Soybean milk powder preparation method capable of improving qualified rate of high-protein soybean milk powder

A technology of soybean milk powder and pass rate, applied in food processing, food drying, food science and other directions, can solve the problems of increased difficulty for production enterprises, inability to meet production targets, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

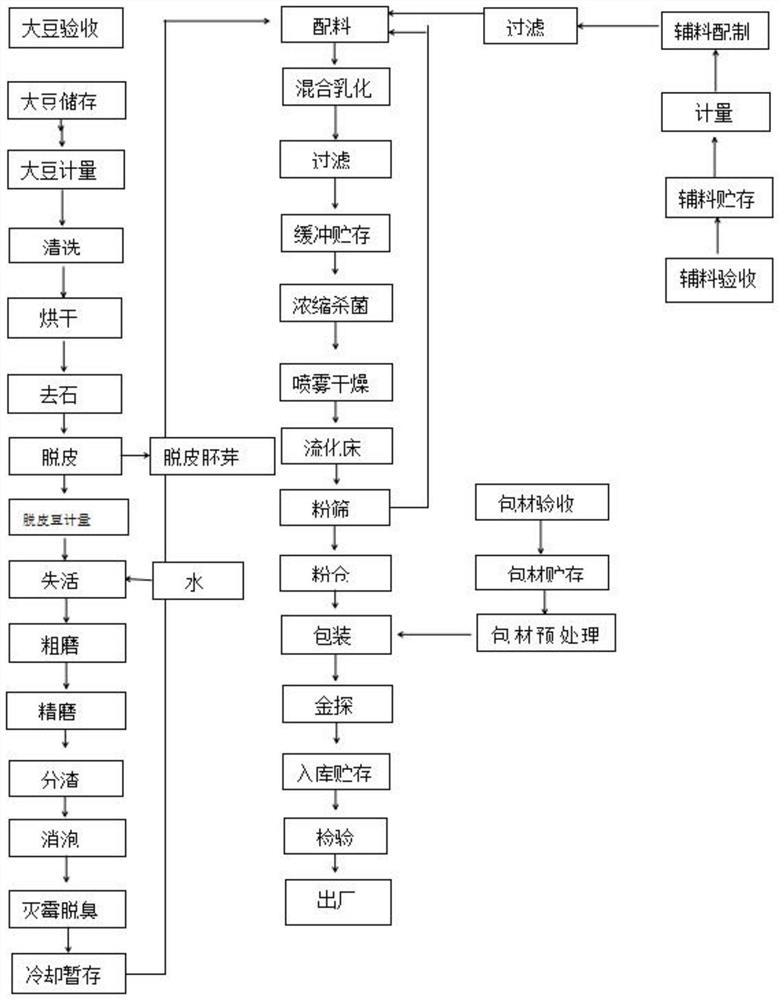

[0036]A method for preparing soymilk powder that improves the qualified rate of high-protein soymilk powder. The process steps of the method for preparing soymilk powder that improve the qualified rate of high-protein soymilk powder are: soybean acceptance → soybean storage → soybean measurement → cleaning →heating→stone removal→peeling→measurement of peeled beans→inactivation→coarse grinding→fine grinding→separation→defoaming→sterilization and deodorization→cooling→auxiliary material acceptance→auxiliary material storage→ingredients→filtering→emulsification mixing→buffering and temporary storage→semi-water bath Sterilization→concentration→spray drying→fluidized bed secondary drying→packaging material acceptance→packaging material storage→packaging→warehouse storage→inspection→delivery;

[0037] A method for preparing soymilk powder that improves the pass rate of high-protein soymilk powder described in this embodiment. Soybean acceptance: require national standard grade 1 or a...

specific Embodiment approach 2

[0069] A method for preparing soymilk powder that improves the qualified rate of high-protein soymilk powder. The process steps of the method for preparing soymilk powder that improve the qualified rate of high-protein soymilk powder are: soybean acceptance → soybean storage → soybean measurement → cleaning →heating→stone removal→peeling→measurement of peeled beans→inactivation→coarse grinding→fine grinding→separation→defoaming→sterilization and deodorization→cooling→auxiliary material acceptance→auxiliary material storage→ingredients→filtering→emulsification mixing→buffering and temporary storage→semi-water bath Sterilization→concentration→spray drying→fluidized bed secondary drying→packaging material acceptance→packaging material storage→packaging→warehouse storage→inspection→delivery;

[0070] In the inactivation step, the peeled soybeans are treated with 5.5 kg of sodium bicarbonate according to the mass ratio: 1220 kg of dehulled beans are added with sodium bicarbonate, an...

specific Embodiment approach 3

[0081] According to a kind of preparation method of soya-bean milk powder that improves the pass rate of high-protein soy-milk powder described in specific embodiment 2, in the pipeline of described production line and tank, use chlorine dioxide 0.5-1mg / L after every 2 shifts, temperature is 10 Wash at -15°C for 20 minutes, and rinse after washing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com