Gas engine for realizing rapid power response by utilizing electronic fuel injection

A gas engine, power response technology, applied in the field of electronics, can solve the problems of combustion environment damage, fire, equipment unable to meet the long-term operation requirements of drilling conditions and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

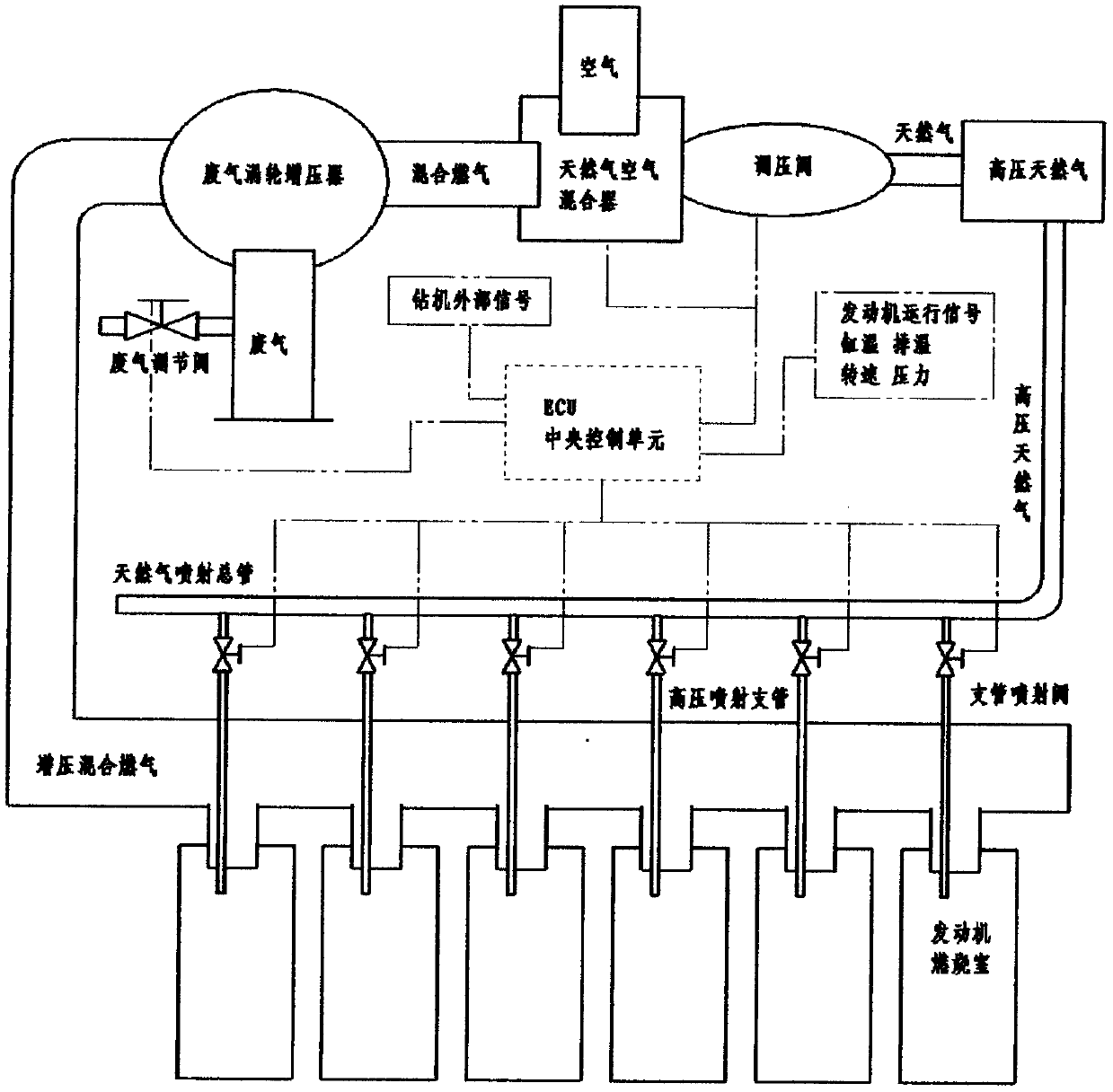

[0022] This embodiment lists a gas engine that uses electronic fuel injection to achieve rapid power response. The operation is completed according to the following method. The ECU collects engine operation signals, including combustion signals (cylinder temperature, exhaust temperature), speed, pressure, and gas conditions. , The status of each main component, receive the power demand equipment signal (redundant design, only as a control auxiliary signal), reduce the calculation and response time of the system, query the ECU experience data table, the experience data table has been packaged and written into the central control unit, The central control unit has a certain self-learning function. According to the experience data sheet output signal control the action of the actuator. The main control items include: the injection start and end time of the high-pressure natural gas electronic injection valve and the injection pressure to determine the injection volume. The air-ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com