Micro-fracture vector scanning method

A scanning method and micro-fracture technology, applied in the field of vector scanning, can solve problems such as high cost, different signal interference, and large noise interference, and achieve the effects of simple and fast construction, noise reduction, and real-time data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

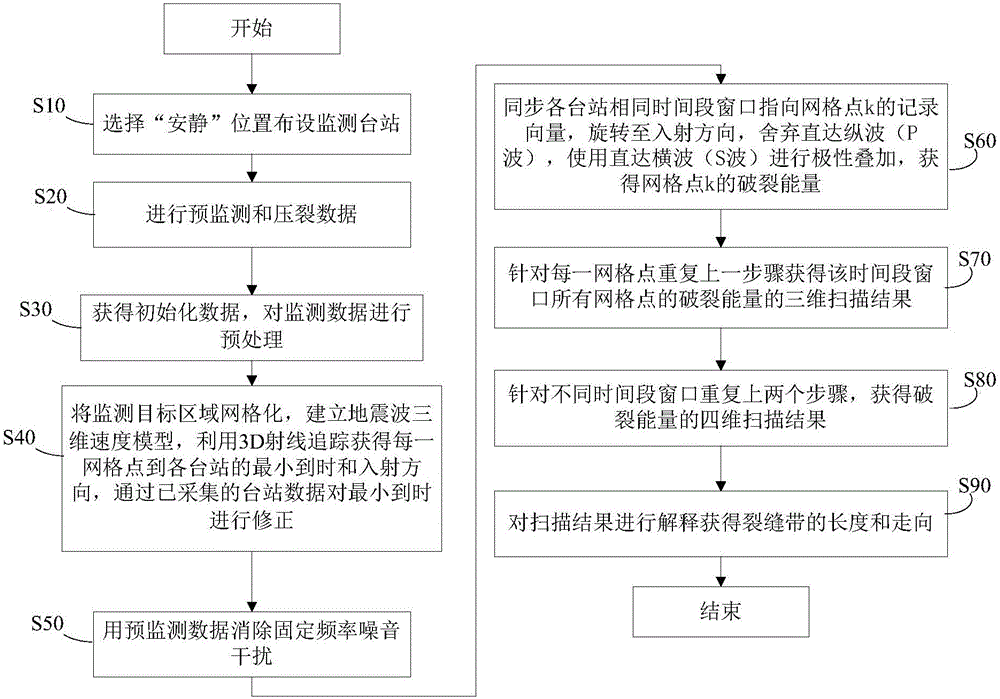

[0034] Introduce the implementation of the micro-fracture vector scanning method of the present invention with the specific implementation operation process of a certain oil well fracturing monitoring project, and its implementation steps are as follows figure 1 shown, including the following steps.

[0035] Step S10: Select a "quiet" location to deploy monitoring stations.

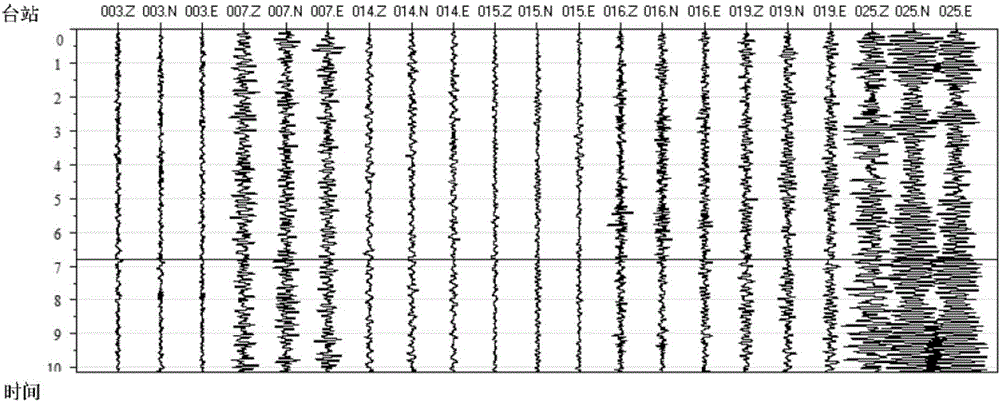

[0036]Within 3km from the projection point of the planned underground fracturing point on the ground, and at the same time, within 1km from the fracturing vehicle group (at the wellhead, not necessarily the above-mentioned projection point), in all azimuths around the projection point, At each distance, M three-component microseismic recorder stations (hereinafter referred to as stations) for monitoring microcracks are discretely arranged at positions with less noise interference. In order to obtain a stronger fracturing signal and improve the signal-to-noise ratio, the closer the station is to the proje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com