Ultrasonic time of flight diffraction (TOFD)-based offline defect judgment method

A discrimination method and defect technology, applied in the direction of processing the detection response signal, etc., can solve the problems of large error, long period, and the diagnosis result is greatly affected by human factors, and achieve the effect of effective identification and precise positioning and improvement of image resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

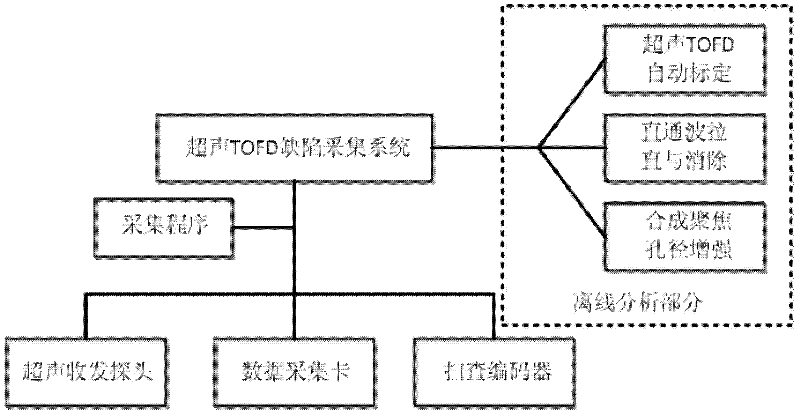

[0052] Such as figure 1 -4 shown.

[0053] A welding defect ultrasonic detection off-line discrimination method, it comprises the following steps:

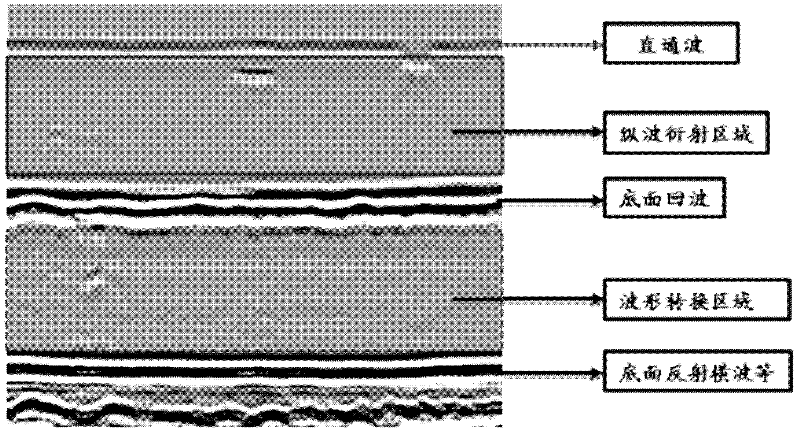

[0054] First, use the ultrasonic detector to perform D-scan on the object to be detected, obtain the through wave, bottom echo and A-scan signal of the object to be detected, and synthesize and generate a D-scan image;

[0055] Secondly, the combination of image processing and through-peak search is used to accurately locate the through-wave and bottom echo, complete the computer calibration of the ultrasonic atlas, and obtain the plate thickness value of the tested object;

[0056] Third, use peak calibration and differential algorithms to straighten and eliminate straight-through waves with aliased near-surface defects;

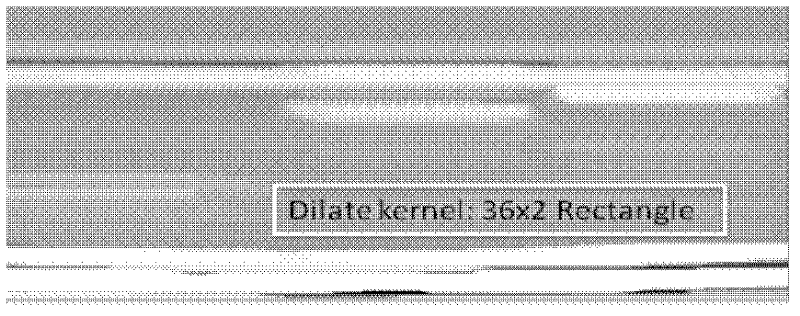

[0057] Fourth, using synthetic aperture aggregation technology, beam sharpeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com