Method for accurately quantifying flaw height of girth welding seam in submarine pipeline

A technology for submarine pipelines and girth welds, which is applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, which can solve problems such as dimensional errors, high weld failure rates, and affecting the normal laying efficiency of submarine pipelines, so as to ensure welding quality, Accurate quantitative accuracy and the effect of improving laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

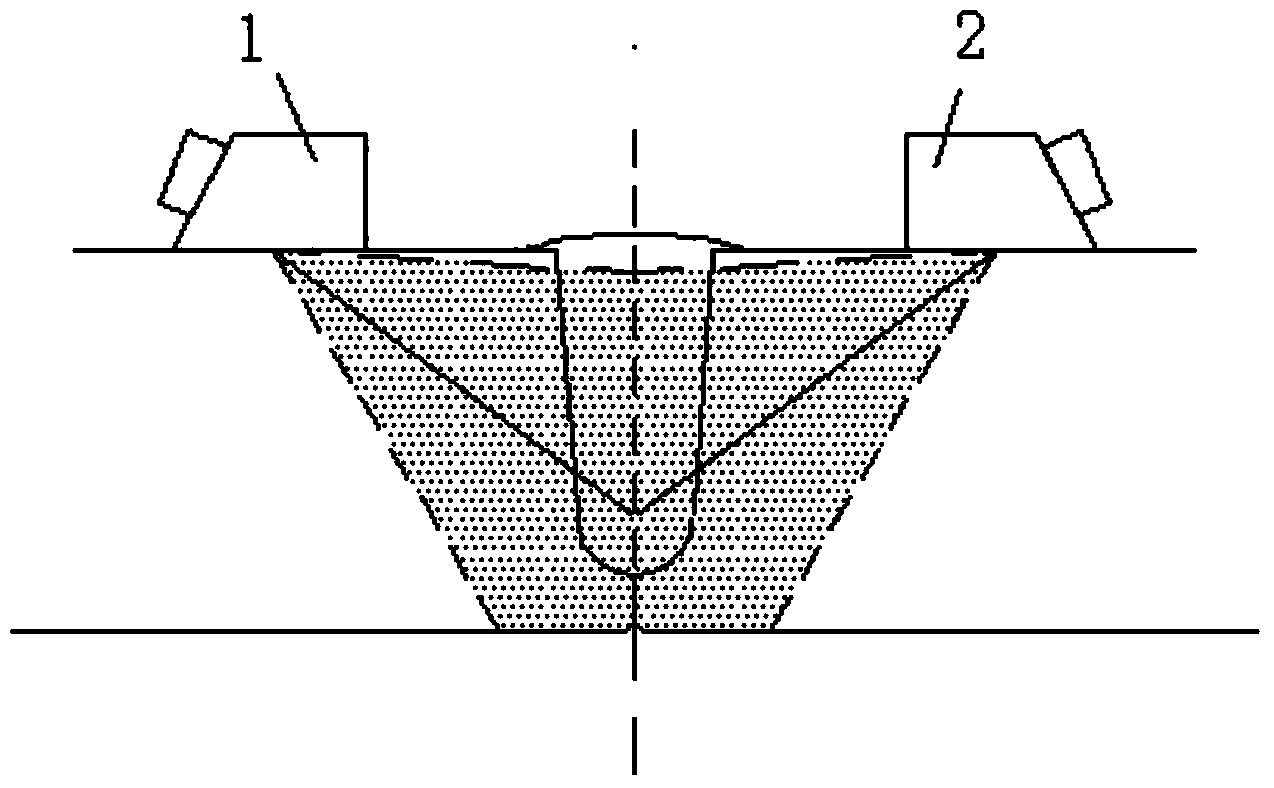

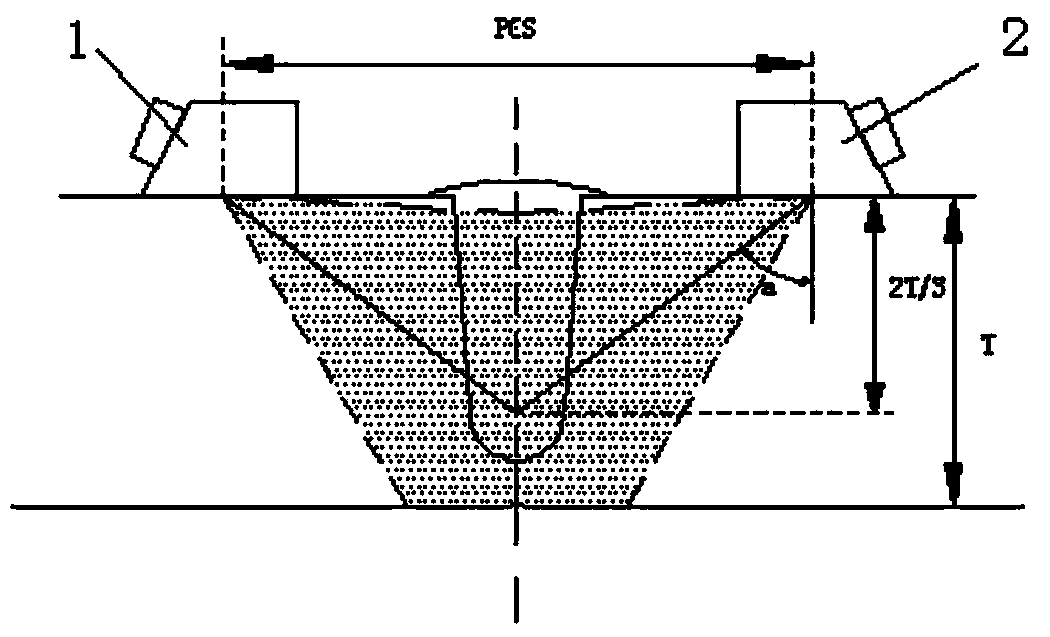

[0045] The present invention uses the diffraction time-difference ultrasonic inspection method to detect the defect height of the girth weld of the submarine pipeline, such as Figure 4 As shown, before testing, use the following installation steps:

