Mould pressing rubber composite product sizing material dynamic filling amount process method

A technology of composite products and process methods, applied in the field of molded rubber products and multi-cavity injection molded rubber products, can solve problems such as low product qualification rate and quality risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

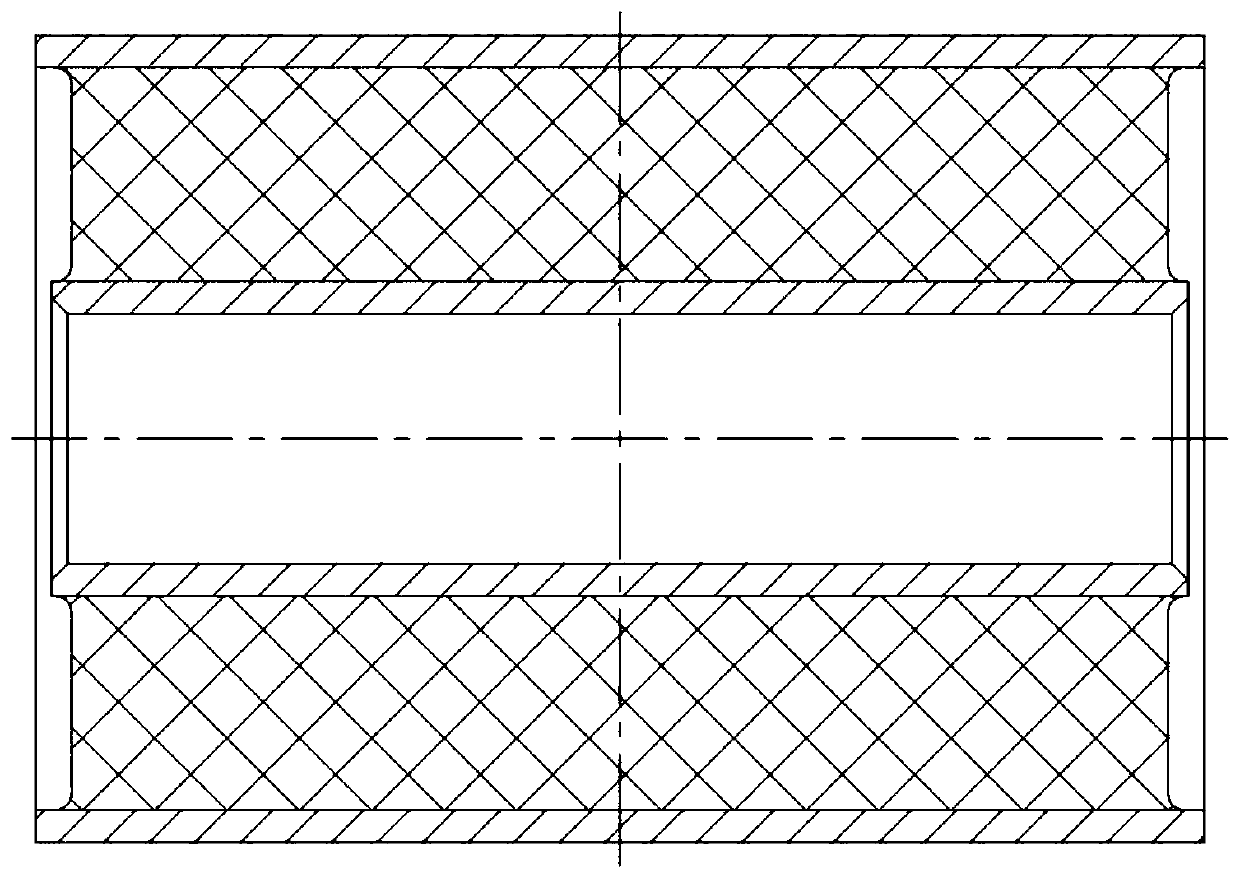

Image

Examples

Embodiment 1

[0029] Related parameters:

[0030] Constant: v=7920cm 3 ; ρ 1 =7.8g / cm 3 ; ρ i =1.37.8g / cm 3 ; η = 2%;

[0031] variable: m 1 ;

[0032] By the formula c(m i =(V-m 1 / ρ 1 -m 2 / ρ 2 ......) / ρ i ), calculate the theoretical glue loading amount corresponding to the skeleton weight m i . Considering the range of skeleton weight fluctuations and the acceptable degree of fluctuations in glue loading, according to the change of rubber material every 5g is a grade, calculate the corresponding skeleton weight and glue loading comparison table. As shown in the following table:

