Water jet source apparatus with constant pressure

A water jet, source device technology, applied in measuring devices, instruments, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of flow velocity change at the nozzle, unstable jet velocity, and easy damage to the plunger pump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

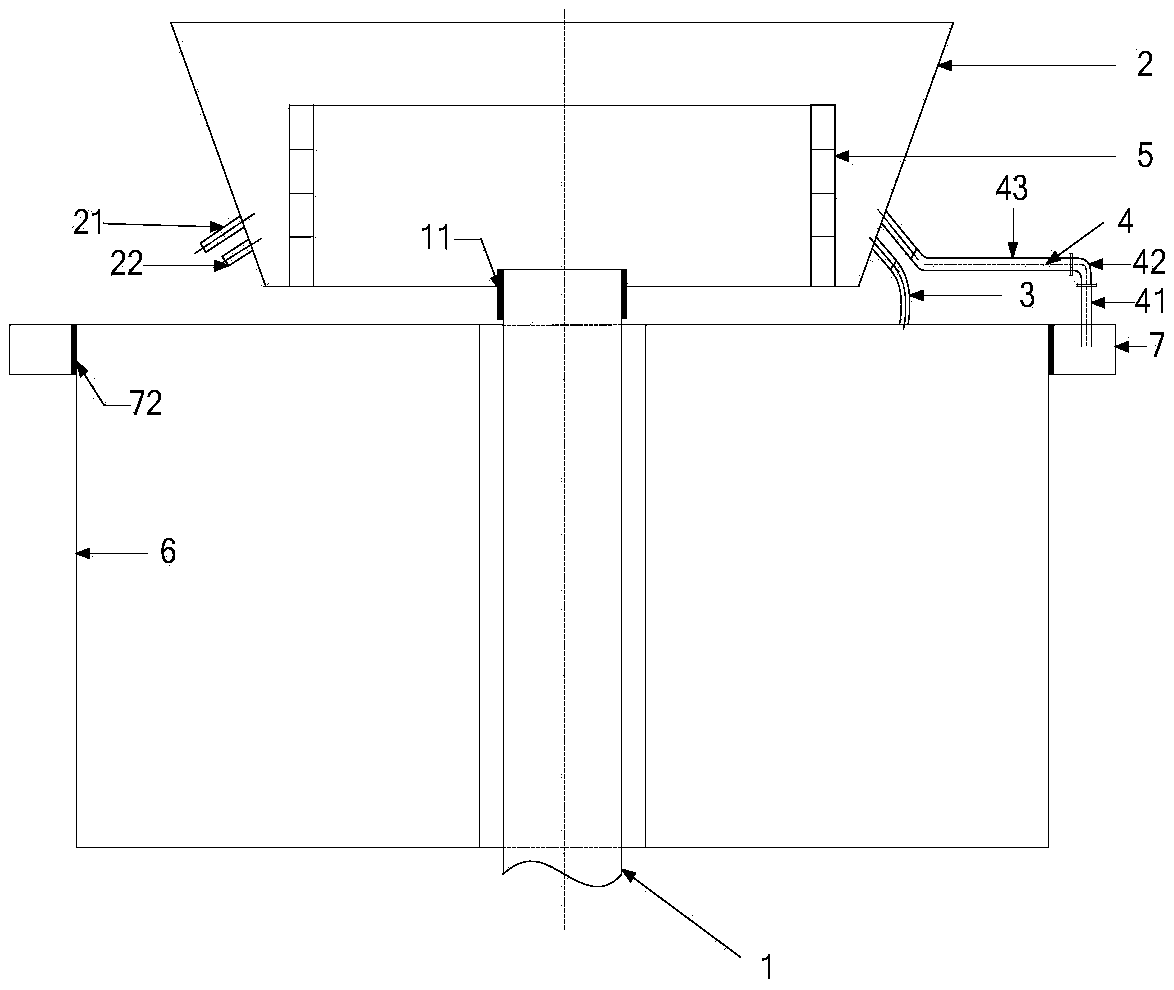

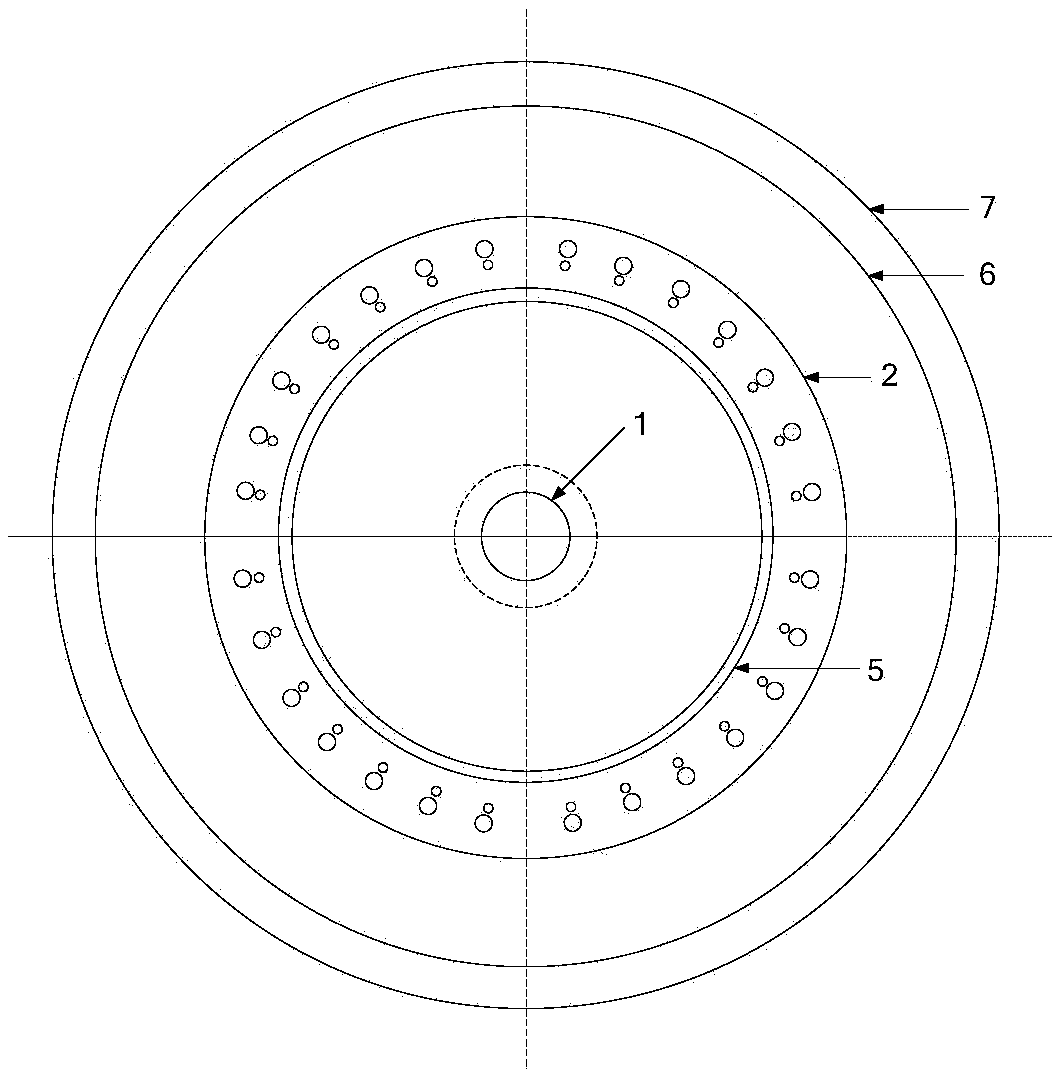

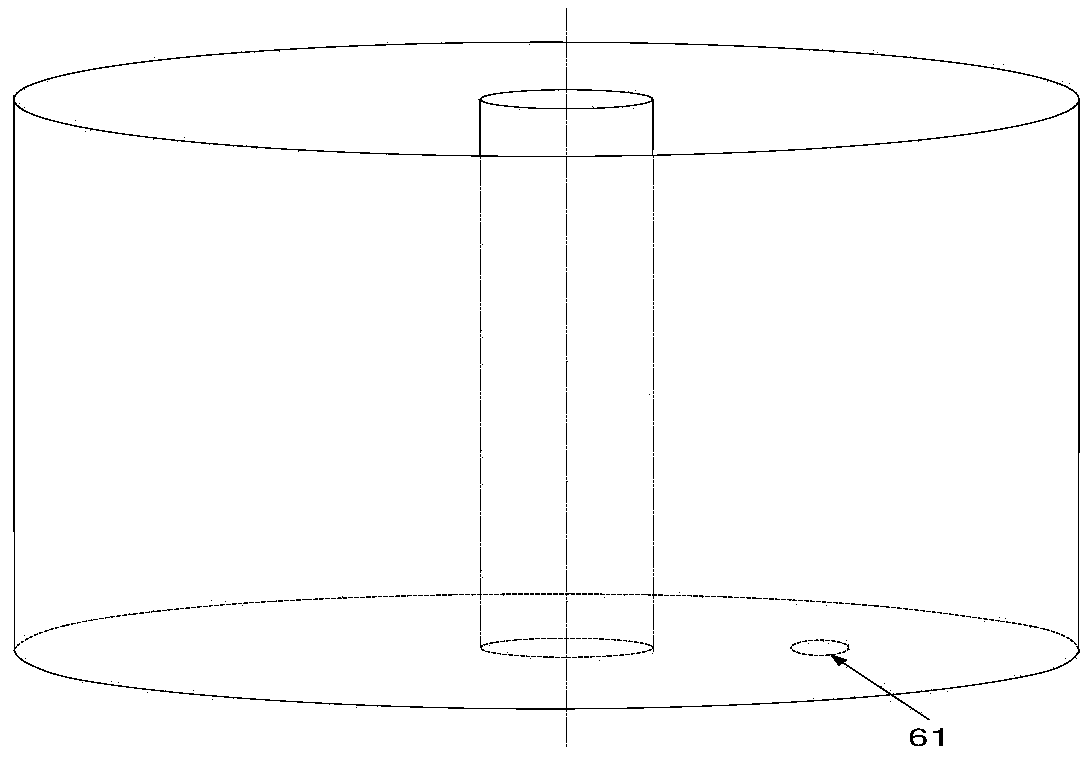

[0018] combine Figure 1 to Figure 6 , the present invention includes a water pump conduit 1, a silicone rubber strip 11, a diversion groove 2, an overflow interface 21, a diversion interface 22, a diversion pipe 3, an overflow pipe 4, a pipe 41, an elbow 42, a pipe 43, and a steady flow Grid 5, polyvinyl chloride plastic hard board 51 placed horizontally, small piece of polyvinyl chloride plastic hard board 52, water storage tank 6, jet source interface 61, overflow tank 7, overflow water outlet 71, silicon rubber strip 72.

[0019] Specifically, the present invention includes a water pump conduit 1, a diversion tank 2, a diversion pipe 3, an overflow pipe 4, a steady flow grid 5, a water storage tank 6, and an overflow tank 7; it is characterized in that one end of the water pump conduit 1 is connected For submersible pumps, the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com