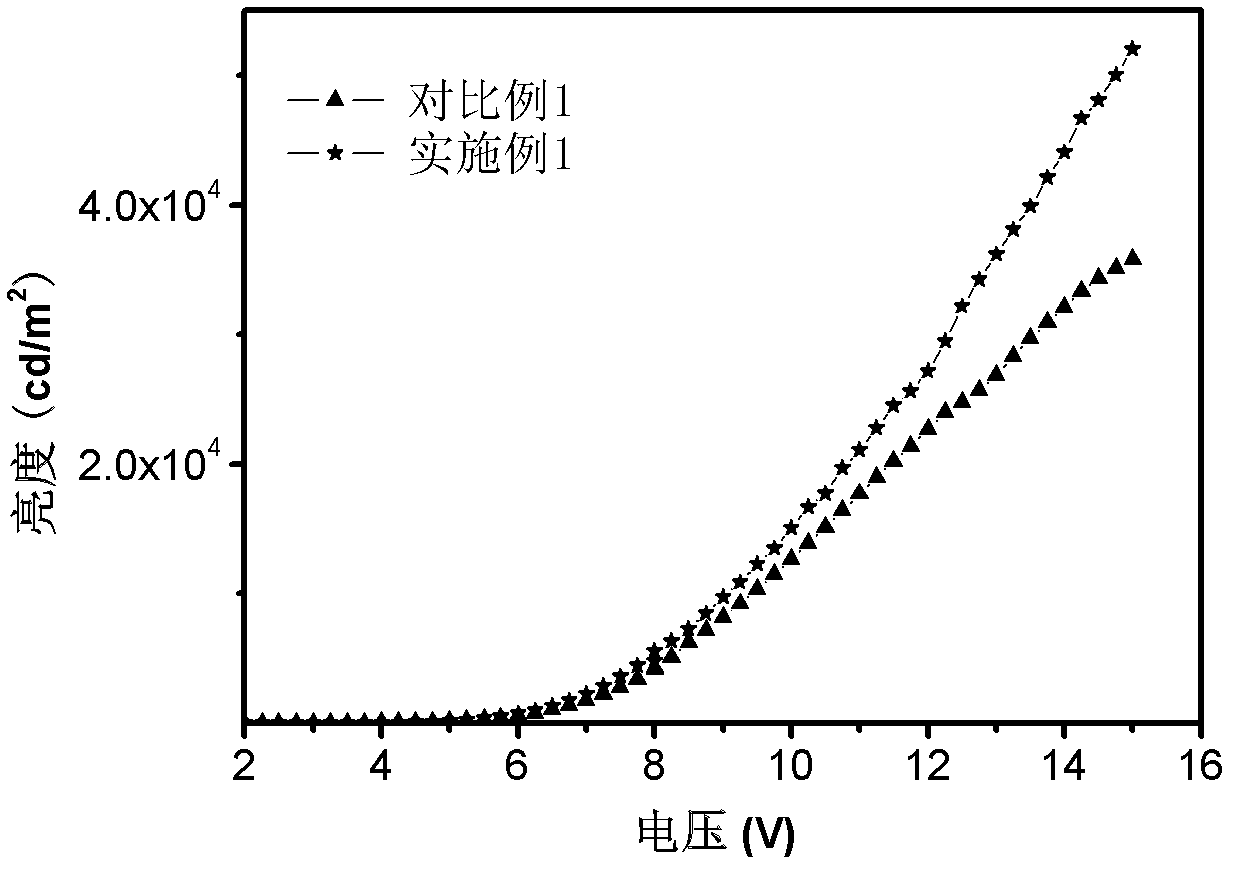

Embodiment 1

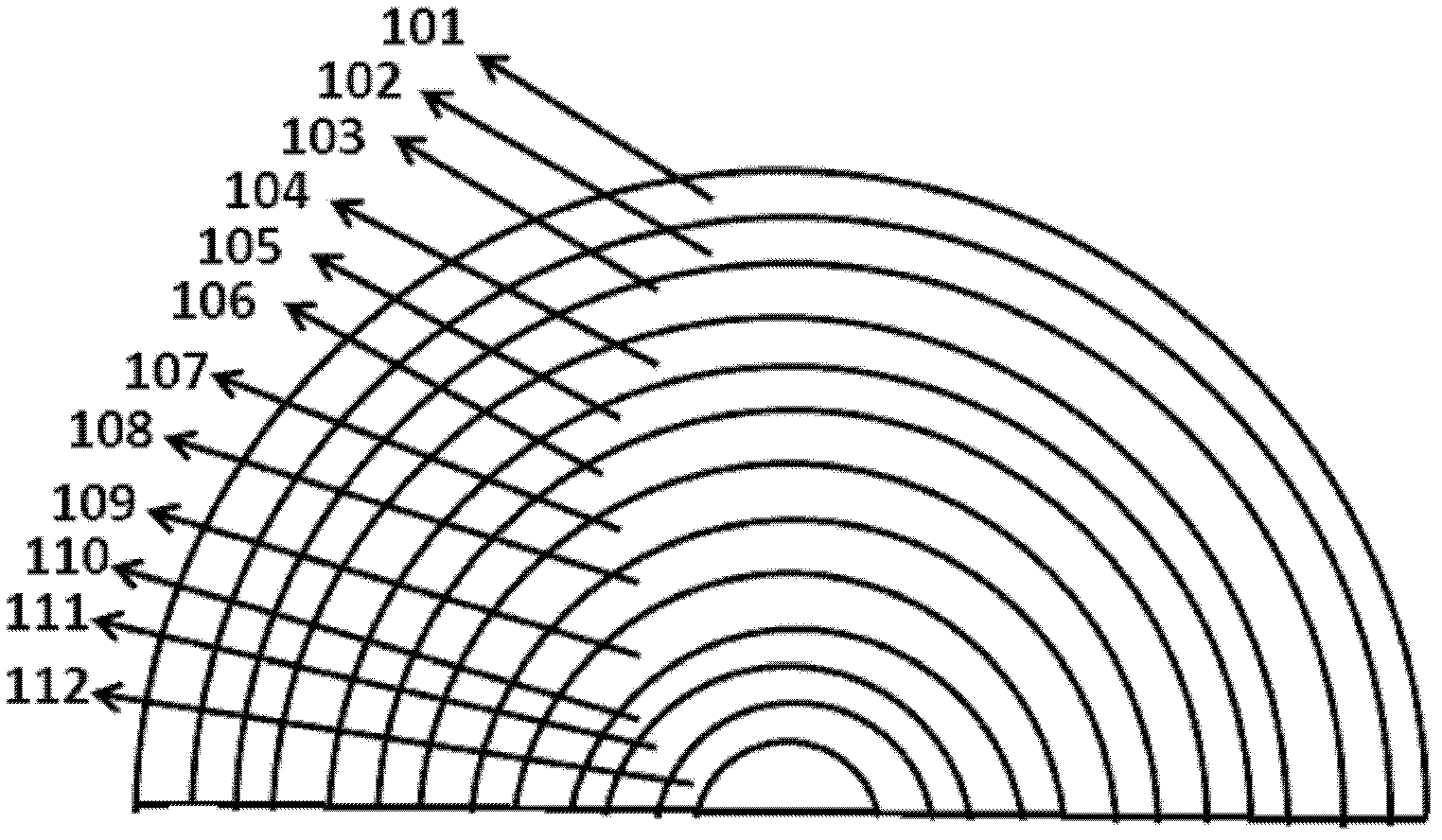

[0054] The hemispherical glass substrate with an inner radius of 5mm and a thickness of 4mm was ultrasonically cleaned with pure water, acetone, ethanol, etc. for 15 minutes in sequence. After cleaning, it was placed in a magnetron sputtering vacuum chamber, and a layer of 150nm thick The ITO. Then put the ITO hemispherical glass into the organic vacuum cavity, and sequentially evaporate the hole injection layer (the material is m-MTDATA, the thickness is 20nm), the spacer layer (the material is HAT, the thickness is 3nm), the hole transport layer (the material is It is TPD, the thickness is 20nm), the main body layer (the material is TCTA, the thickness is 15nm), the blue light emitting layer (the material is Firpic, the thickness is 1nm), the red light emitting layer (the material is Ir(piq) 3 , thickness is 0.3nm), green light emitting layer (material is Ir(ppy) 3 , thickness is 0.5nm), electron transport layer (material is Bphen, thickness is 40nm), and then the substrate...

Embodiment 2

[0056] A hemispherical glass substrate with an inner radius of 3 mm and a thickness of 3 mm was ultrasonically cleaned with pure water, acetone, ethanol, etc. for 15 minutes in sequence. AZO. Then put the AZO hemispherical glass into the organic vacuum cavity, and sequentially evaporate the hole injection layer (the material is m-MTDATA, the thickness is 30nm), the spacer layer (the material is F4-TCNQ, the thickness is 1nm), and the hole transport layer (the material is TCTA, the thickness is 20nm), the main body layer (the material is TCTA, the thickness is 10nm), the blue light emitting layer (the material is Firpic, the thickness is 0.5nm), the red light emitting layer (the material is Ir(piq) 3 , thickness is 0.1nm), green light emitting layer (material is Ir(ppy) 3 , thickness is 0.2nm), electron transport layer (material is Bphen, thickness is 20nm), and then the substrate is moved into the metal chamber, continue to evaporate metal compound layer (material is Cs 2 CO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com