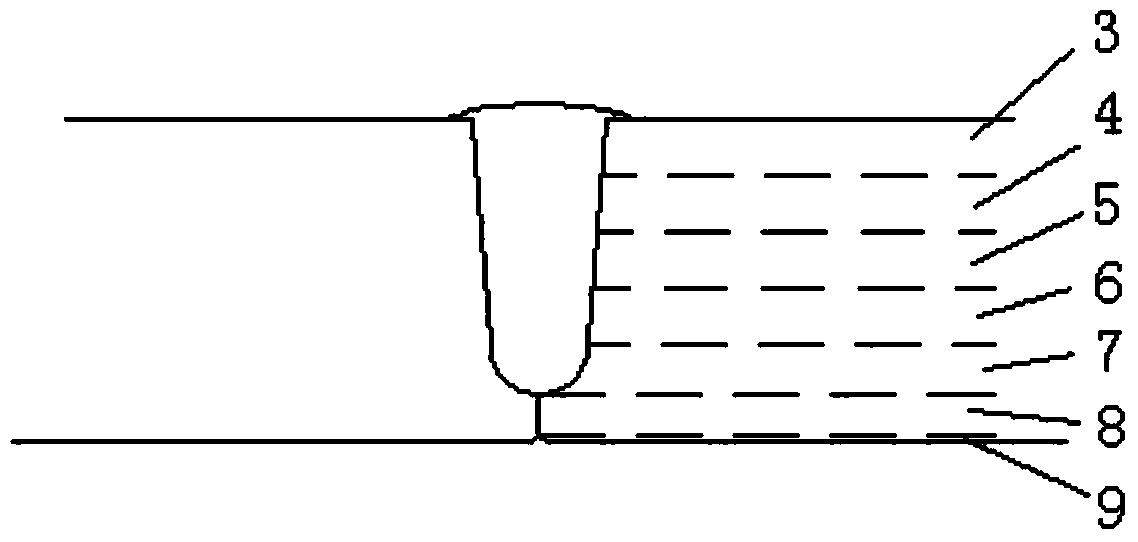

[0046] 1. According to the weld wall thickness, groove form and other parameters, process the 2mm diameter on the filling 1 division 3, filling 2 division 4, filling 3 division 5, filling 4 division 6, and heat welding division 7 corresponding to the calibration test block 17. For flat-bottomed holes, a root groove with a height of 2mm is processed on the blunt edge partition 8, and a root groove with a height of 1mm is processed on the root partition 9; the guide rail 16 is fastened to the set position from the centerline of the calibration test block 17; this implementation For example: the guide rail is fastened at a position 170mm from the center line of the calibration test block.

[0047]2. Connect the computer 11 to the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com