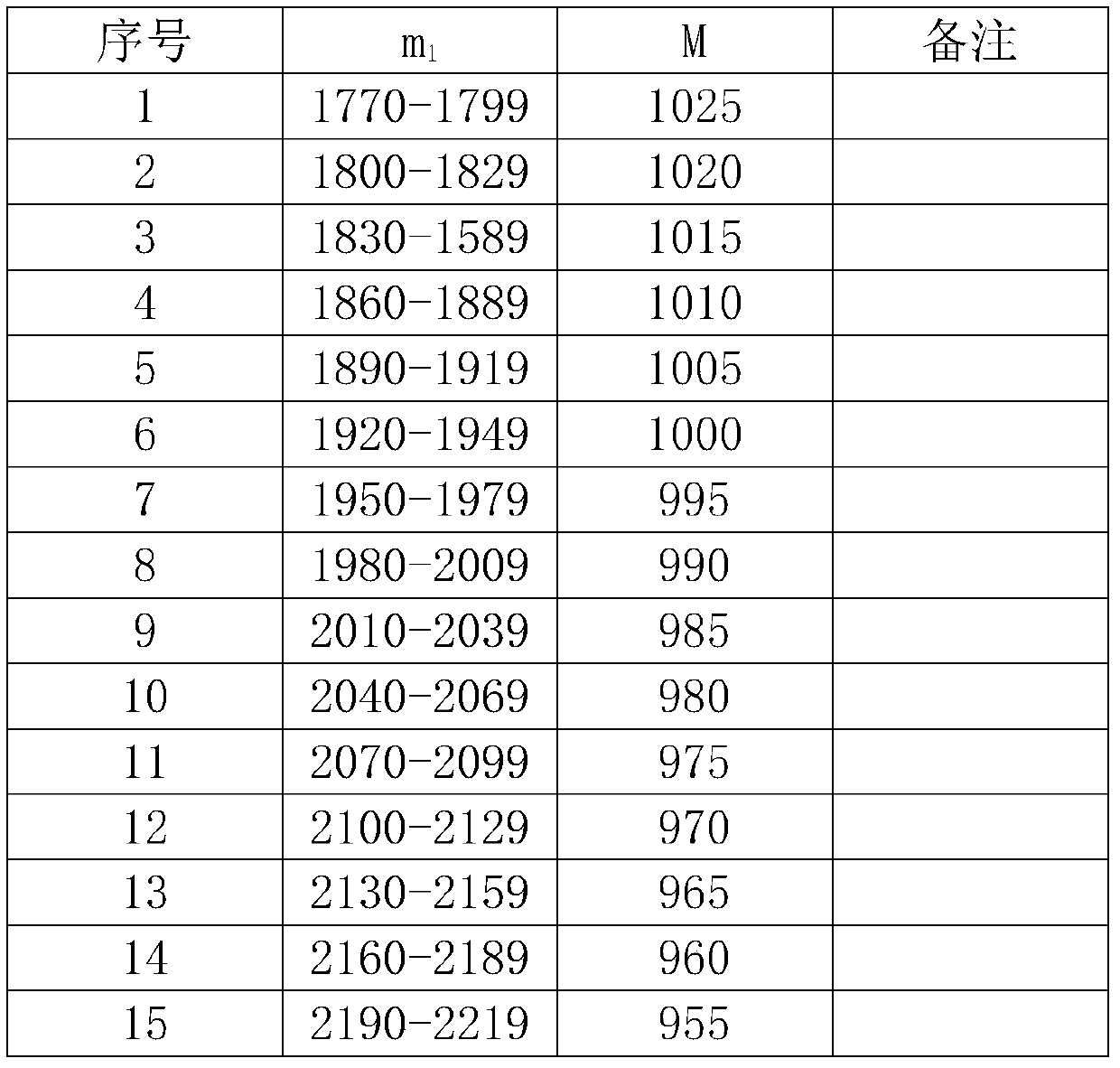

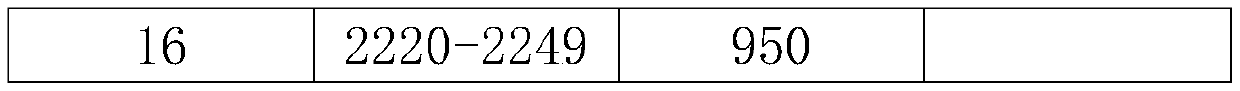

[0033] Skeleton weight and glue loading comparison table Unit: g

[0034]

[0035]

[0036] In actual production, weigh a set of skeleton weights, and look up the table to obtain the corresponding glue loading weight. For example, the weight of the skeleton is 1912g, and the amount of glue required to look up the table is 1005g, which is simple and easy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com