Casing-through induction logging method based on lateral wave detection

A technology of induction logging and casing passing, which is used in surveying, earth-moving drilling, wellbore/well components, etc., can solve problems such as poor measurement results, achieve good results, reduce primary field interference, and improve signal-to-noise ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

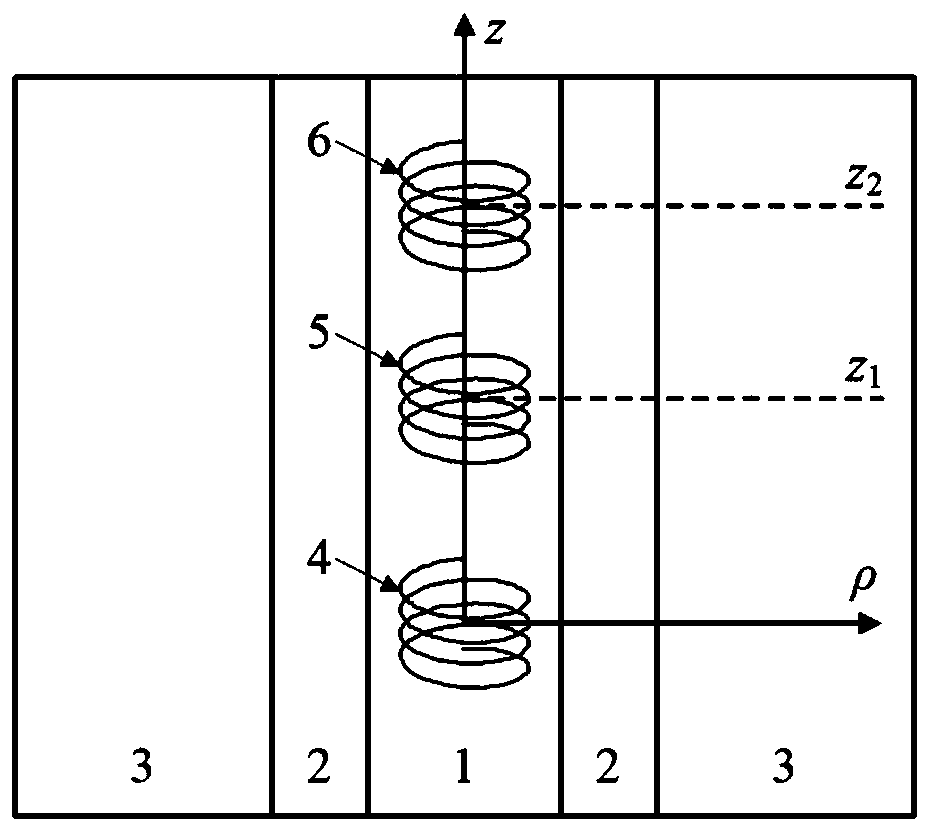

[0043] 1) if figure 1 As shown, the detection device is arranged in the cased well 1. The detection device includes a transmitting coil 4 and two main receiving coils 5 and 6. The coil winding directions of the transmitting coil 4 and the two main receiving coils 5 and 6 are the same, and the two main receiving coils The receiving coils 5 and 6 and the transmitting coil 4 are coaxially arranged up and down in the cased well respectively, and the transmitting coil 2 is located below the two main receiving coils 3, and the transmitting coil 4 is excited by a sine wave current, in the inside 1 and outside 3 of the cased well Generate an induced electromagnetic field and use the main receiving coils 5 and 6 to measure the magnetic field inside the cased hole;

