Remote digital type ultrasound wave/frequency conversion antiscaling descaling equipment

An ultrasonic and digital technology, applied in the field of digital composite equipment, can solve problems such as waste of energy and human resources, inability to act on scale, and increase of connections, so as to improve equipment efficiency, reduce maintenance costs, and prolong equipment life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

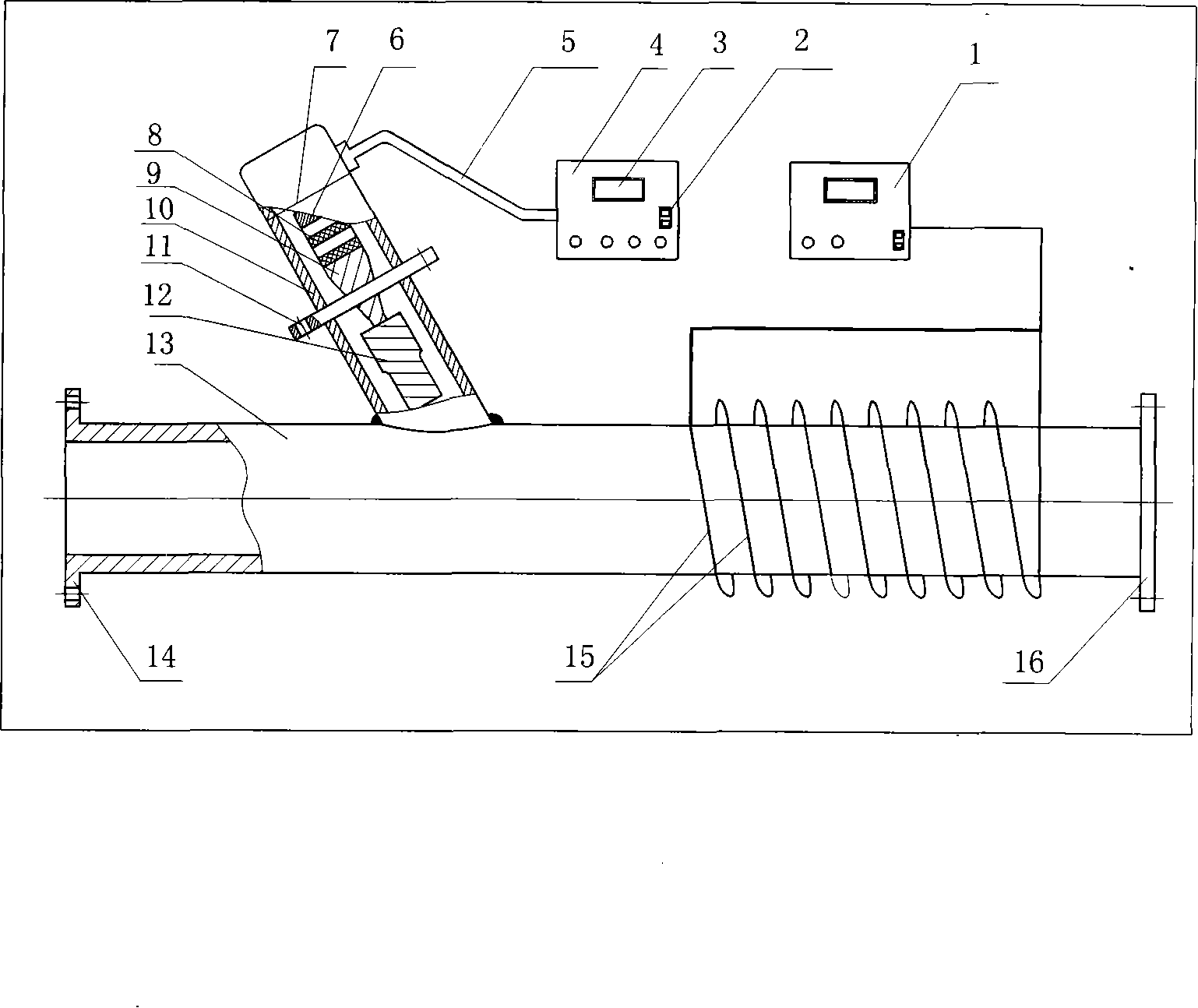

[0017] Among the figure, the digital liquid crystal display (3) displays and controls the ultrasonic power supply (4) to send power through the cable (5) and enters the protective cover (7) through the cable socket to connect the transducer (6). The number of annular piezoelectric ceramic sheets (8) is connected to the rear end of the metal horn (9), and the front end of the metal horn 9) is connected to the rear end of the metal energy gathering block (12). Ultrasonic waves are emitted through the metal energy-concentrating block (12), and transverse waves and longitudinal waves act on the inner wall of the entire pipeline at the same time. Using the cavitation effect of ultrasonic waves, countless tiny vacuum cavities are formed under negative pressure, and the gas in the water quickly enters the vacuum cavities. , forming bubbles, which are forced to be squeezed by positive pressure to form a critical pressure of about 1000 atmospheres, burst instantly, and repeatedly and hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com