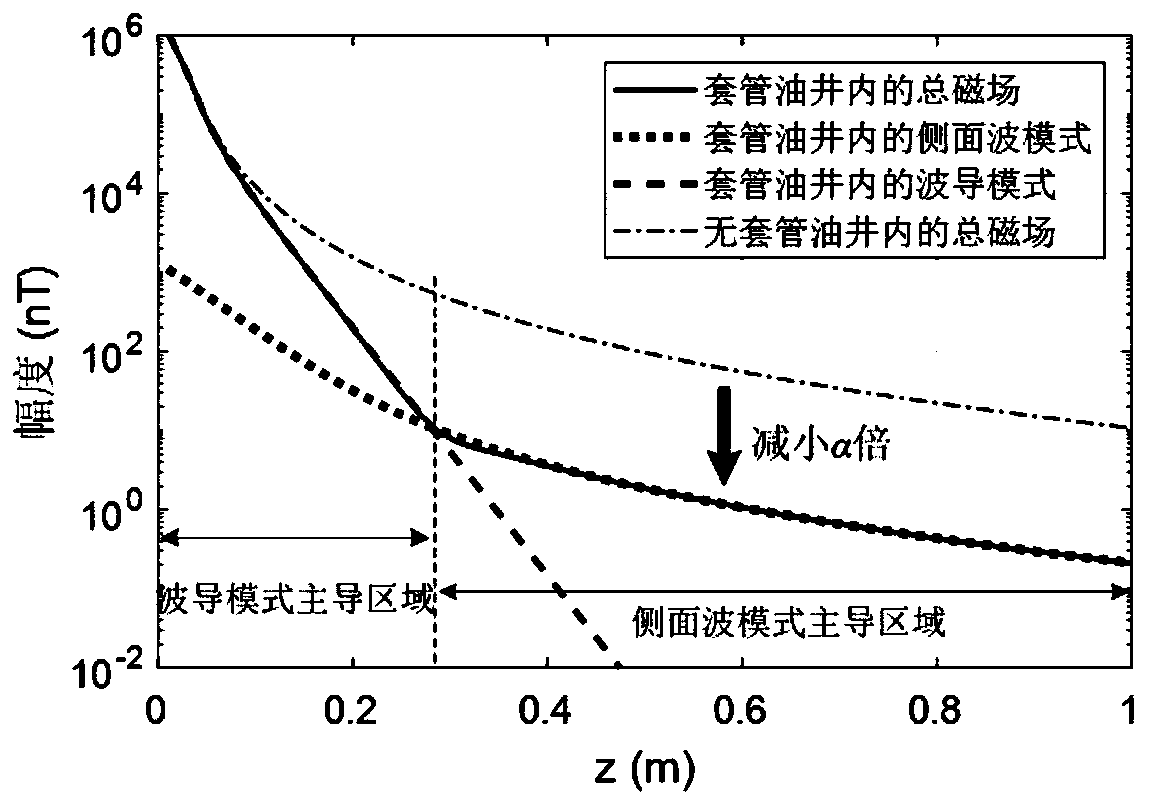

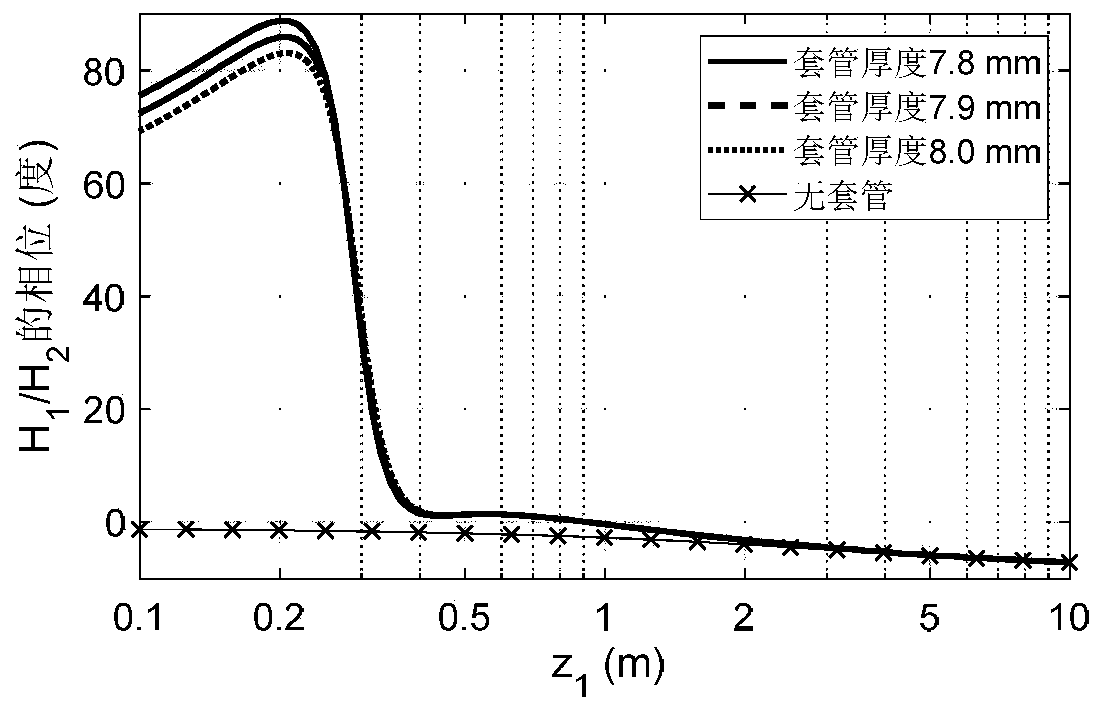

[0044] Wherein, the main receiving coils 5 and 6 are arranged in the dominant area of the side wave mode of the induced electromagnetic field generated by the transmitting coil 4 . The side wave mode dominant area means...

Embodiment 2

[0069] In the side-wave dominant area, the magnetic field distribution in the well is the same as that in the uncased well, but the amplitude is weakened by α times. Therefore, similar to open hole logging, the interference of the primary field can be weakened by using the reverse winding compensating receiving coil.

[0070] The specific method is as follows: Figure 5 As shown, the detection device is arranged in the cased well 1, and the detection device includes a transmitting coil 4, two main receiving coils 5 and 6 and two compensating receiving coils 7 and 8, two compensating receiving coils, two main receiving coils and The transmitting coils are coaxially arranged up and down in the cased well respectively, and the transmitting coil 4 is excited by a sine wave current to generate an induced electromagnetic field inside 1 and outside 3 of the cased well. The number of turns of the compensation receiving coil 7 is proportional to the induced voltage generated by the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com